Blade locating structure of small-sized wind power generator

A technology for positioning wind turbines and blades, which is applied to wind turbine components, wind engines, wind power generation, etc., and can solve problems such as failure to install blades and body, stator and rotor damage, and blade breakage

Inactive Publication Date: 2011-06-22

陈玉田

View PDF0 Cites 2 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0002] During the packaging and transportation of small wind turbines, the blades and body cannot be installed properly due to their shape, and the blades can only be installed on site, and because of their low value, it is impossible to send high-level engineering and technical personnel to each site to guide the installation. Can only be installed by normal personnel

At present, there is a problem of installation accuracy between blades and rotating flanges of small wind turbines, which are usually positioned through screw holes, but due to drilling accuracy and process costs, it is generally difficult to meet the requirements for use. The generator will experience severe blade vibration during high-speed operation. Long-term vibration of the blade will accelerate the fatigue of the blade material, and material fatigue will eventually lead to the breakage of the blade

The vibration of the blades will also cause damage to the generator bearings, reduce the service life of the bearings, cause damage to the stator and rotor, and cause loosening of all fastening screws, shorten the service life of the wind turbine, and more importantly, reduce the utilization of wind energy. coefficient

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

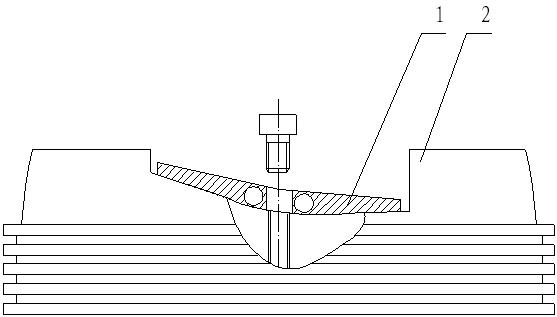

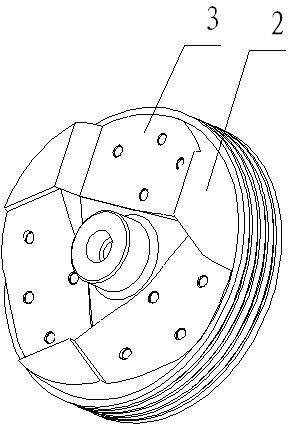

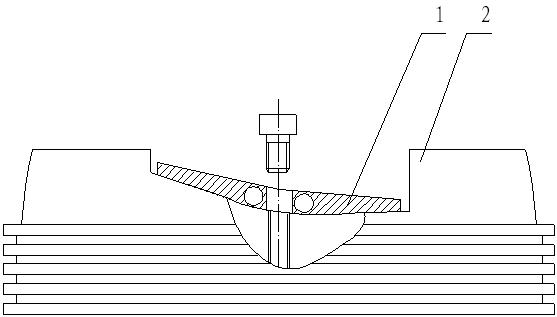

[0008] Such as figure 1 , 2 As shown, a blade positioning structure of a small wind power generator includes a blade 1 and a rotating flange 2 , and each blade mounting surface 3 of the rotating flange 2 is the same curved surface as the back of the blade 1 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention relates to a blade locating structure of a small-sized wind power generator, belonging to the technical field of wind power generation. The blade locating structure of the small-sized wind power generator comprises a blade and a rotary flange disc, wherein each blade installation surface of the rotary flange disc is a curved surface which has a same curve with the back surface of the blade. The invention ensures high-speed running of the small-sized wind power generator, reduces fatigue of blade materials due to little jittering of the blade, prolongs the service life of the wind power generator and has high wind power efficiency and high safety.

Description

technical field [0001] The invention belongs to the technical field of wind power generation, and in particular relates to a blade positioning structure of a wind power generator. Background technique [0002] During the packaging and transportation of small wind turbines, the blades and body cannot be installed properly due to their shape, and the blades can only be installed on site, and because of their low value, it is impossible to send high-level engineering and technical personnel to each site to guide the installation. It should only be installed by ordinary personnel. At present, there is a problem of installation accuracy between blades and rotating flanges of small wind turbines, which are usually positioned through screw holes, but due to drilling accuracy and process costs, it is generally difficult to meet the requirements for use. The generator will experience severe blade vibration during high-speed operation. Long-term vibration of the blade will accelerate...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): F03D11/00

CPCY02E10/72Y02E10/722

Inventor 陈玉田

Owner 陈玉田

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com