Patents

Literature

40results about How to "Limit extension" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

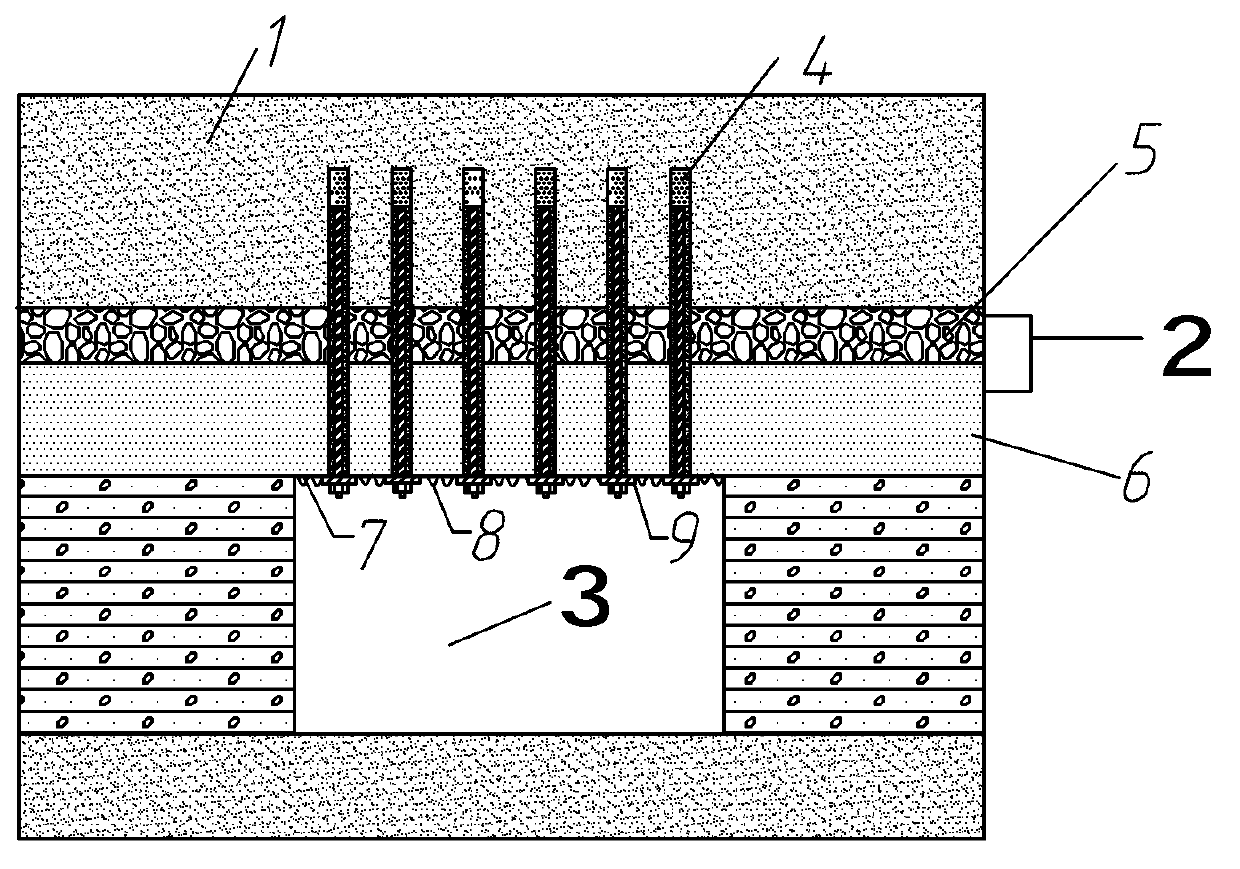

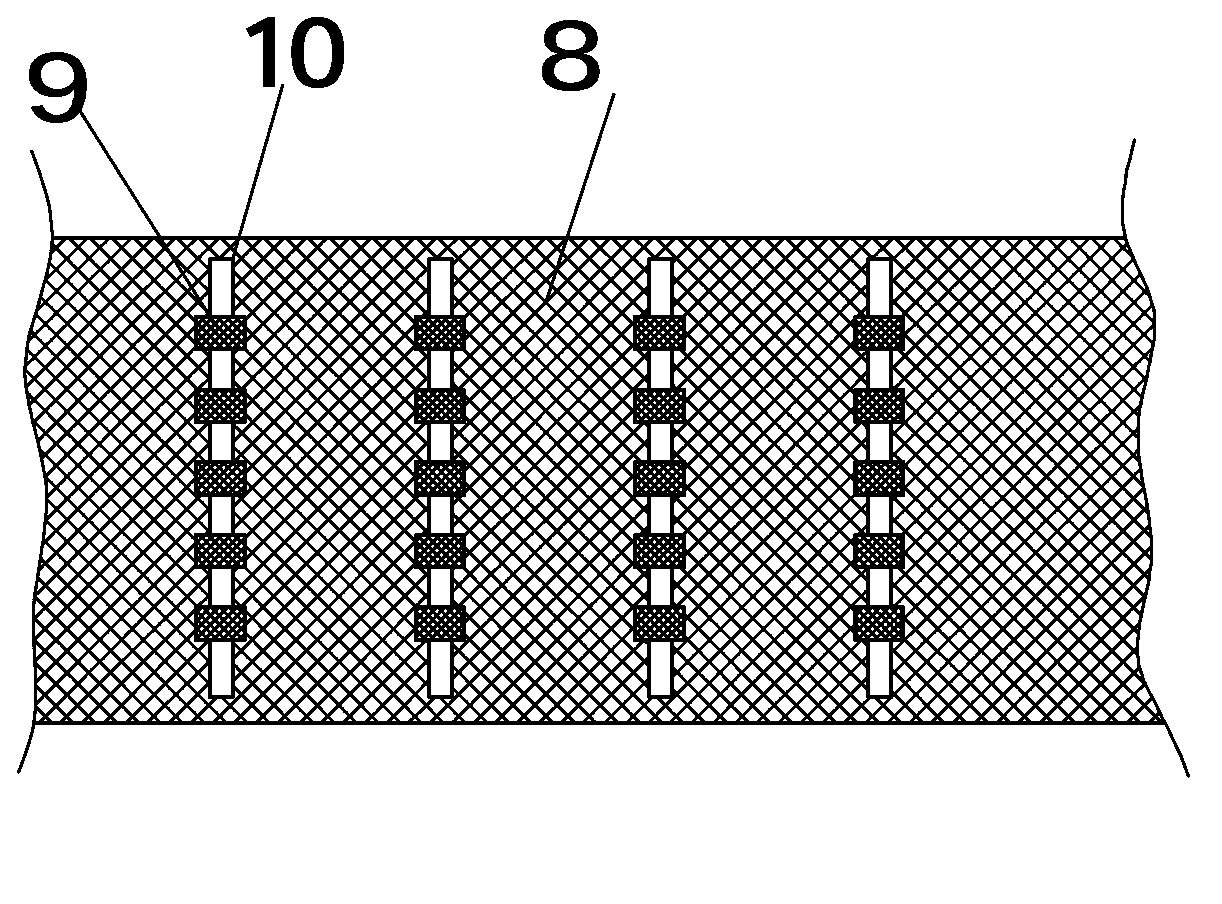

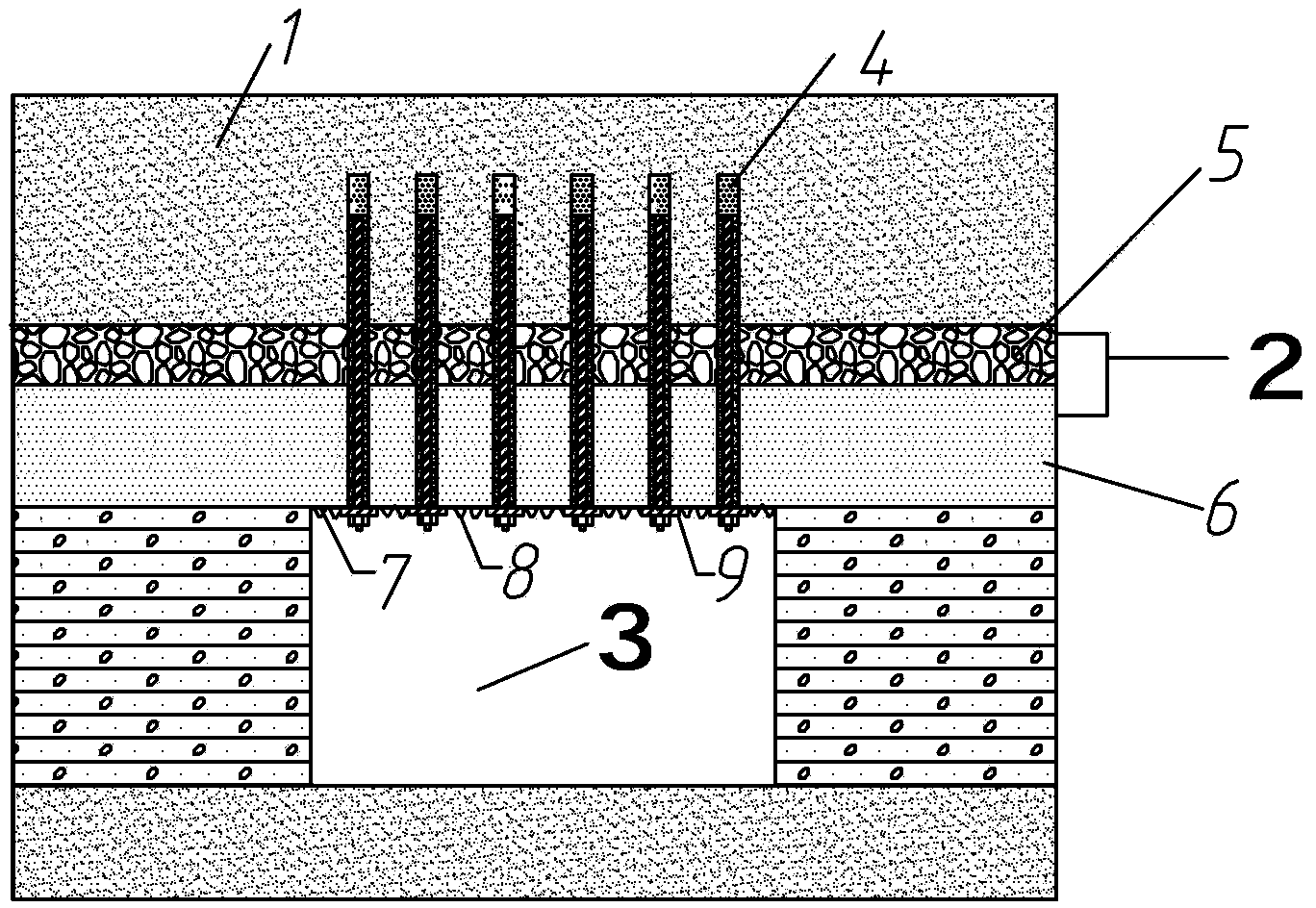

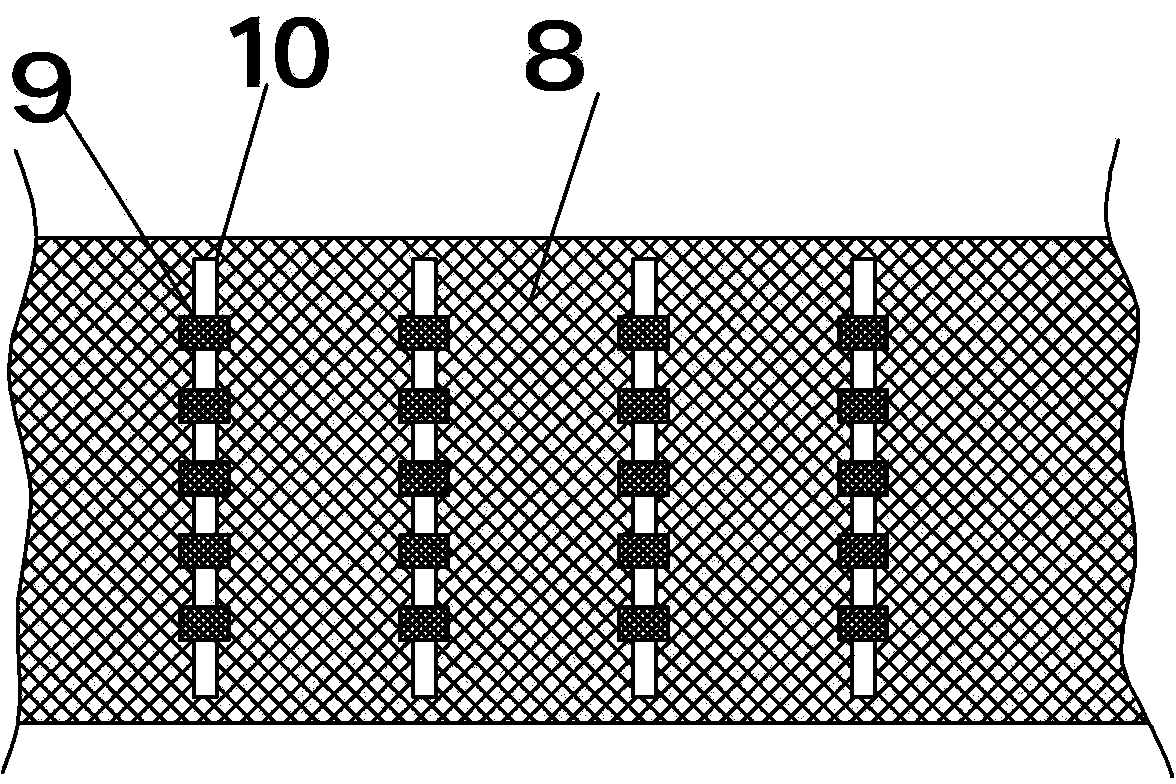

Support method for bolt-grouting composite crushing dynamic-pressure roadway soft rock roof by high-pre-stressed anchor cable

The invention discloses a support method for bolt-grouting a composite crushing dynamic-pressure roadway soft rock roof by a high-pre-stressed anchor cable. The support method comprises the following steps of: after excavating a roadway, keeping up with a roadway driving head for drilling a deep part in a roadway roof, sending a deep hole camera shooting detecting instrument to the bottom of a drilled hole, recording inner wall lithological characters, fracture spacing and crushing region thickness range of surrounding rocks of different depths; keeping up with the roadway driving head, firstly drilling grouted holes in the surfaces of surrounding rocks, installing grouting pipes, then spraying thin-layer concrete on the surfaces of the surrounding rocks of the roadway for closing the surfaces of the surrounding rocks of the roadway to prevent slurry from overflowing; grouting the insides of the surrounding rocks through the grouting pipes, after slurry is solidified, drilling anchor cable holes in the surfaces of the surrounding rocks of the roadway, and when the depths of the anchor cable holes exceed the range of a crushing region, installing an anchor cable for reinforcing. The support method has the advantages of being simple in operation, bringing convenience for construction, saving secondary or multi-time support procedure, lowering the cost, saving the time and manpower, increasing the working efficiency, realizing dual-anchoring, and achieving the strong support effect, and is especially suitable for the roof which is difficult to support under the condition of dynamic pressure.

