Vacuum pulse drying networking remote multi-parameter monitoring and information service system

An information service system, vacuum pulsation technology, applied in data processing applications, instruments, and preservation of fruits/vegetables through dehydration, etc., can solve the problems of high manpower and time costs, low technical level of operators, online detection of key parameters and system integration Insufficient and other problems to achieve the effect of improving efficiency and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be described in further detail below with reference to the drawings and specific examples. The following examples are descriptive, not restrictive, and cannot limit the protection scope of the present invention.

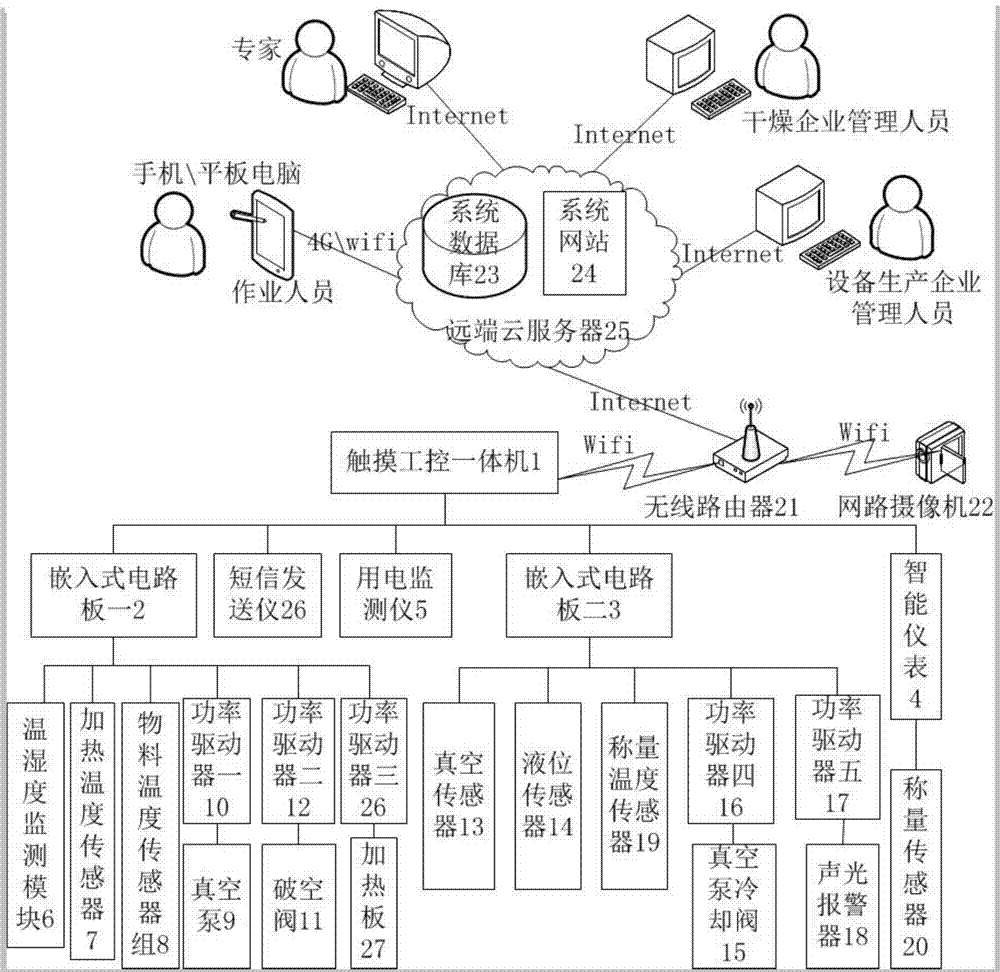

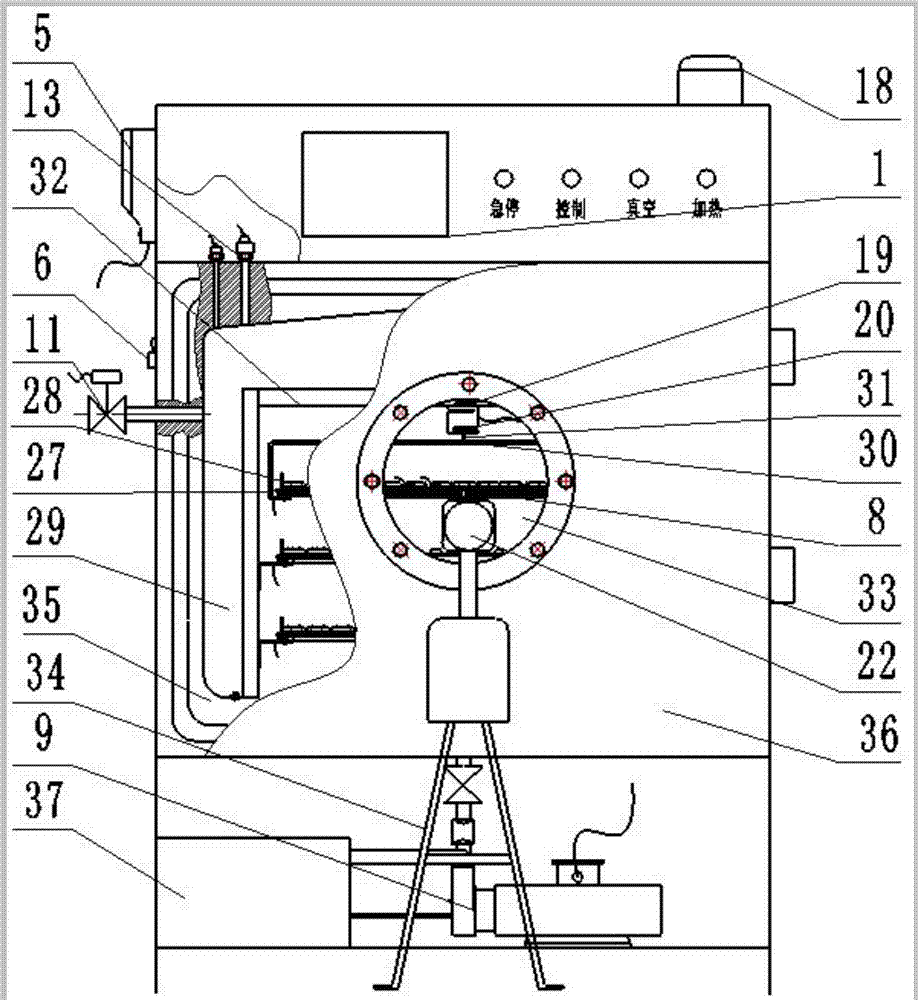

