Ordered dual mesoporous metal oxide composite material loaded with noble metal and preparation method thereof

A composite material and oxide technology, applied in metal processing equipment, chemical instruments and methods, titanium oxide/hydroxide, etc., can solve the problem that the surface ligands of precious metal nanoparticles are difficult to remove, and it is difficult to control the pore structure, size, material Problems such as low internal utilization efficiency, to achieve good application prospects, overcome uneven load, and large window size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

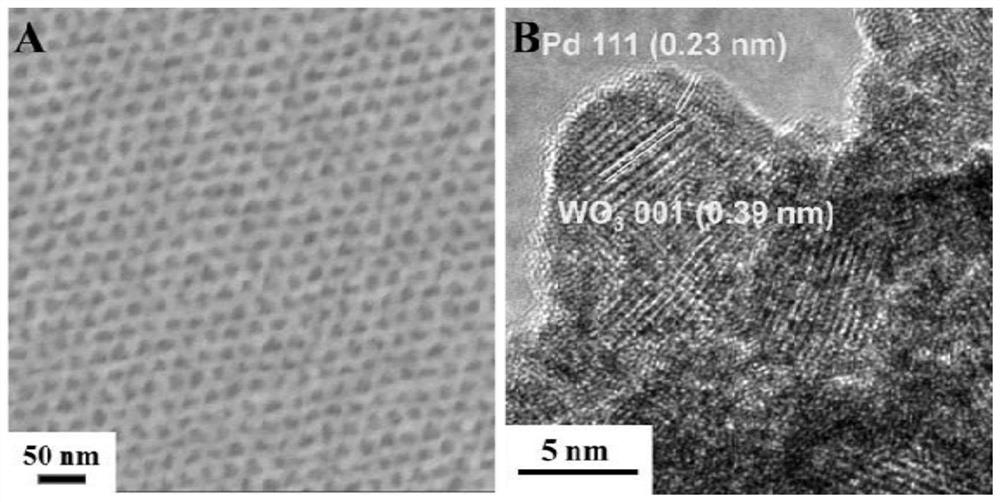

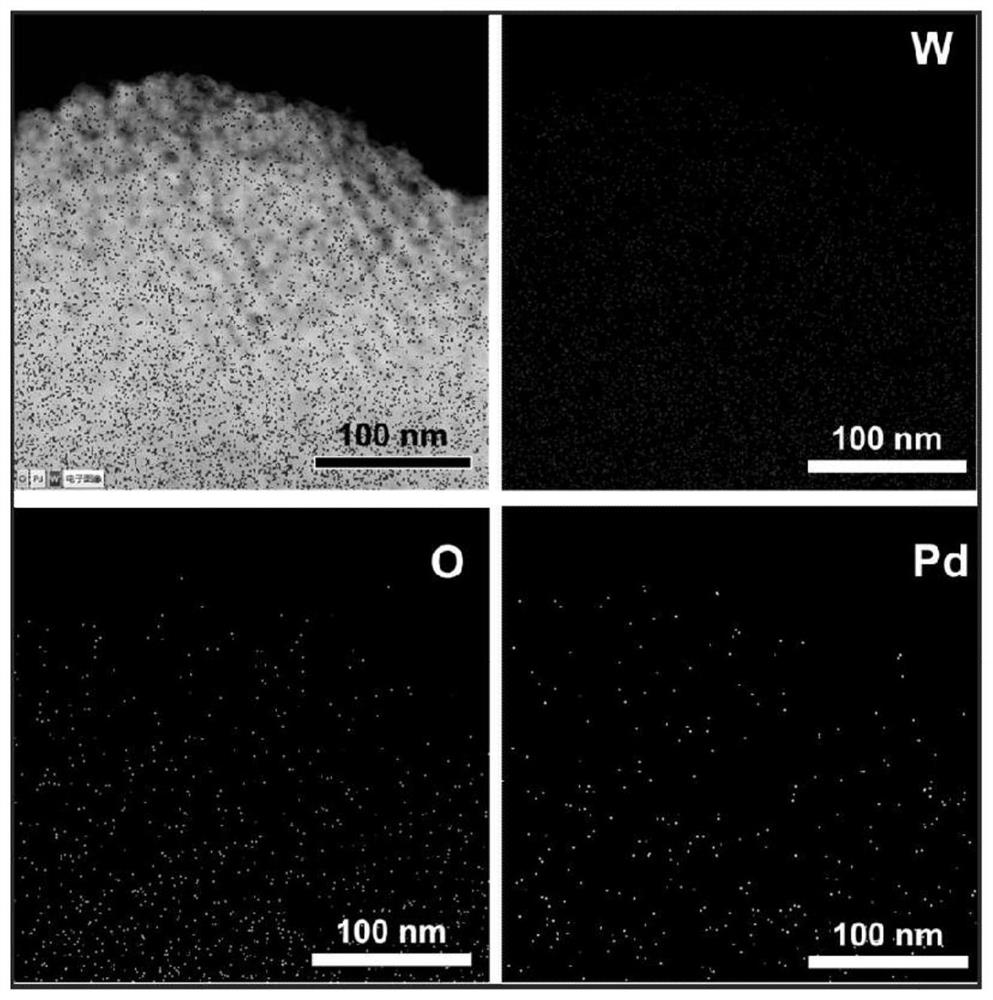

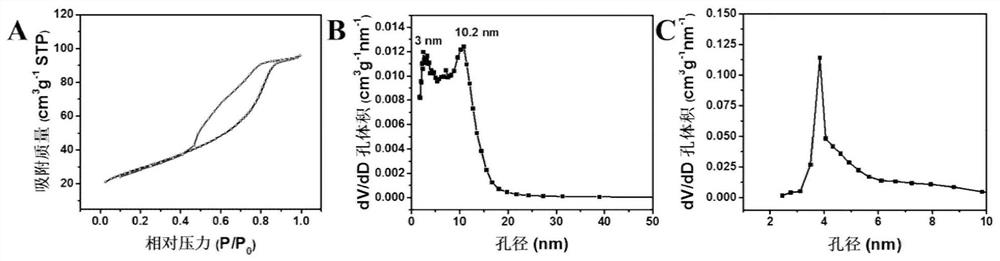

[0027] Example 1: Synthesis of ordered dual mesoporous tungsten oxide composites loaded with palladium nanoparticles

[0028] (1) First, a mercapto-containing phenolic resin prepolymer is prepared. Melt p-hydroxythiophenol under heating at 45°C, add 20wt.% NaOH aqueous solution, and adjust the pH to 10. After stirring at 45° C. for 15 min, 37 wt. % formaldehyde aqueous solution was added and stirred at 70° C. for 2 h. Naturally cool to room temperature, adjust the pH to 7 with 2mol / L hydrochloric acid aqueous solution, remove water by rotary evaporation in a vacuum under heating in a water bath at 45°C, and disperse in tetrahydrofuran for later use. Among them, the molar ratio of p-hydroxythiophenol to formaldehyde is 1:2.4;

[0029] (2) The amphiphilic block copolymer polyethylene oxide-b-polystyrene (PEO 114 -b-PS 183 ,M n =~24000) was dissolved in tetrahydrofuran, added mercapto-containing phenolic resin prepolymer and palladium acetylacetonate, stirred thoroughly to o...

Embodiment 2

[0037] Example 2: Synthesis of ordered dual mesoporous titanium oxide composites loaded with gold nanoparticles

