Preparation method of trace Mo-doped lamellar lithium-enriched ternary positive electrode material

A cathode material and layered technology, applied in the field of preparation of layered lithium-rich ternary cathode materials, can solve the problems of low capacity and poor rate performance of cathode materials, and achieve excellent electrochemical performance, good rate performance and cycle performance, The effect of facilitating industrial production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

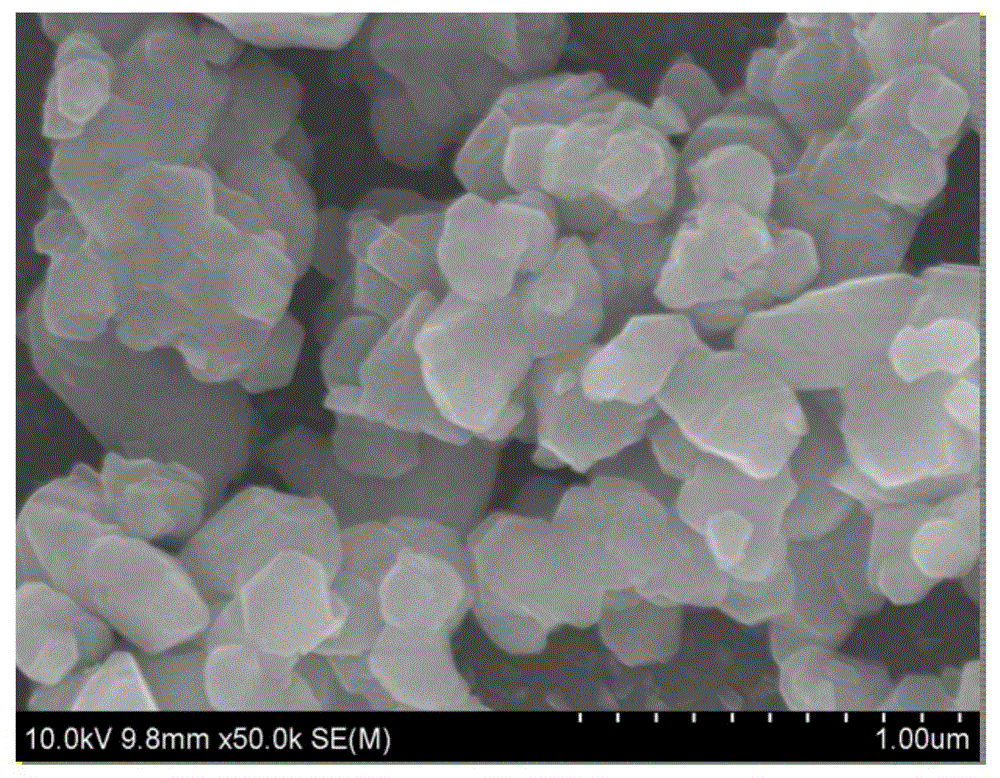

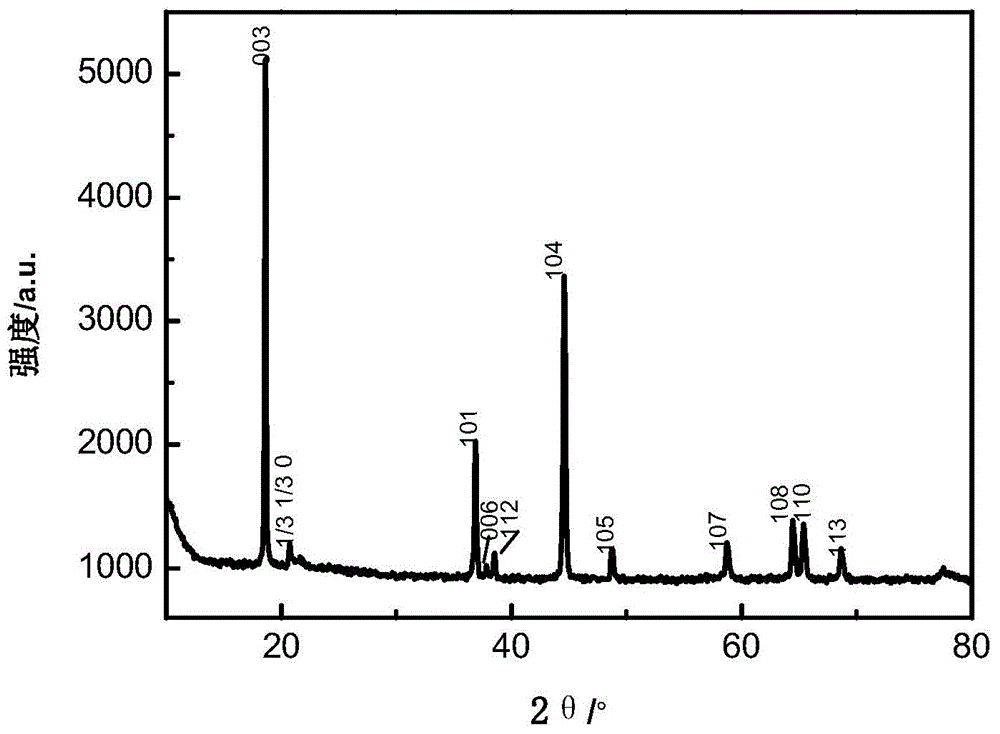

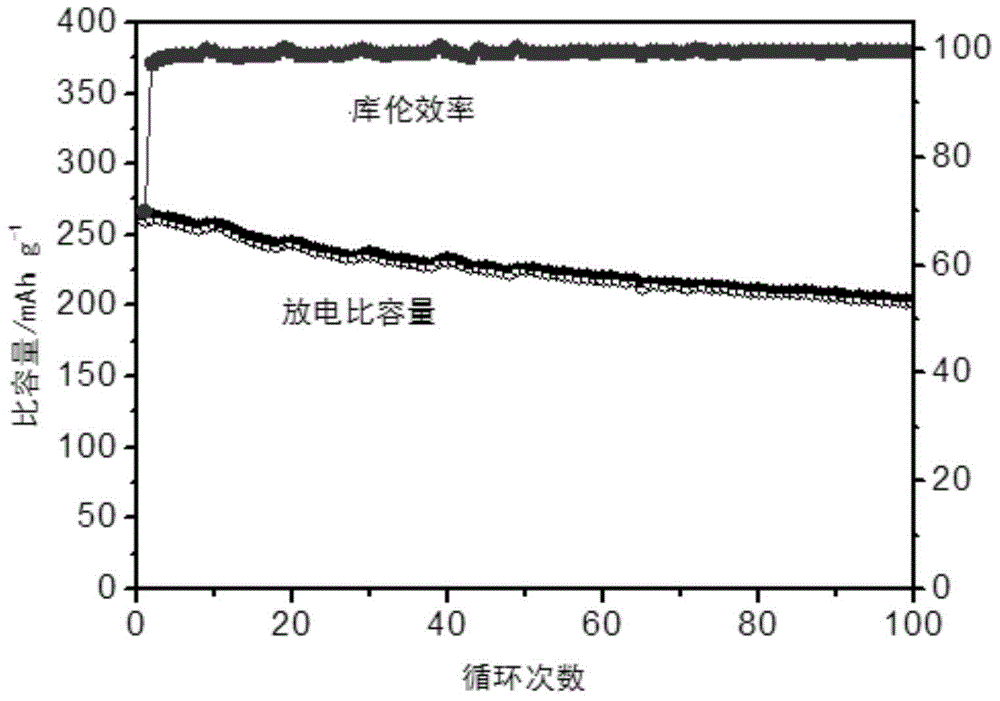

[0033] A method for preparing a layered lithium-rich ternary positive electrode material doped with a trace amount of Mo. The Mo-doped layered lithium-rich ternary positive electrode battery material contains Li, Ni, Co, Mn, Mo and O elements, and its molecular formula is Li 1.2 (Mn 0.54 Ni 0.13 co 0.13 ) 1-x Mo x o2 (0

[0034] The above-mentioned preparation method of a layered lithium-rich ternary positive electrode material doped with a trace amount of Mo specifically comprises the following steps:

[0035] (1), mix 6.3870g (1% excess) of organic precipitant with 55ml of organic solvent according to the ratio of organic precipitant: organic solvent is 1mol:1L, and then control the rotating speed to be 800r / min and the temperature to be 80°C Stir and dissolve to obtain solution A;

[0036] Described organic precipitation agent is 8-hydroxyquinoline;

[0037] Described organic solvent is ethanol;

[0038] (2), with soluble 1.6190g cobalt salt, 1.6176g nickel sa...

Embodiment 2

[0057] A method for preparing a layered lithium-rich ternary positive electrode material doped with a trace amount of Mo. The lithium-rich ternary lithium-ion battery positive electrode material contains Li, Ni, Co, Mn, Mo and O elements, and its molecular formula is Li 1.2 (Mn 0.54 Ni 0.13 co 0.13 ) 1-x Mo x o 2 (x=0.01).

