Method of producing carbon nanoparticles

a carbon nanoparticle and nanoparticle technology, applied in the direction of carbon cleaning rags, fibre chemical treatment, chemistry apparatus and processes, etc., can solve the problems of failure to produce single-walled nanoparticles, failure to produce carbon nanotubes, fluidised bed methods, etc., to enhance gas-solid mixing and increase reaction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example 2

[0055] A hot-injection synthesis was conducted using the same supported catalyst of Example 1.

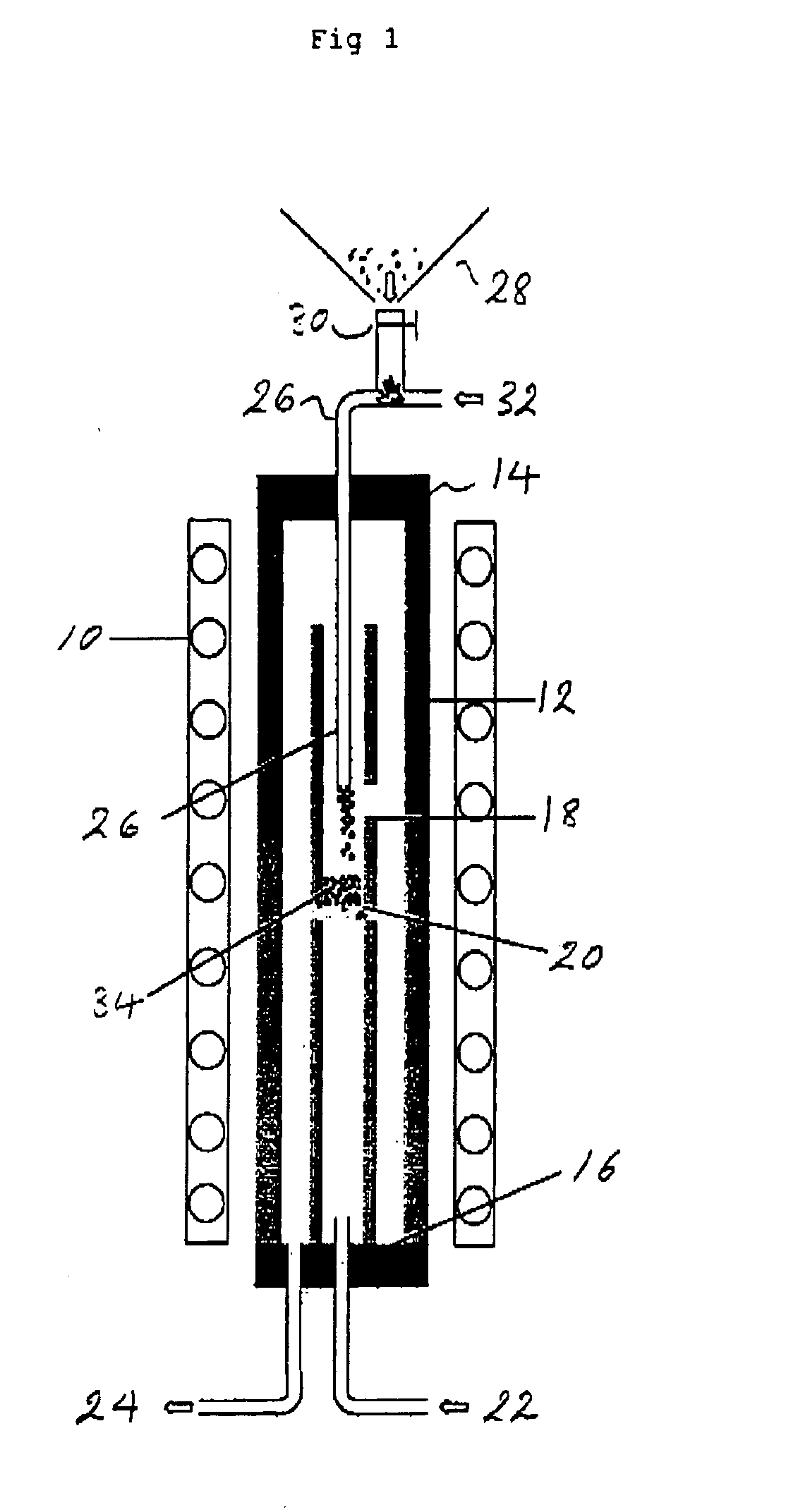

[0056] The supported catalyst was held outside the reactor under an inert argon atmosphere whilst the fluidised bed reactor was heated to 860° C. Once the reactor had reached this temperature, the supported catalyst particles were blown into the top of the vertical reactor using argon (600 ml / min) as the carrier gas.

[0057] During addition of the supported catalyst, a methane-argon mixture (ratio 1:2, 2.0 l / min) was kept flowing through the bed. The catalyst particles were fluidized on the bed in a 1:1 methane-argon mixture, at a flow rate of 2.0 l / min, at 860° C. for 20 min.