Owner:SHANDONG UNIV OF SCI & TECH

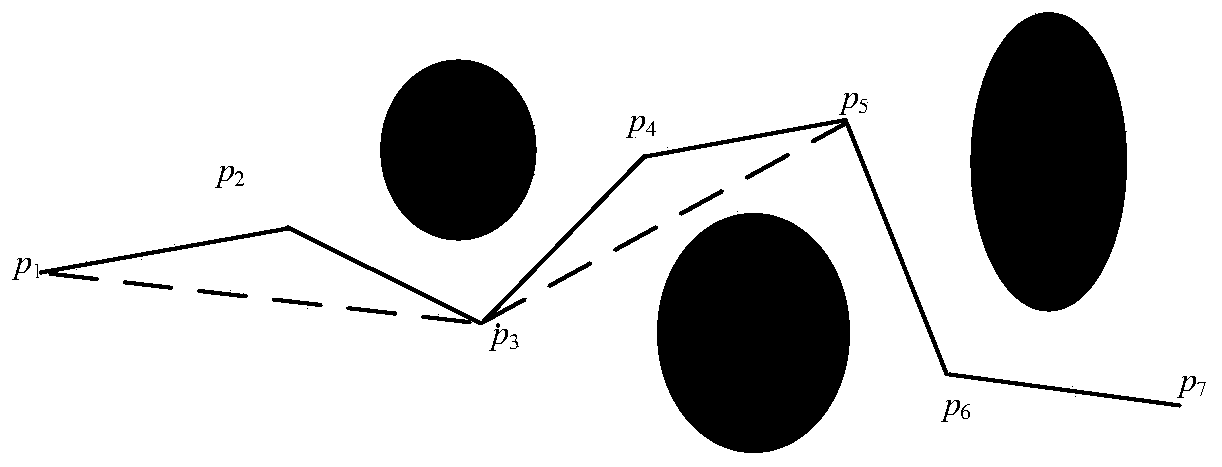

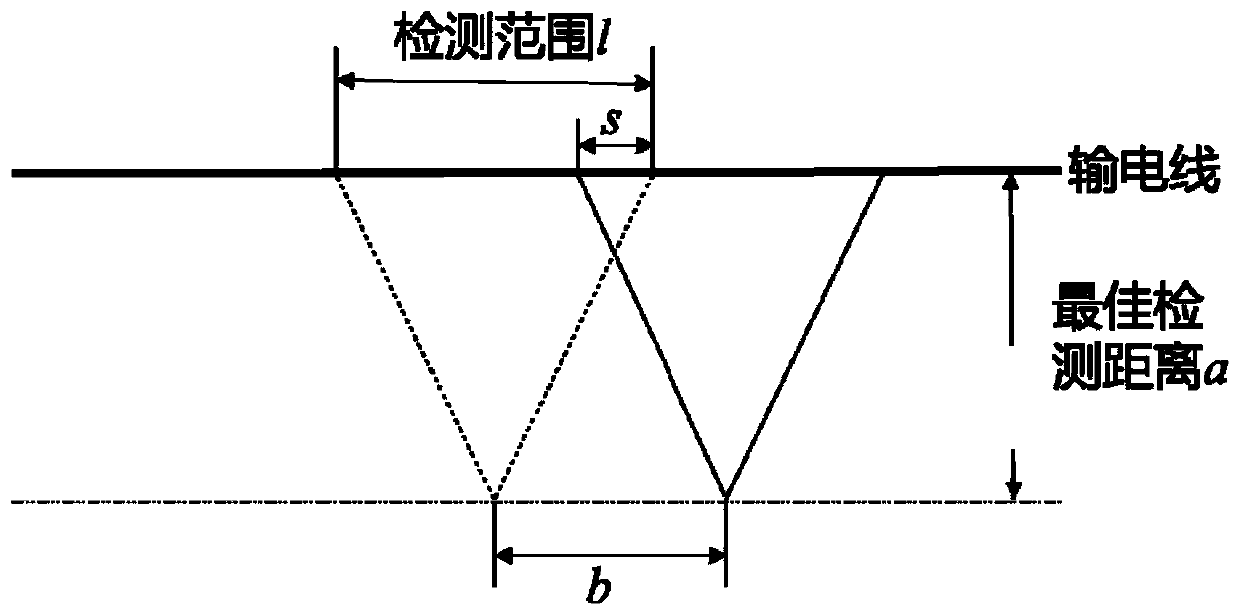

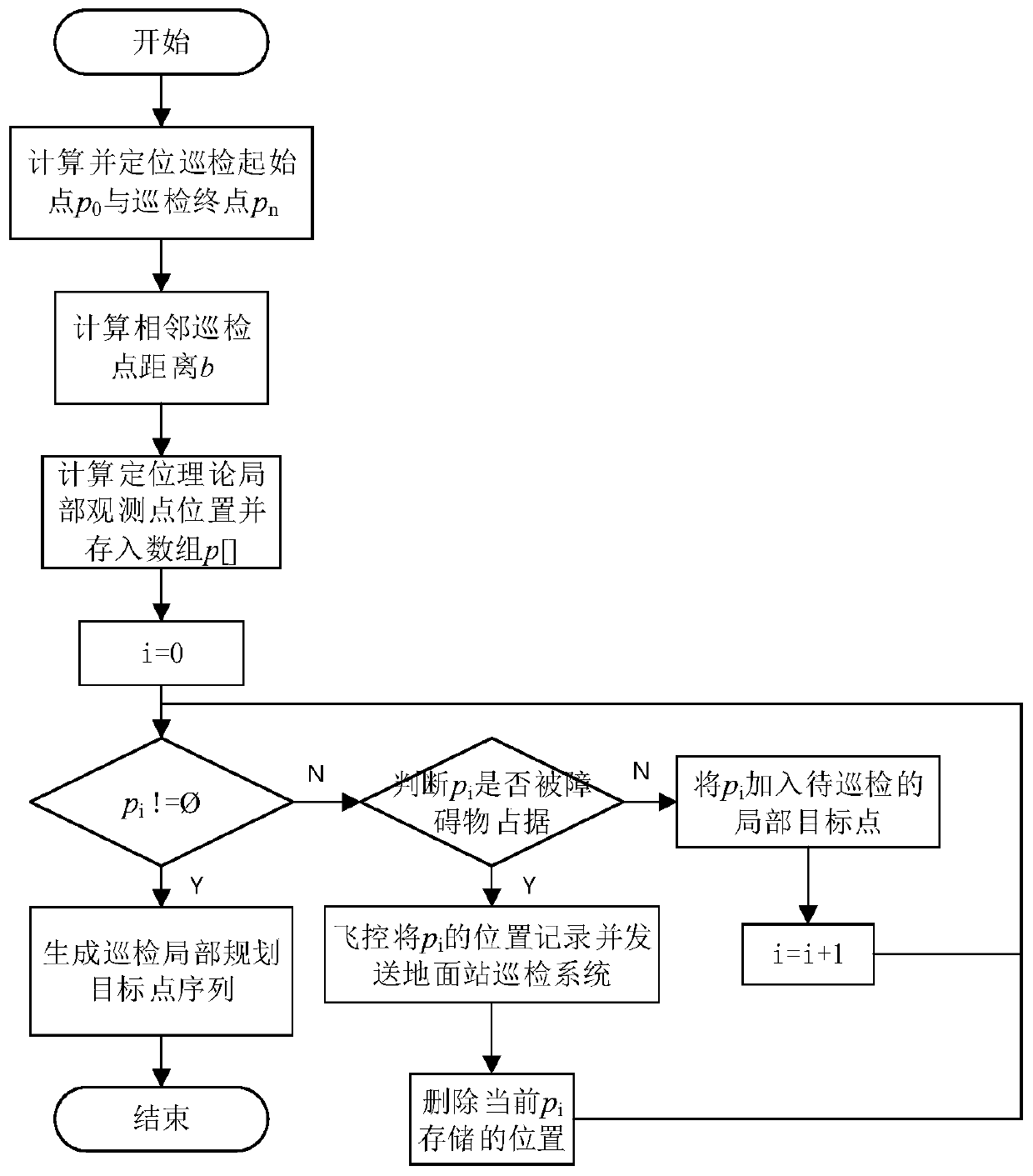

Power patrol unmanned aerial vehicle path planning method and power transmission line patrol method

ActiveCN110673634AGuaranteed observationImprove planning qualityPosition/course control in three dimensionsSimulationUncrewed vehicle

The invention discloses a power patrol unmanned aerial vehicle path planning method and a power transmission line patrol method. The path planning method comprises the following steps of S1, dividingan ideal path into a plurality of segments according to the set camera shooting power transmission line coincidence degree, setting a local target point, and deleting the point from a local target point array if the point is occupied by an obstacle to obtain a local target point sequence; S2, detecting whether the obstacle exists between points pi and pi+1 or not, adding pi+1 as a child node of piinto a random tree list if the obstacle does not exist, and planning a path from pi to pi+1 by using RRT if the obstacle exists; and S3, continuously planning a route to the next local target point according to the step S2 from a patrol starting point p0 until a patrol end point pn is reached so as to complete patrol flight path planning of the whole power transmission line. According to the method, a power line patrol task is ensured to observe the whole section of the power transmission line as much as possible, the obstacle can be avoided and crossing of electronic fences is limited.

Owner:HEFEI UNIV OF TECH

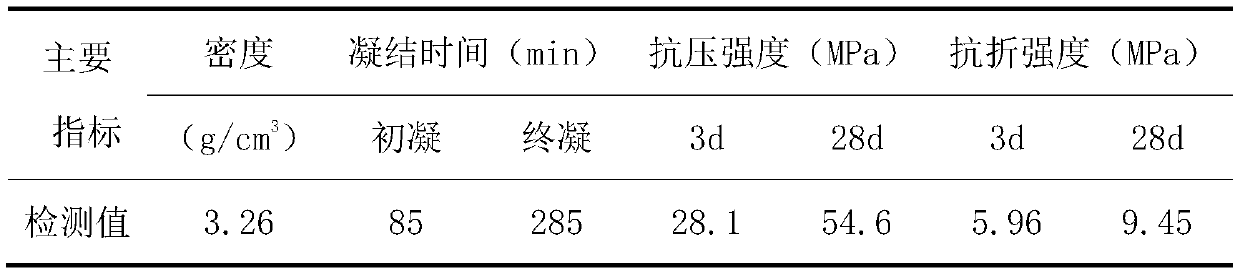

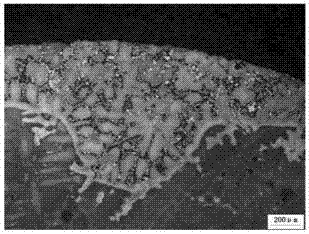

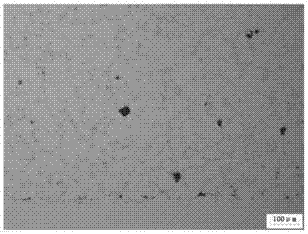

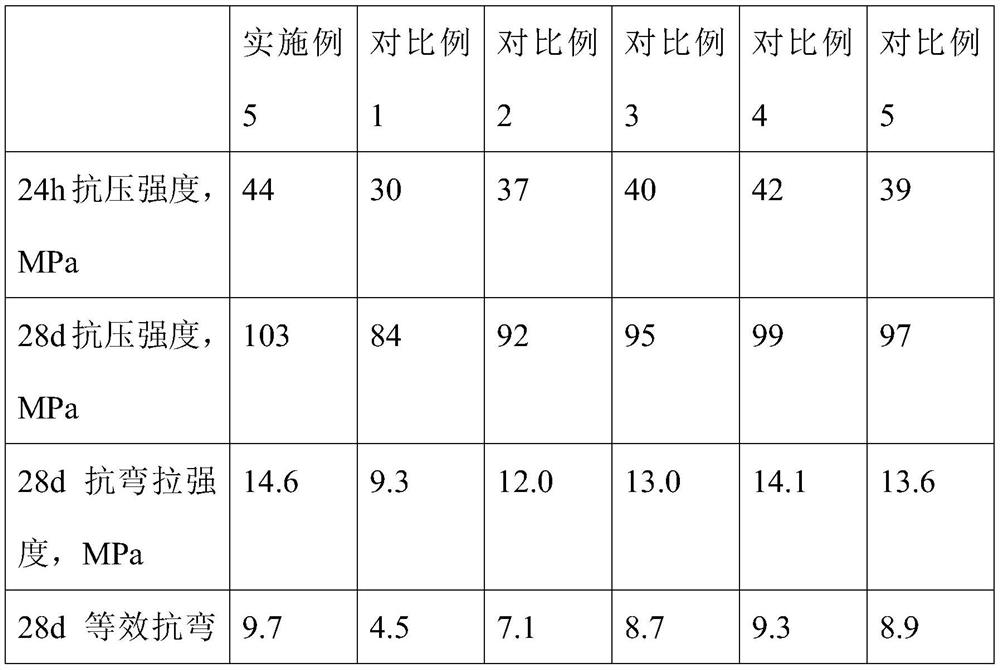

Cement-based composite material for steel box girder bridge deck, as well as preparation and pavement thereof

ActiveCN103449786AImprove toughnessLimit extensionBridge erection/assemblyBridge materialsEpoxyBridge deck

The invention relates to a cement-based composite material for pavement of a steel box girder bridge deck, as well as a preparation method and a pavement method thereof. The invention aims at providing a lightweight and high-toughness cement-based composite material which is suitable for pavement of larger-span steel box girder bridge decks, and the cement-based composite material comprises the following components in parts by weight: 849-881 parts of cement, 339-425 parts of quartz sand, 215-273 parts of pottery sand, 100-226 parts of fly ash, 30-56 parts of silica fume, 275-295 parts of water, 10-13 parts of water reducing agent, 40-80 parts of steel fiber, 6.5-13 parts of organic fiber and 20-30 parts of epoxy resin. Through material optimization, the durability of a bridge deck paving layer is improved, the overall dead weight is reduced, the cost of a project is simultaneously saved, and the cement-based composite material is suitable for pavement of the larger-span steel box girder bridge decks.

Owner:WUHAN UNIV OF TECH

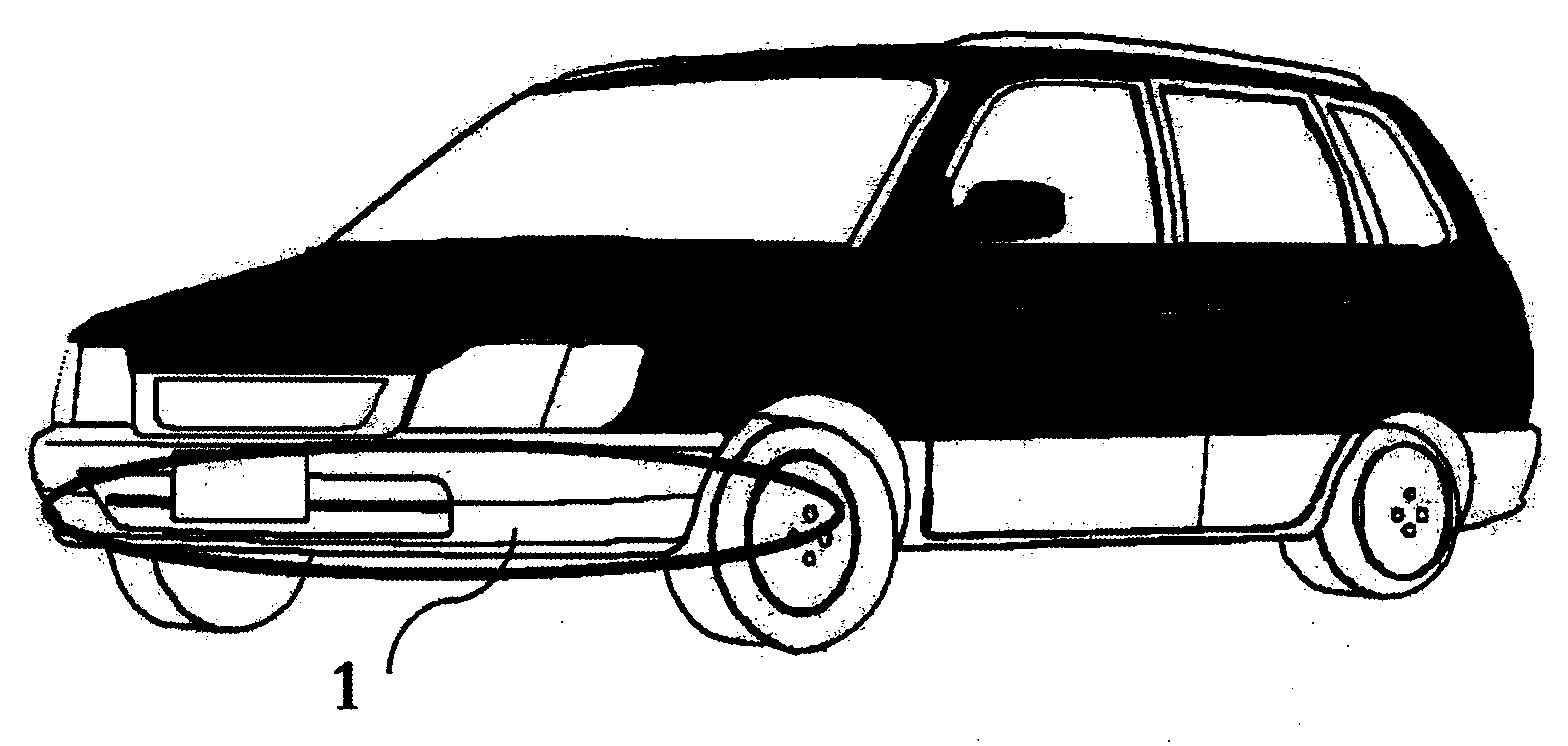

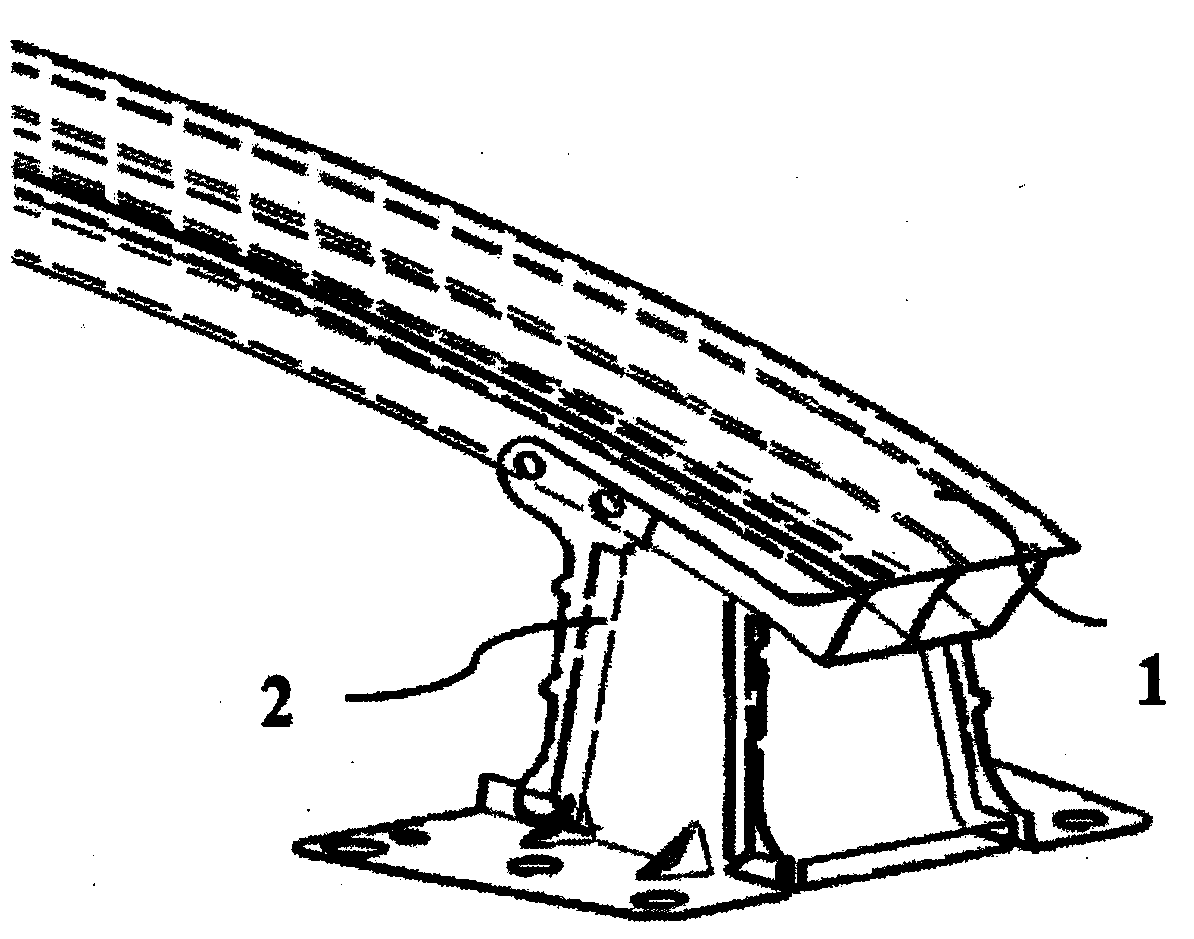

Hybrid composite energy absorbing part for automobile and manufacturing method thereof

InactiveCN103661183AIncrease the number of breaksAvoid damageSynthetic resin layered productsBumpersCarbon fibersEnergy absorption

The invention discloses a hybrid composite energy absorbing part for an automobile and a manufacturing method thereof. The hybrid composite energy absorbing part is round and tubular and comprises a first aramid fiber layer, a carbon fiber layer and a second aramid fiber layer. The manufacturing method of the hybrid composite energy absorbing part for the automobile comprises the steps that aramid fibers, carbon fibers and aramid fibers are wound around a core mold in sequence, and the first aramid fiber layer, the carbon fiber layer and the second aramid fiber layer are formed respectively, wherein base materials are infiltrated in the aramid fibers, the carbon fibers and the aramid fibers respectively; the core mold is removed after the wound energy absorbing part is well solidified. The hybrid composite energy absorbing part for the automobile and the manufacturing method thereof have the advantages that the development requirements for light weight and safety of the automobile are met, the process route is reasonable, the treatment technology and the treatment method are low in cost, high in cost performance and high in safety performance, and the hybrid composite energy absorbing part for the automobile and the manufacturing method thereof conform with the development direction of lower energy consumption and low pollution and comply with the development tendency of energy saving, emission reduction and environmental friendliness.

