Liquid sample cavity for characterization by transmission electron microscope and preparation method thereof

A technology of transmission electron microscopy and liquid samples, which is applied in the fields of material analysis using radiation, material analysis using wave/particle radiation, and measuring devices, etc. It can solve the problems of high technical level requirements, small observation window size, and small number of observation windows, etc. , to achieve the effect of low technical level, low material cost and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

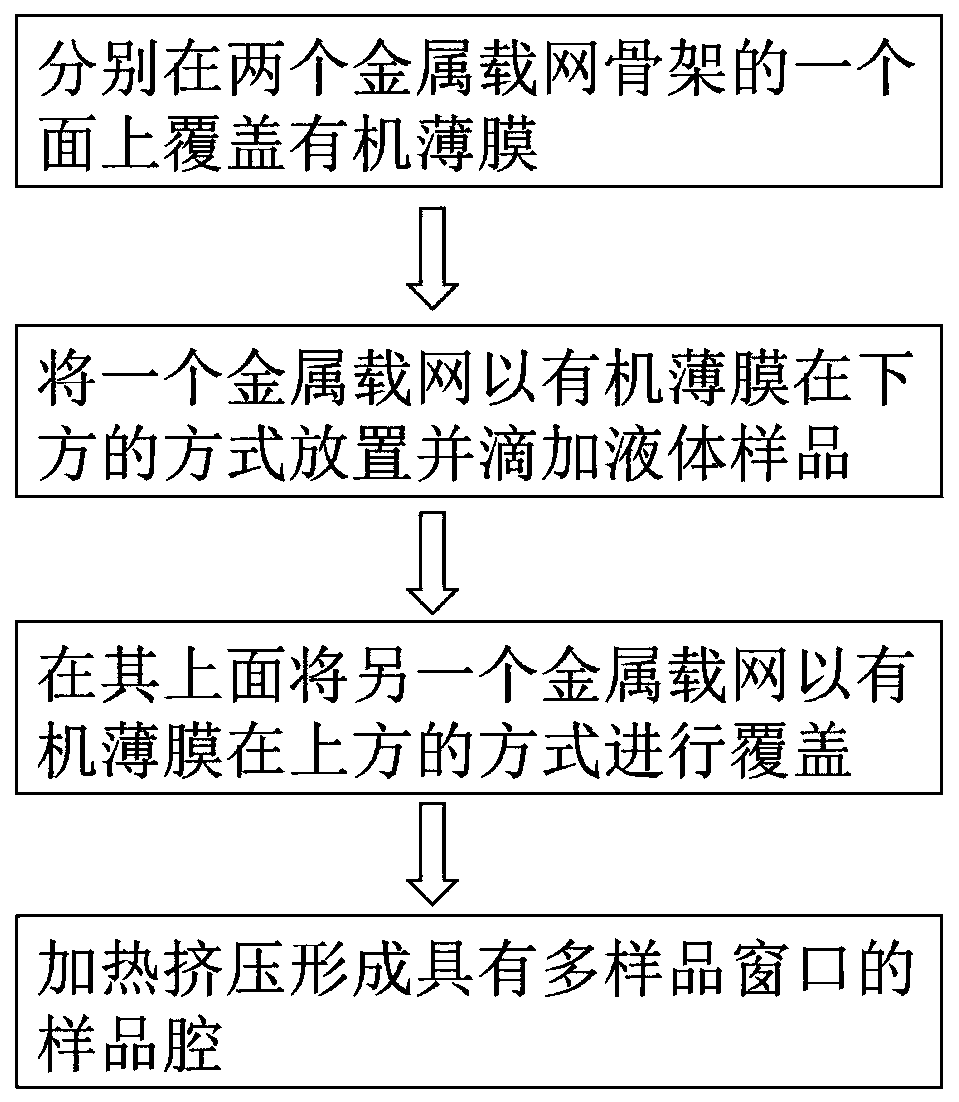

[0029] A preparation method for a liquid sample chamber characterized by transmission electron microscopy, the method comprising the following steps:

[0030] 1) Take two transmission electron microscopes with a diameter of 3mm to characterize the lead-tin-indium alloy grid skeleton with a melting point of 50°C. One surface of a lead-tin-indium alloy grid skeleton is covered with a 10nm thick square film to obtain a metal grid;

[0031] 2) Place one of the lead-tin-indium alloy grids on a flat heating platform with an organic film underneath, drop the liquid sample to be characterized from above the lead-tin-indium alloy grid, and then place an organic film on its surface cover another lead-tin-indium alloy carrier grid in a way;

