Method for synthesizing urea-formaldehyde resin microspheres with uniform particle size distribution

A technology of urea-formaldehyde resin and particle size distribution, which is applied in the field of synthesizing urea-formaldehyde resin microspheres with uniform particle size distribution, and can solve the problems of not obtaining urea-formaldehyde resin microspheres

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

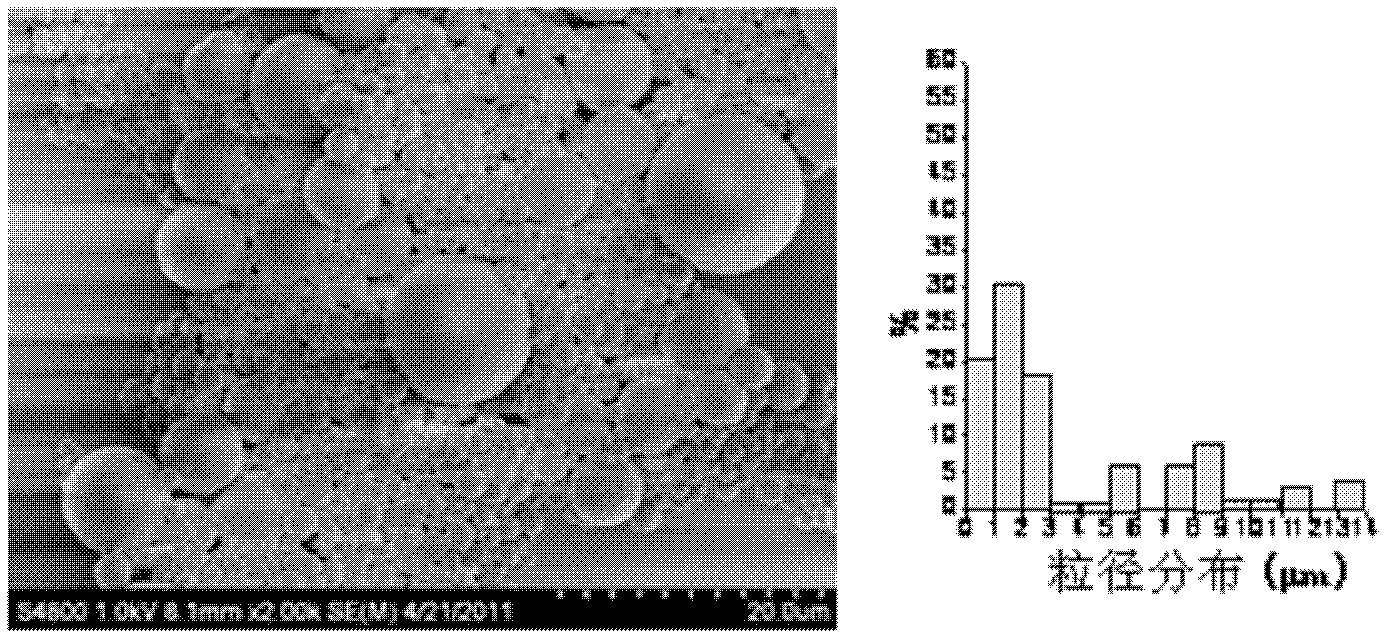

[0027] figure 1 It is the SEM photo of urea-formaldehyde resin microspheres without surfactant and its particle size distribution. It can be seen intuitively that the particle size distribution of the microspheres is not uniform and there are some adhesions. Therefore, adopting a brand-new method, that is, adding a surfactant, hopes to prepare urea-formaldehyde resin microspheres with uniform particle size distribution and dispersion.

[0028] Add 1mL of 1.00% Tween80 into a 100mL beaker containing 40mL of distilled water, add 2.25g of urea to dissolve, then add 6mL of formaldehyde and stir evenly, and finally add 0.2mL of hydrochloric acid. Stand until the solution reacts to form a cloudy white state, continue to react for ten minutes and separate by suction filtration, wash with a small amount of deionized water and ethanol three times respectively to obtain a urea-formaldehyde resin precipitate. The separated urea-formaldehyde resin microspheres were dried at room temperat...