Owner:DONGHUA UNIV

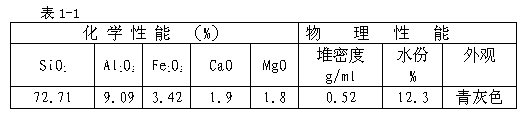

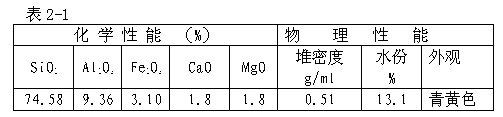

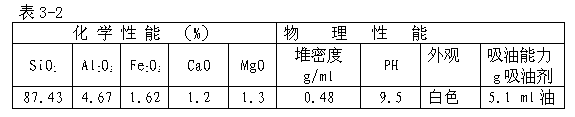

Oil absorbent prepared from low grade diatomite and preparation method thereof

InactiveCN103252209AGood compatibilityGood dispersionFatty/oily/floating substances removal devicesOther chemical processesVolumetric Mass DensityPollution

The invention relates to a preparation method of an oil absorbent, in particular to a method for preparing the oil absorbent from low grade diatomite. The preparation method comprises the following 9 steps of: low grade diatomite raw material selection, crushing, acidification treatment, washing, drying, adding of the assistant (3%-5%) Na2Cl (industrial salt) and mixing, roasting at 750-850DEG C, breaking winnowing, and adding of the silane coupling agent KH-550 (gamma-aminopropyl triethoxysilane, Nanjing Union silicon Chemical Co., LTD. 5%-7%) to conduct modification treatment, thus obtaining the particle and powder diatomite oil absorbent. The oil absorbent has simple and easy preparation method, wide raw material sources and low cost, solves the current solid waste pollution problem of low grade diatomite, opens up a new way for low grade diatomite application, and realizes recycling of waste materials. The oil absorbent has good selectivity, strong absorptivity up to 500% of its own weight, rapid oil absorption speed, small oil absorbent stacking density, a melting point of 1450DEG C, and a high use temperature, and can float on the water surface before and after oil absorption, thus being convenient for recovery and post-treatment.

Owner:任象玉

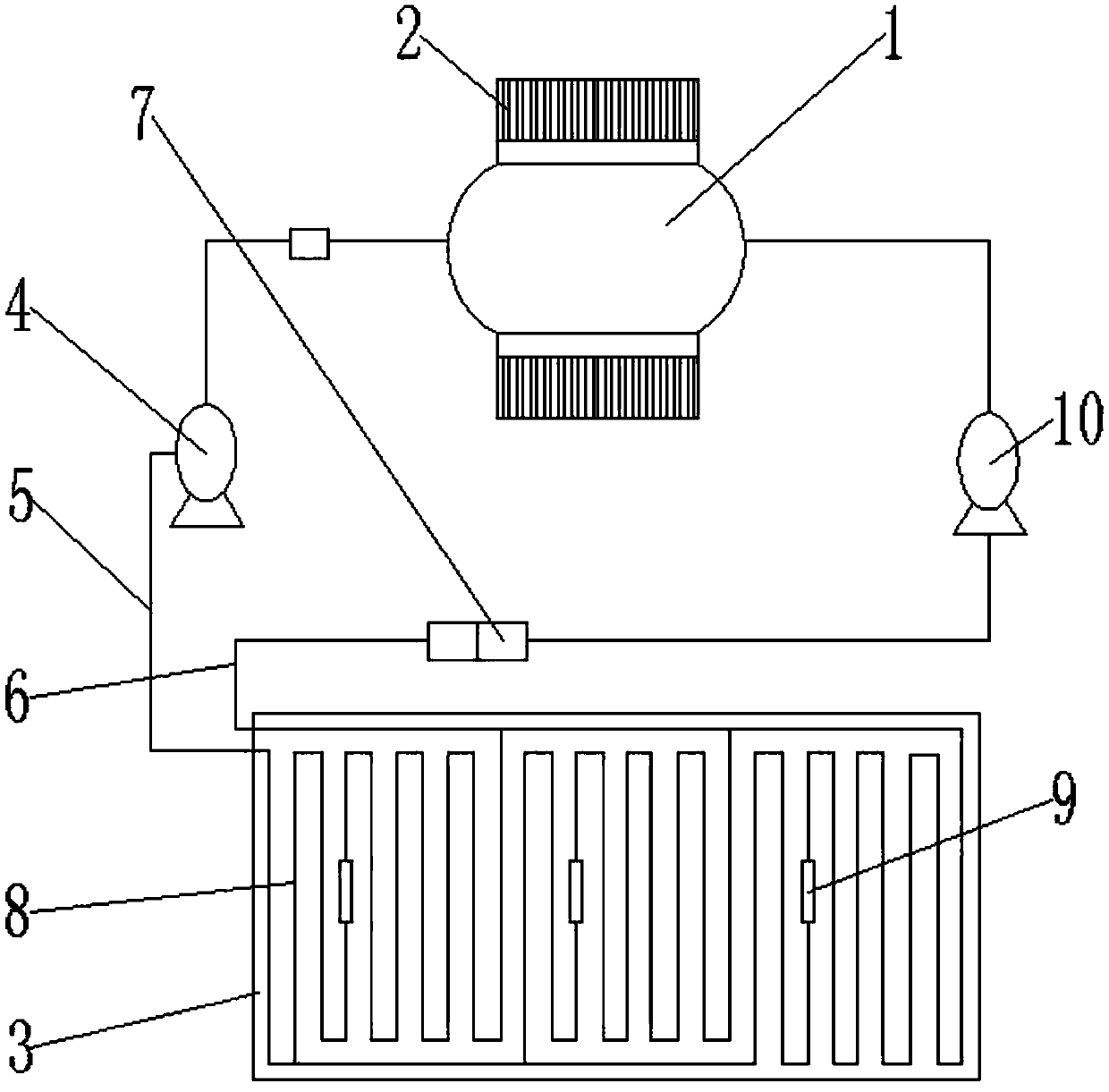

Mass concrete circulating cooling system

InactiveCN109098177AReduce temperature differenceReduce temperature stressFoundation engineeringEngineeringWater supply

The invention belongs to the technical field of concrete pouring, and particularly relates to a mass concrete circulating cooling system. According to the technical scheme, the mass concrete circulating cooling system comprises a water storing tank and a plurality of cooling water screens. The water storing tank communicates with a water inlet end of a water inlet pump by a pipeline. The water outlet end of the water inlet pump communicates with a water supplying pipeline. Water inlets of the cooling water screens communicate with the water supplying pipeline. Water outlets of the cooling water screens communicate with a backwater pipeline. The backwater pipeline is provided with a flow limiting valve. The backwater pipeline communicates with the water inlet end of a backwater pump. The water outlet end of the backwater pump communicates with the water storing tank by a pipeline. Cooling water in the water storing tank is conveyed to the water inlet pump to the cooling water screens. The cooling water screens are positioned in raft foundation concrete, can stably cool the poured concrete, and can conduct effective heat dissipation to concrete in the hydration process. The cooling water absorbs mass heat in the cooling water screens and is conveyed back to the water storing tank by the backwater pump, and therefore circulating application is achieved.

Owner:SHANXI CONSTR ENG CO LTD

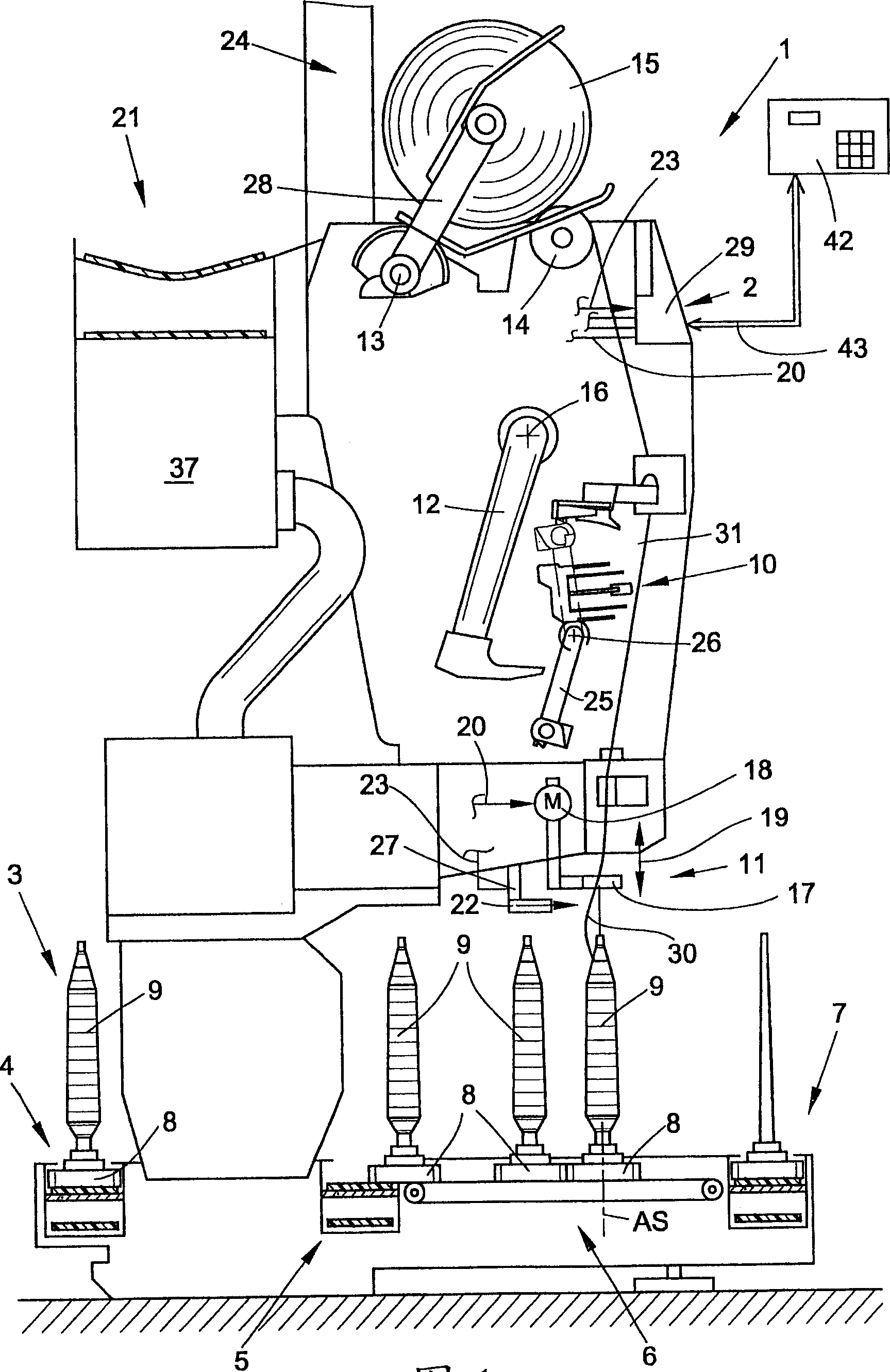

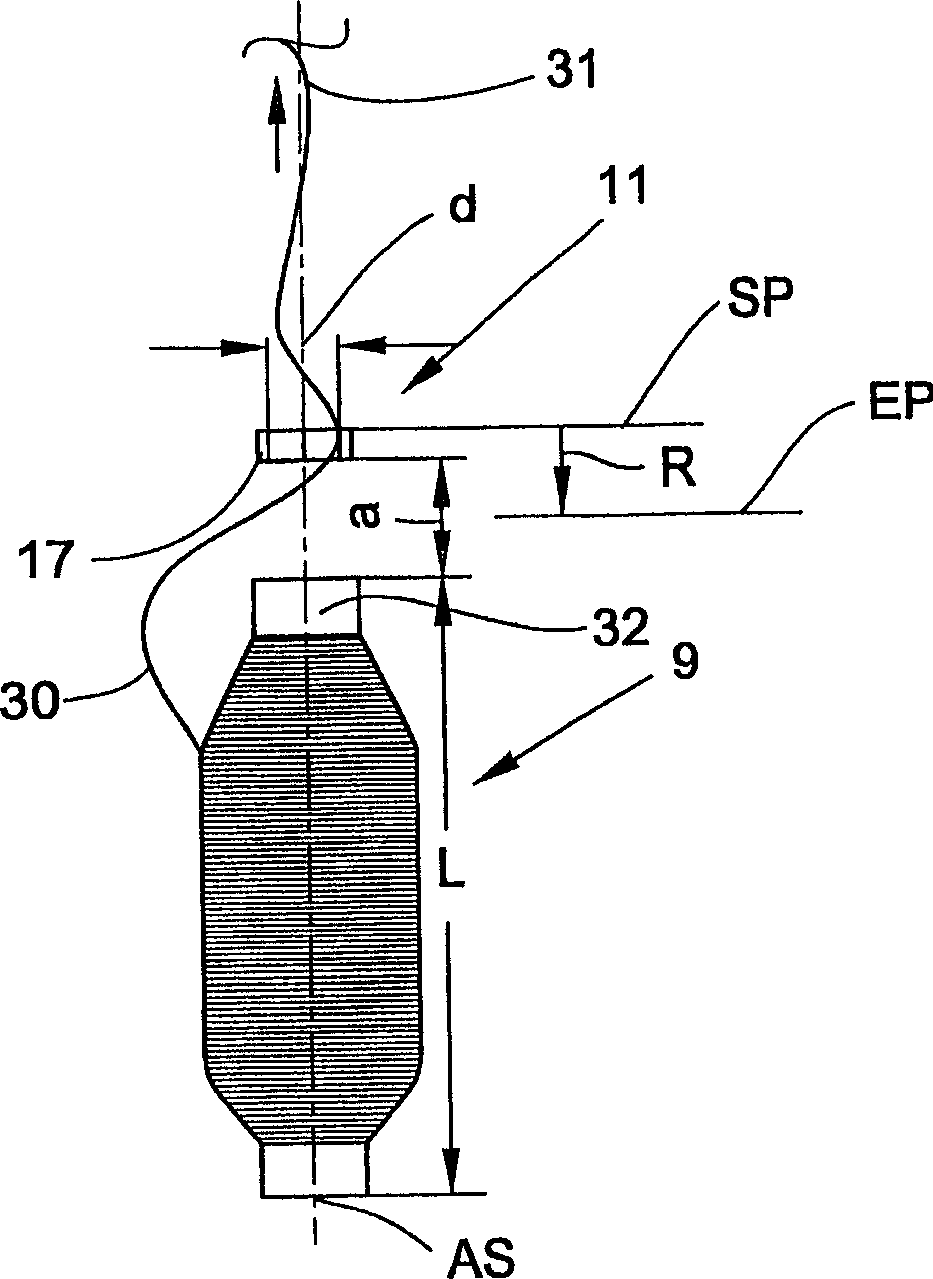

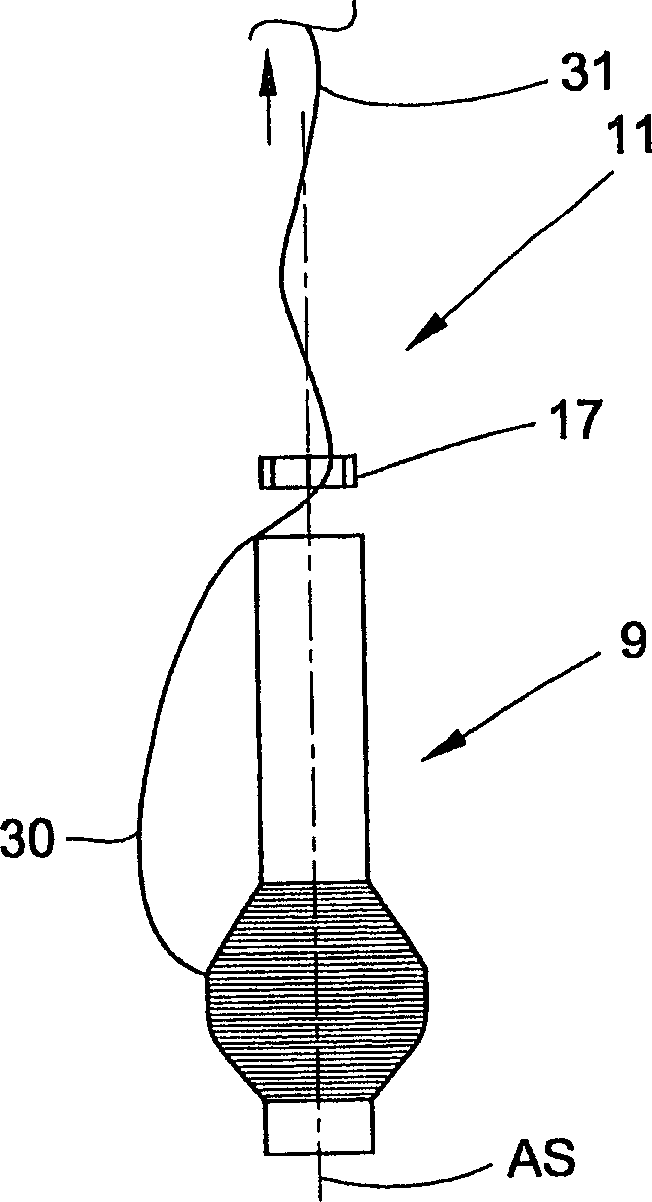

Modified device for withdrawing yarn of automatic cross-winding apparatus

A device for optimizing the yarn unwinding of the winding head of a cross-winding robot, with a vertically moving yarn guide positioned above the unwinding spool, characterized in that a yarn guide (17) is provided The adjusting device (18) of the adjusting device (18) makes the yarn guide (17) which acts as an upper limit on the rotating yarn balloon be positioned vertically in such a way that the formed yarn balloon is a single yarn balloon (30 ), the position of the yarn guide (17) is determined at least according to the winding state of the corresponding unwinding bobbin (9) when the yarn is unwound.

Owner:SAURER GERMANY GMBH & CO KG

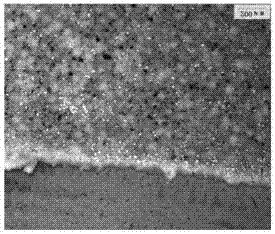

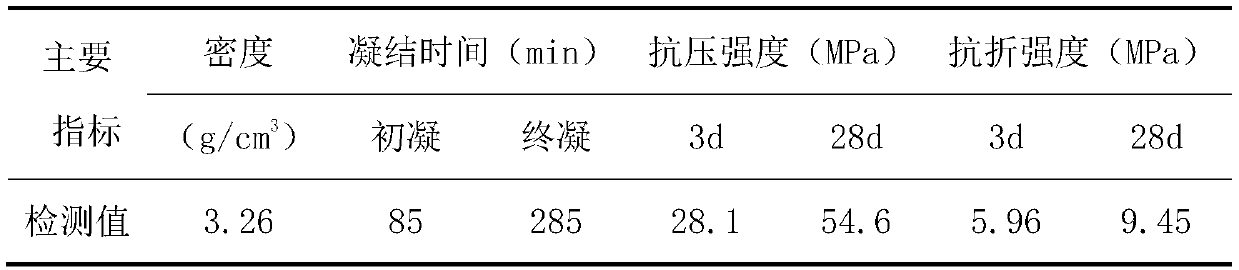

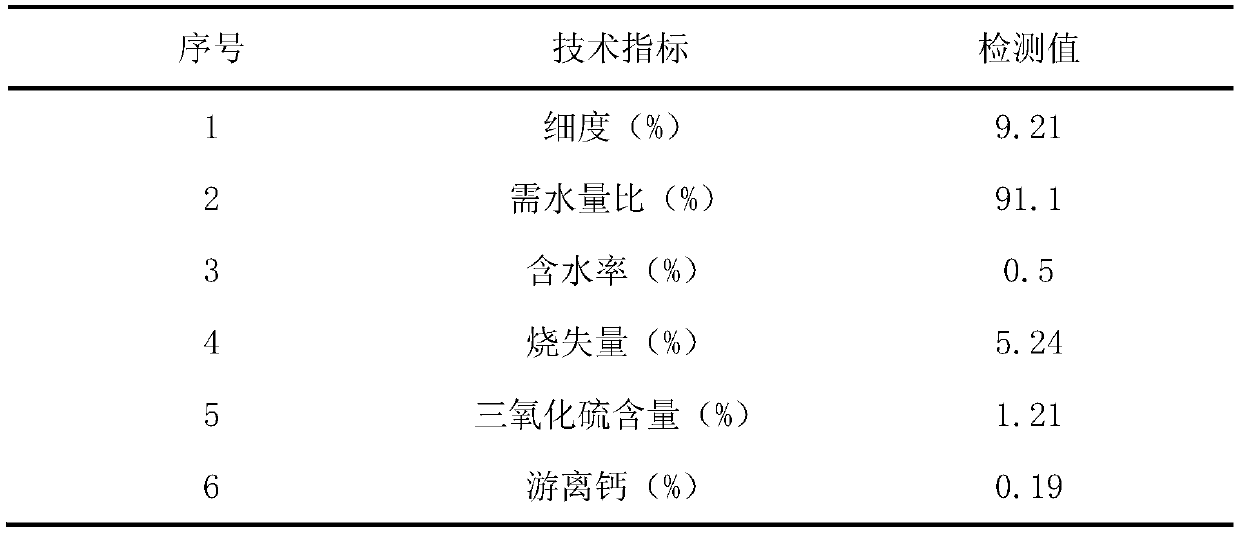

Nano-silica and steel fiber reinforced concrete

PendingCN110357528AImprove performanceImprove mechanical propertiesBridge deckConstruction aggregate

Belonging to the field of inorganic polymeric materials, the invention discloses a nano-silica and steel fiber reinforced concrete. The concrete comprises the following raw materials: 150-180 parts ofaggregate, 40-45 parts of cement, 0.1-4 parts of a water reducing agent, 5-10 parts of fly ash, 15-25 parts of water, 1-5wt% of nano-SiO2 and 0.5-2.5% by volume of steel fiber. By adding a specific amount of fiber and nano materials into the concrete, the novel composite material fiber reinforced nano-concrete can be prepared, and the concrete has the characteristics of high ductility, good compactness, good durability, etc., and meets the performance requirements of the concrete for bridge deck pavement.

