Frame type wooden floor

A solid wood floor, frame-type technology, applied in the direction of wood layered products, floors, layered products, etc., can solve the problems of an economical society that does not meet the rational and full utilization of resources, the inability to use narrow and small wood, and waste. Achieve the effect of saving precious wood, increasing pressure resistance and load, and low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

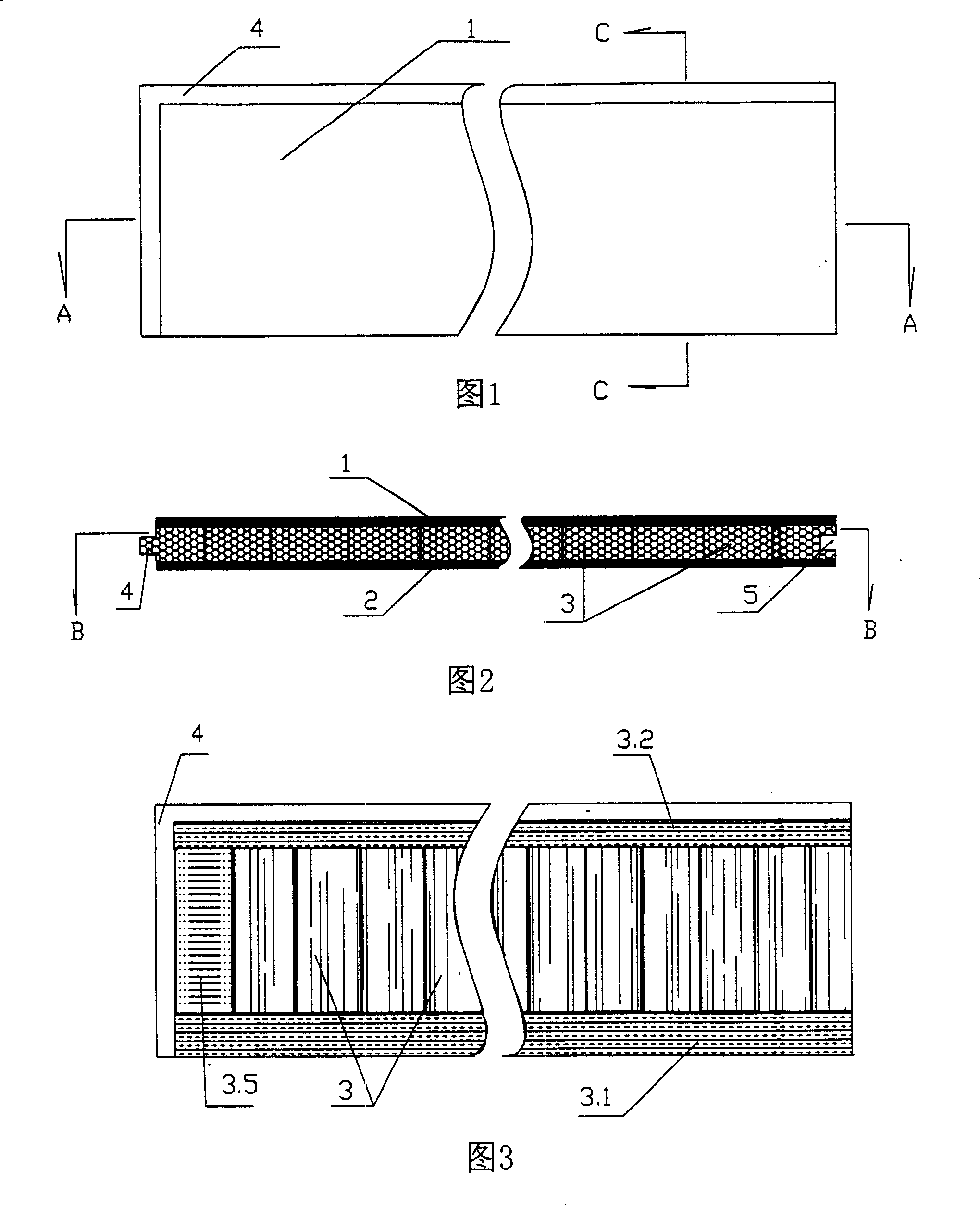

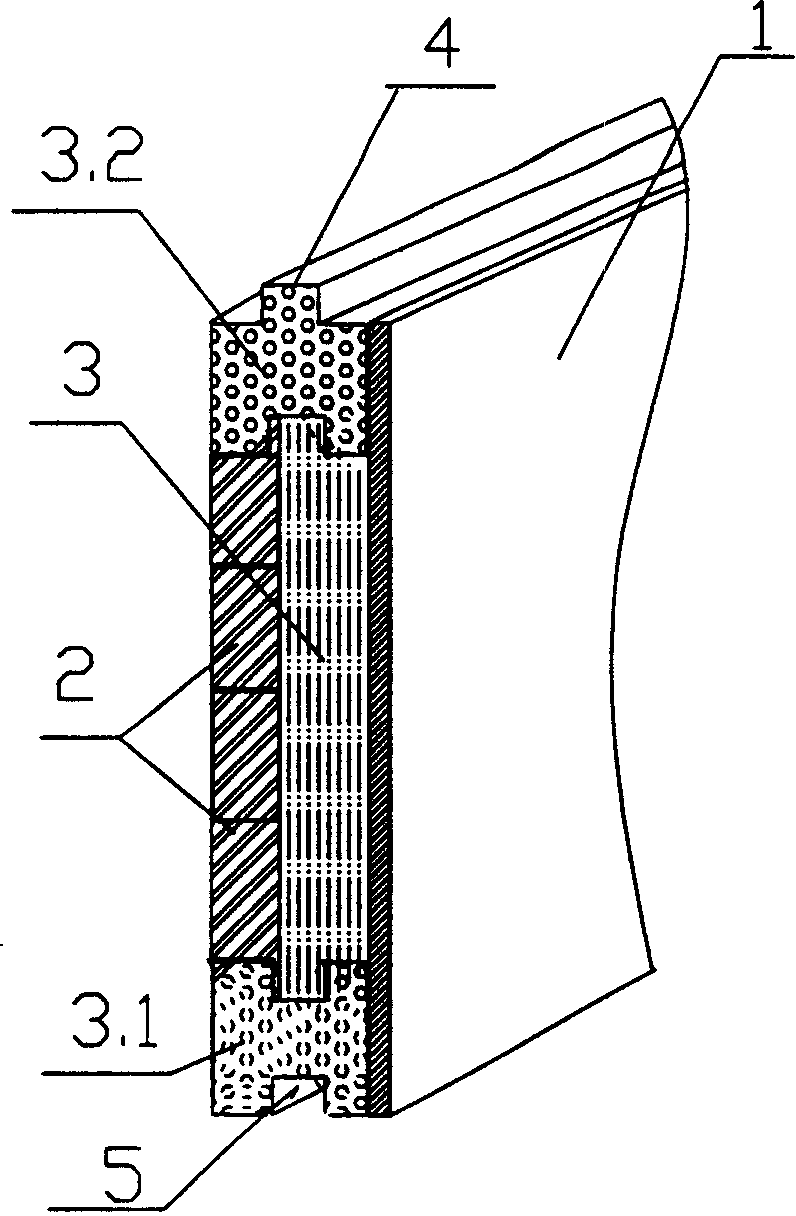

[0023] Fig. 1 is a front view of the present invention. 2 and 3 are sectional views.