Embodiment 2

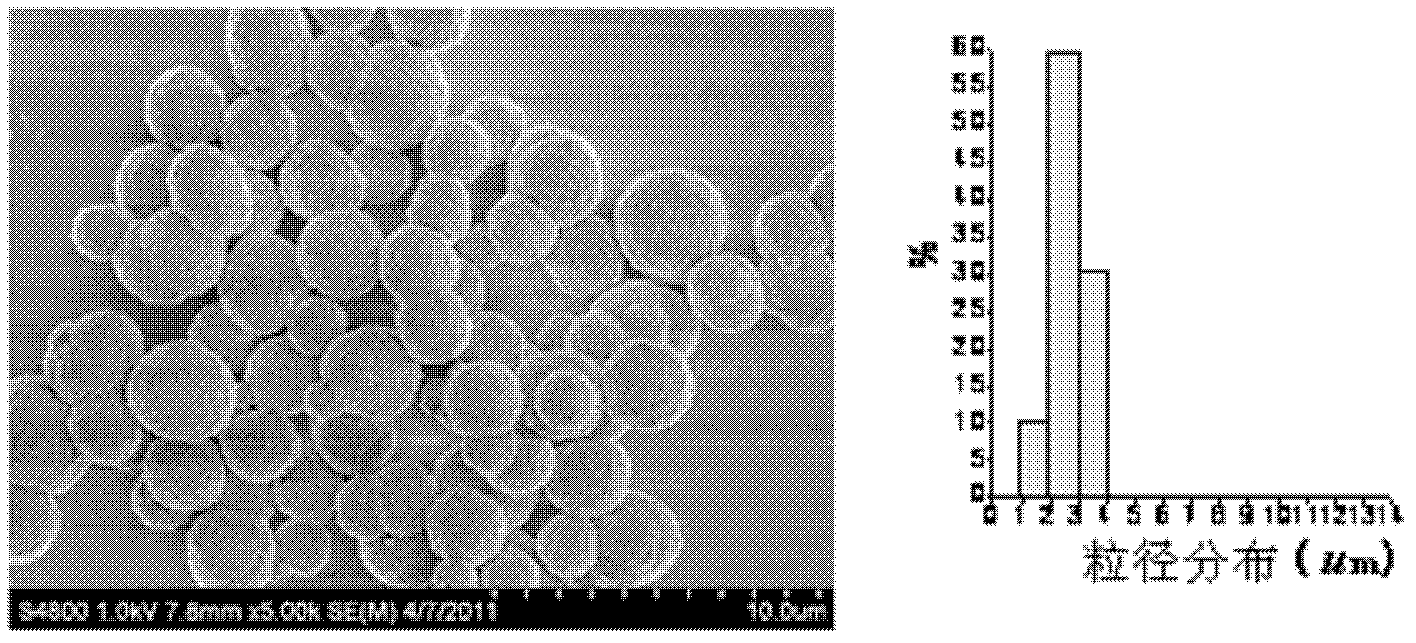

[0030] Add 1mL of 2.00% CTAB into a 100mL beaker containing 40mL of distilled water, add 2.25g of urea to dissolve, then add 6mL of formaldehyde and stir evenly, and finally add 0.2mL of hydrochloric acid. Stand until the solution reacts to form a cloudy white state, continue to react for ten minutes and separate by suction filtration, wash with a small amount of deionized water and ethanol three times respectively to obtain a urea-formaldehyde resin precipitate. The separated urea-formaldehyde resin microspheres were dried at room temperature for 5 hours, and then dried in an oven at 70° C. for 24 hours to obtain urea-formaldehyde resin microspheres such as image 3 shown.

Embodiment 3

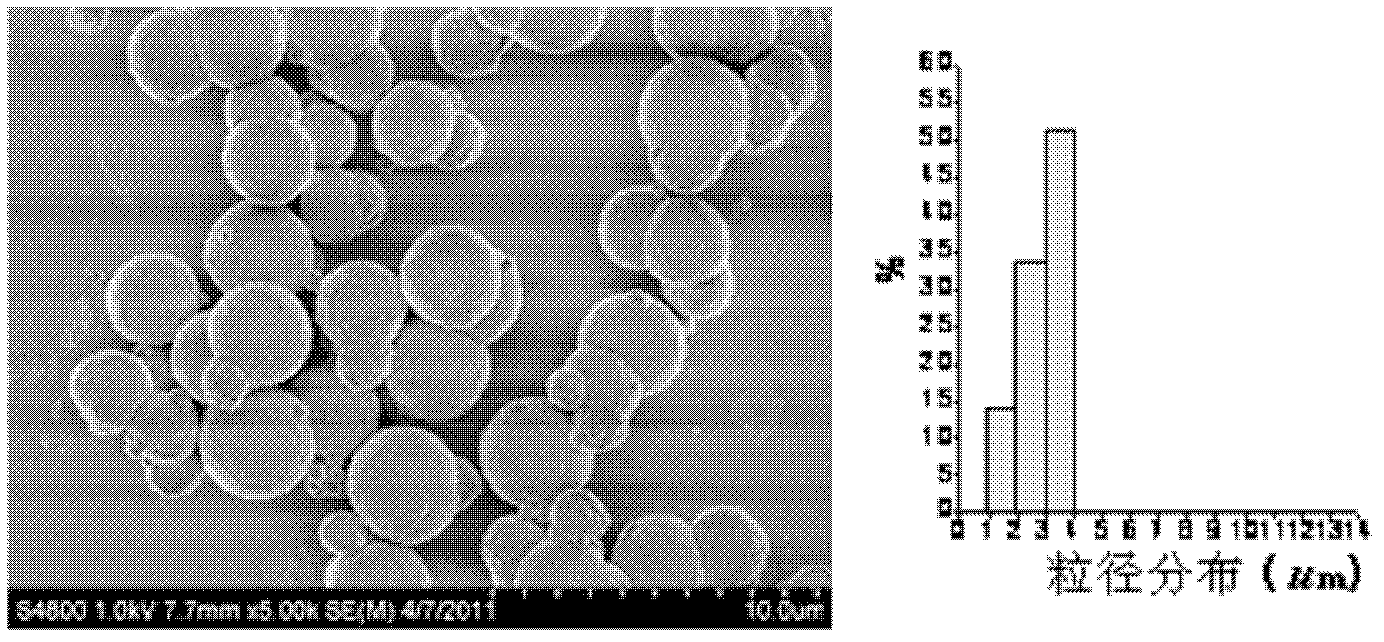

[0032] Add 2.25g of urea to 100mL of 40mL of distilled water to dissolve, add 6mL of formaldehyde and stir evenly, then add 0.2mL of hydrochloric acid. Let stand until the solution appears cloudy white, then quickly add 1mL of 1.00% Tween80, shake well, continue to react for 10 minutes and separate by suction filtration, wash with a small amount of deionized water and ethanol three times respectively to obtain a precipitate of urea-formaldehyde resin. The separated urea-formaldehyde resin microspheres were dried at room temperature for 5 hours, and then dried in an oven at 70° C. for 24 hours to obtain urea-formaldehyde resin microspheres such as Figure 4 shown.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com