Melamine resin hollow microspheres and preparation method and application thereof

A technology of melamine resin and microspheres, which is applied in the direction of microsphere preparation, microcapsule preparations, chemical instruments and methods, etc., can solve the problem that the thickness and phase composition of hollow spherical shells are difficult to effectively and precisely control, the particle size of spheres is difficult to control, and there is no Industrialized products and other problems, to achieve the effect of low cost, good hollowness and short reaction time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

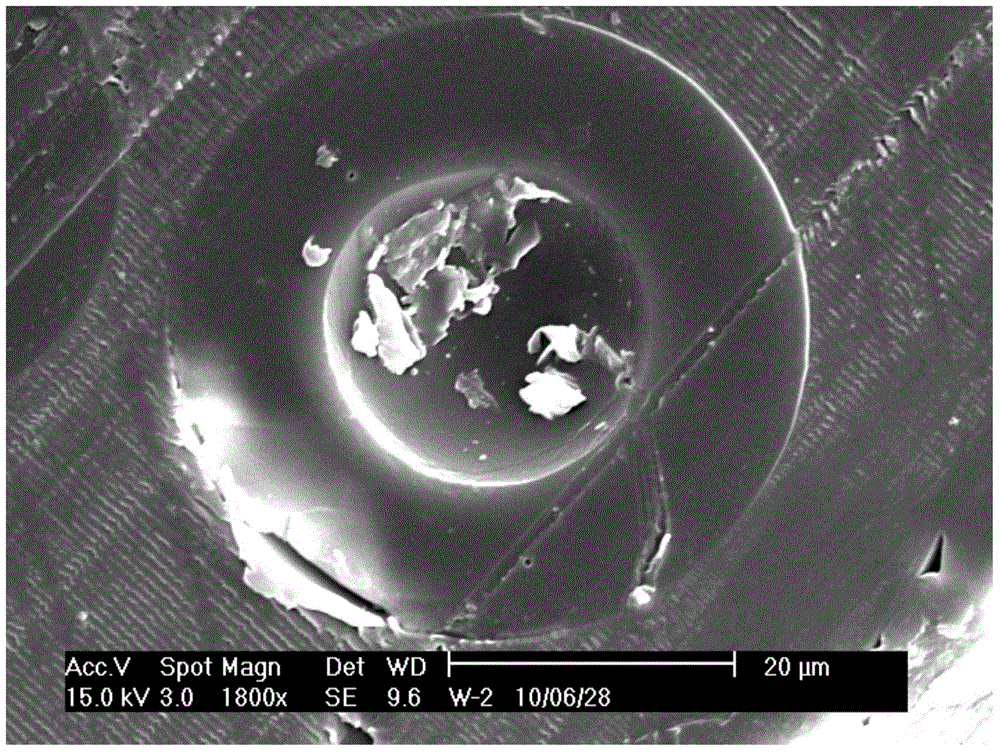

Image

Examples

Embodiment 1

[0042] (1) Adjust the melamine resin prepolymer to a solid content of 10%wt, weigh the 1000g liquid containing 10%wt solid content, adjust the pH value to 6 with acetic acid, and stir evenly to obtain a slurry;

[0043] (2) Start the spray drying equipment, set the inlet temperature parameter as 160°C, the cyclone wind speed as 800 l / h, and the cyclone air volume as 100%, so that the temperature field of the equipment is constant and uniform, and the air flow is stable; the speed of the volume pump is adjusted to 10mL / min , the uniformly dispersed slurry is evenly sprayed under the working chamber, and the slurry is dried instantly to become hollow microspheres, and the microspheres are respectively collected in the material receiver, bag filter and tower bottom under the drive of the air-inducing device; measured The obtained melamine resin hollow microspheres have a particle diameter of 60-100 μm and a density of 0.78 g / cm 3 .

Embodiment 2

[0045] (1) Adjust the melamine resin prepolymer to a solid content of 15%wt, weigh 1000g of the liquid, adjust the pH to 6 with acetic acid, add 5g of ammonium bicarbonate, 2.5g of ammonia, and 0.12g of dodecylbenzenesulfonic acid Sodium, stir evenly to obtain slurry;

[0046] (2) Start the spray drying equipment, set the inlet temperature parameter as 200°C, the cyclone wind speed as 700 l / h, and the cyclone air volume as 100%, so that the temperature field of the equipment is constant and uniform, and the air flow is stable; the speed of the volume pump is adjusted to 15mL / min , the uniformly dispersed slurry is evenly sprayed under the working chamber, and the slurry is dried instantly to become hollow microspheres, and the microspheres are respectively collected in the material receiver, bag filter and tower bottom under the drive of the air-inducing device; measured The obtained melamine resin hollow microspheres have a particle diameter of 80-130 μm and a density of 0.63...

Embodiment 3

[0048] (1) Adjust the melamine resin prepolymer to a solid content of 20%wt, weigh 1000g of the liquid, adjust the pH to 4 with hydrochloric acid, add 20g of urea, 0.12g of sodium dodecylbenzenesulfonate, and stir evenly to obtain a slurry ;

[0049] (2) Start the spray drying equipment, set the inlet temperature parameter as 250°C, the cyclone wind speed as 500l / h, and the cyclone air volume as 100%, so that the temperature field of the equipment is constant and uniform, and the air flow is stable; the speed of the volume pump is adjusted to 20mL / min , the uniformly dispersed slurry is evenly sprayed under the working chamber, and the slurry is dried instantly to become hollow microspheres, and the microspheres are respectively collected in the material receiver, bag filter and tower bottom under the drive of the air-inducing device; measured The obtained melamine resin hollow microspheres have a particle diameter of 90-140 μm and a density of 0.45 g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com