Water column forming method of spherical aluminum oxide

A technology of spherical alumina and molding method, applied in the direction of alumina/aluminum hydroxide, etc., can solve the problems of poor adaptability of raw materials, uneven strength distribution, large loss of pore volume, etc., and achieve enhanced adaptability, high purity, and strength distribution. concentrated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

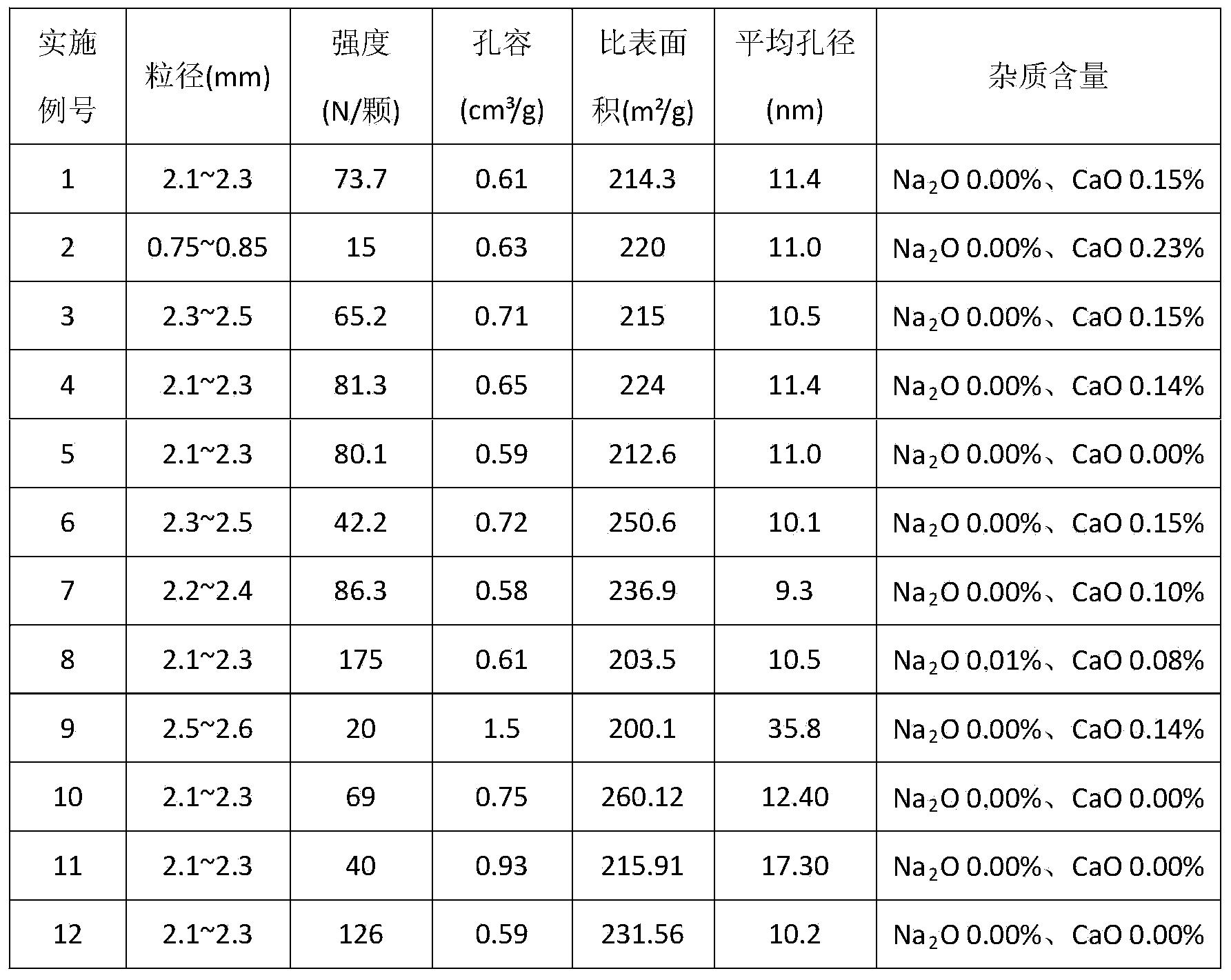

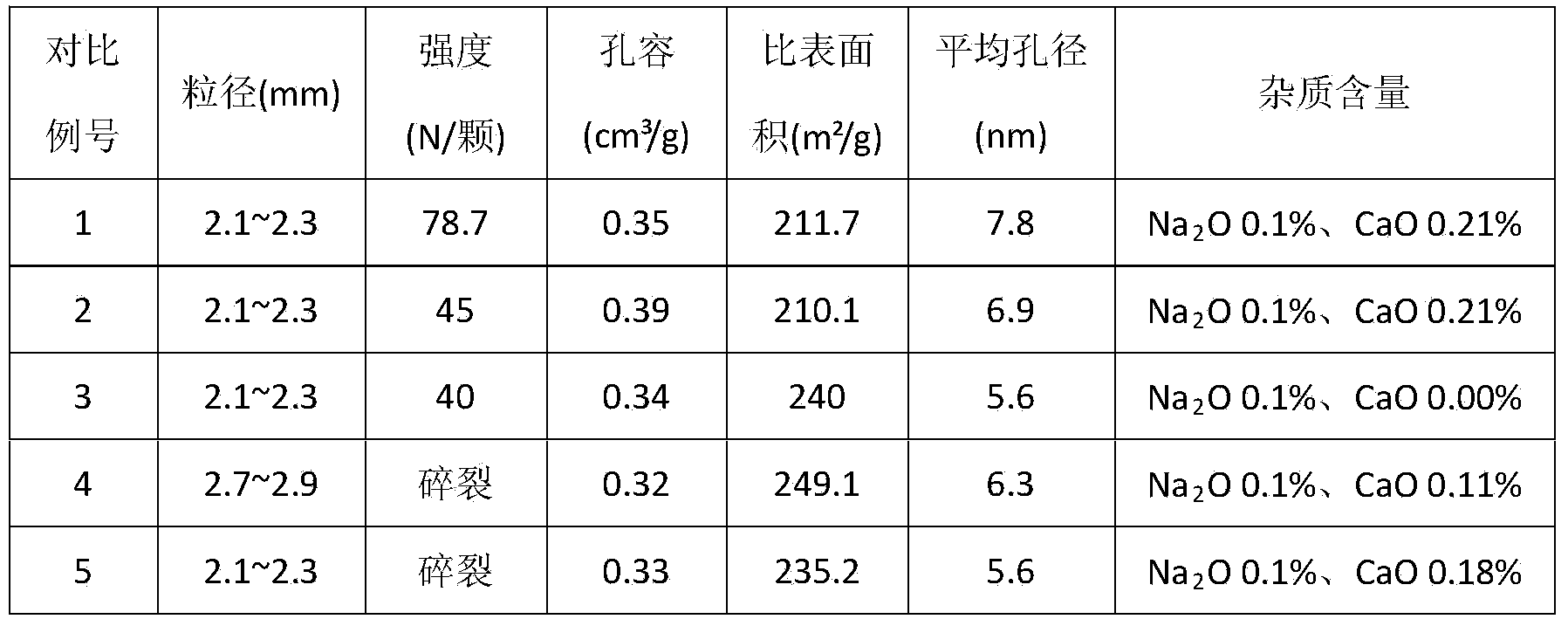

Examples

Embodiment 1

[0022] Prepare spherical alumina by the method step of the present invention:

[0023] ① Ingredients: 100g of pseudo-boehmite, added to 500g of ammonium alginate solution with a mass fraction of 0.75%, fully stirred to form ammonium alginate-pseudo-boehmite suspension;

[0024] ② Forming: Drop the ammonium alginate-pseudoboehmite suspension into the liquid column of 0.3mol / L calcium nitrate solution, and the droplets will gel to form calcium alginate-pseudo-thin diaspore composite gel pellets, then take out the gel pellets and wash with deionized water for 3 to 4 times;

[0025] ③Acid treatment: Soak the gel pellets in 0.15mol / L nitric acid solution for 15 minutes, then take them out;

[0026] ④Humid heat treatment: react for 4 hours in a heat preservation and humidity box with a temperature of 75°C and a relative humidity of 82%;

[0027] ⑤Chemical pore expansion: Soak the pellets after wet heat treatment with 0.18mol / L urea solution in a water bath at 35°C for 10 minutes; ...

Embodiment 2

[0030] Prepare gamma-A by the step in embodiment 1 2 o 3 The difference is that 1200g of ammonium alginate solution with a mass fraction of 0.75% is used for the ingredients. The physical properties and impurity content of the prepared samples are shown in Table 1.

Embodiment 3

[0032] Prepare gamma-A by the step in embodiment 1 2 o 3 The difference is that the pellets are treated with 0.5mol / L acetic acid solution. The physical properties and impurity content of the prepared samples are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com