Fixture automatically adjusting specifications of main board and automatic assembling device for automobile radiator core

An automobile radiator and automatic adjustment technology, which is applied to workpiece clamping devices, assembling machines, manufacturing tools, etc., can solve the problems of inability to realize automatic assembly of automobile radiators, improve assembly accuracy and pass rate, facilitate use, The effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

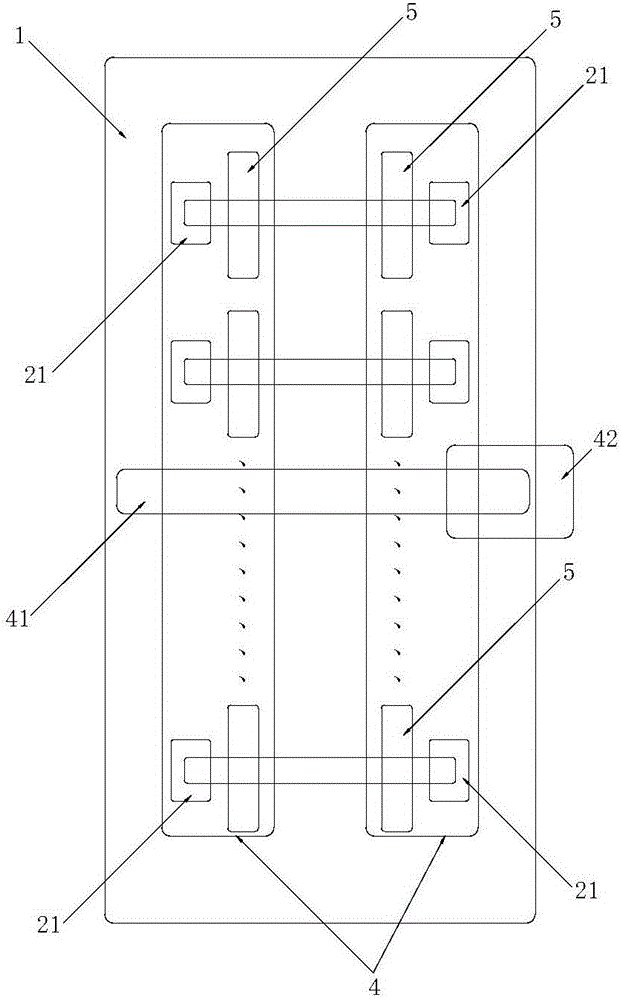

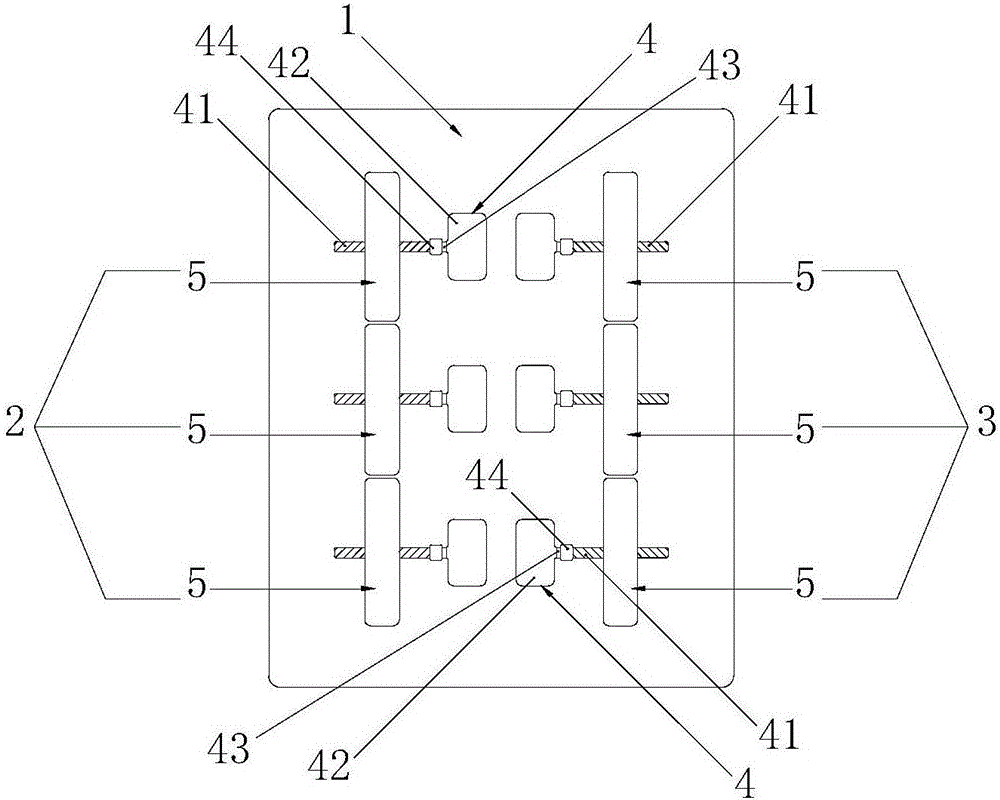

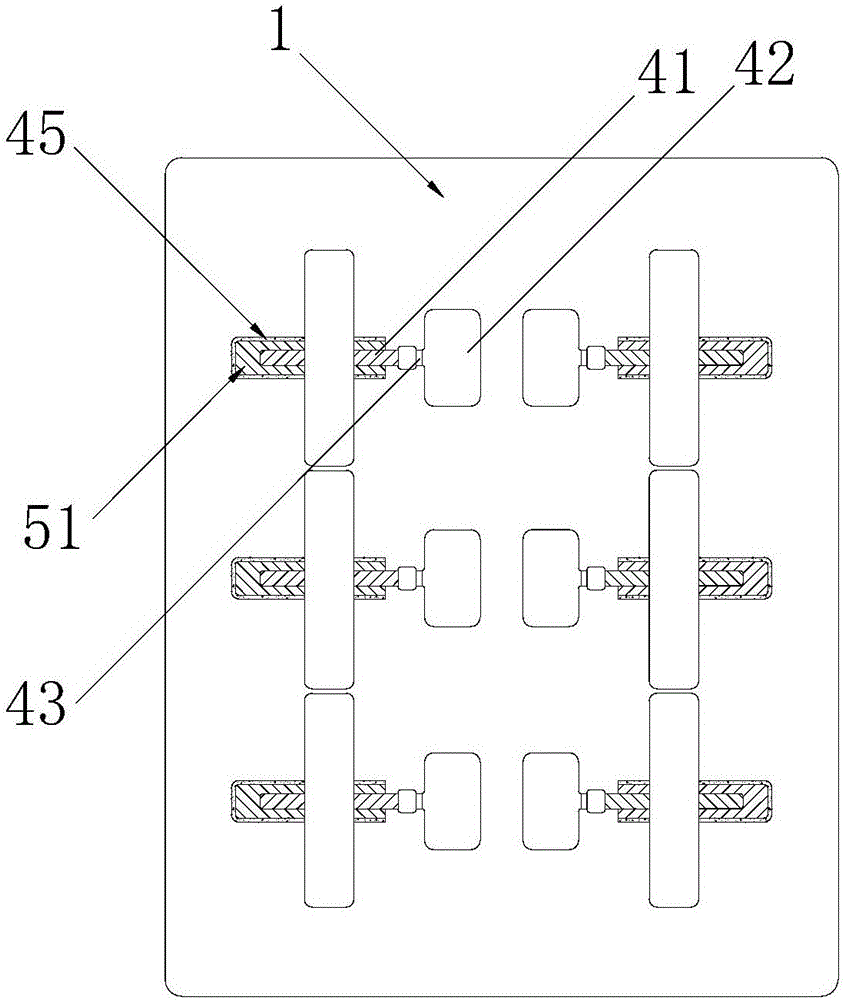

[0042] In the views of all drawings, corresponding reference signs indicate corresponding parts.

[0043] A fixture for automatically adjusting the specifications of the motherboard, including a base 1, a first clamping edge 2 and a second clamping edge 3. The base 1 is provided with a first clamping edge 2 and a second clamping edge 3, and a fixture for automatically adjusting the specifications of the motherboard , It also includes a reciprocating mechanism 4 arranged on the base 1. The first clamping edge 2 and / or the second clamping edge 3 are assembled from two or more edge strips 5, and the base 1 is provided with the edge strip 5 connection, the reciprocating mechanism 4 used to change the position of the side strip 5; by changing the position of the side strip 5 to adjust the length of the first clamping edge 2 and / or the second clamping edge 3, as well as the first clamping edge 2 and the second clamping edge The relative position of the side 3 realizes the clamping func...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com