Phenol formaldehyde resin carbon micro-sphere preparation method and application of phenol formaldehyde resin carbon micro-sphere in lithium ion battery electrode

A technology of phenolic resin and carbon microspheres, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of difficult control of particle size, harsh synthesis conditions, complex synthesis equipment, etc., and achieve controllable particle size, good shape, The effect of simplifying the synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Example 1 Mix 5g of phenol, 8.62ml of formaldehyde solution, and 0.106g of sodium hydroxide in a molar ratio of 1:2:0.05 and add them into a 100ml three-necked flask, and react at 60°C for 12h to obtain the first mixed solution. Mix 2ml of the first mixed solution (adjusted to pH 4) and 30ml of vegetable oil at a volume ratio of 1:15, then add a nonionic surfactant with a volume fraction of 0.06 and mix evenly to obtain the second mixed solution, and stir the second mixed solution at room temperature After the emulsification treatment, put it into a blast oven at 100° C. to react for 12 hours to obtain a reaction product, which was centrifuged and washed with acetone to obtain phenolic resin microspheres.

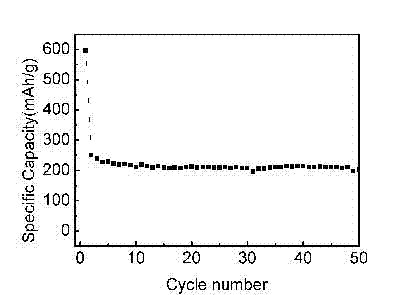

[0029] Under an inert atmosphere, heat the phenolic resin balls at 700°C for 4 hours to obtain phenolic resin carbon microspheres.

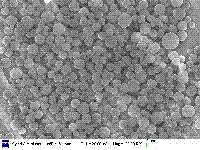

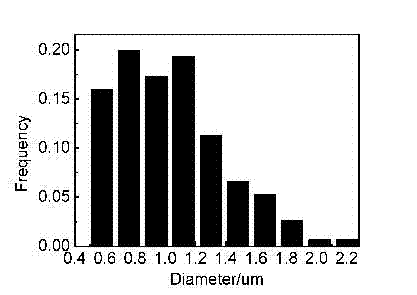

[0030] Utilize scanning electron microscope to analyze the phenolic resin microsphere that obtains in embodiment 1 namely carbon micro...

Embodiment 2

[0035] Example 2 Mix 5 g of phenol, 4.31 ml of formaldehyde solution, and 1.704 g of sodium hydroxide in a molar ratio of 1:1:0.8 and add them into a 100 ml three-necked flask, and react at 30°C for 24 hours to obtain the first mixed solution. Mix 2ml of the first mixed solution (adjusted to pH 7) and 30ml of vegetable oil at a volume ratio of 1:15, then add a nonionic surfactant with a volume fraction of 0.06 and mix evenly to obtain the second mixed solution, and stir the second mixed solution at room temperature After the emulsification treatment, put it into a blast oven at 150° C. to react for 12 hours to obtain a reaction product, which was centrifuged and washed with acetone to obtain phenolic resin microspheres.

[0036] Under an inert atmosphere, heat the phenolic resin balls at 700°C for 4 hours to obtain phenolic resin carbon microspheres.

Embodiment 3

[0037] Example 3 Mix 5 g of phenol, 17.25 ml of formaldehyde solution, and 0.0022 g of sodium hydroxide in a molar ratio of 1:4:0.001 and add them into a 100 ml three-necked flask, and react at 200° C. for 1 hour to obtain the first mixed solution. Mix 2ml of the first mixed solution (adjusted to pH 7) and 30ml of vegetable oil at a volume ratio of 1:15, then add a nonionic surfactant with a volume fraction of 0.06 and mix evenly to obtain the second mixed solution, and stir the second mixed solution at room temperature After the emulsification treatment, put it into a blast oven at 90° C. to react for 12 hours to obtain a reaction product, which was centrifuged and washed with acetone to obtain phenolic resin microspheres.

[0038] Under an inert atmosphere, heat the phenolic resin balls at 700°C for 5 hours to obtain phenolic resin carbon microspheres.

[0039] The particle size test of the phenolic resin microsphere obtained in embodiment 3, its average diameter is 3um, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com