Industrial control system bottom layer integrated architecture of digital foundry factory

A foundry factory and industrial control system technology, which is applied in the field of foundry factories, can solve problems such as inability to be liberated, and achieve the effects of reducing workload, easy handover, and easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

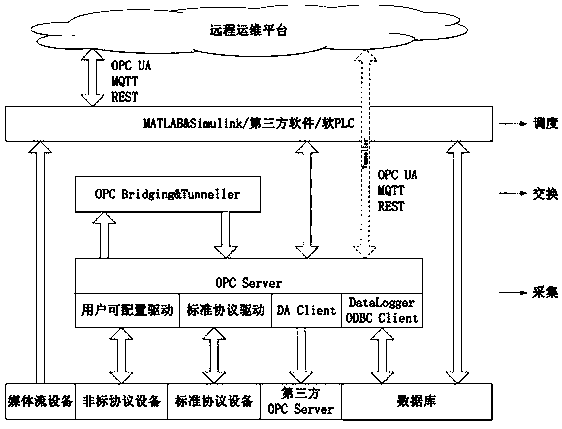

[0043] like figure 1 The underlying integrated architecture of the industrial control system of a digital foundry factory is shown, including: OPC Server, which is used to control the entire system; a data acquisition unit, which is used to collect the underlying data of the foundry factory; Data interlocking and data communication among various equipment units; data dispatching unit, which conducts comprehensive analysis and calculation of multiple data in different systems, and gives the final result, which is used to guide on-site equipment or personnel to execute; the data acquisition unit , the data exchange unit and the data dispatch unit are all connected to the OPC Server.

[0044] The specific implementation of the present invention will be further described below.

[0045] data collection

[0046] When the bottom layer of the industrial control system of the digital foundry factory is integrated, the data sources directly faced by the OPC Server mainly include imag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com