Laminating member for battery package

A technology for battery outer packaging and laminates, which is applied to battery pack components, electrical components, hybrid boxes/housing/packages, etc. It can solve problems such as poor corrosion resistance, environmental protection is not the preferred solution, and peeling, etc., to achieve The effect of reducing defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

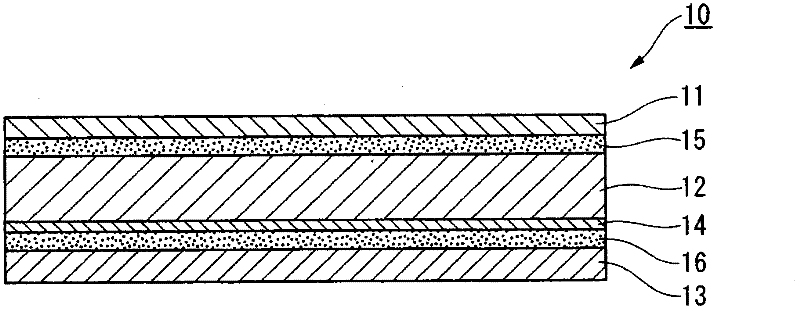

[0069] A substrate layer in which a stretched polyethylene terephthalate film with a thickness of 6 μm and a stretched polyamide film with a thickness of 25 μm was dry-laminated with a 40 μm-thick The aluminum foil was laminated with an adhesive layer (thickness 7 μm) formed of a urethane adhesive (containing an epoxy adhesive).

[0070] On the innermost surface of the aluminum foil, an amorphous polymer (manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name: G Polymer Resin) and 1 wt. An aqueous solution of chromium(III) fluoride by weight % is laminated with a film coating layer, and further heated in an oven at 200° C. to cause a cross-linking reaction, so that the thickness after drying reaches 1 μm.

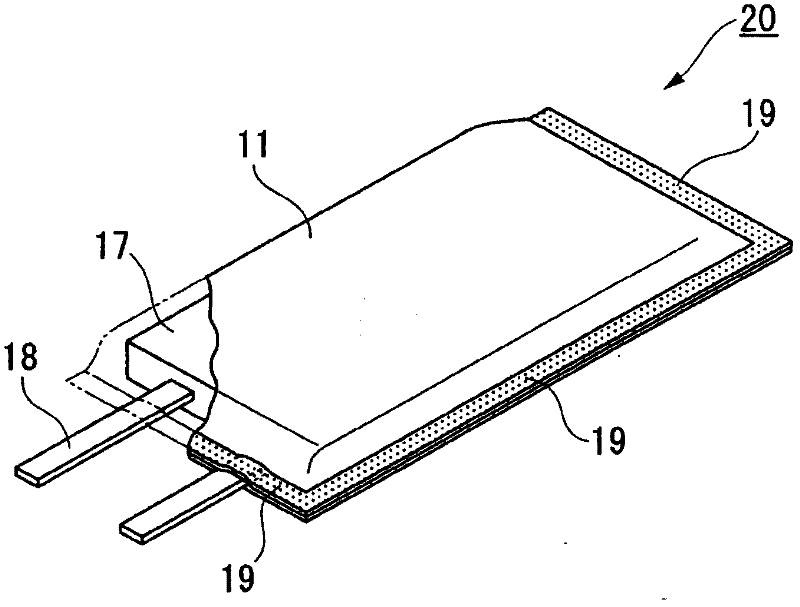

[0071] Further, on the film coating layer of aluminum foil with 3g / m 2 An acid-denatured polypropylene-based heat-sealing agent was applied, and a 30 μm polypropylene layer was laminated thereon, whereby the battery exterior laminate 10 of Example 1 was produced....

Embodiment 2

[0074] A substrate layer in which a stretched polyethylene terephthalate film with a thickness of 3 μm and a stretched polyamide film with a thickness of 25 μm was dry-laminated with a 40 μm-thick The aluminum foil was laminated with an adhesive layer (thickness 7 μm) formed of a urethane adhesive (containing an epoxy adhesive). And, on the surface of the innermost layer side of the aluminum foil, an amorphous polymer (manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name: G Polymer Resin) and 1 wt. An aqueous solution of chromium (III) fluoride by weight % is laminated with a film coating layer, and further heat-dried in an oven at 200° C. so that the thickness after drying reaches 3 μm.

[0075] The melting point of the thin-film coating layer was confirmed by a differential thermal analysis device, and it was found that crosslinking occurred from the fact that there was no peak in the melting point. Figure 4 shows the results of measuring the thin film coating ...

Embodiment 3

[0089] A polyethylene terephthalate film with a thickness of 3 μm and a polyamide film with a thickness of 25 μm were passed through at a rate of 2 g / m 2 The substrate layer and the aluminum foil in which the applied urethane adhesive layer was laminated were bonded via a 7 μm urethane adhesive layer containing an epoxy adhesive. And, on the surface of the opposite side to the base material layer of the aluminum foil, an amorphous polymer (manufactured by Nippon Synthetic Chemicals Co., Ltd., trade name: G polymer resin) having a polyvinyl alcohol skeleton containing a hydroxyl group dissolved in 3% by weight was applied. And 1% by weight of chromium (III) fluoride aqueous solution, so that the thickness after drying reaches 3μm, on it with 3g / m 2 An acid-denatured polypropylene-based heat-sealing agent was applied, and then a 40 μm polypropylene layer was thermally laminated to produce the laminate 10 for battery outer packaging of Example 3 having a four-layer structure.

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com