[0058] As the catalyst was exposed to the carbon source at the high temperature, an immediate colour change of the catalyst particles from their original green colour to brown or black was observed on those particles which were swept out of the fluidised bed reactor.

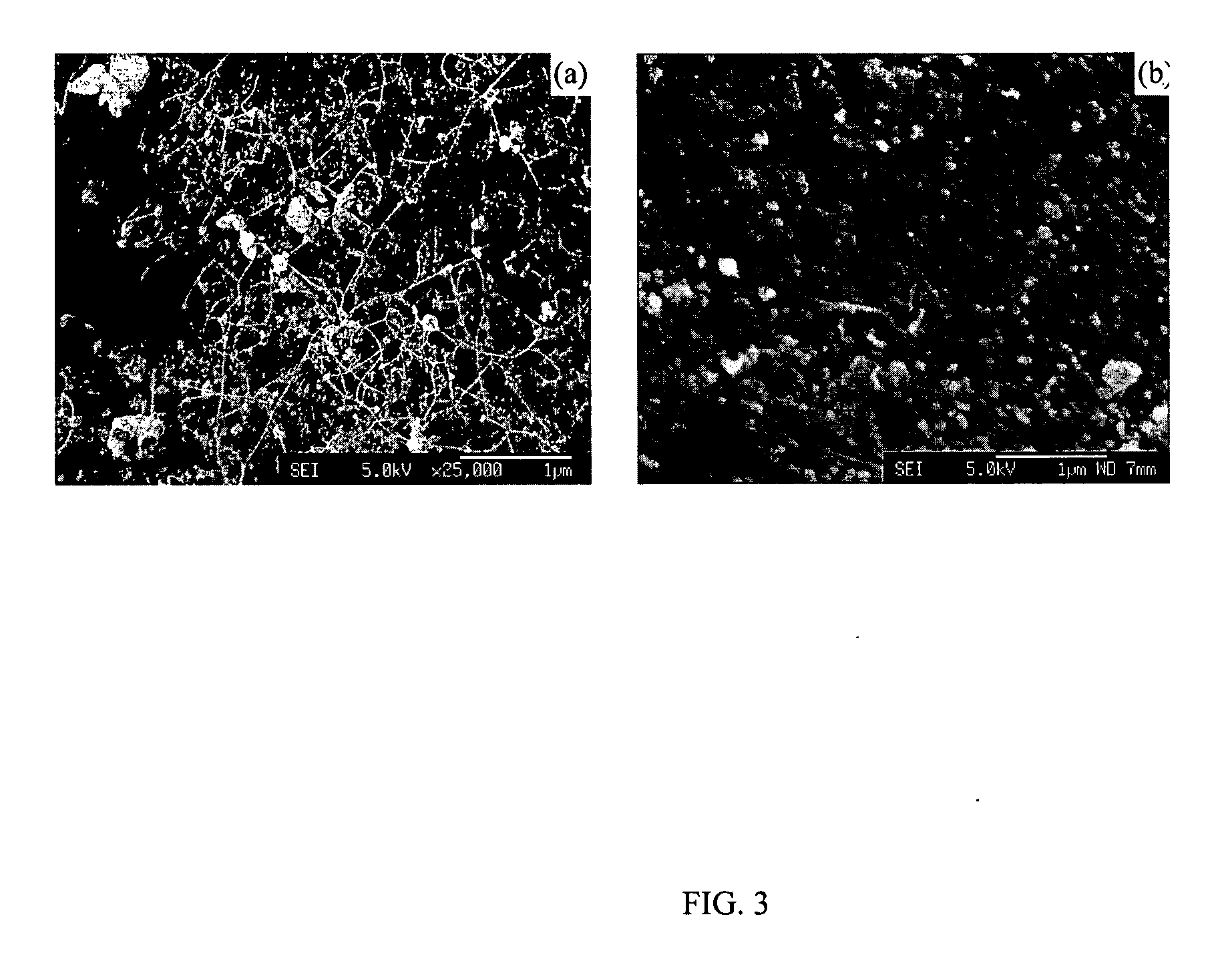

[0059] SEM observation (FIG. 1a)) of the black prod...

example 3

[0060] The supported catalyst injection method of Example 2 was carried out using pure methane rather than a mixture of methane and argon as the injection gas. The synthesis was carried out under the same conditions as Example 2, using 1:1 methane-argon. Multi-walled carbon nanotubes were grown on the surface of the silica-gel particles rather than single-walled nanotubes.

[0061] The advantages of the method of Example 2 include: [0062] 1. The method improves the efficiency of the catalyst, that is, the percentage of catalyst which produces single-walled nanotubes. [0063] 2. The addition and subsequent removal of the catalyst while the reactor is hot means that the plant is run more efficiently than a conventional fluidised bed reactor plant. [0064] 3. The plant can be run in a continuous or semi-continuous mode. A conventional fluidised bed reactor plant is run in a batchwise mode.

[0065] Without wishing to be bound by theory, the applicants believe that good results are achieved i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

| temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com