Polymethyl methacrylate bone cement and preparation method thereof

A technology of polymethyl methacrylate and methyl methacrylate, which is used in medical science, prosthesis, tissue regeneration, etc., can solve the problems of incapability of arbitrary plasticity and large heat release.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

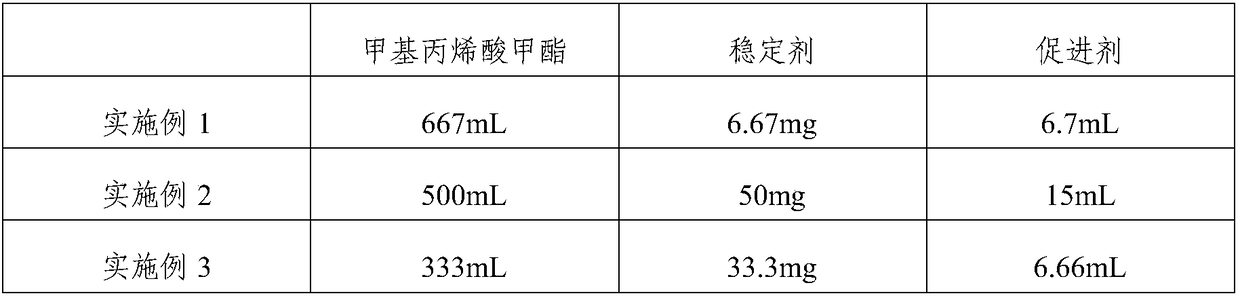

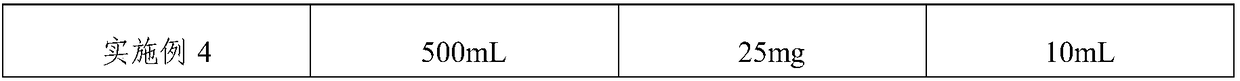

[0094] The polymethyl methacrylate bone cement provided in this embodiment, each component and its dosage are shown in Table 1 and Table 2, wherein:

[0095] The molecular weight of the polymethyl methacrylate (i.e. PMMA) used is 150,000, the molecular weight of the used methyl methacrylate-styrene block copolymer (i.e. ps-b-mma) is 100,000, and the block ratio PMMA / PS =80:20;

[0096] In the liquid component, the stabilizer is hydroquinone and p-tert-butylcatechol, and the accelerator is N,N-dimethyl-p-toluidine.