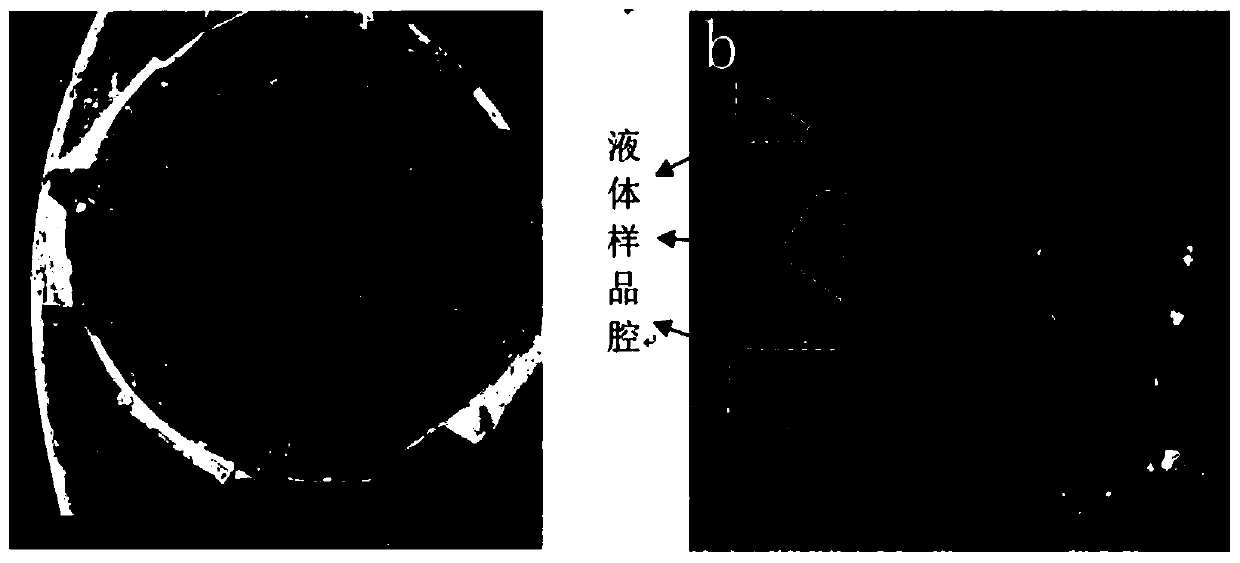

[0032] 3) Heat the two lead-tin-indium alloy grids covered together until the lead-tin-indium alloy framework of the metal grid begins to soften, and then apply pressure perpendicular to the direction of the metal grid until the lead-tin-indium all...

Embodiment 2

[0036] A preparation method for a liquid sample chamber characterized by transmission electron microscopy, the method comprising the following steps:

[0037] 1) Take two lead-tin alloy grid skeletons with a melting point of 70°C for TEM characterization with a diameter of 3 mm. One surface of the lead-tin alloy grid skeleton is covered with a 30nm thick Fanghua film to obtain a metal grid;

[0038] 2) Place one of the lead-tin alloy grids on a flat heating table with the organic film on the bottom, drop the liquid sample to be characterized from above the lead-tin alloy grid, and then place the organic film on its surface. Overlay another pewter grid;

[0039] 3) Heat the two lead-tin alloy grids covered together until the lead-tin alloy skeleton of the metal grid begins to soften, and then apply pressure perpendicular to the direction of the metal grid until the lead-tin skeletons are fused with each other. A sealed liquid sample window is formed in the cross grid of the l...

Embodiment 3

[0043] A preparation method for a liquid sample chamber characterized by transmission electron microscopy, the method comprising the following steps:

[0044]1) Take two bismuth-tin alloy grid skeletons with a diameter of 3 mm for characterization with a melting point of 80 ° C, the mesh number of which is 800 mesh, the internal mesh is square holes, and the thickness of the skeleton is 18 μm. One surface of the bismuth-tin alloy grid skeleton is covered with a 10nm thick collodion film to obtain a metal grid;

[0045] 2) Place one of the bismuth-tin alloy grids on a flat heating table with the organic film on the bottom, drop the liquid sample to be characterized from above the bismuth-tin alloy grid, and then place the organic film on its surface Cover another bismuth-tin alloy grid;

[0046] 3) Heat the two bismuth-tin alloy grids covered together until the bismuth-tin alloy skeleton of the metal grid begins to soften, and then apply pressure perpendicular to the direction...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com