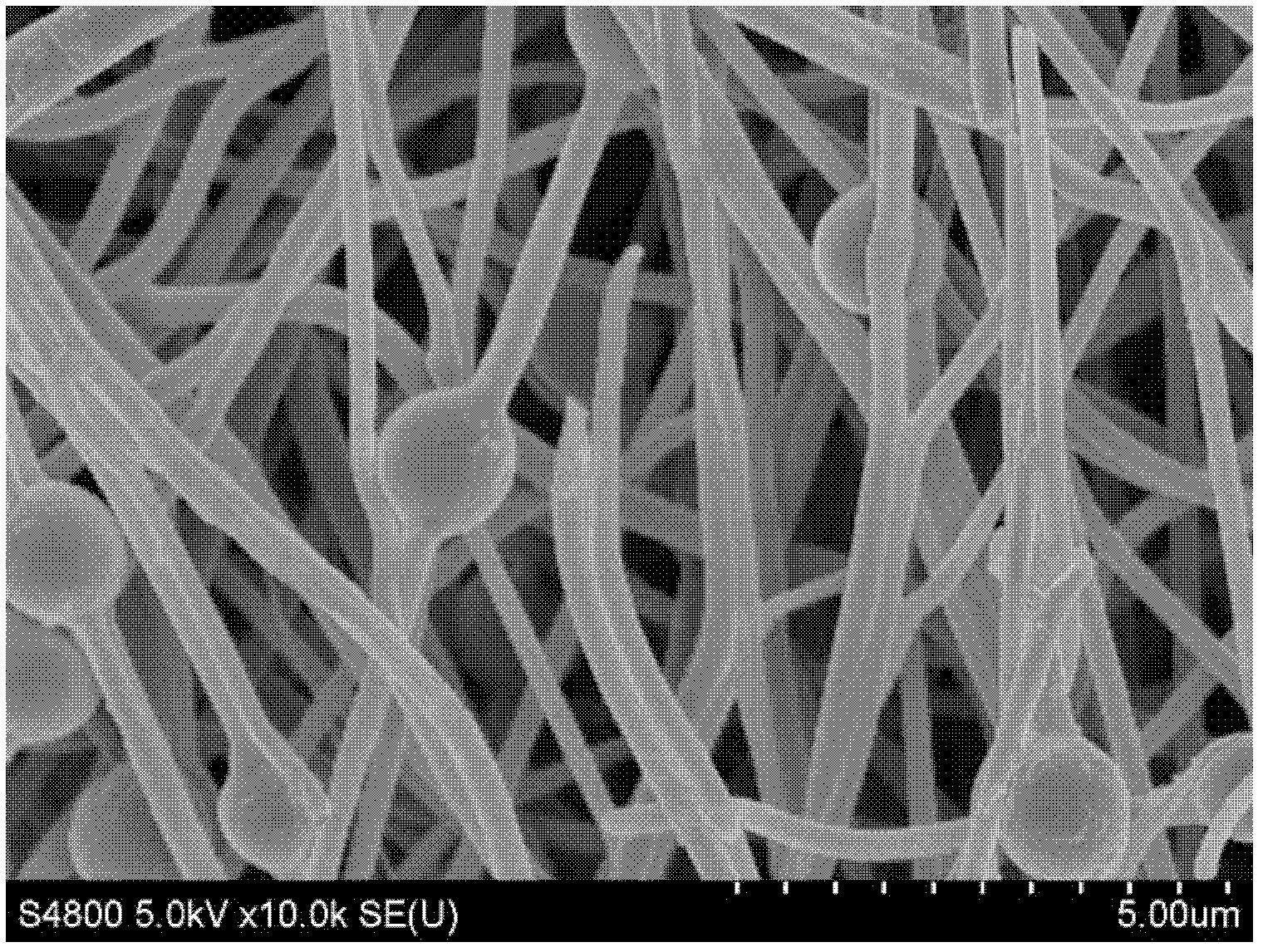

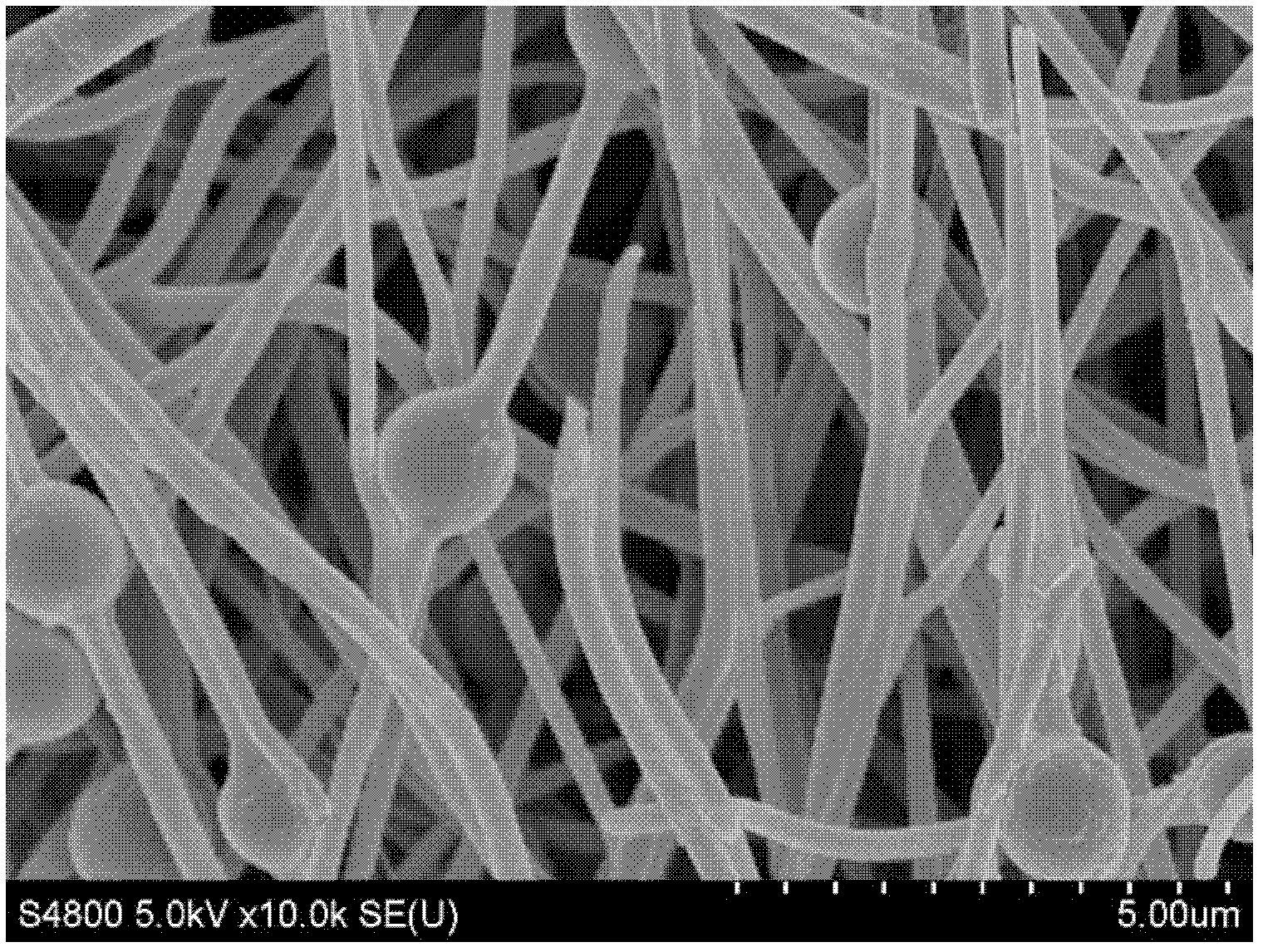

Method for producing bead-stringed PAN (polyacrylonitrile)-based carbon fiber electrode materials by electrostatic spinning

An electrospinning method and carbon fiber electrode technology are applied in the field of preparation of PAN-based carbon fiber electrode materials, which can solve problems such as low capacitance, and achieve the effects of improving specific surface area, simple preparation method, and increasing felt body strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0009] Specific embodiment one: adopt electrospinning method to prepare the method for bead-chain PAN-based carbon fiber electrode material in this embodiment through the following steps:

[0010] Step 1. Dissolving polyacrylonitrile (PAN), phenolic resin microspheres and dimethylformamide (DMF) at a temperature of 20 to 70°C for 1 to 7 days to obtain a spinning solution with a solid content of 8%~15%, the mass ratio of PAN and phenolic resin microspheres is 1:0.05~2;

[0011] Step 2, adopting electrospinning method to prepare PAN fiber mat;

[0012] Step 3, pre-oxidizing the PAN fiber mat obtained in step 2 at a temperature of 70-250° C. and an air atmosphere for 2-6 hours to obtain a PAN-based pre-oxidized fiber mat;

[0013] Step 4. Put the PAN-based pre-oxidized fiber mat obtained in Step 3 into a tube furnace, feed nitrogen gas at a flow rate of 1-4L / min, and at the same time raise the temperature to 700-1000°C at a rate of 5-10°C / min, and keep it warm. Carry out the ca...

specific Embodiment approach 2

[0014] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the diameter of the phenolic resin microspheres in Step 1 is 100-5000 nm. Other steps and parameters are the same as in the first embodiment.

specific Embodiment approach 3

[0015] Embodiment 3: This embodiment differs from Embodiment 1 or Embodiment 2 in that: the solid content in the spinning solution described in step 1 is 12%, and the mass ratio of PAN to phenolic resin microspheres is 1:1.2. Other steps and parameters are the same as those in Embodiment 1 or Embodiment 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com