Thermal expansion resin powder with high dispersity and preparation method thereof

A thermal expansion and resin technology, applied in the field of resin micropowder, can solve the problems that resin micropowder is not easy to disperse, limit the industrial application of thermal expansion resin micropowder, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

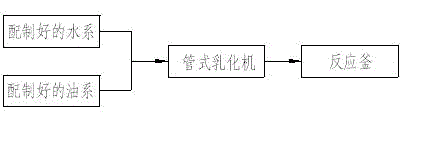

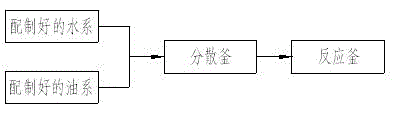

Method used

Image

Examples

Embodiment 1

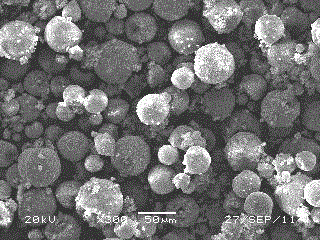

[0034] The configuration of water-based material is to add 0.08 grams of sodium styrene sulfonate on the basis of the configuration of Comparative Example 1. The oil-based material of the configuration is the same as in Comparative Example 1, and other conditions such as dispersion, reaction temperature, reaction time, and material handling from the kettle are different. Change. The average particle diameter measured by the same method is 28 microns, and the maximum expansion ratio is 38 times, scanned by electron microscope at Figure 4 , the detailed comparison is in the table below.

[0035] Preparation of water system Formulated Oil Scatter, React, Handle Situations Dispersion in water Microscope observation Comparative example 1 See Comparative Example 1 see comparative example 1 see comparative example 1 turbid Partially aggregated particles suspended in water Example 1 Add 0.08 grams of sodium styrene sulfonate on the basis of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com