Owner:ZHENGZHOU UNIV

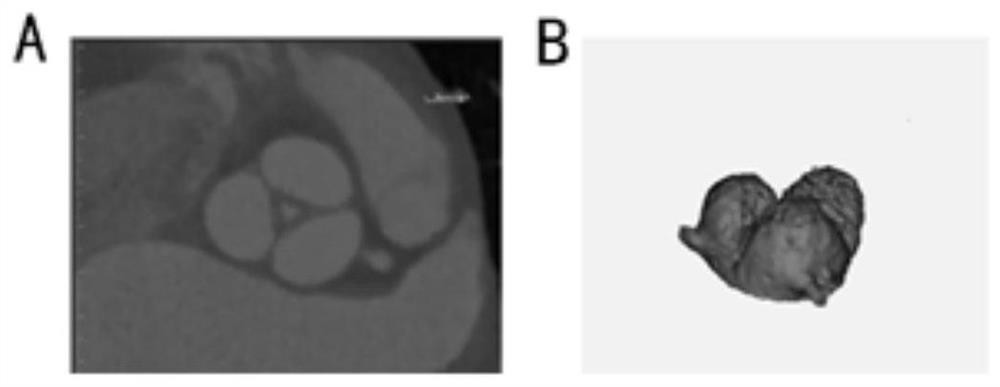

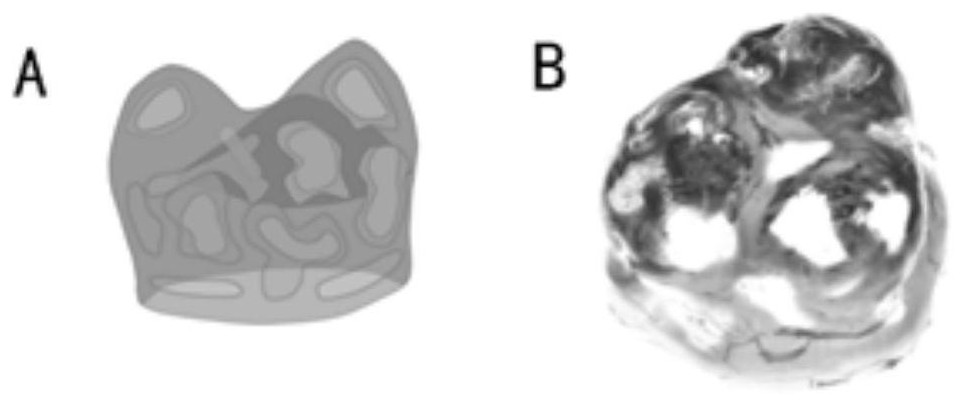

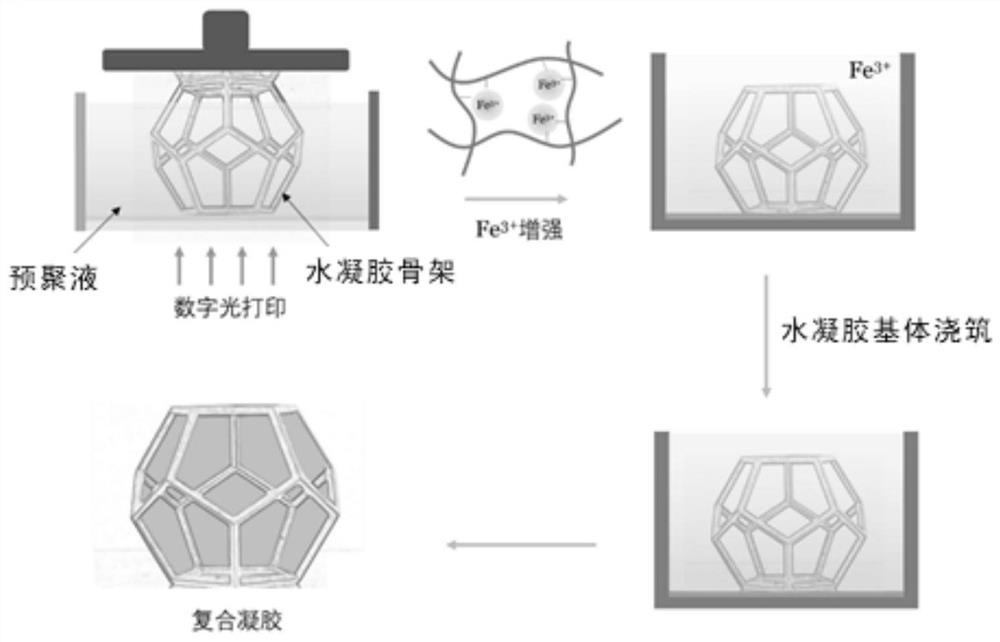

Anti-fatigue all-hydrogel composite material as well as preparation method and application thereof

PendingCN112111073AEasy to operateEase of industrial productionAdditive manufacturing apparatusTissue regenerationCrazingPolymer network

The invention relates to an anti-fatigue all-hydrogel composite material as well as a preparation method and application thereof. The anti-fatigue all-hydrogel composite material comprises a hydrogelskeleton and a hydrogel matrix filling in and bonded in the hydrogel skeleton, wherein the modulus of the hydrogel skeleton is 10 times or more the modulus of the hydrogel matrix. The all-hydrogel composite material is composed of the hydrogel skeleton and the hydrogel matrix with large modulus contrast, and polymer networks of the hydrogel skeleton and the hydrogel matrix are topologically entangled; the composite material can effectively limit crack propagation, and compared with a skeleton material and a matrix material, the all-hydrogel composite material has moderate modulus, but the fracture performance of the all-hydrogel composite material exceeds 4000 J / m<2> and is greatly improved; and the fatigue threshold value of the composite material exceeds 400 J / m<2>, so the composite material has important significance for an application scene in need for bearing of cyclic load. The composite material has the same fatigue resistance as a mechanical valve and the same biocompatibilityas a tissue valve.

Owner:苏州凝智新材料发展有限公司

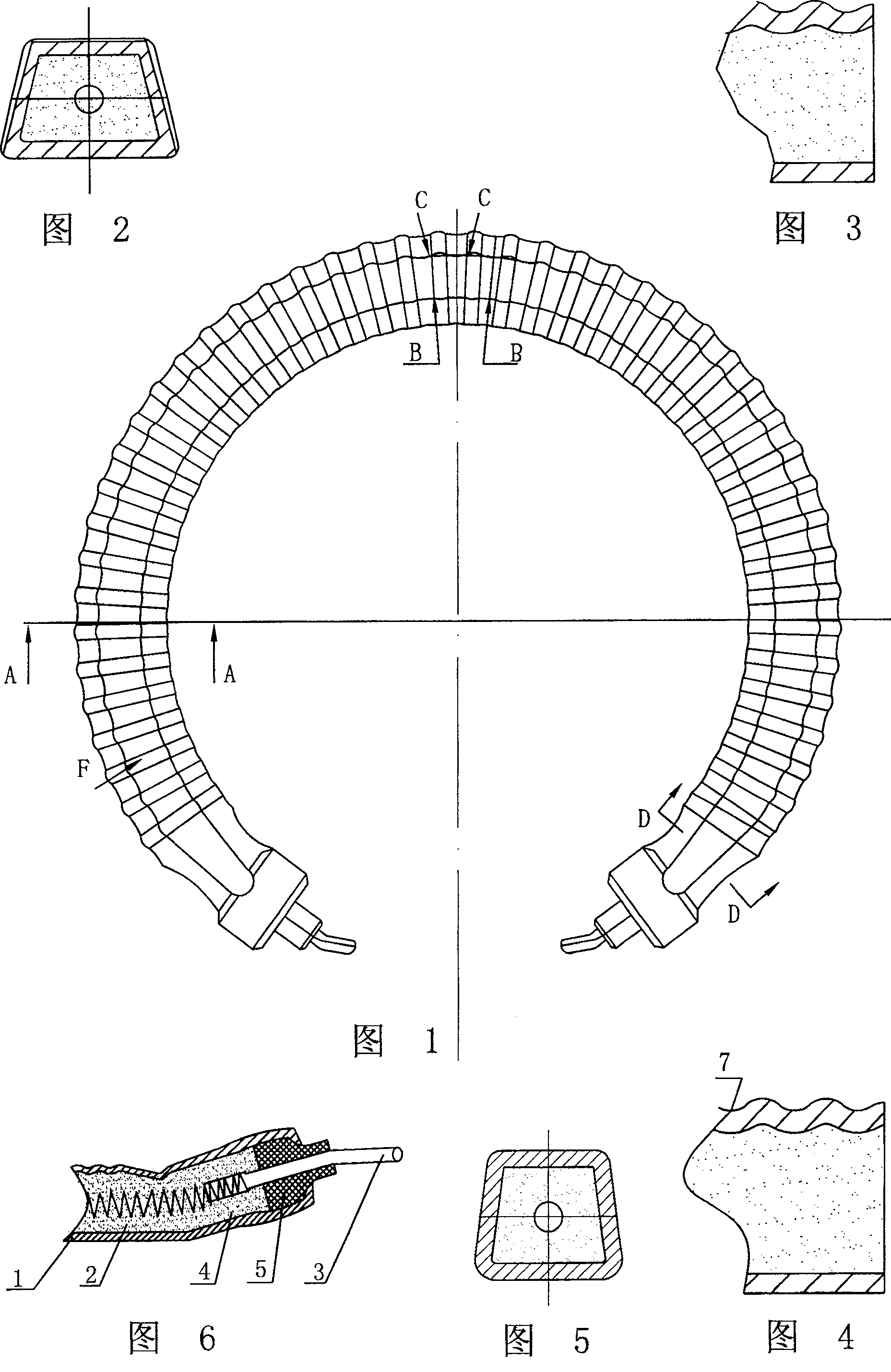

Electrothernal tube and its forming method

This invention is an electro-thermal tube and its molded method. It solves the question of electro-thermal tube which would be extended in length when they heating in the mould, then its length and shape cannot be controlled very accurately, and the insulation power inside the tube would not be compressed tightly. In the figure we can see the electro-thermal tube and in its inner insulation powder and electric resistance, block up at inlet of the metal tube, they keep distance with the rube and keep distance with the metal rod too. This tube has been shaped by a metal tube which has ellipse section in its face having concave and convex structure and at least has one plane structure. The step of forming the tube is to put the tube on the proper place into the model A, at the concave place on this model, and press model B upon model A. shape concave and convex structure on the metal tube's face and extend this action along the tube, when the shaping action finished, take out of the models.

Owner:何伟

Preparation method of prestressed prefabricated component

InactiveCN111531702AFireproof constructionImprove appearance qualityCeramic shaping apparatusExcavationsChemical treatmentRough surface

The invention relates to the technical field of prestressed prefabricated components, and discloses a preparation method of a prestressed prefabricated component. The preparation method comprises thefollowing steps that when an original component is heated and cured, a curing system to control the time for standing, heating, constant temperature and cooling is formulated, standing is performed atnormal temperature for 2-6 hours, the difference value between the surface temperature of the prefabricated component discharged out of a pool and the environment temperature does not exceed 25 DEG C, the original component adopts a prefabricated component joint surface connected by post-poured concrete or mortar and grouting materials, and rough surface treatment is carried out according to design requirements during manufacturing. When the design has no specific requirements, the rough surface can be manufactured through chemical treatment, galling or chiseling and other methods, a sandwichexternal wallboard of the original component is suitable for being produced through a flat die technology, and during production, an external wallboard concrete layer needs to be poured firstly, thena heat preservation material and a pulling piece need to be installed, and finally an internal wallboard concrete layer needs to be poured; and when a vertical die technology is adopted for production, inner and outer wallboard concrete layers should be poured synchronously, and measures should be taken to ensure accurate positions of thermal insulation materials and tie pieces.

