Silane modified polyether sealant with excellent water soaking bonding performance and preparation method thereof

A technology of silane-modified polyether and adhesive properties, which is applied in the direction of polyether adhesives, adhesives, adhesive types, etc., can solve problems such as adverse effects of sealant bonding, bonding failure, etc., and achieve improved water-immersion adhesion. Bonding effect, good adhesion, protective effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] The embodiment of the present invention also provides a preparation method of the above-mentioned silane-modified polyether sealant with excellent water-immersion adhesive performance, comprising the following steps:

[0030] In terms of parts by mass, put 50-100 parts of plasticizer, 100-150 parts of nano-calcium carbonate, and 50-100 parts of silicon micropowder into the high-speed disperser. Dehydration blending is carried out under the condition of 0.09MPa, the stirring rate of the dehydration blending process is 800-900 rpm, and the stirring time is 60-200 minutes;

[0031] Cool to 80±5°C, under nitrogen protection, add 100 parts of silane-modified polyether, stir at 800-900 rpm for 30-60 minutes;

[0032] Add 2 to 10 parts of resin microspheres, 1 to 3 parts of vinyltrimethoxysilane, 0.5 to 3 parts of amino coupling agent, 0.1 to 1 part of organotin catalyst, and 0.3 to 3 parts of pigment in sequence. Stirring for 30-40 minutes under the condition that the degree...

Embodiment 1

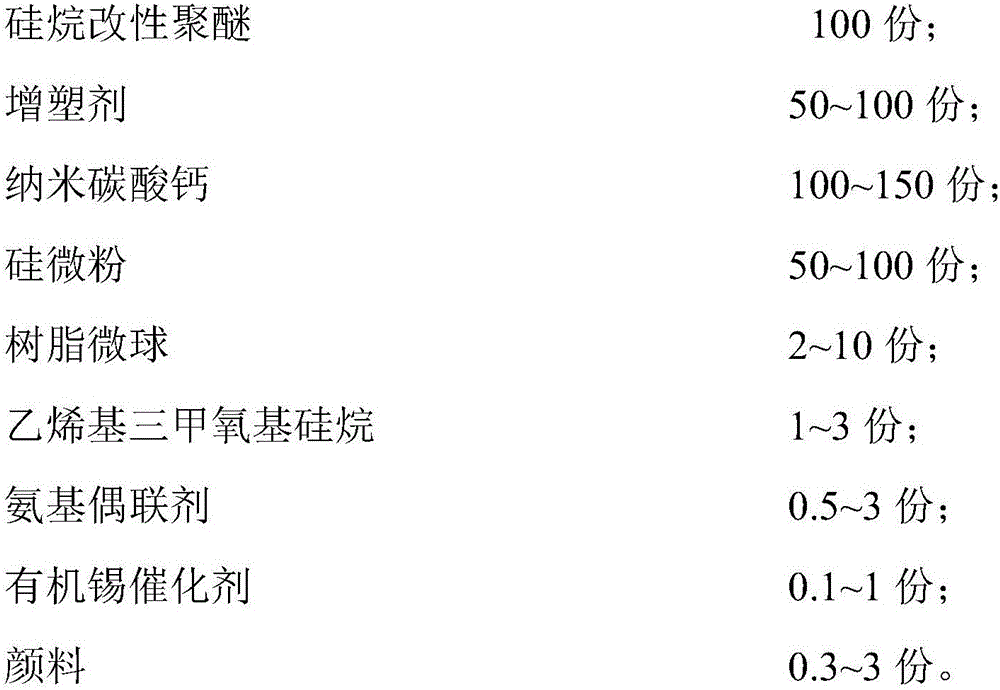

[0035] The silane-modified polyether sealant with excellent water-immersion bonding performance provided in this example includes the following components in parts by mass:

[0036]

[0037]

[0038] This example provides a method for preparing the above-mentioned silane-modified polyether sealant with excellent water-immersion bonding performance, which includes the following steps:

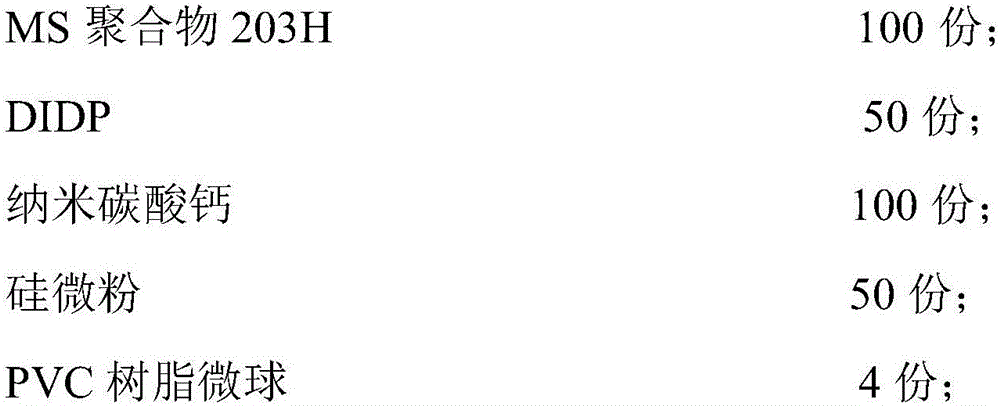

[0039] In terms of parts by mass, put 100 parts of plasticizer DIDP, 100 parts of nano-calcium carbonate, and 50 parts of silicon micropowder into a high-speed disperser, and dehydrate and blend at a temperature of 90°C to 95°C and a vacuum degree greater than -0.09MPa , stirred at a rate of 800-900 rpm for 60 minutes; cooled to 80±5°C, under nitrogen protection, added 100 parts of polymer MS 203H, stirred at a rate of 850 rpm for 30 minutes; then added PVC resin in sequence 4 parts of microspheres, 1 part of vinyltrimethoxysilane, 0.5 parts of amino coupling agent, 0.1 part of organotin c...

Embodiment 2

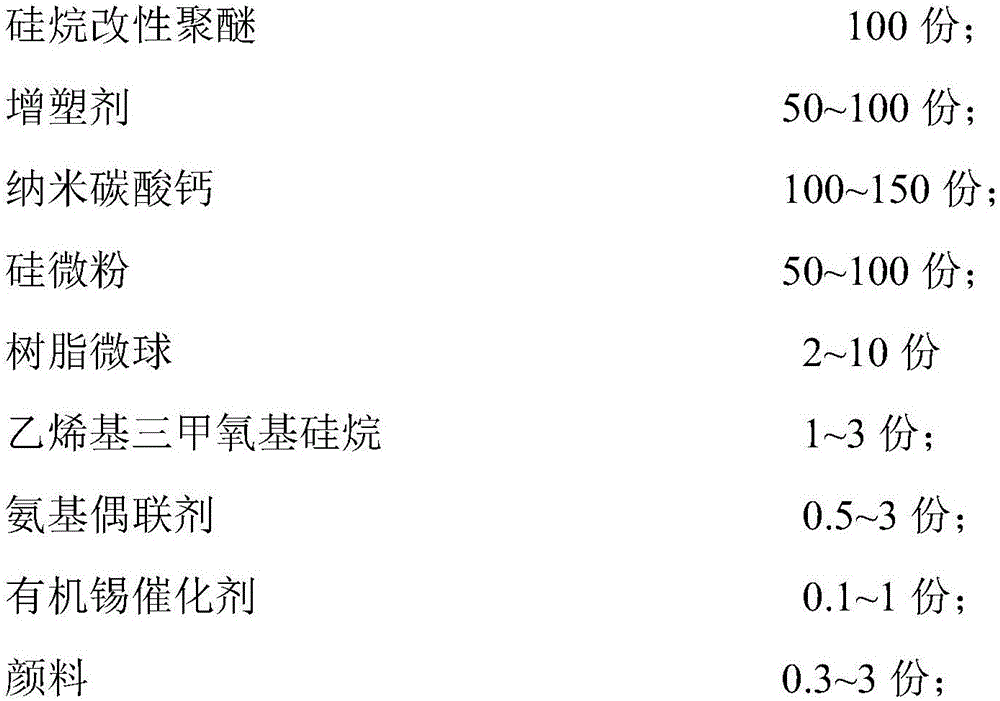

[0041] The silane-modified polyether sealant with excellent water-immersion bonding performance provided in this example includes the following components in parts by mass:

[0042]

[0043]

[0044] This example provides a method for preparing the above-mentioned silane-modified polyether sealant with excellent water-immersion bonding performance, which includes the following steps:

[0045] In terms of parts by mass, put 100 parts of plasticizer DINP, 120 parts of nano-calcium carbonate, and 80 parts of silicon micropowder into a high-speed disperser, and dehydrate and blend at a temperature of 95°C to 100°C and a vacuum degree greater than -0.09MPa , stirred at a rate of 900 rpm for 60 minutes; cooled to 80±5°C, under nitrogen protection, added 100 parts of MS polymer 303H, stirred at a rate of 900 rpm for 60 minutes; then added PVC resin microspheres in sequence 6 parts, 3 parts of vinyltrimethoxysilane, 3 parts of aminopropyltriethoxysilane, 1 part of organotin cata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com