Preparation method of epoxy resin hollow microsphere

A technology of epoxy resin and microspheres, which is applied in the preparation of microspheres, microcapsule preparations, etc., can solve the problems of good solvent resistance, low linear expansion rate, low dielectric constant, etc., and achieve high mechanical strength and low manufacturing cost , The effect of simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

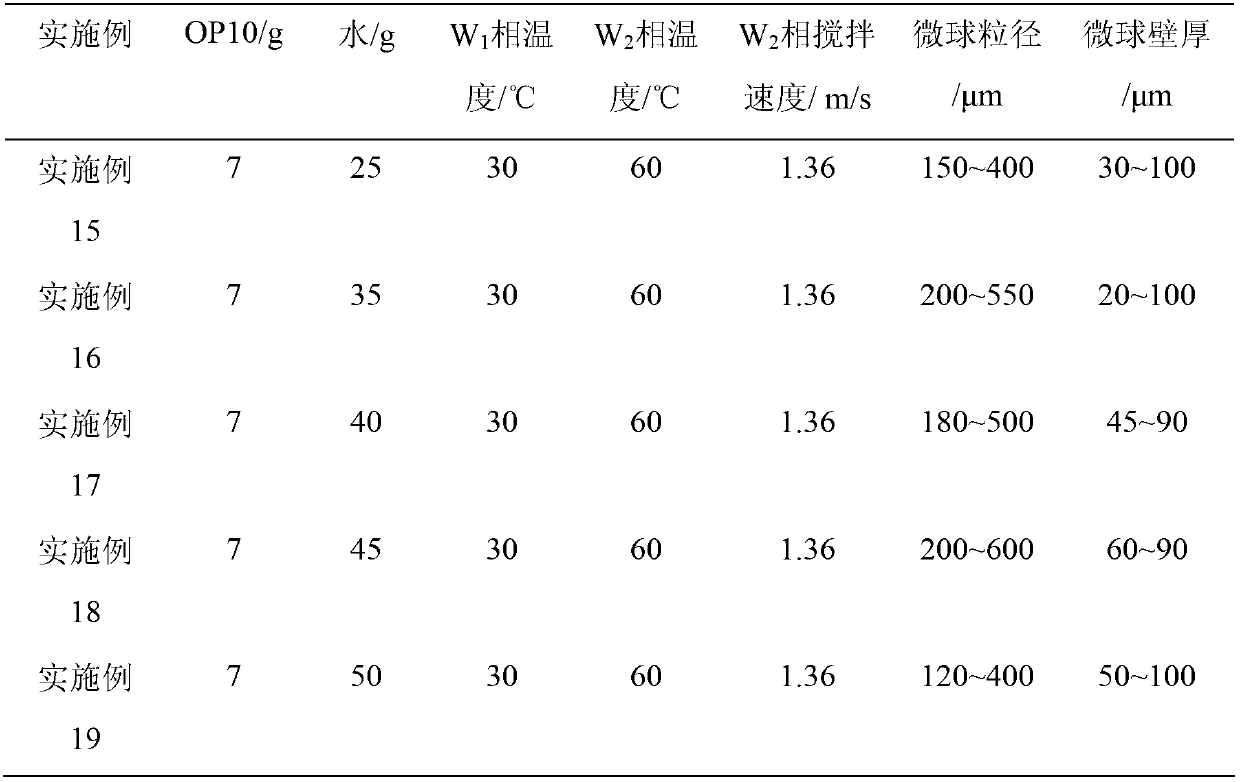

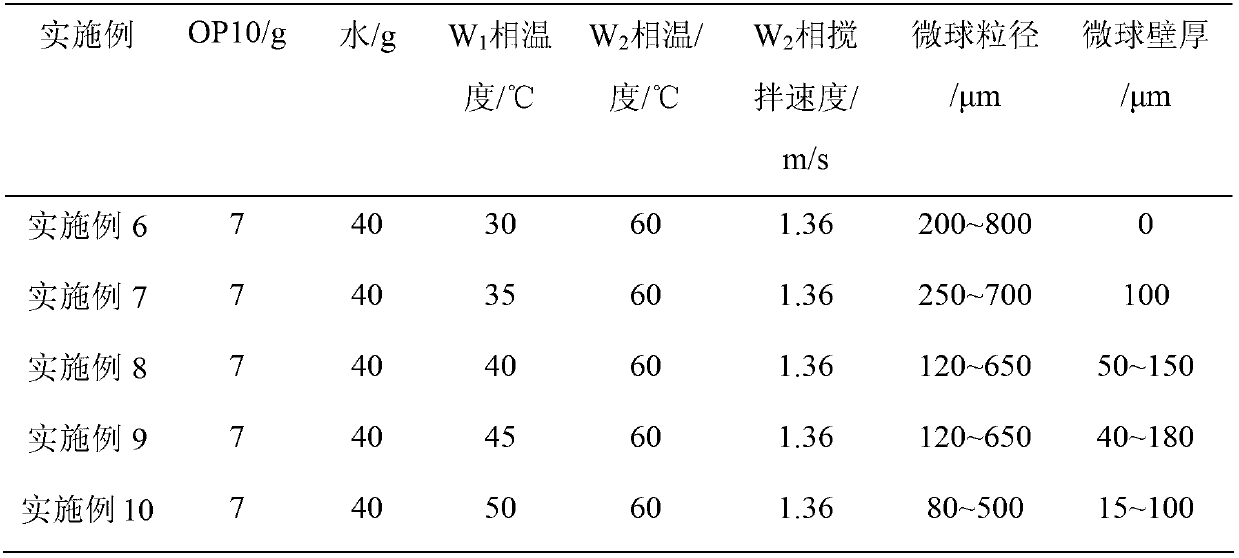

[0018] In the invention, epoxy resin hollow microspheres are prepared by using epoxy resin as the shell and water as the inner core. The preparation method comprises the following steps:

