Preparation process for semi-automatically producing seamless underpants

A preparation process, semi-automatic technology, applied to sewing tools, underwear, clothing, etc., can solve problems that affect product quality and production efficiency, low efficiency, complex process, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

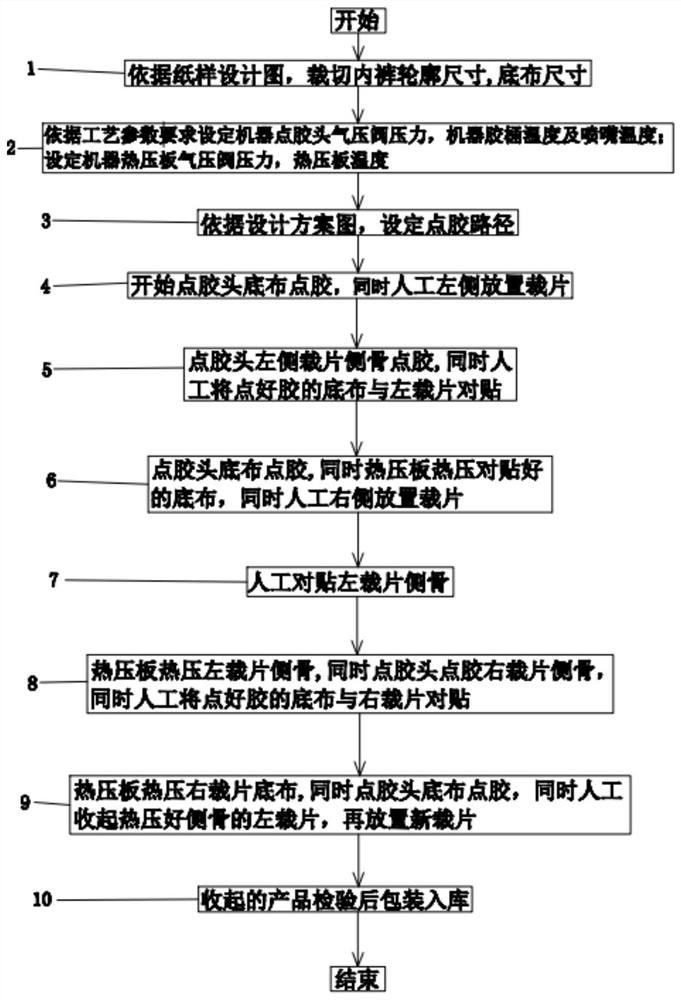

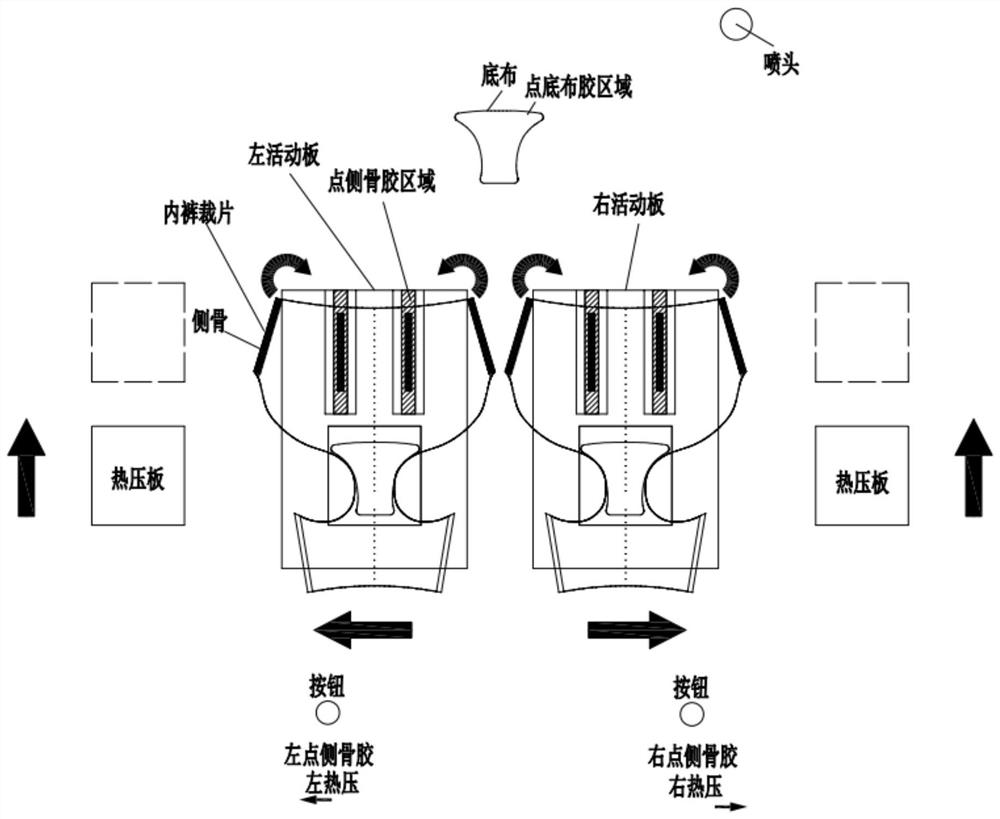

[0033] see Figure 1-Figure 4 As shown, the technical solution adopted in this specific embodiment is: specifically comprise the following steps:

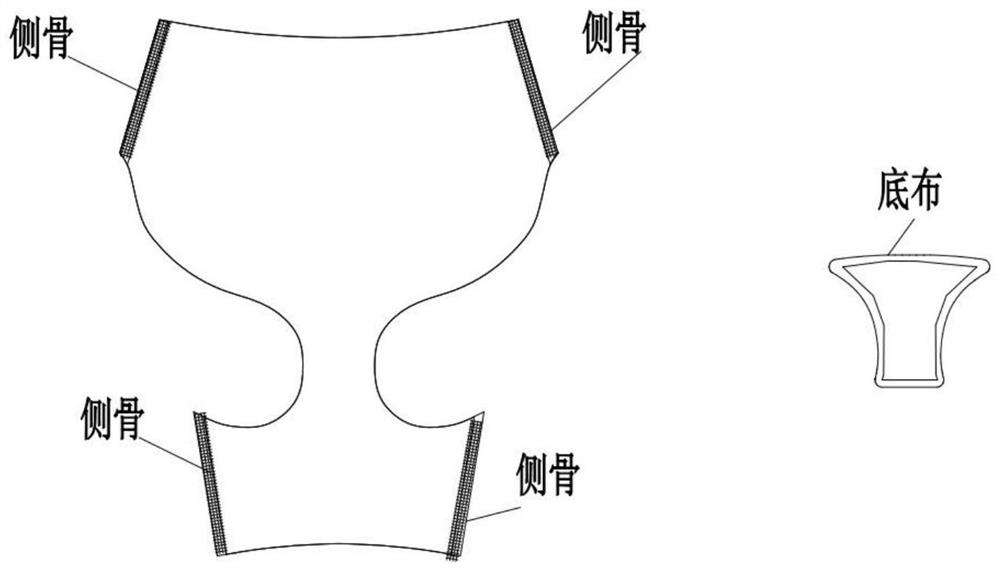

[0034] Step 1. According to the pattern design drawing, cut the outline size of the underwear and the size of the base fabric. The underwear material is made of a material with good air permeability and high resilience to improve the wearing comfort of the underwear;

[0035] Step 2. Set the pressure of the air valve of the dispensing head of the machine, the temperature of the rubber barrel of the machine and the temperature of the nozzle according to the requirements of the process parameters; set the pressure of the air pressure valve of the machine hot plate, the temperature of the hot plate, and the pressure of the air valve of the dispensing head to 6.5bar. The temperature of the rubber barrel is 140°C, the temperature of the nozzle is 240°C, the pressure of the air pressure valve of the hot plate is 3bar, and the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com