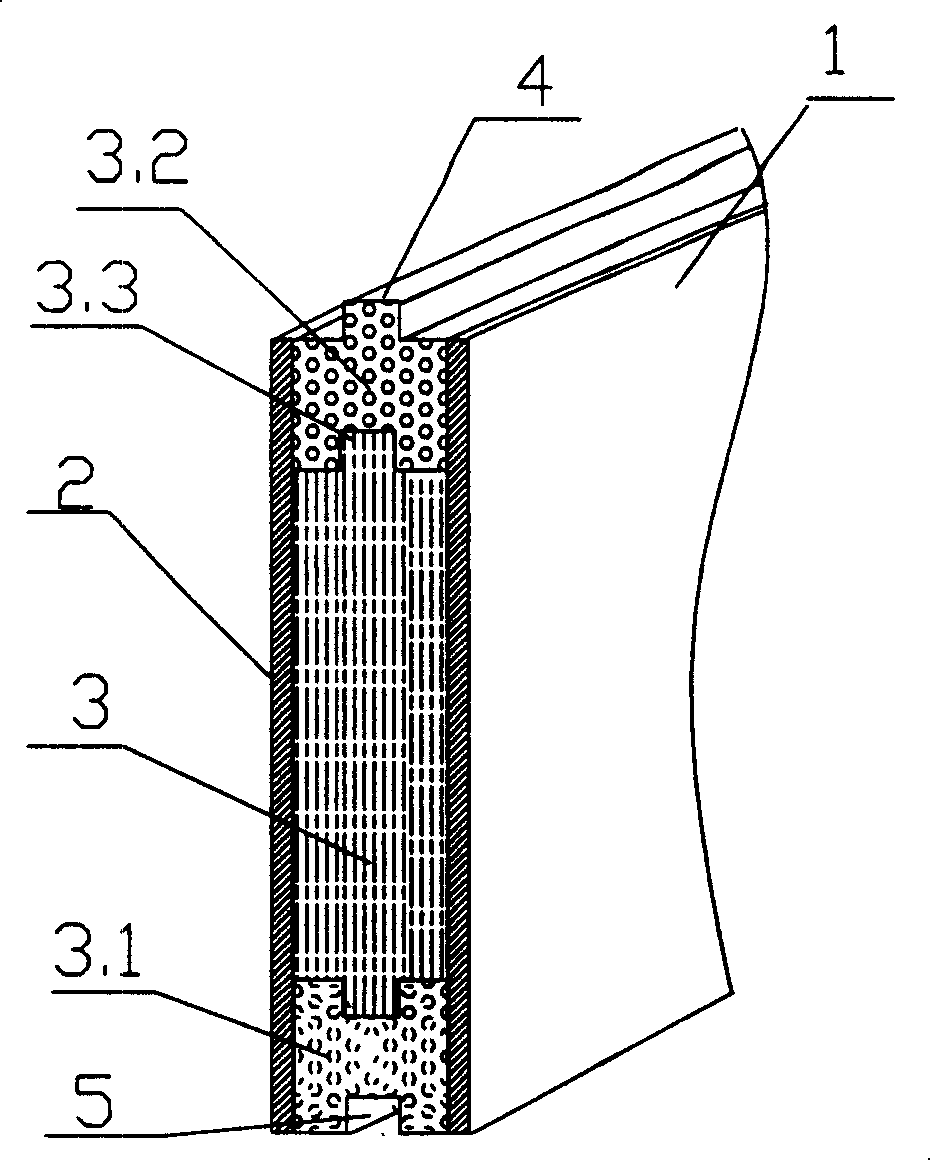

[0024] As shown in the figure: the board body includes a surface layer 1 and a substrate board. The base board is composed of a central filling board 3, a bottom layer 2, and moldings 3.1 and 3.2 on both sides. The tongue 4 and groove 5 on both sides are on both sides. Fillet 3.1, 3.2 on. The wood grain of the surface layer is longitudinal, and the central filling board 3 of the base plate is composed of multiple short boards arranged in the transverse wood grain in the length direction, but the wood grain of a short board 3.5 at the end with the tongue is longitudinal, and its length It is 40-70mm.

[0025] Figure 4 It is a schematic cross-sectional view of the combination of the central filling board and the bottom layer and the mortise joints on both sides (C-C cross-sectional diagram of Figure 1): the base board is composed of the central filling board 3, the bottom layer 2 and the m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com