Metal die hot working one-time forming device

A metal mold and forming equipment technology, applied in the field of one-time forming equipment for metal mold thermal processing, can solve the problems of high production cost, poor product quality, complex structure, etc., and achieve the effects of low cost, reasonable structure and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

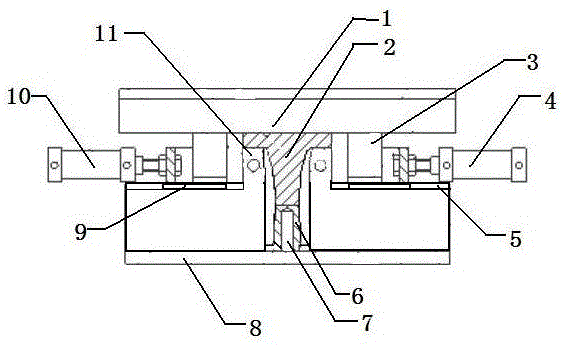

[0011] This embodiment provides a metal mold thermal processing one-time forming equipment, which is characterized in that: the metal mold thermal processing one-time forming equipment includes an upper core mounting seat (1), an upper core (2), a nozzle (3), Right hydraulic cylinder (4), chute (5), lower core (6), protrusion (7), lower core mounting seat (8), slider (9), left hydraulic cylinder (10), riser (11 );

[0012] Among them: the equipment is a symmetrical structure, with a left hydraulic cylinder (10) and a right hydraulic cylinder (4) on both sides of the equipment, the left and right hydraulic cylinders (10, 4) are connected to the nozzle (3) through connecting pins, and the hydraulic cylinders (4, 10 ) is installed under the slider (9), and the slider (9) is installed in the chute (5) of the lower core mounting base (8) under the device, and the center of the lower core mounting base (8) is provided with a protrusion (7) , the lower core (6) is set on the protrus...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com