[0038] (1) First, a mercapto-containing phenolic resin prepolymer is prepared. Melt p-hydroxythiophenol under heating at 45°C, add 20wt.% NaOH aqueous solution, and adjust the pH to 10. After stirring at 45° C. for 15 min, 37 wt. % formaldehyde aqueous solution was added and stirred at 70° C. for 2 h. Naturally cool to room temperature, adjust the pH to 7 with 2mol / L hydrochloric acid aqueous solution, remove water by rotary evaporation in a vacuum under heating in a water bath at 45°C, and disperse in tetrahydrofuran for later use. Among them, the molar ratio of p-hydroxythiophenol to formaldehyde is 1:2.4;

[0039] (2) The amphiphilic block copolymer polyethylene oxide-b-polystyrene (PEO 114 -b-PS 183 ,M n =~24000) dissolved in tetrahydrofuran, add mercapto-containing phenolic resin prepolymer and chloroauric acid tetrahydrate, stir well to obtain solution A...

Embodiment 3

[0042] Example 3: Synthesis of Platinum Nanoparticles Loaded Ordered Dual Mesoporous Titanium Oxide Composite

[0043] (1) First, a mercapto-containing phenolic resin prepolymer is prepared. Melt p-hydroxythiophenol under heating at 50°C, add 10wt.% NaOH aqueous solution, and adjust the pH to 9. After stirring at 50° C. for 10 min, 35 wt. % formaldehyde aqueous solution was added and stirred at 70° C. for 3 h. Naturally cool to room temperature, adjust pH to 8 with 1 mol / L hydrochloric acid aqueous solution, remove water by vacuum rotary evaporation under heating in a water bath at 40°C, and disperse in tetrahydrofuran for later use. Among them, the molar ratio of p-hydroxythiophenol to formaldehyde is 1:2;

[0044] (2) Amphiphilic triblock copolymer polyoxyethylene-polyoxypropylene-polyoxyethylene (PEO-PPO-PEO, EO 106 -PO 70 -EO 106 , Pluronic F127) was dissolved in tetrahydrofuran, added mercapto-containing phenolic resin prepolymer and chloroplatinic acid hexahydrate, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com