High flame resistance transparent light diffusion polycarbonate and preparation method thereof

A light diffusion and high flame retardant technology, applied in the field of high flame retardant transparent light diffusion PC and its preparation, can solve the problems of reducing the light transmission performance and haze of PC, and achieve good flame retardant effect, good dispersion, and small amount of addition Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

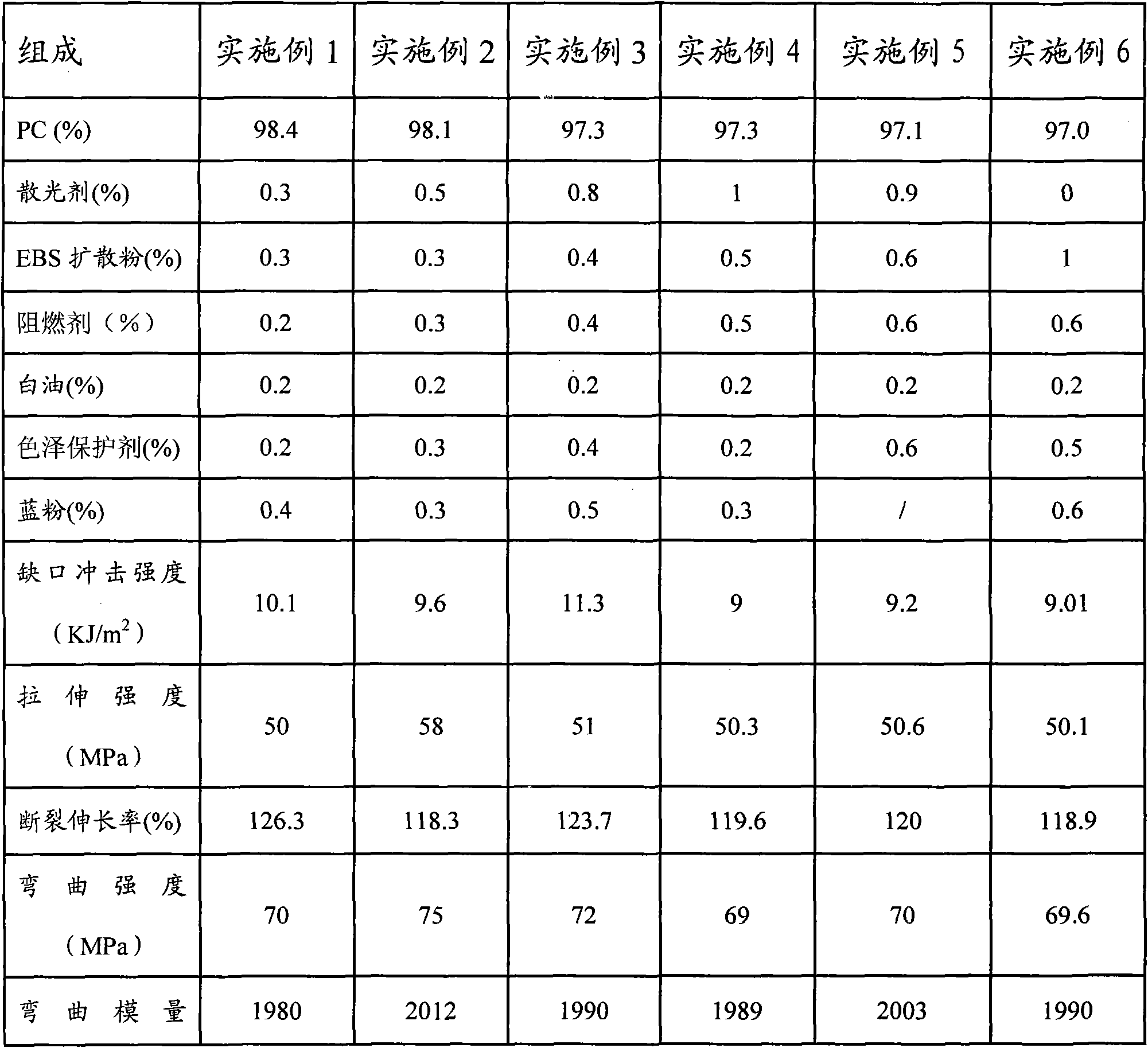

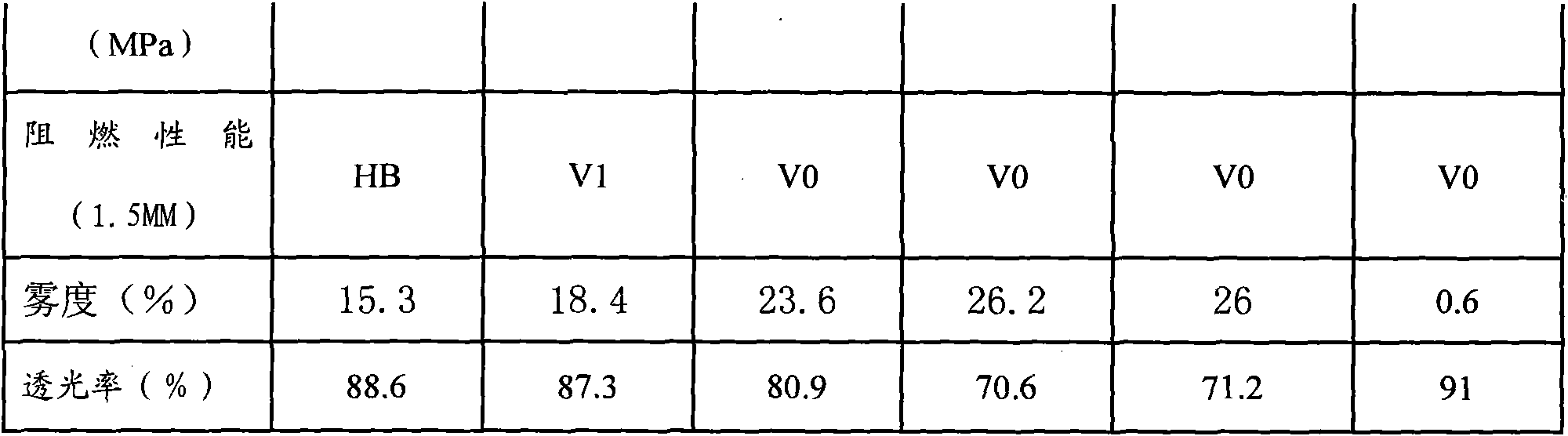

Embodiment 1

[0028] Mix the diffusing agent 0.3% diffusing agent, EBS diffusing powder 0.3% and flame retardant 0.2% in a plastic container by weight, and then mix PC engineering plastics 98.4%, white oil 0.2% and color protection agent 0.2% in another Mix the plastic container evenly, then put the mixed scattering agent, engineering plastic and blue powder 0.4% into the high-speed mixing container, and mix at high and low speed for 3-5min at room temperature. Afterwards, the mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the processing temperature settings of each zone of the screw are: the temperature of the first zone is 160-180°C, the temperature of the second zone is 240-260°C, the temperature of the third zone is 270-280°C, the temperature of the fourth zone is 270-280°C, the temperature of the fifth zone is 270-280°C, The temperature of the sixth zone is 270-280°C, the temperat...

Embodiment 2