Owner:武汉市华江幸福装配式建筑有限公司

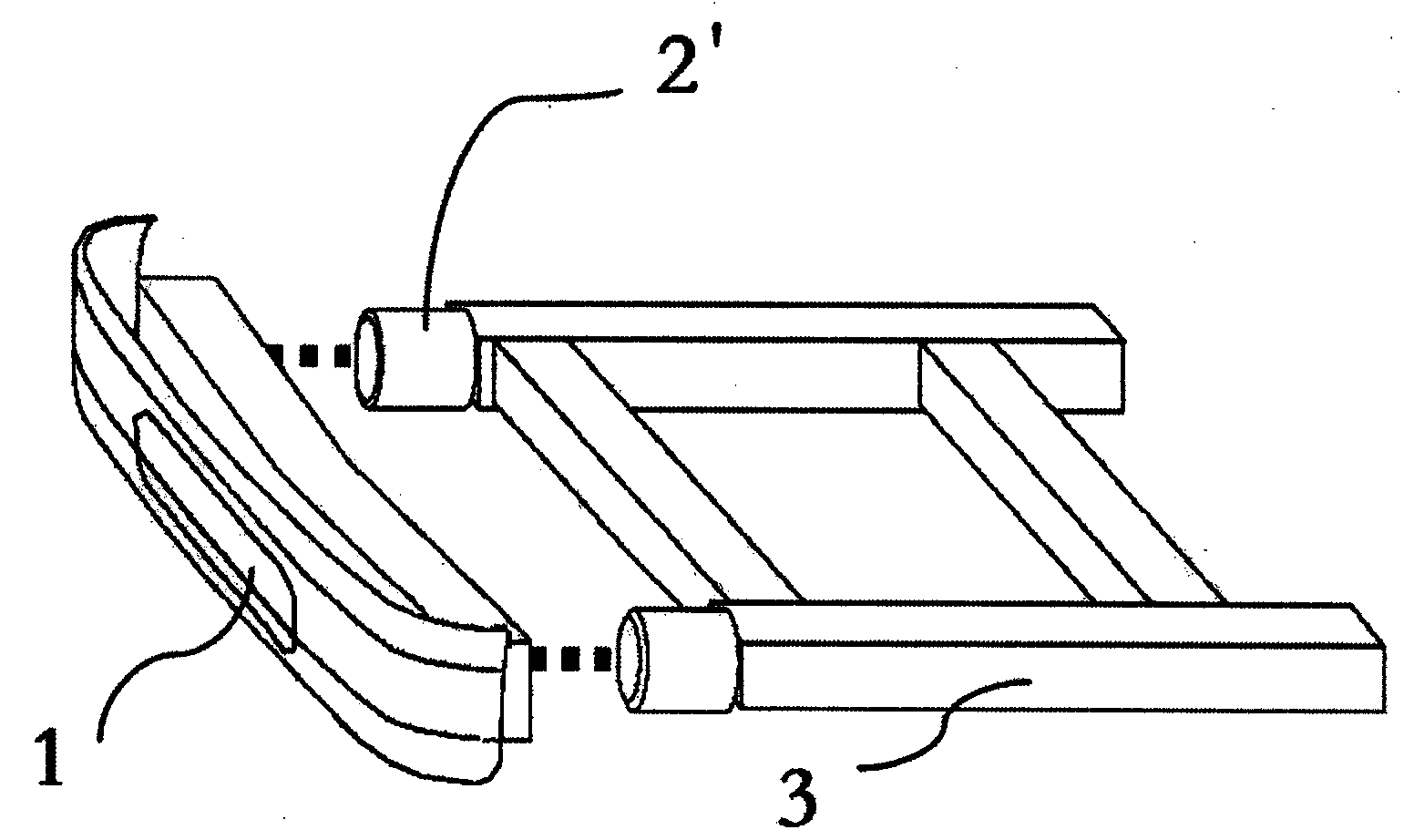

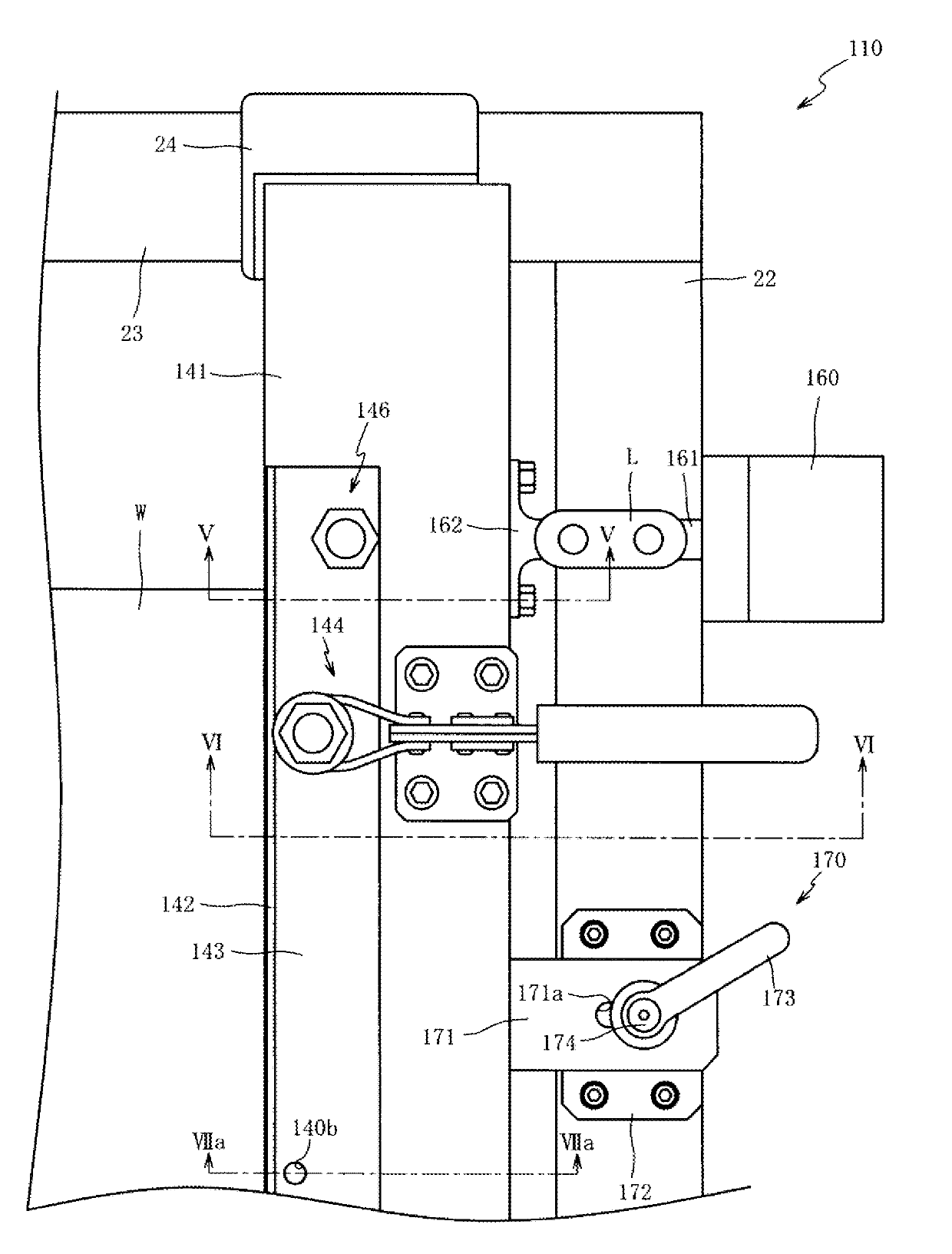

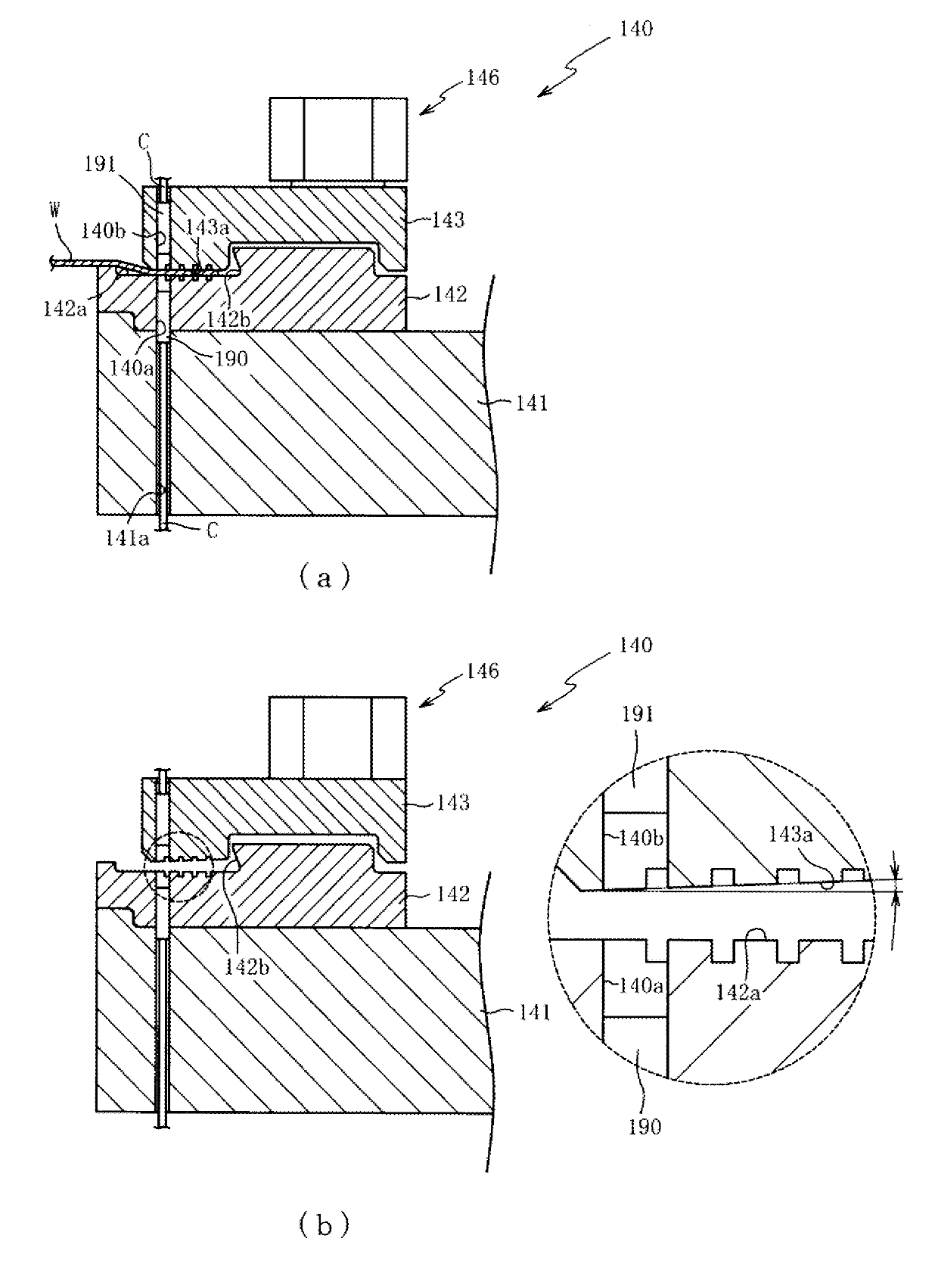

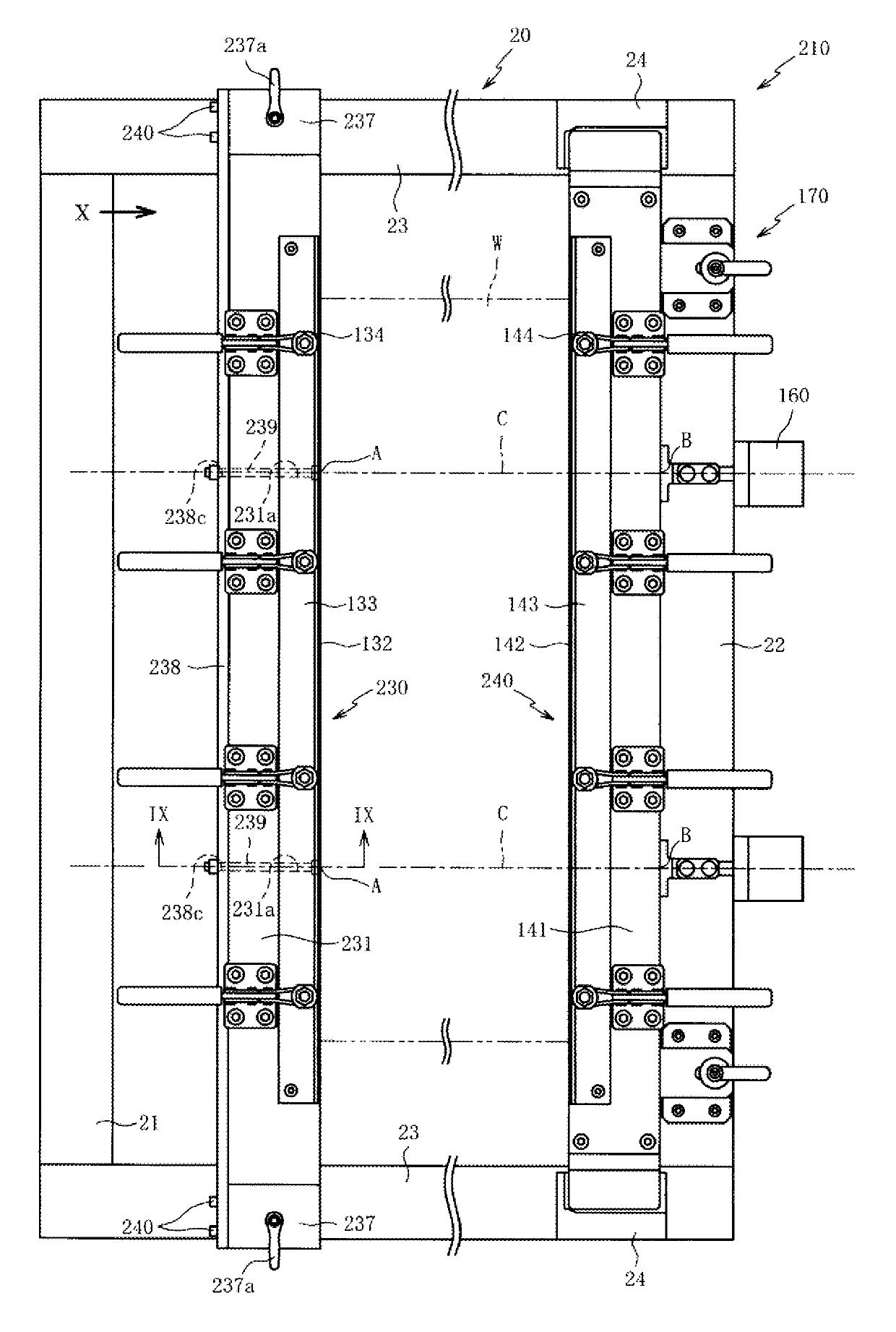

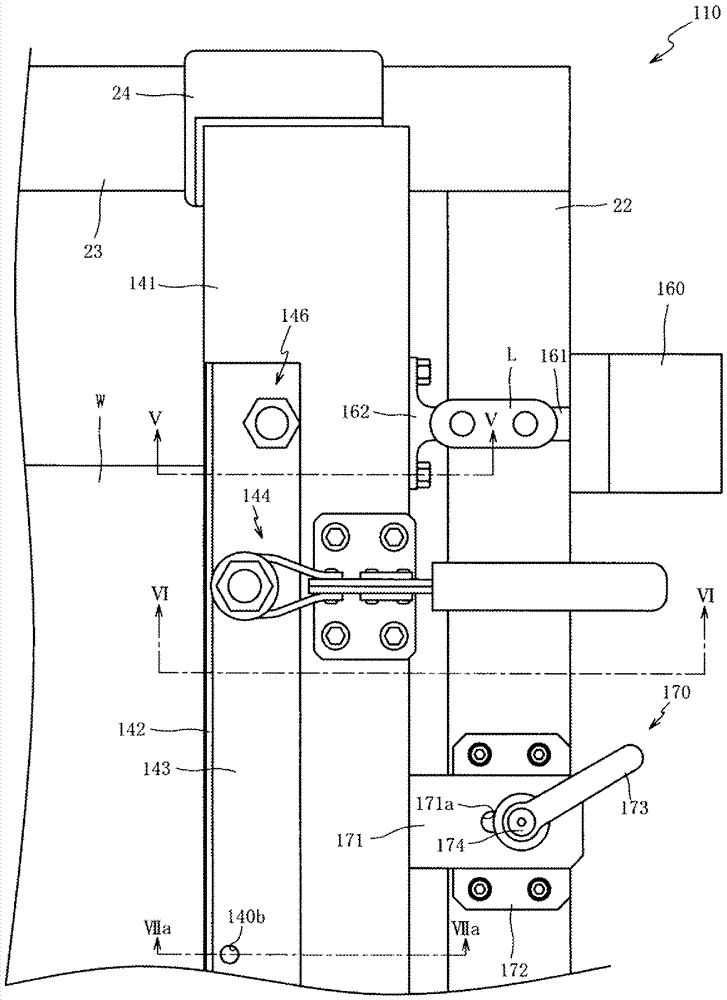

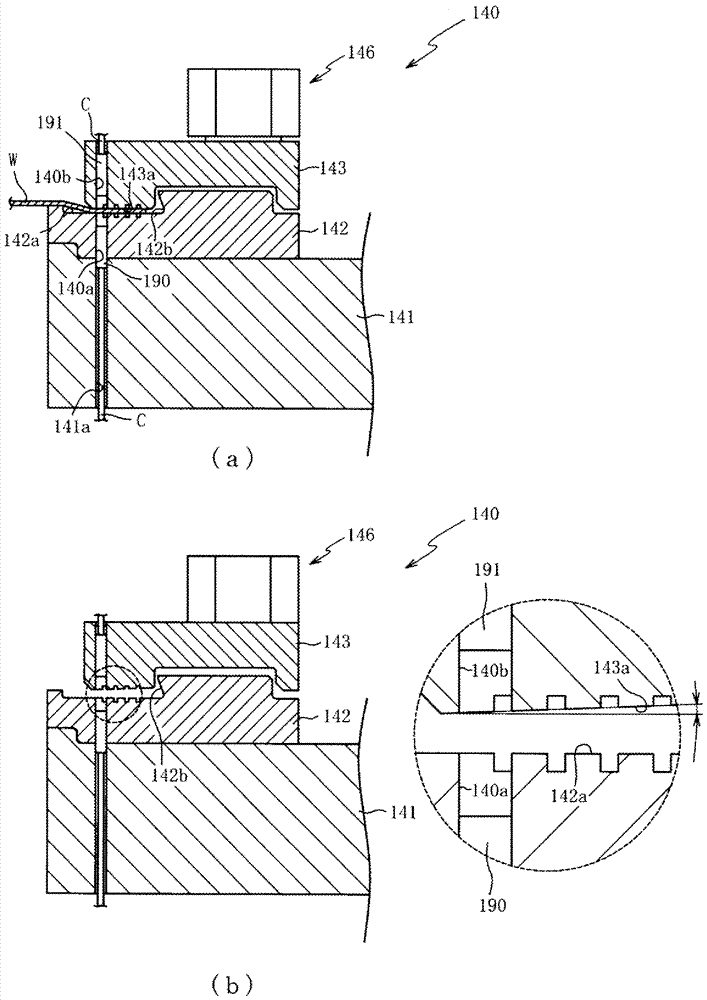

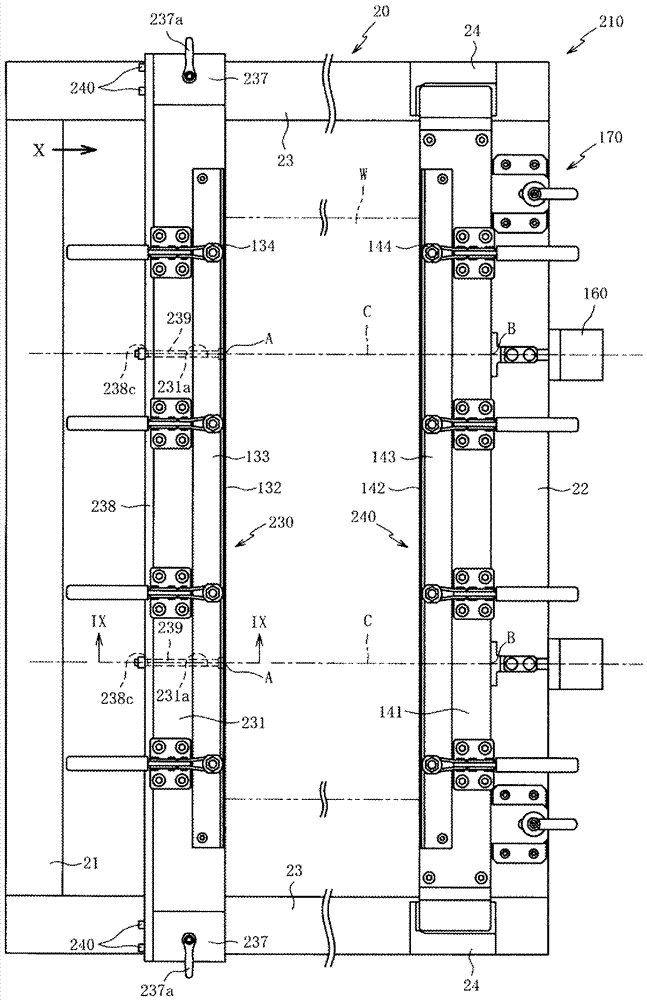

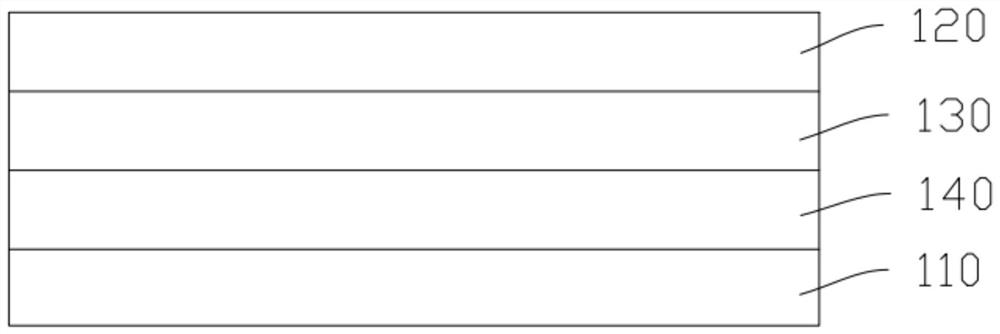

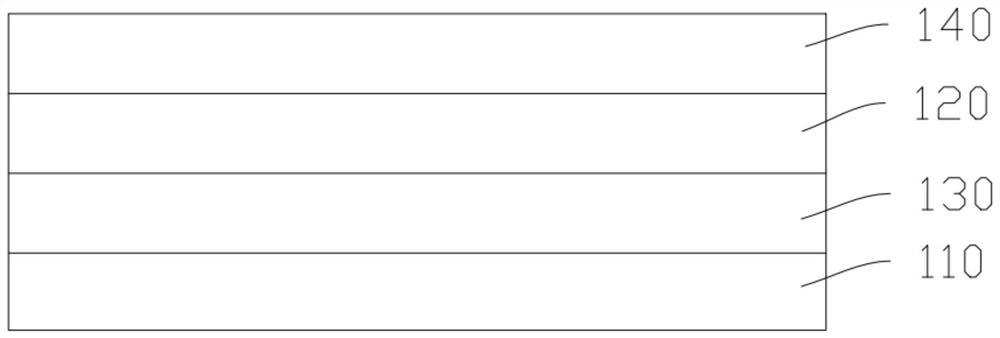

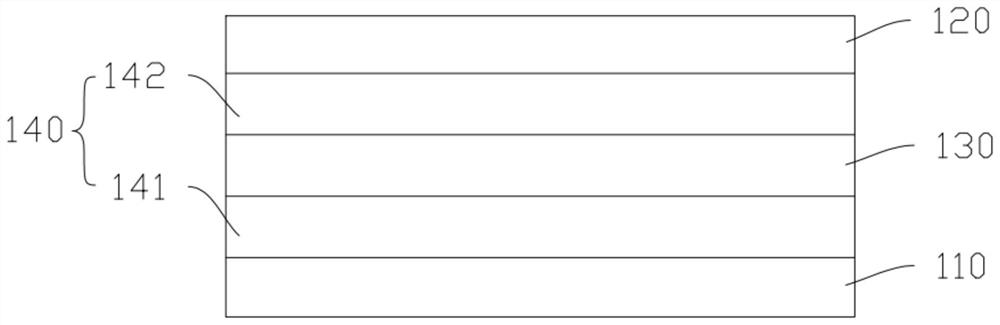

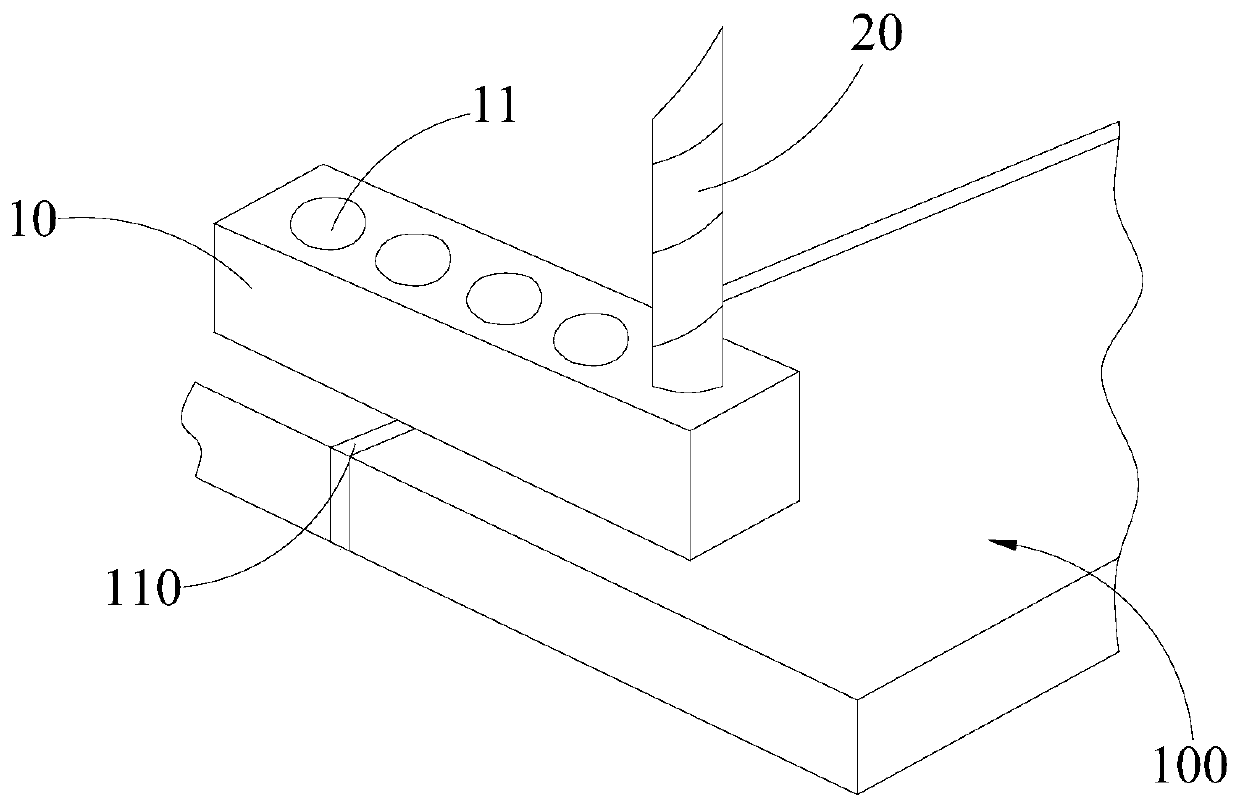

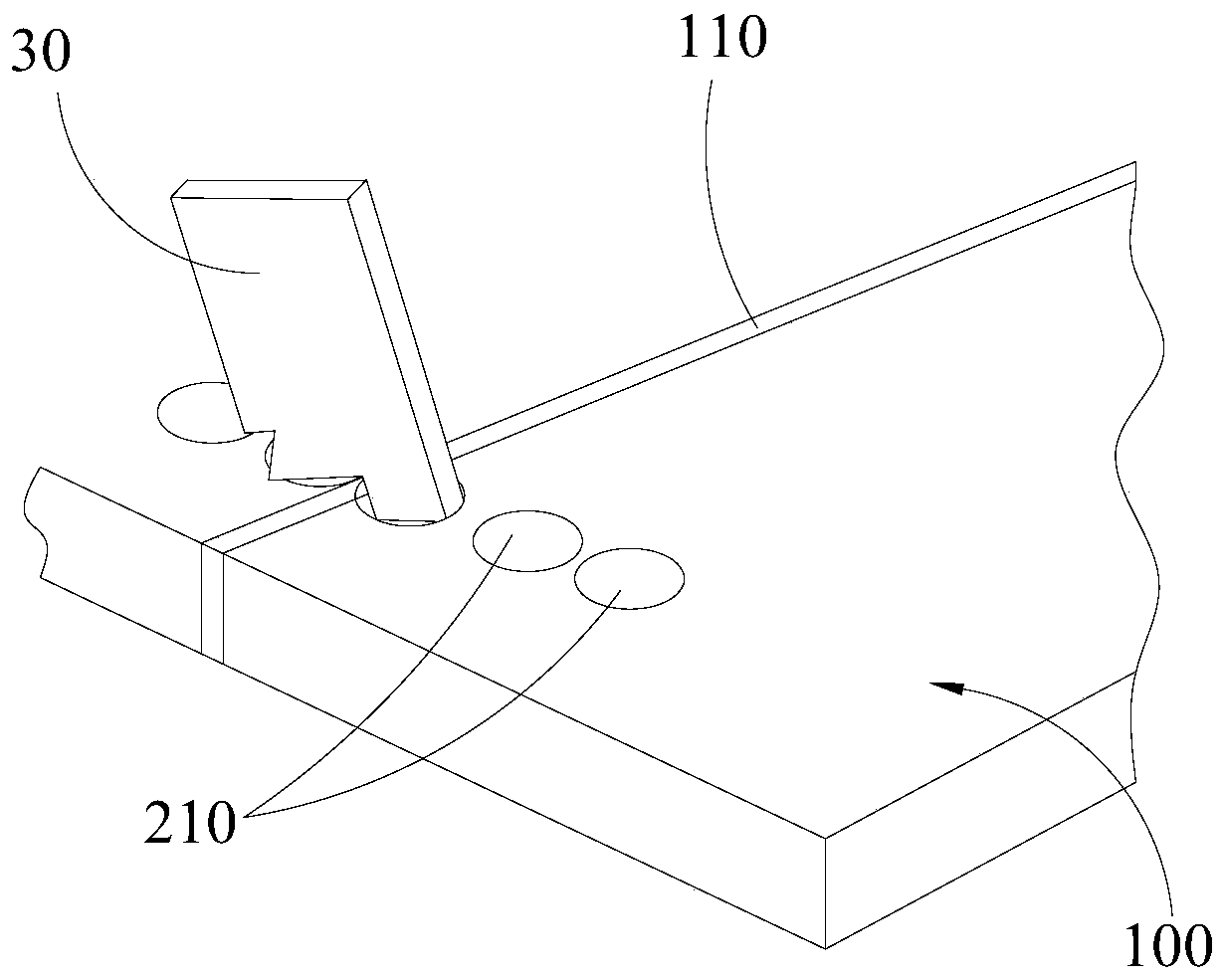

Thin plate retaining device

ActiveCN104175005ASimple and fast operationAvoid deflectionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a thin plate retaining device capable of arranging a thin plate on an XY platform in an opening mode by simple and convenient operation in a laser machine. A first frame material (21) and a second frame material (22) are fixedly arranged on the XY platform (11), and are spaced from each other by a given distance. A first part (130) is arranged between the first frame material (21) and the second frame material (22), and one end of a thin plate (W) is clamped by the first part (130). A second part (140) is formed by relatively moving from a direction away from the first part (130), and is arranged between the first frame material (21) and the second frame material (22) along the second frame material (22), and the other end of the thin plate (W) is clamped by the second part (22). The ends of multiple connecting rods (L) which are formed in a swinging way are connected with the corresponding multiple parts of the second part (22), and the other ends of the connecting rods (L) are connected with a cylinder (160). The thin plate (W) can be arranged on the XY platform (11) by the simple and convenient operation that force is applied to the second frame material (22) by the second part (140).

Owner:SUMITOMO HEAVY IND LTD

Turbine guider crake brazing repair method

InactiveCN107234311AEnsure safetyExtend your lifeSoldering apparatusTurbineUltimate tensile strength

The invention discloses a turbine guider crake brazing repair method. The method comprises the following steps that a crack of a turbine guider is removed, a groove is formed, and a bottom nickel-based alloy powder layer is laid in the groove; mixed brazing filler metal is arranged on the bottom nickel-based alloy powder layer, vacuum brazing is conducted, and the mixed brazing filler metal