Core-shell structure oil-absorptive resin microsphere suitable for oil well cement as well as preparation method and application of core-shell structure oil-absorptive resin microsphere

A technology of oil-absorbing resin and core-shell structure, which is used in the preparation of microspheres, microcapsule preparations, chemical instruments and methods, etc., can solve the problems of resin structure damage and poor dispersion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

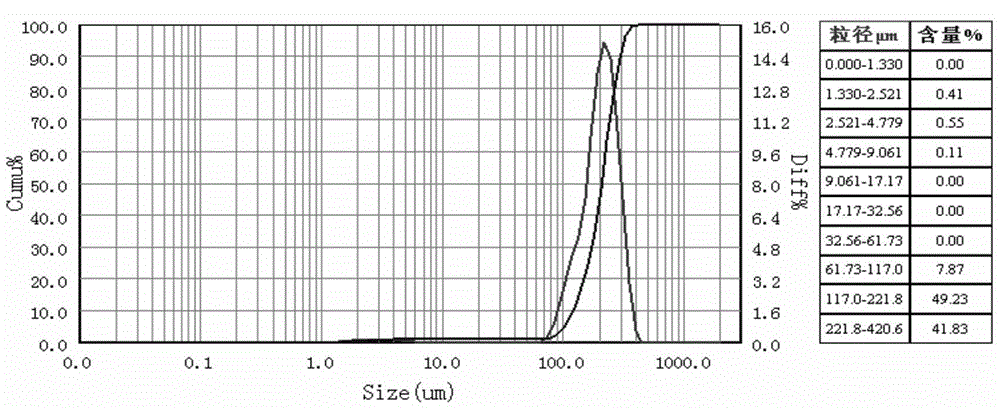

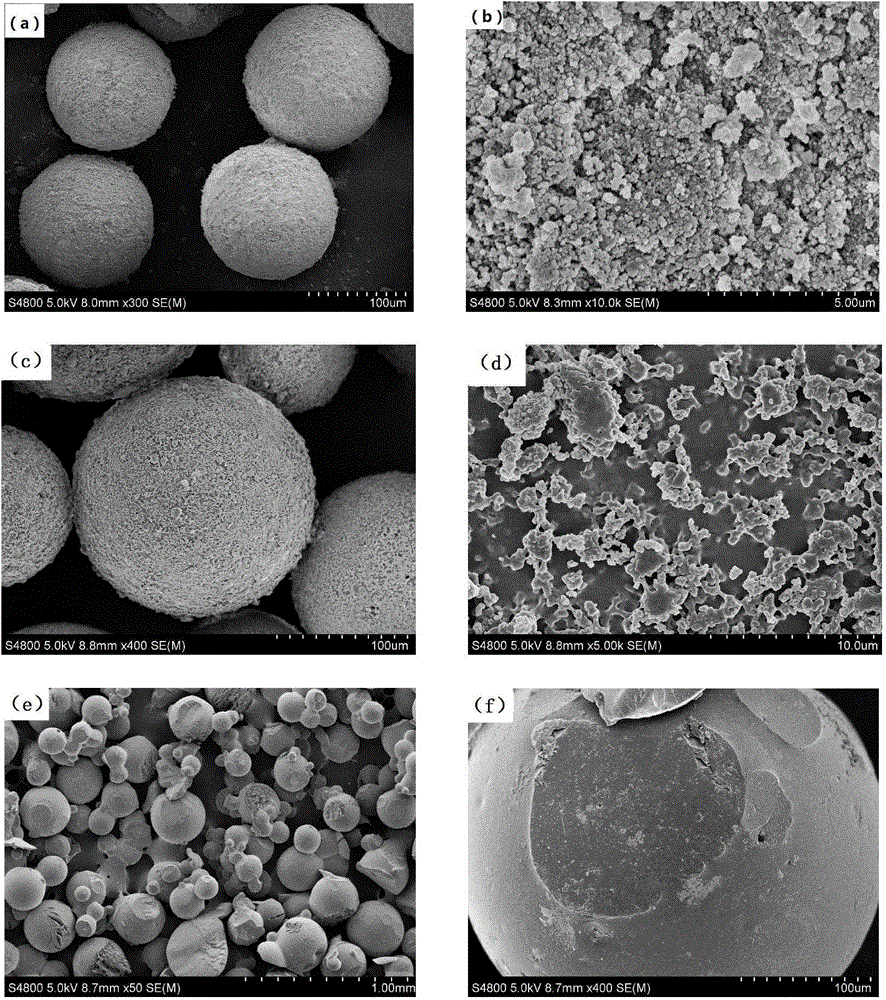

[0032] Equipped with stirrer, reflux condenser, N 2 1. Add 200 g of distilled water and 1 g of modified fumed silica into a four-necked flask with a dropping funnel, stir until the modified fumed silica is completely dispersed, and heat up to 85° C. Stir and mix 6.25g methyl methacrylate, 6.25g lauryl methacrylate, 0.063g divinylbenzene, 0.375g benzoyl peroxide and 7g ethyl acetate until the benzoyl peroxide is completely dissolved, Add the oil phase solution dropwise to water at 1000r / min, stir at a high speed for 10min, then react at 300r / min for 2h, filter after the reaction, wash with 80°C distilled water three times, and finally dry at 50°C for 24h.

Embodiment 2

[0034] Equipped with stirrer, reflux condenser, N 21. Add 200 g of distilled water and 2 g of gelatin into a four-necked flask with a dropping funnel, stir until the gelatin is completely dissolved, and heat up to 85° C. Stir and mix 6.25g methyl methacrylate, 6.25g lauryl methacrylate, 0.063g divinylbenzene, 0.375g benzoyl peroxide and 7g ethyl acetate until the benzoyl peroxide is completely dissolved. Add the oil phase solution dropwise to water at 1000r / min, stir at high speed for 10min, then react at 300r / min for 2h, filter after the reaction, wash with 80°C distilled water three times, and finally dry at 50°C for 24h.

Embodiment 3

[0036] Equipped with stirrer, reflux condenser, N 2 1. Add 200 g of distilled water and 1.3 g of modified fumed silica into a four-necked flask with a dropping funnel, stir until the modified fumed silica is completely dispersed, and heat up to 80° C. Stir and mix 5.5g methyl methacrylate, 7g lauryl methacrylate, 0.06g divinylbenzene, 0.2g benzoyl peroxide and 12.5g ethyl acetate until the benzoyl peroxide is completely dissolved, The oil phase solution was added dropwise to water at a speed of 1000r / min, stirred at a high speed for 10min, then reacted at a speed of 300r / min for 3h, filtered after the reaction, washed with 80°C distilled water for 3 times, and finally dried at 50°C for 24h.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com