High-specific surface polymer microsphere resin with even particle size and preparation method thereof

A high specific surface area, polymer technology, applied in the direction of microsphere preparation, microcapsule preparation, alkali metal compounds, etc., can solve the problem that the particle size of synthetic resin microspheres cannot be effectively controlled, the synthesis steps are shortened, and it is difficult to meet actual needs, etc. problem, to achieve the effect of facilitating large-scale production, simple steps and strong repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

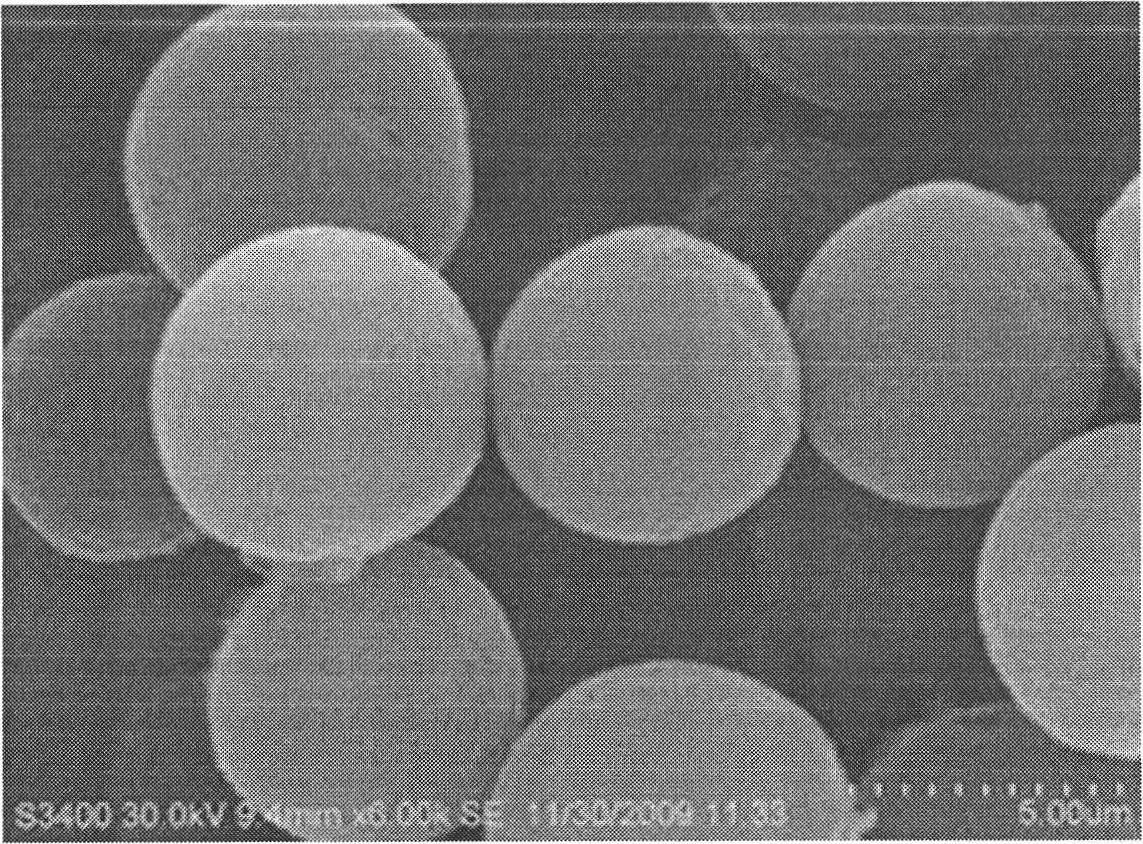

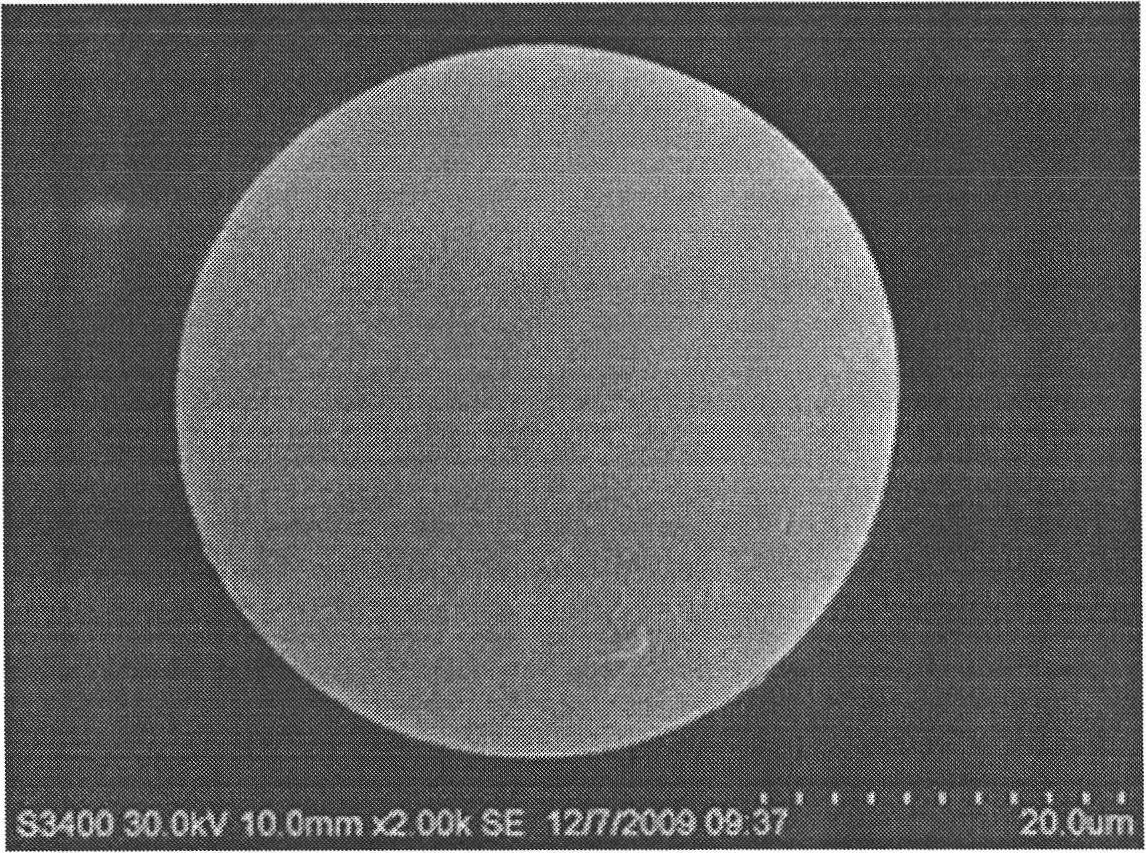

Embodiment 1

[0035] The mass ratio of chloromethylstyrene, divinylbenzene, n-heptane and benzoyl peroxide in the oil phase is 95:5:60:2, 50g in total. In the aqueous phase, 3 g of polydiene dimethyl ammonium chloride and 2 g of polyvinyl alcohol were dissolved in 450 g of water. The selected SPG membrane has a pore size of 0.5 μm and forms an emulsion under a nitrogen pressure of 0.2 MPa. Transfer the emulsion into a three-necked bottle, stir slowly, and raise the temperature to 70°C under the protection of nitrogen to initiate the reaction, polymerize for 6 hours, then gradually raise the temperature to 95°C, and react for 12 hours. Centrifuge the obtained chlorine balls, wash with water, ethanol, and acetone, add dichloroethane to swell for 6 hours after drying, and react at 80°C under the catalysis of ferric chloride (the mass ratio of catalyst addition to microsphere resin is 1:5) Resin microspheres were obtained after 12 hours, and the finished product was obtained by washing with et...

Embodiment 2