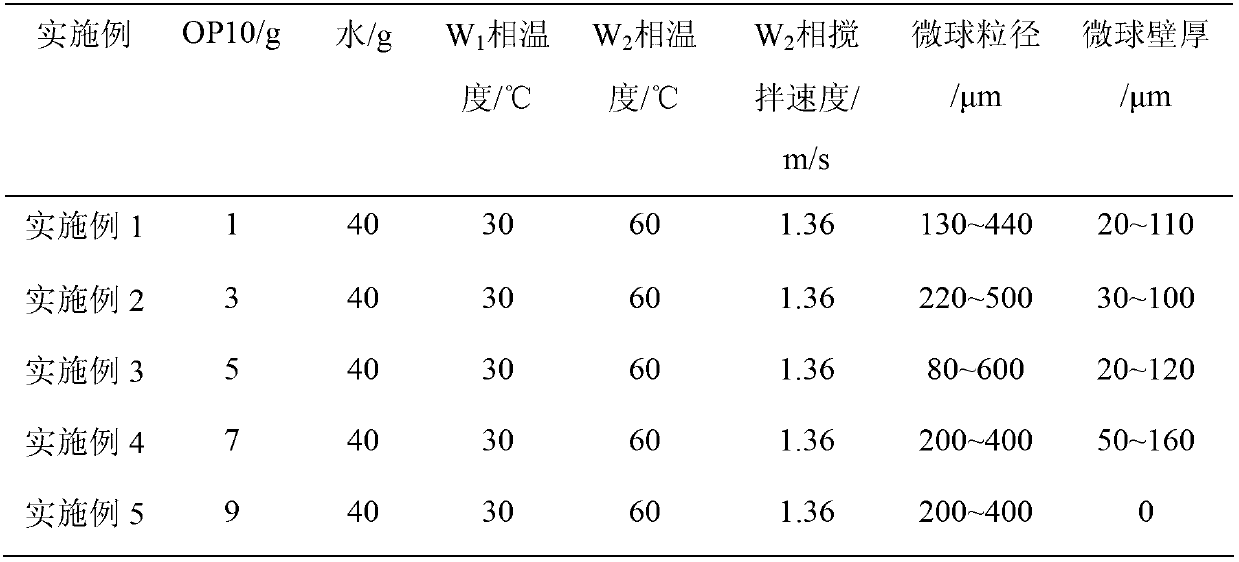

[0019] (b) Preparation of water / epoxy emulsion: After mixing 100g of epoxy resin monomer, 12.9g of triethylenetetramine, and 1~9g of OP10 (alkylphenol polyoxyethylene ether) at 30~50°C, Add 25~50g of deionized water dropwise at a stirring speed of 2.7m / s to obtain a water / epoxy emulsion;

[0020] (b) Preparation of water / epoxy / ethylene glycol emulsion: Add the water / epoxy emulsion prepared in step (a) dropwise to ethylene glycol ( 200g, technical grade), obtain water / epoxy / ethylene glycol emulsion;

[0021] (c) Preparation of water-containing epoxy resin microspheres: the water / epoxy / ethylene glycol emulsion prepared in step (b) was heated up to 100° C. for 1 h to cure the epoxy resin. Filtration and washing to obtain water-containing epoxy resin microspheres;

[0022] (d) Preparation of...

Embodiment 1

[0026] A preparation method of epoxy resin hollow microspheres, comprising the following steps:

[0027] (a) Preparation of water / epoxy emulsion: After mixing 100g of epoxy resin monomer, 12.9g of triethylenetetramine, and 1g of OP10 at 30°C, add deionized water dropwise at a stirring speed of 2.7m / s 40g, obtain water / epoxy emulsion;

[0028] (b) Preparation of water / epoxy / ethylene glycol emulsion: Add the water / epoxy emulsion prepared in step (a) dropwise into ethylene glycol (200g) at 60°C at a stirring speed of 1.36m / s, Obtain water / epoxy / ethylene glycol emulsion;

[0029] (c) Preparation of water-containing epoxy resin microspheres: the water / epoxy / ethylene glycol emulsion prepared in step (b) was heated up to 100° C. for 1 h to cure the epoxy resin. Filtration and washing to obtain water-containing epoxy resin microspheres;

[0030] (d) Preparation of epoxy resin hollow microspheres: vacuum-dry the water-containing epoxy resin microspheres prepared in step (c) for 24 h...

Embodiment 2

[0032] A preparation method of epoxy resin hollow microspheres, comprising the following steps:

[0033] (a) Preparation of water / epoxy emulsion: After mixing 100g of epoxy resin monomer, 12.9g of triethylenetetramine, and 3g of OP10 at 30°C, add deionized water dropwise at a stirring speed of 2.7m / s 40g, obtain water / epoxy emulsion;

[0034] (b) Preparation of water / epoxy / ethylene glycol emulsion: Add the water / epoxy emulsion prepared in step (a) dropwise into ethylene glycol (200g) at 60°C at a stirring speed of 1.36m / s, Obtain water / epoxy / ethylene glycol emulsion;

[0035] (c) Preparation of water-containing epoxy resin microspheres: the water / epoxy / ethylene glycol emulsion prepared in step (b) was heated up to 100° C. for 1 h to cure the epoxy resin. Filtration and washing to obtain water-containing epoxy resin microspheres;

[0036] (d) Preparation of epoxy resin hollow microspheres: vacuum-dry the water-containing epoxy resin microspheres prepared in step (c) for 24 h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com