A liquid sample cavity for transmission electron microscope characterization and its preparation method

A technology of transmission electron microscopy and liquid samples, which is applied in the direction of material analysis using radiation, material analysis using wave/particle radiation, instruments, etc. It can solve the problems of small observation window size, high technical level requirements, and small number of observation windows. Achieve the effect of low material, low technical level and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

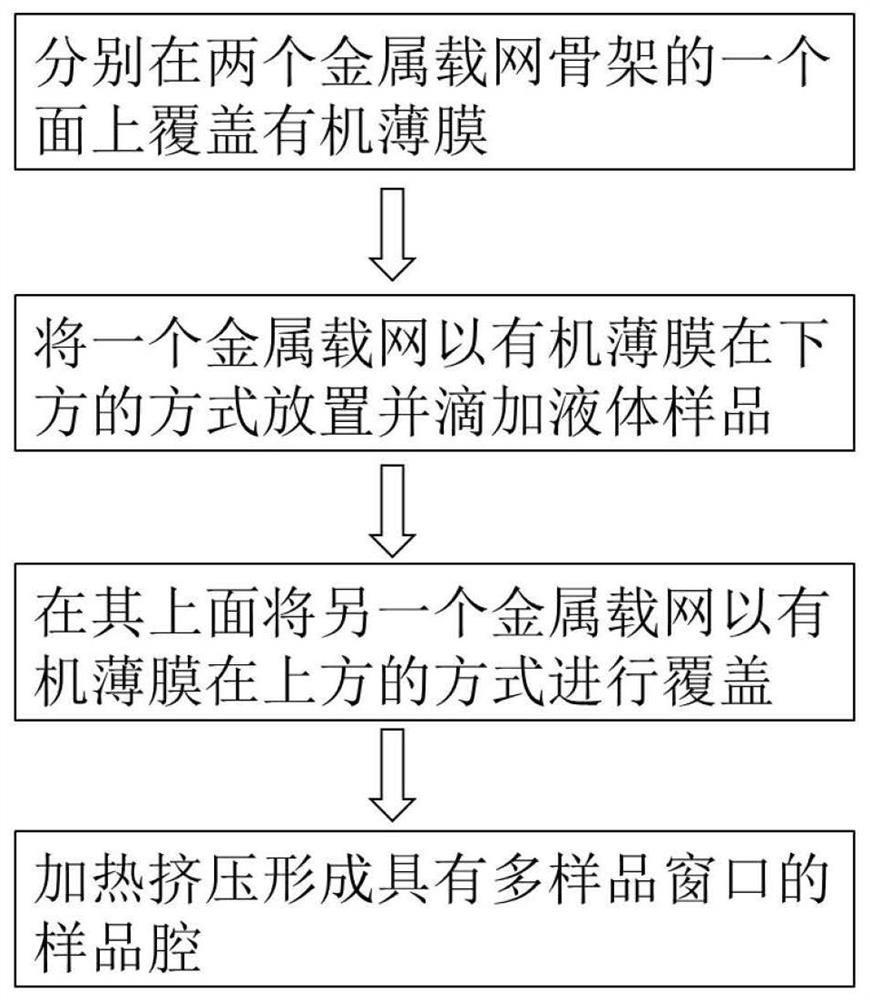

[0029] A preparation method for a liquid sample chamber characterized by transmission electron microscopy, the method comprising the following steps:

[0030] 1) Take two transmission electron microscopes with a diameter of 3mm to characterize the lead-tin-indium alloy grid skeleton with a melting point of 50°C. One surface of a lead-tin-indium alloy grid skeleton is covered with a 10nm thick square film to obtain a metal grid;

[0031] 2) Place one of the lead-tin-indium alloy grids on a flat heating platform with an organic film underneath, drop the liquid sample to be characterized from above the lead-tin-indium alloy grid, and then place an organic film on its surface cover another lead-tin-indium alloy carrier grid in a way;

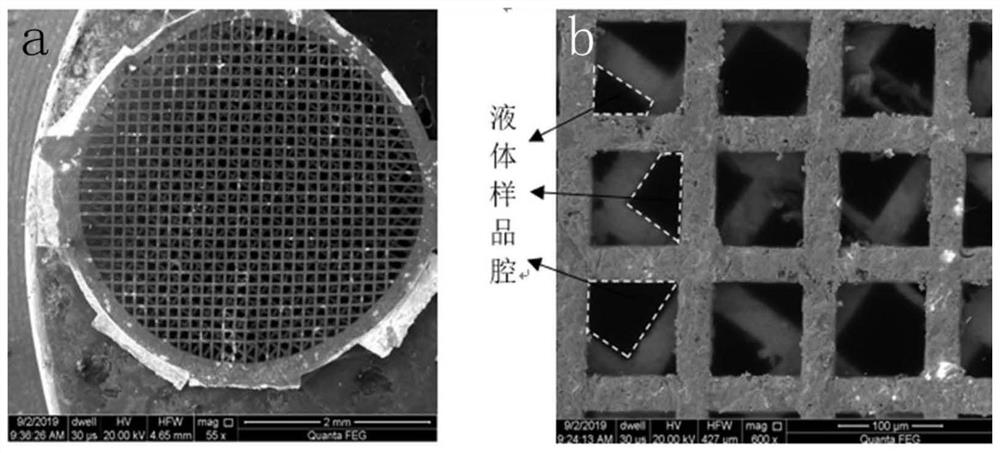

[0032] 3) Heat the two lead-tin-indium alloy grids covered together until the lead-tin-indium alloy framework of the metal grid begins to soften, and then apply pressure perpendicular to the direction of the metal grid until the lead-tin-indium all...

Embodiment 2

[0036] A preparation method for a liquid sample chamber characterized by transmission electron microscopy, the method comprising the following steps:

[0037] 1) Take two lead-tin alloy grid skeletons with a melting point of 70°C for TEM characterization with a diameter of 3 mm. One surface of the lead-tin alloy grid skeleton is covered with a 30nm thick Fanghua film to obtain a metal grid;

[0038] 2) Place one of the lead-tin alloy grids on a flat heating table with the organic film on the bottom, drop the liquid sample to be characterized from above the lead-tin alloy grid, and then place the organic film on its surface. Overlay another pewter grid;

[0039] 3) Heat the two lead-tin alloy grids covered together until the lead-tin alloy skeleton of the metal grid begins to soften, and then apply pressure perpendicular to the direction of the metal grid until the lead-tin skeletons are fused with each other. A sealed liquid sample window is formed in the cross grid of the l...

Embodiment 3

[0043] A preparation method for a liquid sample chamber characterized by transmission electron microscopy, the method comprising the following steps:

[0044]1) Take two bismuth-tin alloy grid skeletons with a diameter of 3 mm for characterization with a melting point of 80 ° C, the mesh number of which is 800 mesh, the internal mesh is square holes, and the thickness of the skeleton is 18 μm. One surface of the bismuth-tin alloy grid skeleton is covered with a 10nm thick collodion film to obtain a metal grid;

[0045] 2) Place one of the bismuth-tin alloy grids on a flat heating table with the organic film on the bottom, drop the liquid sample to be characterized from above the bismuth-tin alloy grid, and then place the organic film on its surface Cover with another bismuth-tin alloy grid;

[0046] 3) Heat the two bismuth-tin alloy grids covered together until the bismuth-tin alloy skeleton of the metal grid begins to soften, and then apply pressure perpendicular to the dire...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com