Preparation device and preparation method for one-dimension photonic crystal band-stop filter

A technology of band-stop filter and dimensional photonic crystal, applied in the direction of optical waveguide light guide, light guide, optics, etc., can solve the problems of difficult operation, complex optical path, tedious and time-consuming, etc., and achieve the effect of simple operation, simple optical path and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

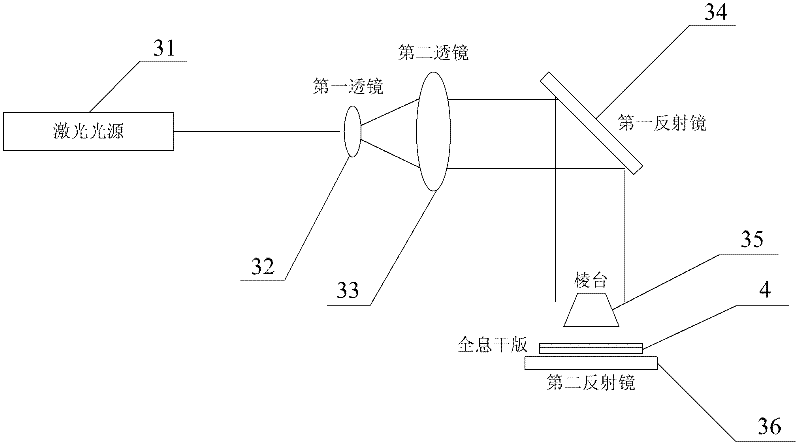

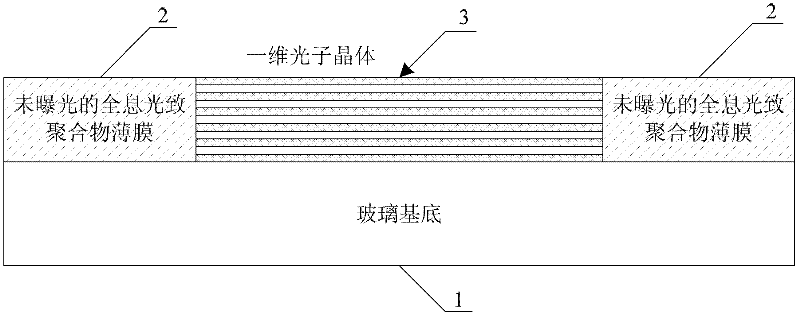

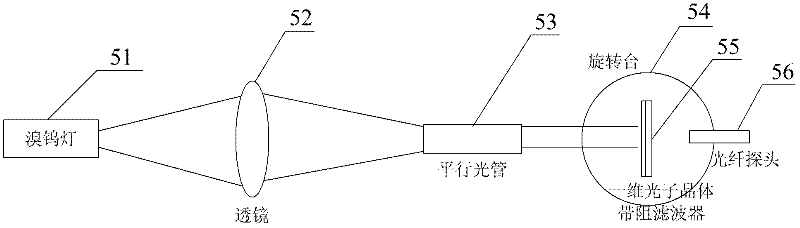

[0033] A preparation device for a one-dimensional photonic crystal band-stop filter, such as figure 1As shown, it includes a laser light source 31, a beam expander unit, a first reflector 34 and a second reflector 36. Generally, the first reflector 34 is placed at an angle of 45° to the horizontal plane, and the second reflector 36 is placed on the The red-sensitive photopolymer holographic dry plate 4 to be processed is placed, and the holographic photopolymer film of the red-sensitive photopolymer holographic dry plate 4 to be processed is facing upward, and the incident light emitted by the laser light source 31 passes through the optical beam expansion unit Form parallel beam expansion light, the light spot of the parallel beam expansion light emitted by the optical beam expansion unit is smaller than the surface of the holographic photopolymer film of the red-sensitive photopolymer holographic dry plate 4 to be processed, and the parallel light beam emitted by the light be...

Embodiment 2

[0038] This embodiment is a method for preparing a one-dimensional photonic crystal band-stop filter using the preparation device of Embodiment 1, which includes the following steps:

[0039] ① Turn on the He-Ne laser and let it warm up for more than 1 hour.

[0040] ②Take out the red-sensitive photopolymer holographic dry plate to be processed from the refrigerator, and place it in the laboratory for more than 30 minutes at room temperature.

[0041] ③The He-Ne laser emits red light with a wavelength of 632.8nm, and the red light passes through the first lens and the second lens of the beam expansion unit to form parallel beam expansion light.

[0042] ④The parallel expanded beams are reflected by the first reflector and then vertically incident on the prism as the non-diffraction stop, and the part of the expanded beam with uniform light intensity passing through the prism is incident vertically on the second reflector.

[0043] ⑤Finely adjust the pitch angle of the first r...

Embodiment 3

[0055] The steps ① to ⑥ and step ⑨ of the preparation method of the one-dimensional photonic crystal band-stop filter in this embodiment are the same as the steps ① to ⑥ and step ⑨ of the preparation method described in Example 2. The preparation method of the present embodiment Steps ⑦ and ⑧ are respectively: ⑦Remove the light screen, expose the red-sensitive photopolymer holographic dry plate to be treated for 30 seconds and then put it back into the light screen, then take out the exposed red-sensitive photopolymer holographic dry plate, put it in the cassette Put it in the middle for about 10 minutes. ⑧ Put the red-sensitive photopolymer holographic dry plate after exposure into distilled water and let it stand for 15 seconds; then dehydrate it in a 40% isopropanol solution for 1 minute; then dehydrate it in a 60% isopropanol solution Dehydration for 1 minute; then dehydration in 80% isopropanol solution for 15 seconds; finally dehydration in 100% isopropanol solution unti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com