comprises 20-60% by mass of auxiliary nickel-based alloy powder and a brazing filler metal body; the bottom layer nickel-based alloy powder and the auxiliary nickel-based alloy powder are the same, and the difference between the melting point of the bottom layer nickel-based alloy powder and the auxiliary nickel-based alloy powder and the melting point of a substrate material of the turbine guider is + / -20 DEG C; and the temperature of brazing is higher than the melting temperature of the brazing filler metal body and is lower than the melting temperature of the bottom nickel-based alloy powder layer, the auxiliary nickel-based alloy powder and the substrate material. According to the turbine guider crake brazing repair method, the brazing filler metal body is completely melted, and the nickel-based alloy powder is not melted during brazing. The nickel-based alloy powder is mainly used as a structure frame, the brazing filler metal body is used for filling, and thus the stable structure and strength are ensured.

Owner:CHINA HANGFA SOUTH IND CO LTD

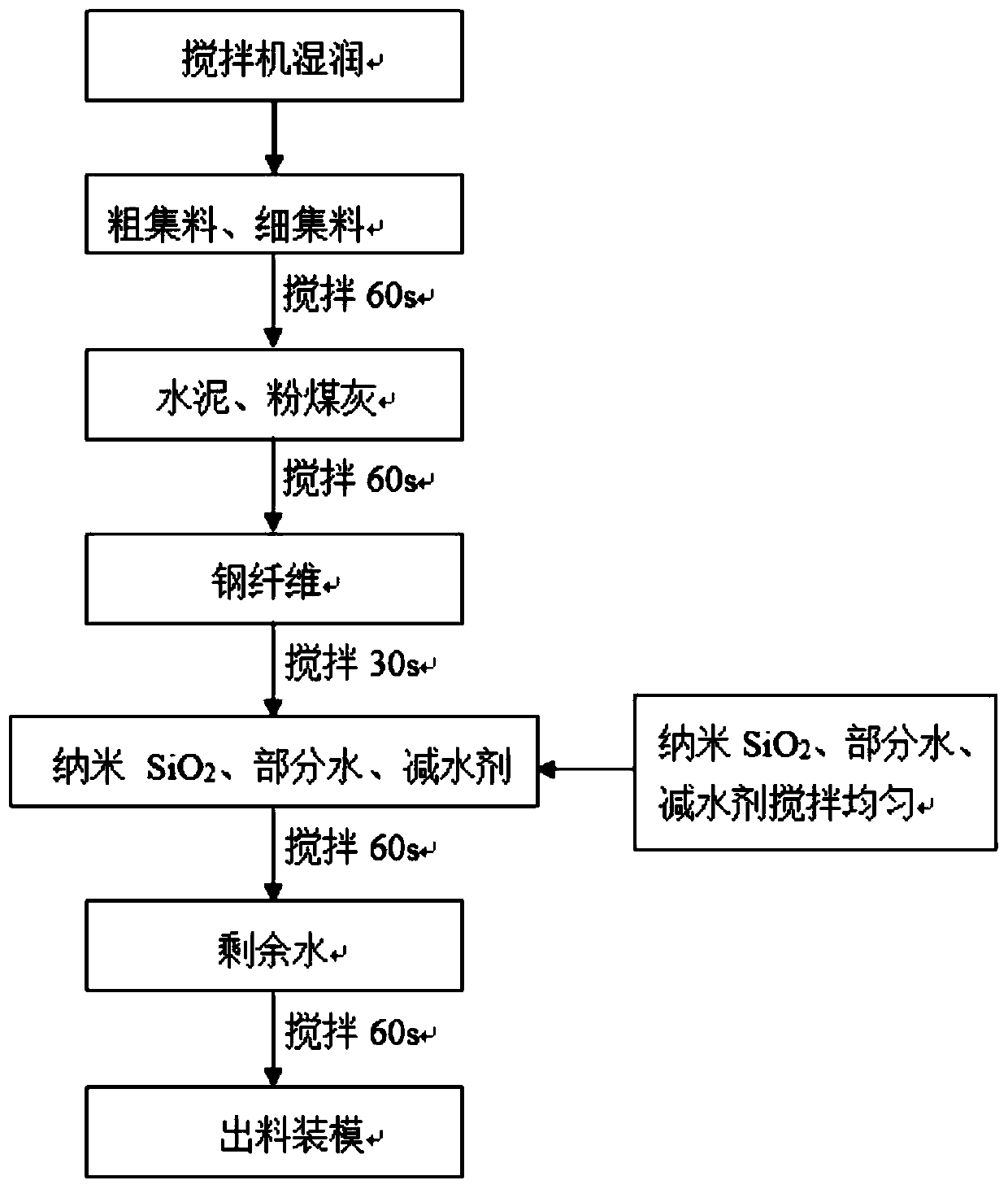

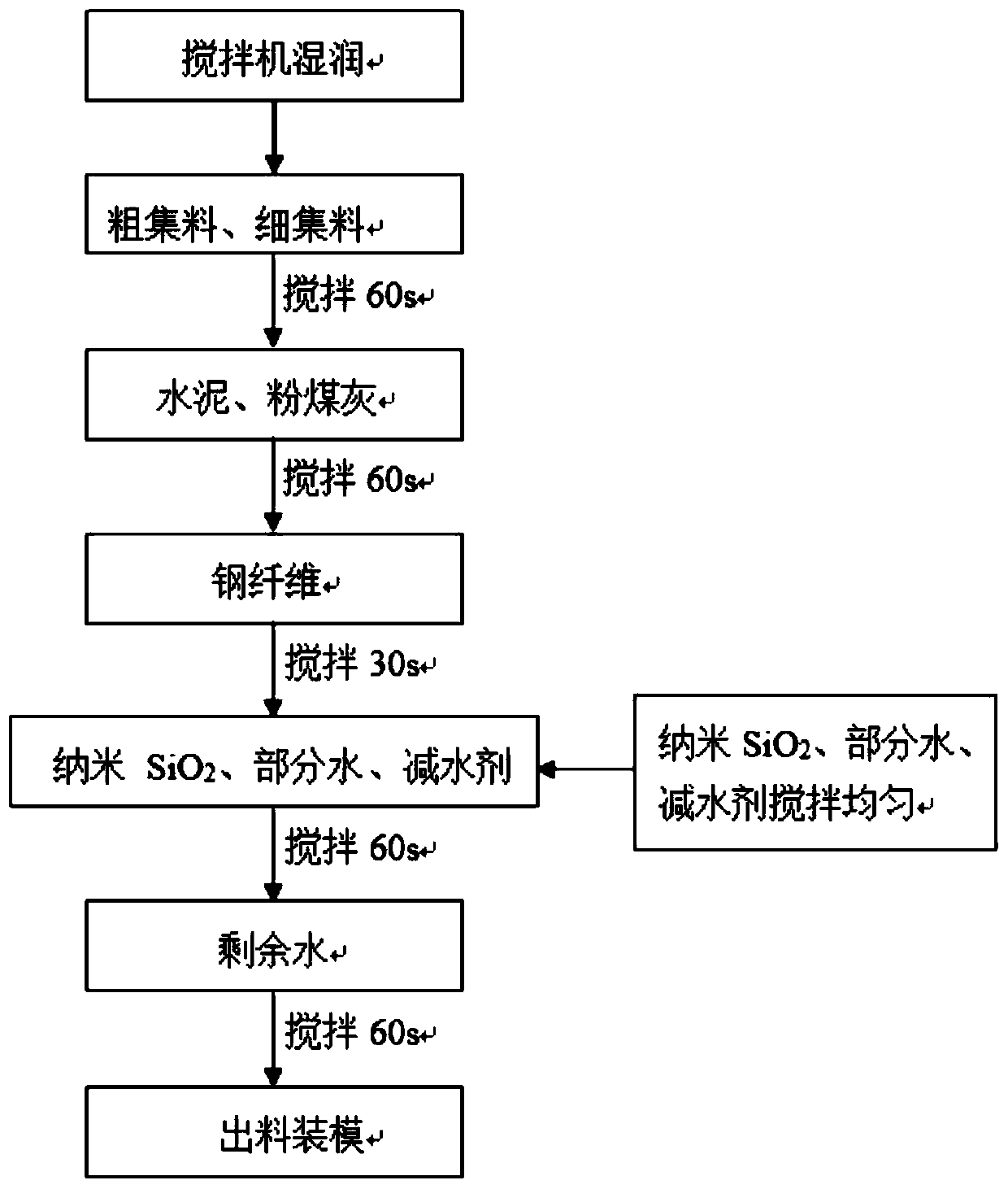

Preparation method of nano-silica and steel fiber reinforced concrete

Belonging to the field of inorganic polymeric materials, the invention discloses a preparation method of a nano-silica and steel fiber reinforced concrete. The method includes: weighing aggregate, cement, a water reducing agent, fly ash, water, nano-SiO2 and steel fiber; adding the nano-SiO2 and the water reducing agent into part of the water, and mixing the substances evenly for standby use; wetting a mixer, then adding coarse aggregate and fine aggregate, performing mixing, then adding the cement and fly ash, conducting mixing, and then incorporating the steel fiber evenly along the mixer impeller rotation direction, performing mixing, then adding the mixture of the nano material, the water reducing agent and part of water, performing stirring, adding the residual water, and conducting mixing, thus obtaining the nano-silica and steel fiber reinforced concrete. By blending a specific amount of fiber and nano material into concrete, the method provided by the invention can prepare thenovel composite material fiber reinforced nano-concrete, which has the characteristics of high ductility, good compactness, good durability, etc., and meets the performance requirements of the concrete for bridge deck pavement.