[0058] The above-mentioned preparation method of a Mo-doped layered lithium-rich ternary positive electrode battery material adopts an organic co-precipitation method, which specifically includes the following steps:

[0059] (1) Mix the organic precipitant and the organic solvent according to the ratio of organic precipitant: organic solvent is 0.5mol:1L, then control the rotation speed to be 800r / min and stir and dissolve under the condition of 40°C to obtain solution A;

[0060] Described organic precipitation agent is 8-hydroxyquinoline;

[0061] Described organic solvent is ethanol;

[0062] (2), mix soluble cobalt salt, nickel salt, manganese...

Embodiment 3

[0068] A method for preparing a layered lithium-rich ternary positive electrode material doped with a trace amount of Mo. The lithium-rich ternary lithium-ion battery positive electrode material contains Li, Ni, Co, Mn, Mo and O elements, and its molecular formula is Li 1.2 (Mn 0.54 Ni 0.13 co 0.13 ) 1-x Mo x o 2 (x=0.06).

[0069] The above-mentioned method for preparing a layered lithium-rich ternary positive electrode battery material doped with a small amount of Mo, that is, using an organic co-precipitation method, specifically includes the following steps:

[0070] (1) Mix the organic precipitant and the organic solvent according to the ratio of organic precipitant:organic solvent is 2.5mol:1L, then control the rotating speed to be 500r / min, stirring and dissolving under the condition of 60°C to obtain solution 1;

[0071] Described organic precipitation agent is 8-hydroxyquinoline;

[0072] Described organic solvent is ethanol;

[0073] (2), with soluble cobalt ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com