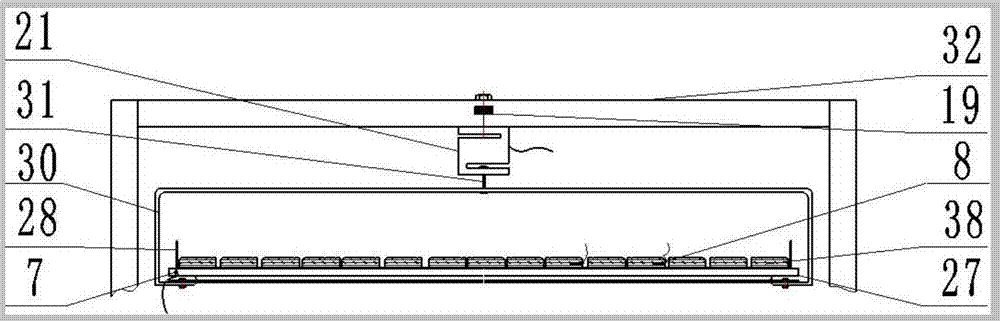

[0041] figure 1 It is a schematic structural diagram of a networked remote multi-parameter monitoring and information service system for vacuum pulsation drying. figure 2 It is a schematic diagram of the connection between the multi-parameter monitoring and information service system and the drying equipment. image 3 It is a schematic diagram of the structure of the suspended weighing material layer in the multi-parameter monitoring and information service system.

[0042] Such as figure 1 As shown, the system includes the equipment on-site monitoring layer, the system cloud website and database layer, and the network user layer.

[0043] The on-site monitoring layer of the above-mentioned equipment includes a touch industrial c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com