Epoxy resin microsphere and preparation method thereof

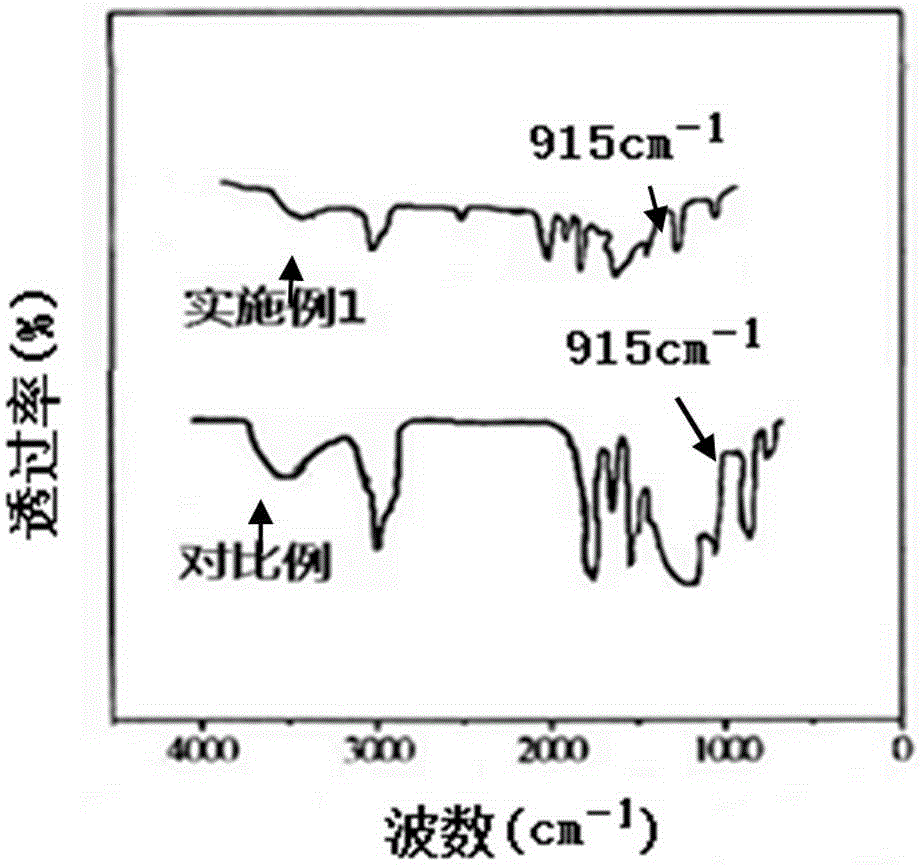

A technology for curing epoxy resin and epoxy resin, which is applied in the field of epoxy resin microspheres and its preparation, can solve the problems of low yield of epoxy resin microspheres, low recycling rate of waste liquid, environmental pollution, etc., and achieve The effect of uniform particle size, low cost and high product yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation method of the epoxy resin microsphere that the present embodiment provides comprises the steps:

[0032] (1) At 30°C, mix 22g of polyethylene oxide diol (molecular weight: 1000) and 19.8g of bisphenol A epoxy resin (E-55) and ultrasonically disperse for 10min to obtain a transparent liquid mixture A;

[0033] (2) Add 2g of triethylenetetramine to the transparent liquid mixture A, and perform ultrasonic dispersion at 35°C for 10 minutes to obtain a uniform transparent mixture liquid B. For its digital photos, see the attached figure 1 As shown in Figure A.

[0034] (3) The mixture liquid B was solidified at 65°C for 1.5h, and cooled naturally to obtain a white emulsion C containing epoxy resin microspheres. For its digital photos, see the attached figure 1 Figure B.