Owner:ZHENGZHOU UNIV

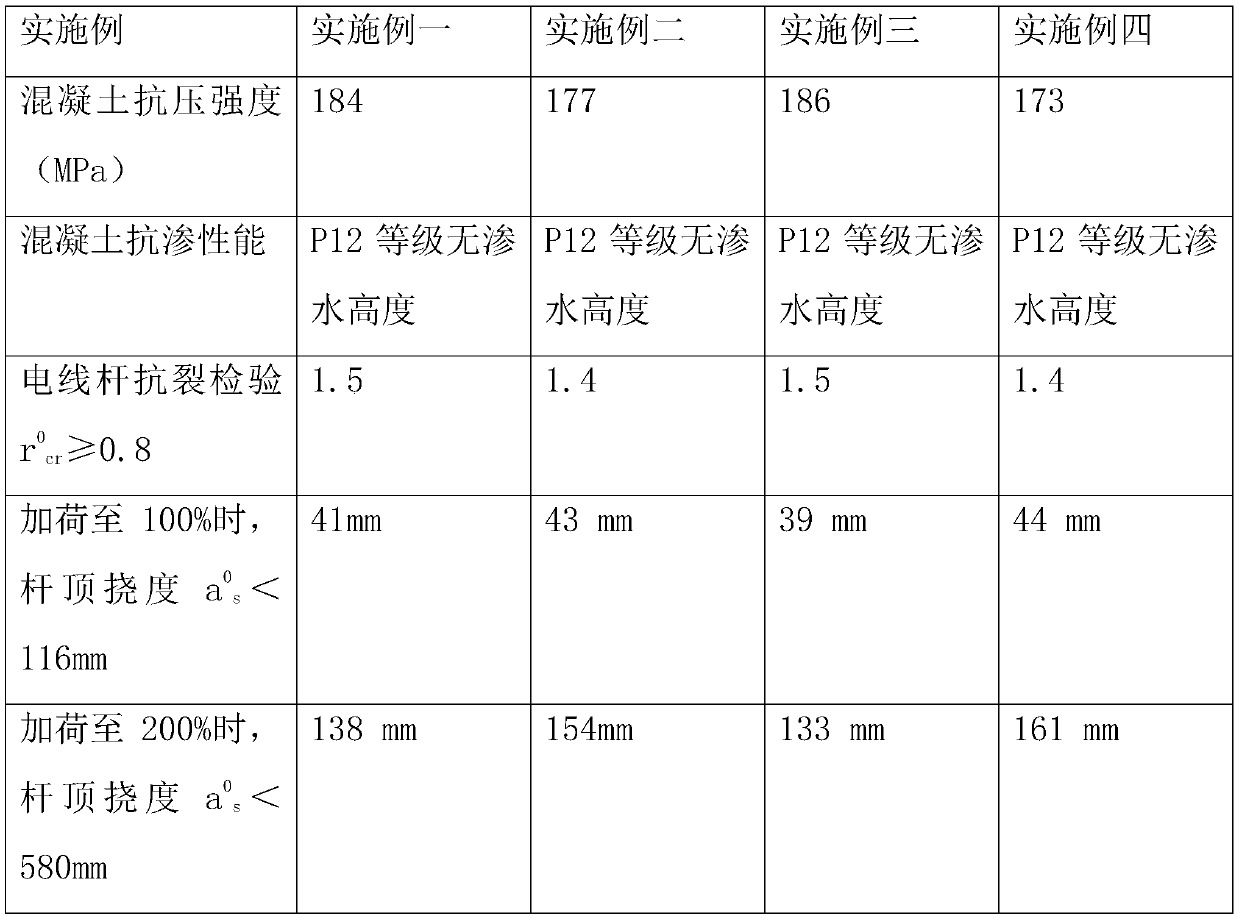

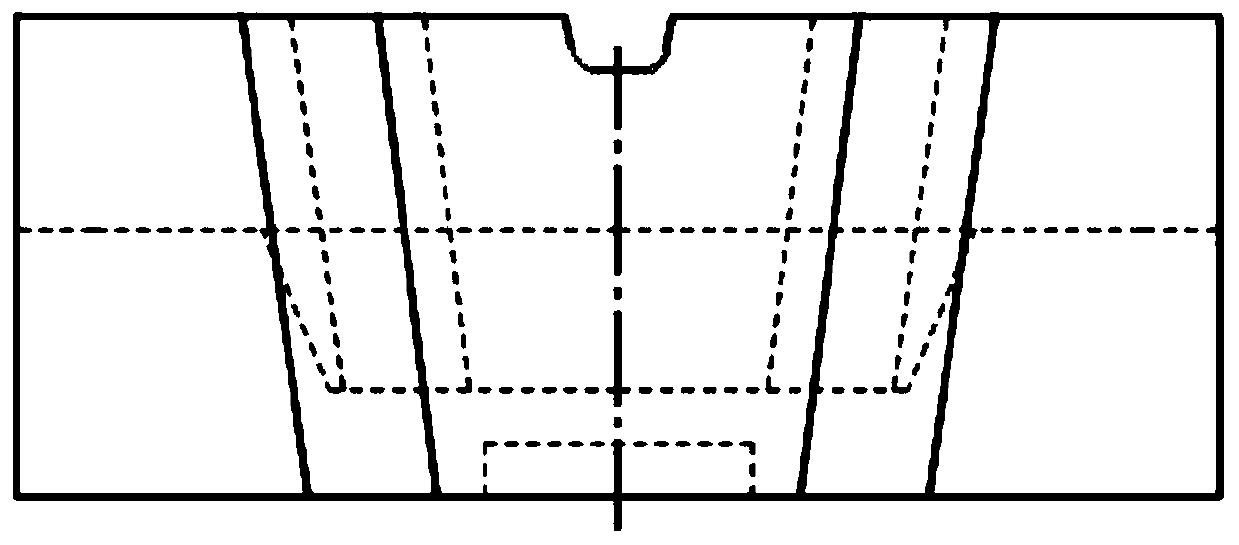

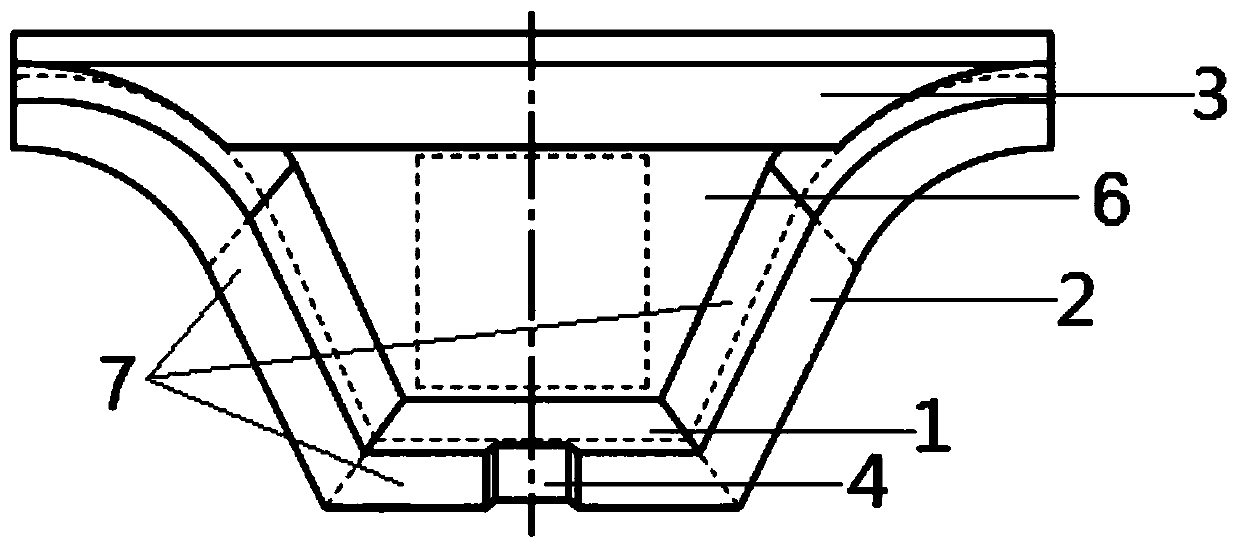

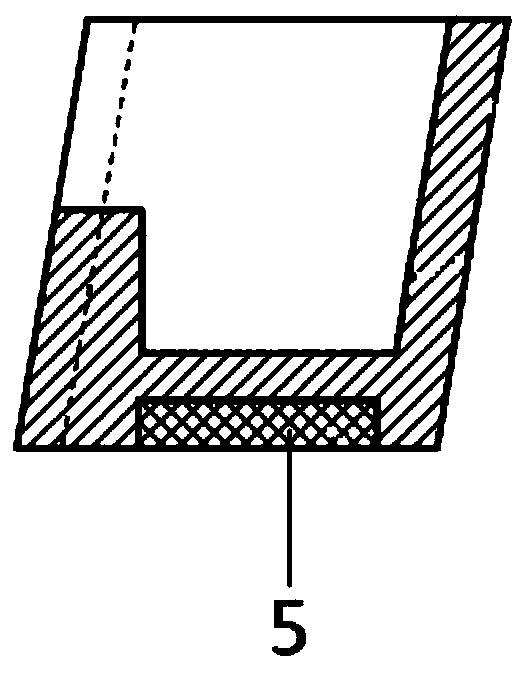

Cement-based telegraph pole

The invention provides a cement-based telegraph pole. The cement-based telegraph pole comprises a pole body formed by compounding a steel reinforcement framework with a concrete material; the steel reinforcement framework is subjected to anticorrosion treatment through epoxy resin anticorrosion paint; the concrete material is prepared from, by weight, 100 parts of Portland cement, 250-260 parts ofbasalt macadam, 150-160 parts of quartz sands, 8-10 parts of polyvinyl alcohol fibers, 5-7 parts of modified towel gourd fibers, 15-20 parts of nano-material capsules, 5-6 parts of rubber powder, 25-30 parts of modified sepiolite powder, 15-20 parts of palygorskite powder, 0.5-1.0 part of a water reducing agent, 5-6 parts of polyoxyethylene and 50-60 parts of water. And the nano-material capsuleis a hard shell capsule filled with nanometer calcium carbonate and nanometer silicon dioxide. The telegraph pole provided by the invention has excellent durability, crack resistance, impermeability and compressive strength.

Owner:重庆金石源电力线路器材有限公司

High-temperature-resistant material, preparation method thereof, combined prefabricated part of tundish impact area and tundish impact area

ActiveCN110885245AImproved thermal shock stabilityHigh strengthMelt-holding vesselsGrogSilicon dioxide

The invention relates to the technical field of high-temperature materials, in particular to a high-temperature-resistant material, a preparation method thereof, a combined prefabricated part of a tundish impact area and the tundish impact area. The high-temperature-resistant material includes following raw materials by weight: 10-50 parts of magnesia, 30-75 parts of bauxite clinker, 2-10 parts ofwhite fused alumina powder, 1-10 parts of silica powder, 1-10 parts of steel fibers, 0.1-1 part of a water reducing agent, 0.1-1 part of explosion-proof fibers and 2-10 parts of water. The high-temperature-resistant material has good thermal vibration stability, strong impact resistance and excellent resistance to steel slag erosion. The combined prefabricated part of the impact area prepared using the material and the matching tundish impact area can significantly improve service lifetime of a tundish.

Owner:山东国茂冶金材料有限公司

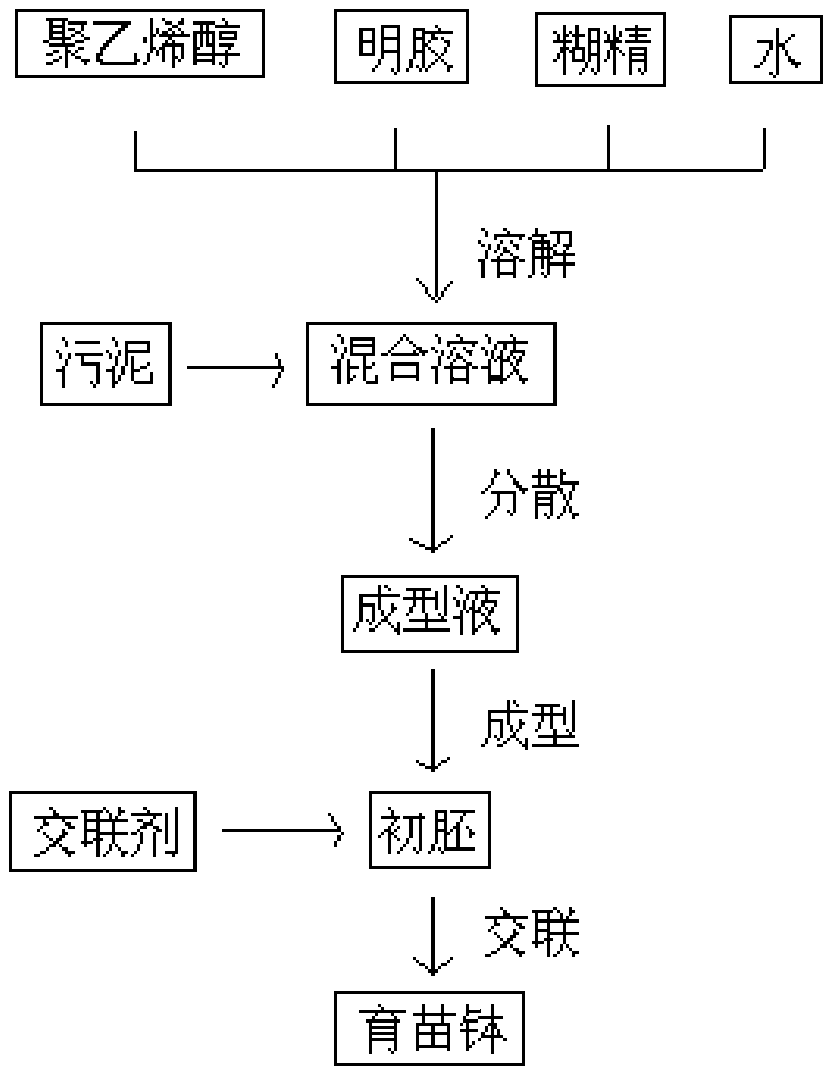

Degradable sludge-based seedling pot and preparation method thereof

InactiveCN108476804AImprove mechanical propertiesShorten degradation timeGrowth substratesCulture mediaCross-linkPlant roots

The invention relates to a degradable sludge-based seedling pot and a preparation method thereof. The seedling pot is prepared from, by weight, 2-5 parts of polyvinyl alcohol, 80-100 parts of water, 5-10 parts of gelatin, 5-10 parts of dextrin, 5-20 parts of sludge and 0.5-1 part of cross-linking agent. In the preparation process of the seedling pot, the forming treatment is conducted before the cross-linking treatment. The seedling pot has high mechanical properties and can meet the requirements of use performance of the seedling pot in seedling cultivation; the seedling pot can also be rapidly degraded in soil, so that the rapid growth and extension of plant roots after transplanting or planting are not limited, which has a positive effect in improvement of the survival rate of seedlingsand the growth rate of plants.

Owner:SICHUAN COLLEGE OF ARCHITECTURAL TECH

Ultrahigh-toughness concrete and preparation method thereof

ActiveCN113831086ALow viscosityGood dispersionSolid waste managementPolymer sciencePolyvinyl alcohol

The invention discloses an ultrahigh-toughness concrete comprising the raw materials: cement, water-borne epoxy resin emulsion, polypropylene fibers, silica fume, clay ceramsite, an expanding agent, a polycarboxylic acid high-efficiency water reducing agent, a polyamine curing agent, triethylene tetramine, methyl methacrylate and polyvinyl alcohol fibers. The mass ratio of the cement to the water-borne epoxy resin emulsion to the polypropylene fibers to the silica fume to the clay ceramsite to the expanding agent to the polycarboxylic acid high-efficiency water reducing agent to the polyamine curing agent to the triethylene tetramine to the methyl methacrylate to the polyvinyl alcohol fibers is (20-40):(1-4):(4-8):(1-5):(2-8):(1-2):(1-2):(0.1-1):(2-6):(1-3):(1-4). The particle size of the clay ceramsite is 5-16 mm, the apparent density is 1200-1500 kg / m<3>, the bulk density is 700-1100 kg / m<3>, and the cylinder compressive strength is greater than or equal to 6.5 MPa.

Owner:斯博锐精细化学品(广东)有限公司

Preparation and application of a concrete anti-crack and anti-seepage composite additive

The invention discloses the preparation and application of a novel anti-crack and anti-seepage compound additive for concrete. Its main components are: sodium stearate, coupling agent, bentonite, kaolin, modified silica fume and modified polyester fiber. While improving the anti-cracking performance of concrete through sodium stearate, the introduction of silane coupling agent improves its impermeability. In addition, various mineral components can effectively adjust the hydration process of cement and improve the pore structure and mechanical properties of concrete. While improving the crack resistance of concrete, it also improves the impermeability of concrete. At the same time, the modified polyester fiber is used to improve the toughness of concrete, limit the expansion of concrete cracks under the action of external force, and effectively avoid shrinkage cracking and self-shrinkage cracking of concrete. The new anti-crack and anti-seepage composite additive of concrete has the characteristics of good economic performance, excellent performance and green environmental protection, which can bring significant economic and social benefits.

