Impermeable structure applied to concrete pressure container

A pressure-resistant container and concrete technology, which is applied in the direction of building components and building insulation materials, can solve the problems of affecting the test results, the decline of watertight performance of prestressed concrete and steel plates, and the occurrence of water seepage, so as to ensure structural strength, control costs, and guarantee The effect of pressure resistance and structural strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below with reference to the accompanying drawings and examples.

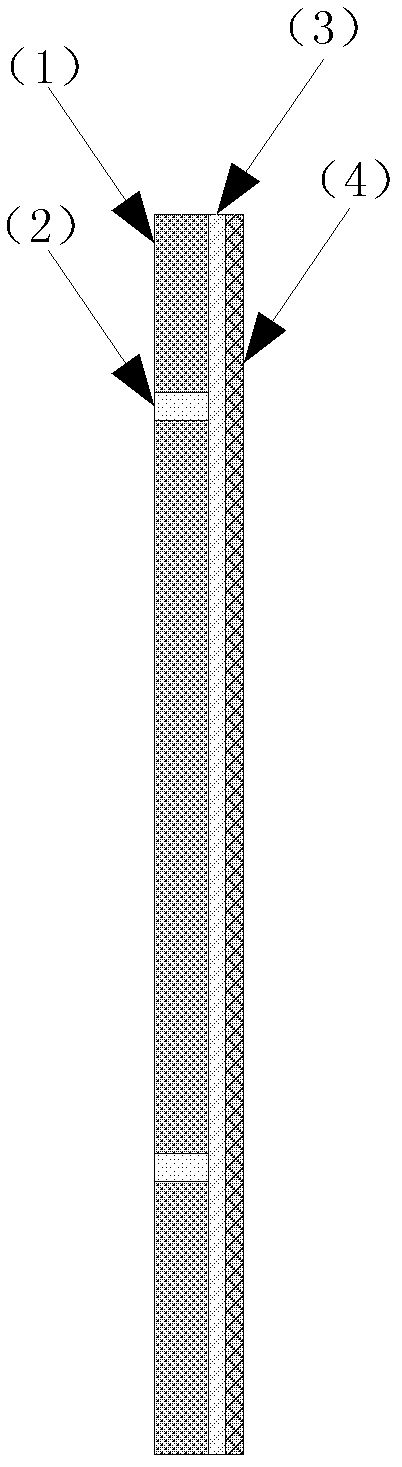

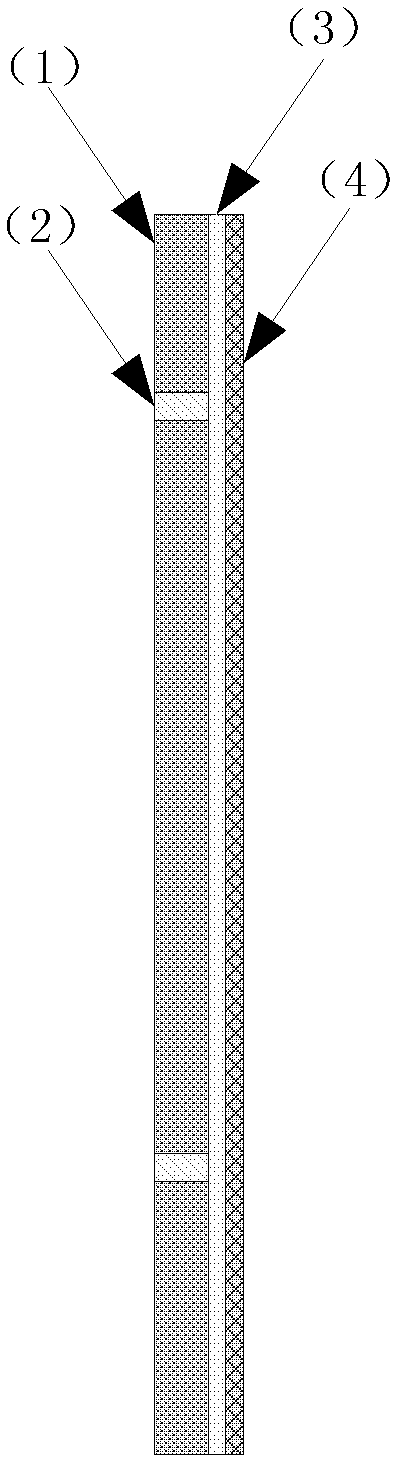

[0016] The anti-seepage structure applied to concrete pressure-resistant containers of the present invention comprises a concrete wall 1, steel embedded parts 2, steel plates 3 and FRP coating 4; the outermost layer of the anti-seepage structure is a concrete wall 1, made of steel The embedded part 2 is placed in the concrete wall 1, and the steel embedded part 2 is welded to the prestressed reinforcement in the concrete. The structure adjacent to the concrete wall 1 is a steel plate 3, and the steel plate 3 is processed with steel The welding hole corresponding to the part of the embedded part 2, the steel plate 3 is welded with the steel embedded part 2 through the welding hole on it, so that the steel plate 3 is closely attached to the concrete wall, and the outer layer of the steel plate 3 is evenly coated with FRP coating 4.

[0017] FRP coating prod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com