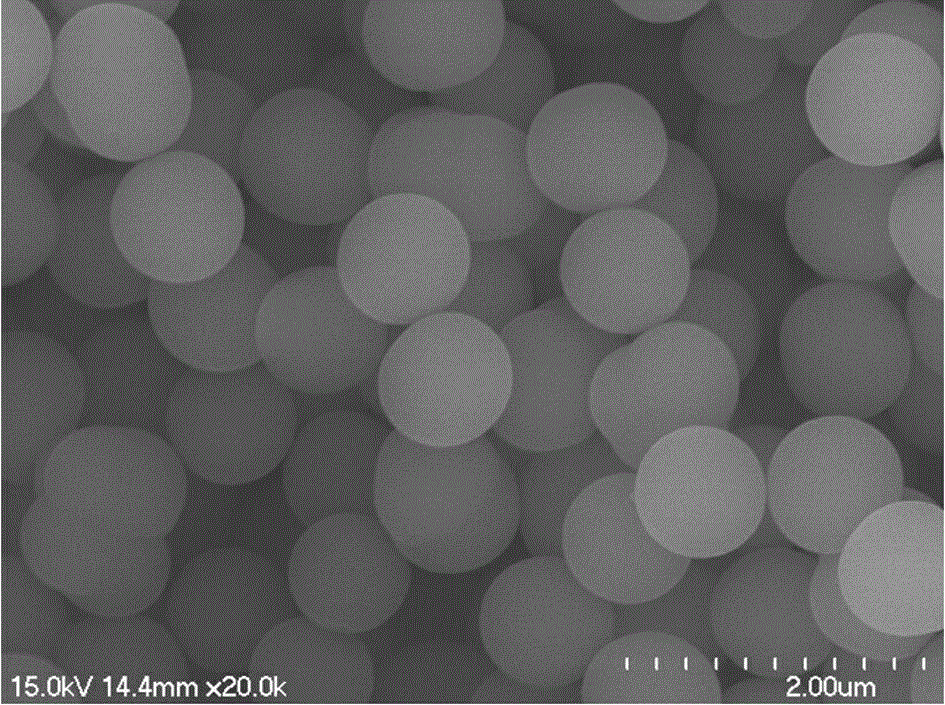

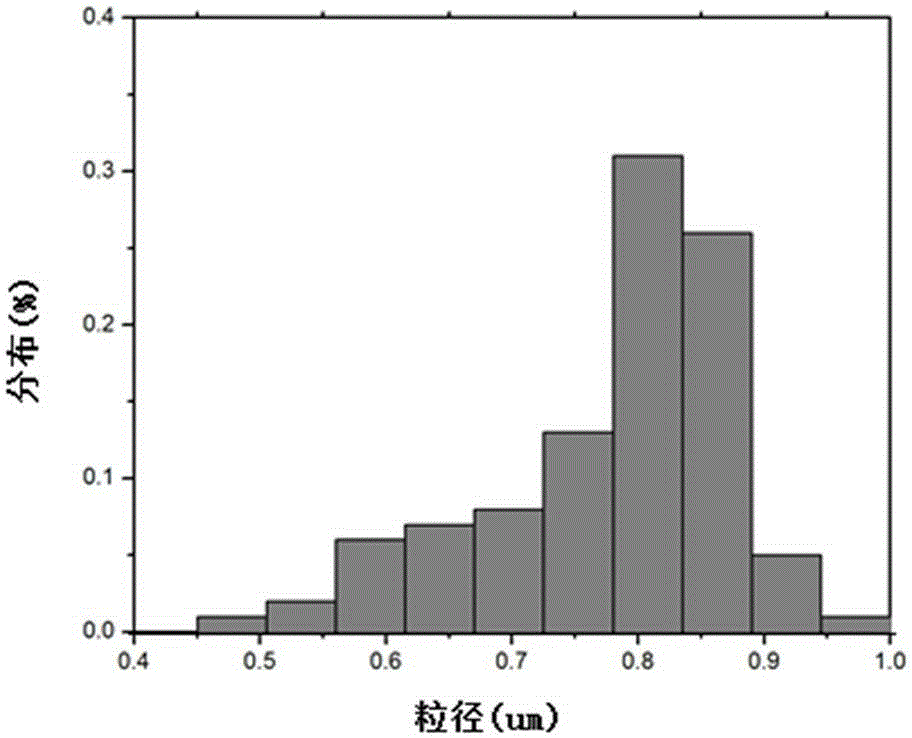

[0035] (4) Filter the white emulsion C, wash with deionized water, and dry to obtain epoxy resin microspheres with a yield of 100%. The average particle size of the microspheres is 800nm. ...

Embodiment 2

[0044] (1) At 35°C, mix 42g of polytetrahydrofuran diol (molecular weight: 1000) and 36g of bisphenol A epoxy resin (E-55) and ultrasonically disperse for 12min to obtain a transparent liquid mixture A;

[0045] (2) Add 3g of ethylenediamine to the transparent liquid mixture A, and carry out ultrasonic dispersion at 35°C for 12 minutes to obtain a uniform transparent mixture liquid B.

[0046] (3) The mixture liquid B was solidified at 65°C for 1.5h, and cooled naturally to obtain a white emulsion containing epoxy resin microspheres.

[0047] (4) Filter the white emulsion, wash with deionized water, and dry to obtain the product epoxy resin microspheres, with a yield of 100% and an average particle size of 850 nm.

[0048] The filtrate can be dehydrated under the conditions of 95° C. and a vacuum of 0.1 MPa, and polytetrahydrofuran diol can be recovered. The recyclables can be recycled, do not pollute the environment, and improve economic benefits.

Embodiment 3

[0050] (1) At 30°C, mix 24g of polyethylene glycol (molecular weight: 1000) and 20g of bisphenol A epoxy resin (E-55) and ultrasonically disperse for 14min to obtain a transparent liquid mixture A;

[0051] (2) Add 2.5g of tetraethylene trian to the transparent liquid mixture A, and carry out ultrasonic dispersion at 35°C for 15 minutes to obtain a uniform transparent mixture liquid B.

[0052] (3) The mixture liquid B was solidified at 65°C for 1.5h, and cooled naturally to obtain a white emulsion containing epoxy resin microspheres.

[0053] (4) Filter the white emulsion, wash with deionized water, and dry to obtain the product epoxy resin microspheres with a yield of 100% and an average particle size of 900 nm.

[0054] The filtrate can be dehydrated under the conditions of 95°C and a vacuum of 0.1MPa, and polyethylene glycol can be recovered. The recyclables can be recycled, do not pollute the environment, and improve economic benefits.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com