[0030] Mix the diffusing agent 0.5% diffusing agent, EBS diffusing powder 0.3% and flame retardant 0.3% in a plastic container by weight, and then mix PC engineering plastics 98.1%, white oil 0.2% and color protection agent 0.3% in another Mix the plastic container evenly, then put the mixed light-dispersing agent, engineering plastic and blue powder 0.3% into the high-speed mixing container, and mix at high and low speed for 3-5min at room temperature. Afterwards, the mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the processing temperature settings of each zone of the screw are: the temperature of the first zone is 160-180°C, the temperature of the second zone is 240-260°C, the temperature of the third zone is 270-280°C, the temperature of the fourth zone is 270-280°C, the temperature of the fifth zone is 270-280°C, The temperature of the sixth zone is 270-280°C, the te...

Embodiment 3

[0032] Mix the diffusing agent 0.8% diffusing agent, EBS diffusing powder 0.4% and flame retardant 0.4% in a plastic container by weight, and then mix PC engineering plastics 97.3%, white oil 0.2% and color protection agent 0.4% in another Mix the plastic container evenly, then put the mixed light-dispersing agent, engineering plastics and blue powder 0.5% into the high-speed mixing container, and mix at high and low speed for 3-5min at room temperature. Afterwards, the mixed materials are put into the hopper of the twin-screw extruder, melted and blended, extruded and granulated to form a composite material. Among them, the processing temperature settings of each zone of the screw are: the temperature of the first zone is 160-180°C, the temperature of the second zone is 240-260°C, the temperature of the third zone is 270-280°C, the temperature of the fourth zone is 270-280°C, the temperature of the fifth zone is 270-280°C, The temperature of the sixth zone is 270-280°C, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com