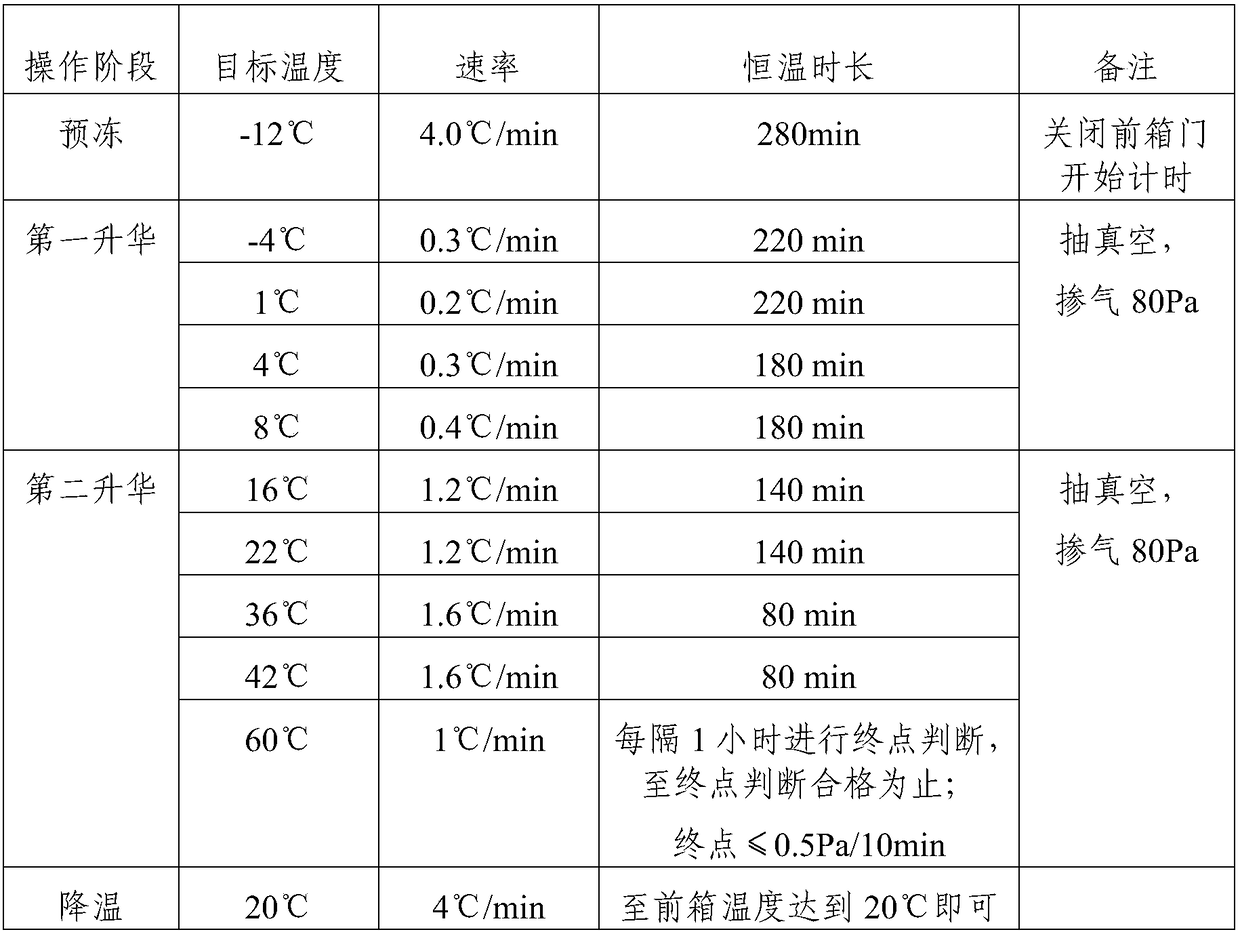

[0097] Its preparation method comprises the following steps:

[0098] After mixing polymethyl methacrylate, methyl methacrylate-styrene block copolymer, contrast agent, initiator and colorant, solid component A is obtained;

[0099] Prepare mineralized bone collagen, and its preparation method comprises the following steps:

[0100] S1: dissolving type I collagen in hydrochloric acid to prepare a collagen acid solution, wherein the collagen concentration is 0.01...

Embodiment 2

[0109] The preparation steps of embodiment two are basically the same as embodiment one, the difference is:

[0110] The molecular weight of polymethyl methacrylate is 260,000, the molecular weight of methyl methacrylate-styrene block copolymer is 300,000, and the block ratio PMMA / PS=60:40; In the step of preparing mineralized collagen:

[0111] S1: dissolving collagen in nitric acid to prepare an acid solution of collagen, wherein the concentration of collagen is 0.5g / mL;

[0112] S2: Continuously stirring the solution obtained in step S1, slowly adding the solution containing calcium ions dropwise, the amount of calcium ions added is 2 mol of calcium ions corresponding to each gram of collagen;

[0113] S3: Continue to stir the solution obtained in step S2, slowly drop the solution containing phosphate ions, the molar ratio of the amount of phosphate ions added to the amount of calcium ions added in step S2 is Ca / P=2 / 1;

[0114] S4: same as embodiment one;

[0115] S5: The m...

Embodiment 3

[0119] The preparation steps of embodiment three are basically the same as embodiment two, and the difference is:

[0120] The molecular weight of polymethyl methacrylate is 200,000, the molecular weight of methyl methacrylate-styrene block copolymer is 200,000, and the block ratio PMMA / PS=70:30;

[0121] In the step of preparing mineralized collagen:

[0122] In S6, the mineralized collagen provided by S5 is mixed with the L-polylactic acid solution, and the preparation method includes the following steps:

[0123] (1) Preparation of L-polylactic acid solution:

[0124] Put the L-polylactic acid in the reaction kettle and add dimethyl sulfoxide to ensure that the concentration can reach 0.15g / mL.

[0125] Put the reaction kettle into a water bath and heat it. The temperature of the water bath is 40°C. When the solution in the reaction kettle becomes transparent, without stratification and no agglomeration, the L-polylactic acid solution is obtained.

[0126] (2) adding min...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com