Mixing device of latex and expandable resin microspheres

An expansion resin and mixing device technology, which is applied in explosive processing equipment, offensive equipment, explosives, etc., can solve the problems of lack of mixing of latex and expansion resin microspheres, difficult control of product components, complex production process, etc., and achieve simple structure, Effect of improving explosive performance and improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

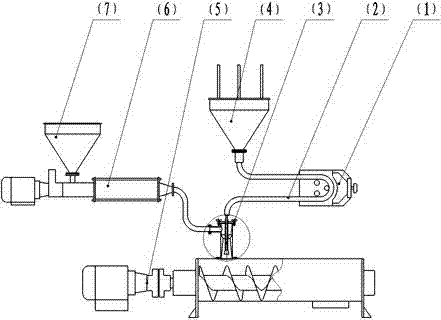

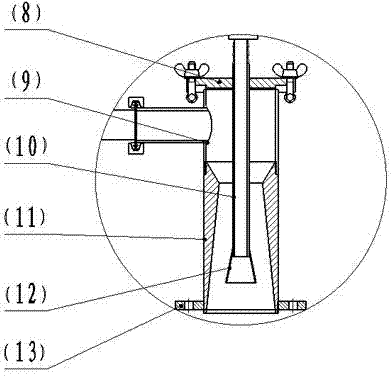

[0007] see Figure 1-Figure 2 : The present invention comprises peristaltic pump ⑴, hose ⑵, mixing nozzle ⑶, microsphere silo ⑷, mixing mixer ⑸, screw pump ⑹, latex hopper ⑺, wherein the mixing nozzle ⑶ mainly consists of upper connection flange ⑻, latex injection pressure silo ⑼, micro powder conveying pipe ⑽, latex injection throat ⑾, diversion cover ⑿, lower connecting flange ⒀, the microsphere silo ⑷ is connected to the upper connecting flange ⑻ of the mixing nozzle through the hose ⑵ through the peristaltic pump ⑴, The latex silo (⑺) is connected to the mixing nozzle (⑶) through the screw pump (⑹) through the process pipe, the feed port of the mixing mixer (⑸) is connected to the connecting flange (⒀) under the mixing nozzle (⑶), and the other end is the outlet.

[0008] In the present invention, the latex is added into the latex silo⑺, relying on the screw pump ⑹ as the power and metering device, the latex is transported to the mixing nozzle ⑶, transported to the latex s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com