[0038] The mass ratio of chloroacetylated styrene, divinylbenzene, toluene and azobisisobutyronitrile in the oil phase is 90:10:100:1, totaling 50 g. Add 2g of gelatin to the water phase, dissolve in 450g of water. The selected SPG membrane has a pore size of 1 μm and forms an emulsion under a nitrogen pressure of 0.1 MPa. Transfer the emulsion into a three-necked bottle, stir slowly, and raise the temperature to 70°C under the protection of nitrogen to initiate the reaction, polymerize for 4 hours, then gradually raise the temperature to 80°C, and react for 5 hours. Centrifuge the obtained chlorine balls, wash with water, ethanol, and acetone, add nitrobenzene to swell after drying, and react under the catalysis of aluminum chloride (the mass ratio of catalyst addition to microsphere resin is 1:6) at 85°C for 16 hours to obtain Resin microspheres, washed with ethanol and acetone to obtain finished products.

[0039] The particle size of the resin microspheres is about 3.7 μ...

Embodiment 3

[0041] The mass ratio of chloroacetylated styrene, divinylbenzene, n-dodecane and azobisisobutyronitrile in the oil phase is 80:20:50:1, 50 g in total. Add 4 g of hydroxyethyl cellulose to the water phase and dissolve in 450 g of water. The selected SPG membrane has a pore size of 1 μm and forms an emulsion under a nitrogen pressure of 0.08 MPa. Transfer the emulsion into a three-necked bottle, stir slowly, and raise the temperature to 70°C under the protection of nitrogen to initiate the reaction, polymerize for 4 hours, then gradually raise the temperature to 80°C, and react for 8 hours. Centrifuge the obtained chlorine balls, wash them with water, ethanol, and acetone, add nitrobenzene to swell after drying, and react under the catalysis of zinc chloride (the mass ratio of catalyst addition to microsphere resin is 1:4) at 85°C for 14 hours to obtain Resin microspheres, washed with ethanol and acetone to obtain finished products.

[0042] The particle size of the resin mic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Membrane pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com