Owner:江苏携砼新材料科技有限公司

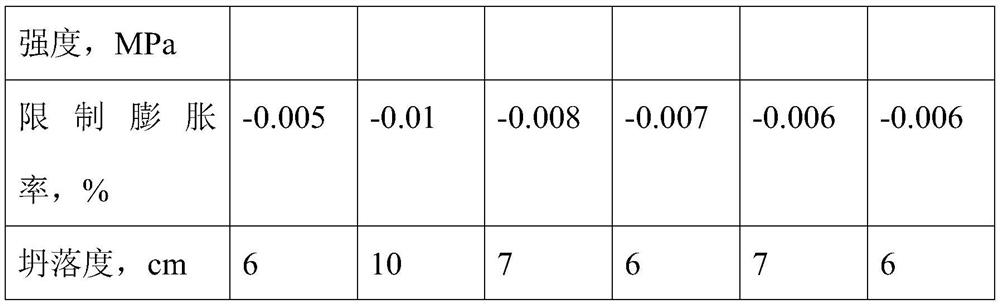

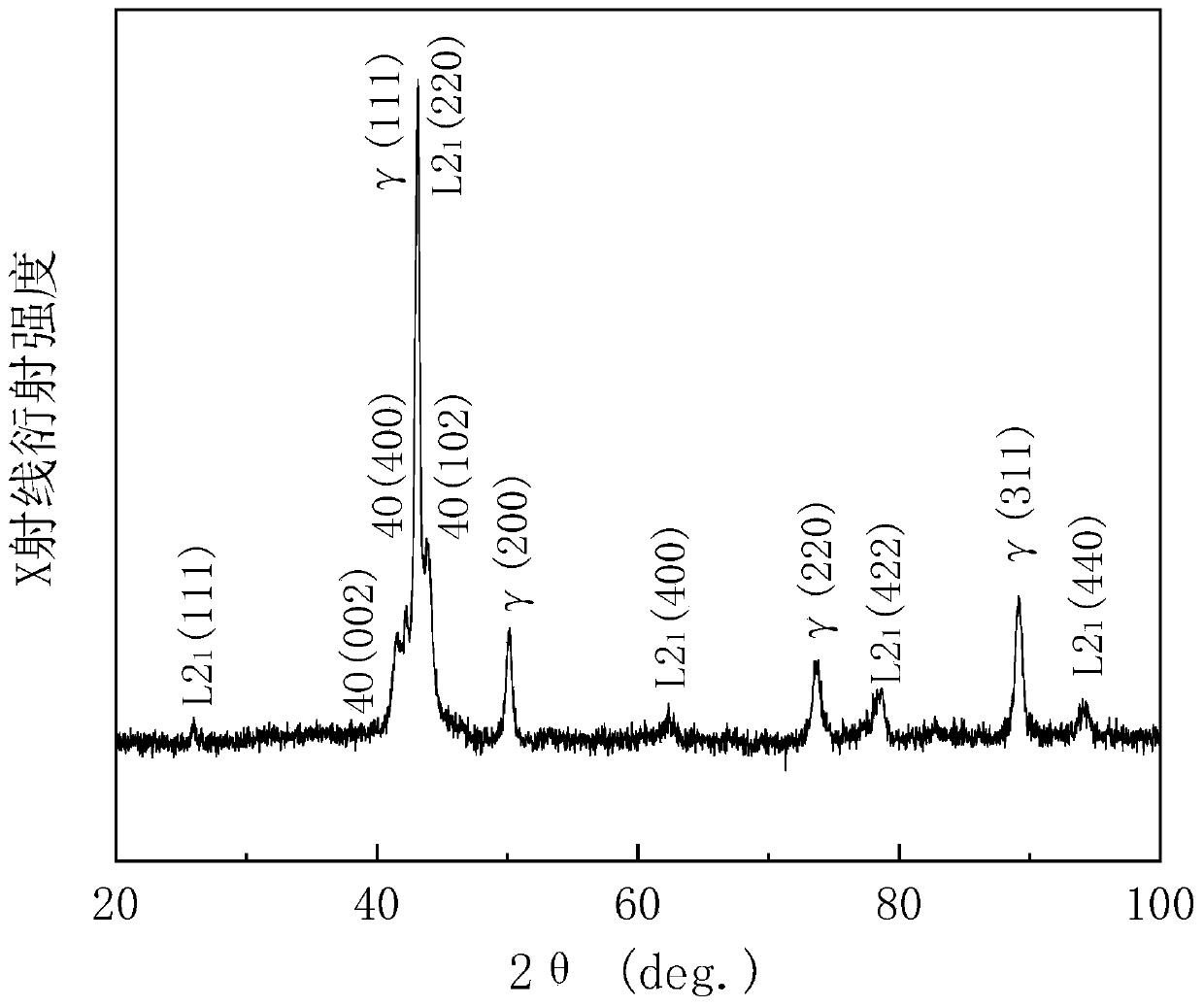

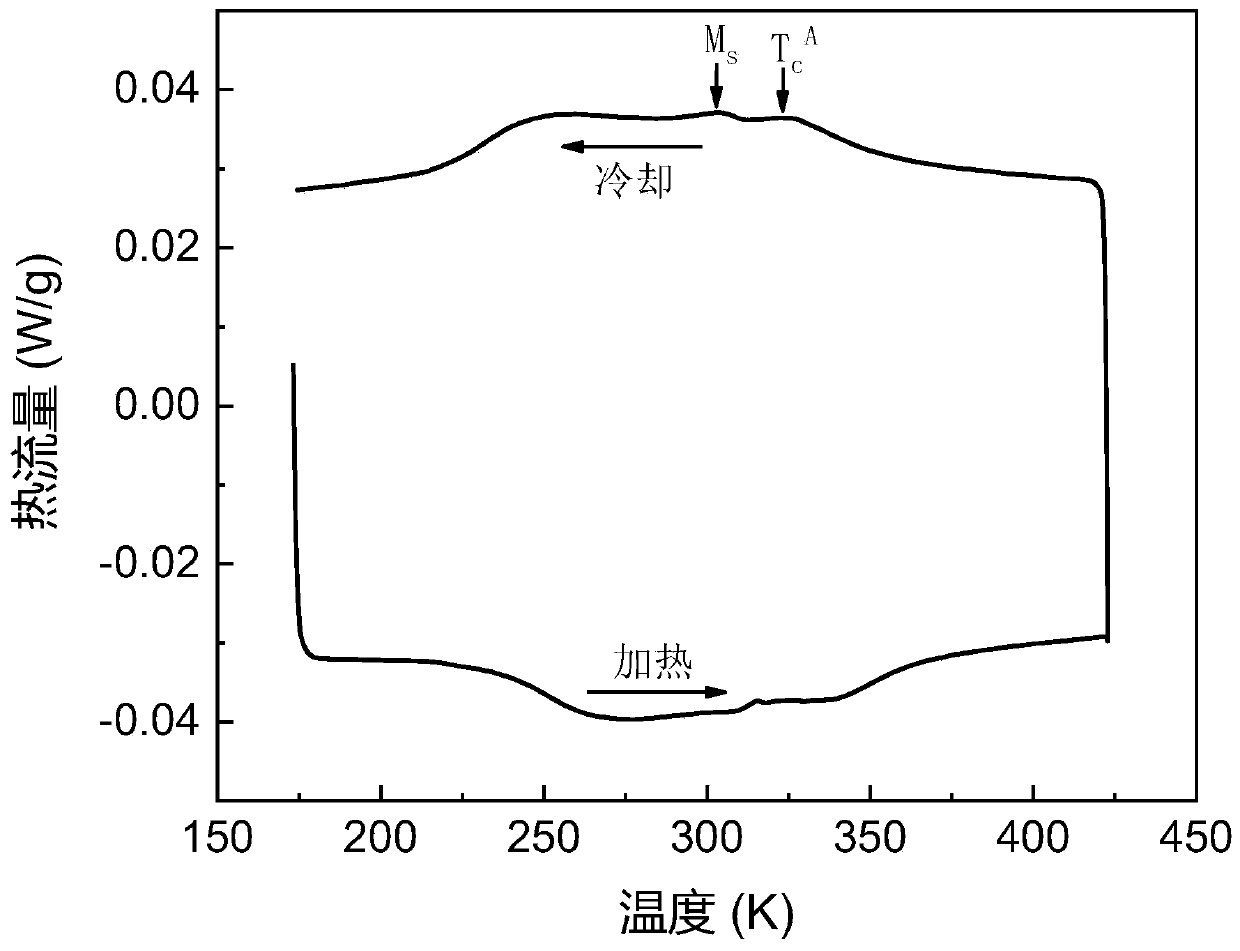

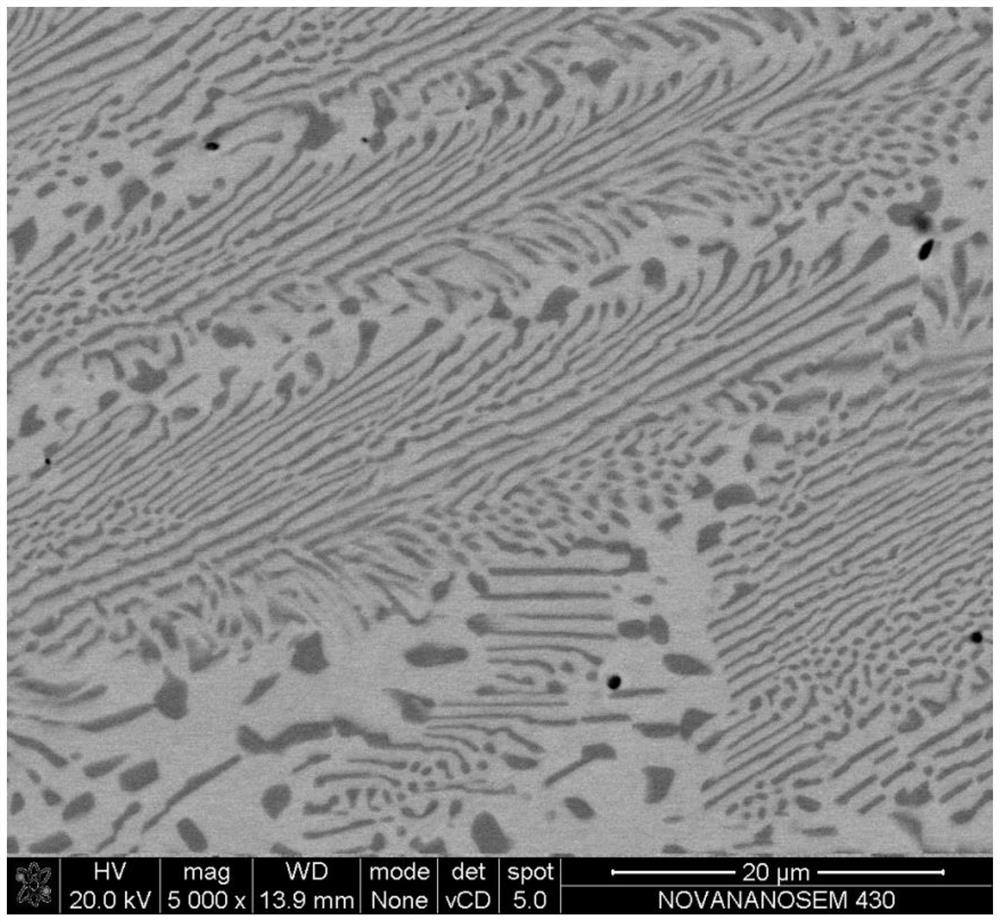

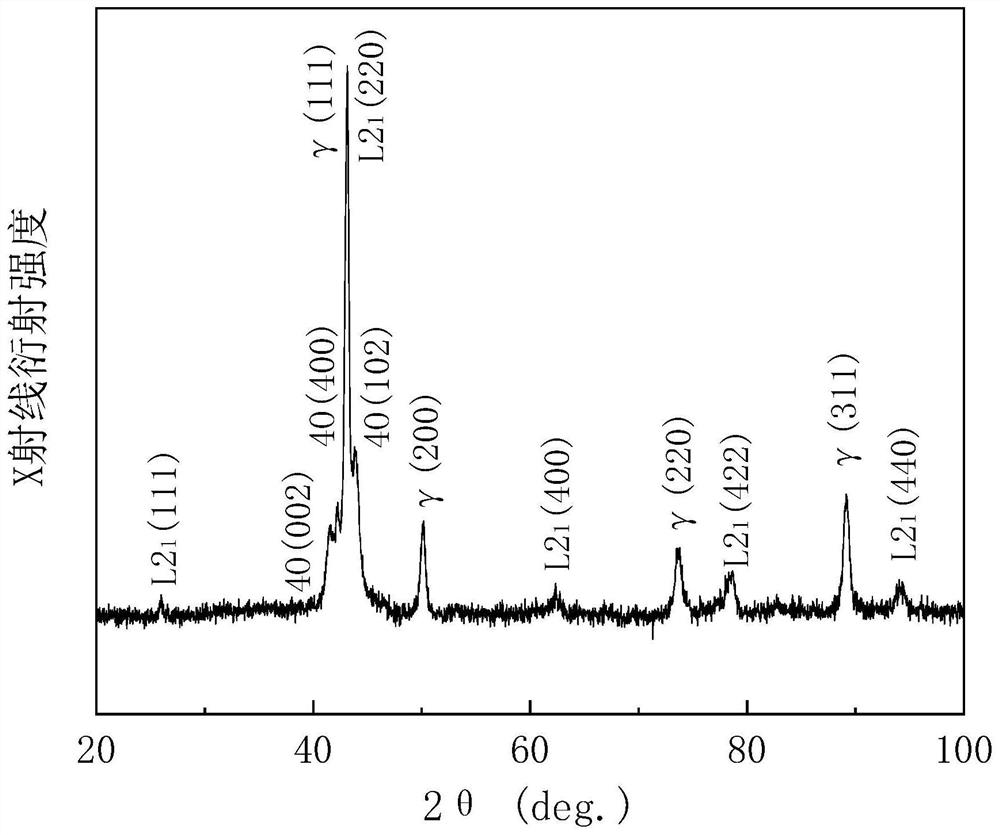

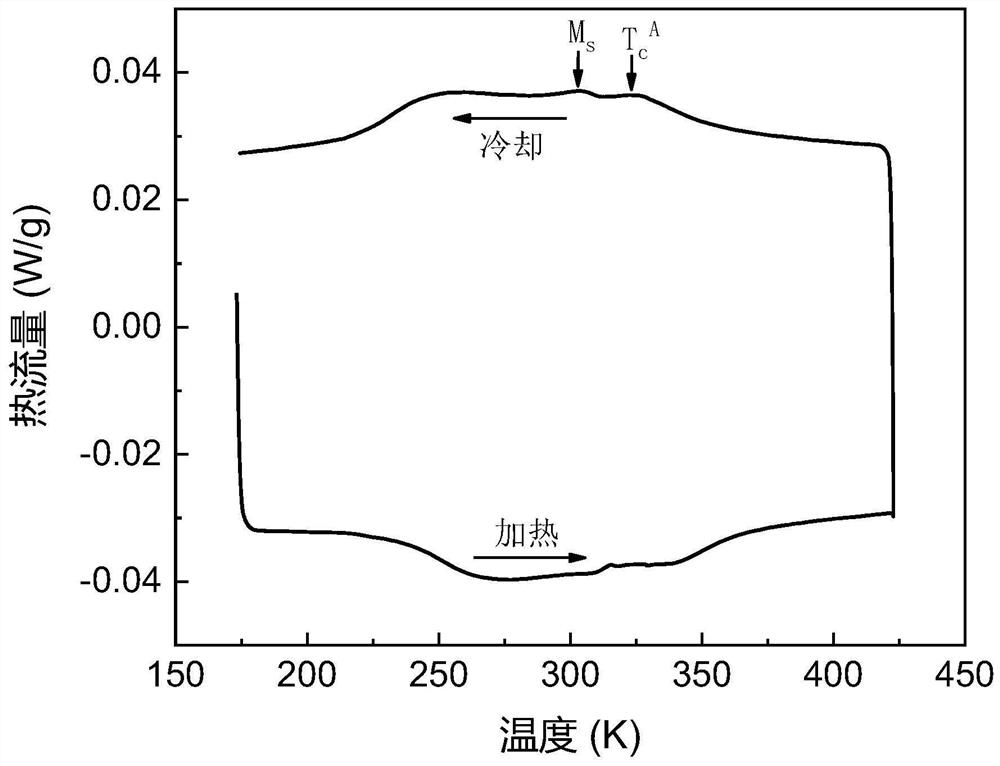

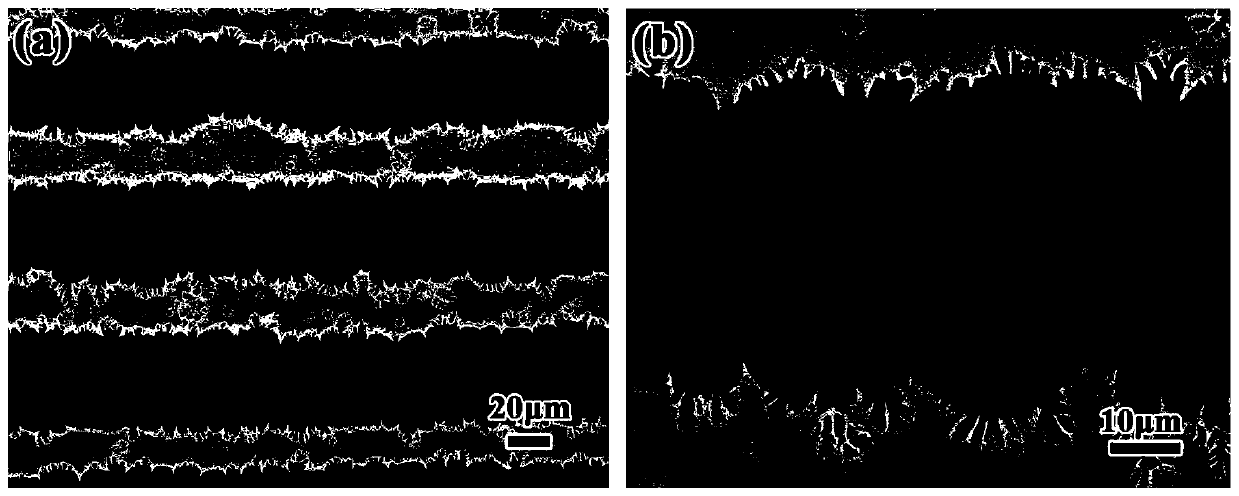

Ferromagnetic shape memory alloy with nanometer eutectic lamella structure

ActiveCN110484802AImprove toughnessHigh strengthInductances/transformers/magnets manufactureMagnetic materialsMartensite transformationShape-memory alloy

The invention discloses a ferromagnetic shape memory alloy with a nanometer eutectic lamella structure. The chemical formula of the ferromagnetic shape memory alloy can be shown as Ni51.5Mn40-xFexSn8.5, wherein x is larger than 0 and smaller than or equal to 8. A preparing method of the ferromagnetic shape memory alloy with the nanometer eutectic lamella structure includes the following steps thatfirstly, a Ni source, a Mn source, a Fe source and a Sn source are mixed according to the atom percent of a Ni51.5Mn34Fe6Sn8.5 alloy and are put into a metal smelting furnace; and secondly, smeltingis conducted under inert gas shielding, and the Ni51.5Mn34Fe6Sn8.5 alloy is obtained. The Ni51.5Mn34Fe6Sn8.5 ferromagnetic shape memory alloy is composed of a Heusler base phase and a gamma phase, themartensite phase transformation temperature of the alloy is 303 k, and the beneficial effects that toughness is large, strength is high, and the production technology is easy and convenient are achieved.

Owner:GUANGZHOU UNIVERSITY

A ferromagnetic shape memory alloy with nanoeutectic layer structure

ActiveCN110484802BImprove toughnessHigh strengthInductances/transformers/magnets manufactureMagnetic materialsShape-memory alloyAlloy

The invention discloses a ferromagnetic shape memory alloy with a nano-eutectic layer structure. The chemical formula of ferromagnetic shape memory alloy can be expressed as Ni 51.5 Mn 40‑x Fe x sn 8.5 , 0<x≤8. The preparation method of the ferromagnetic shape memory alloy with nano-eutectic layer structure includes the following steps: 1) according to Ni 51.5 Mn 34 Fe 6 sn 8.5 The atomic percentage composition of the alloy, the Ni source, the Mn source, the Fe source and the Sn source are mixed and put into a metal melting furnace; 2) Smelting is carried out under the protection of an inert gas to obtain Ni 51.5 Mn 34 Fe 6 sn 8.5 alloy. Ni of the present invention 51.5 Mn 34 Fe 6 sn 8.5 The ferromagnetic shape memory alloy is composed of a nano-eutectic layer structure of Heusler base phase and γ phase. Its martensitic transformation temperature is 303K, and it has the characteristics of high toughness, high strength and simple production process.

Owner:GUANGZHOU UNIVERSITY

Support method for bolt-grouting composite crushing dynamic-pressure roadway soft rock roof by high-pre-stressed anchor cable

The invention discloses a support method for bolt-grouting a composite crushing dynamic-pressure roadway soft rock roof by a high-pre-stressed anchor cable. The support method comprises the following steps of: after excavating a roadway, keeping up with a roadway driving head for drilling a deep part in a roadway roof, sending a deep hole camera shooting detecting instrument to the bottom of a drilled hole, recording inner wall lithological characters, fracture spacing and crushing region thickness range of surrounding rocks of different depths; keeping up with the roadway driving head, firstly drilling grouted holes in the surfaces of surrounding rocks, installing grouting pipes, then spraying thin-layer concrete on the surfaces of the surrounding rocks of the roadway for closing the surfaces of the surrounding rocks of the roadway to prevent slurry from overflowing; grouting the insides of the surrounding rocks through the grouting pipes, after slurry is solidified, drilling anchor cable holes in the surfaces of the surrounding rocks of the roadway, and when the depths of the anchor cable holes exceed the range of a crushing region, installing an anchor cable for reinforcing. The support method has the advantages of being simple in operation, bringing convenience for construction, saving secondary or multi-time support procedure, lowering the cost, saving the time and manpower, increasing the working efficiency, realizing dual-anchoring, and achieving the strong support effect, and is especially suitable for the roof which is difficult to support under the condition of dynamic pressure.

Owner:SHANDONG UNIV OF SCI & TECH

Cement-based composite material for steel box girder bridge deck, as well as preparation and pavement thereof

ActiveCN103449786BImprove toughnessLimit extensionBridge erection/assemblyBridge materialsEpoxyBridge deck

The invention relates to a cement-based composite material for pavement of a steel box girder bridge deck, as well as a preparation method and a pavement method thereof. The invention aims at providing a lightweight and high-toughness cement-based composite material which is suitable for pavement of larger-span steel box girder bridge decks, and the cement-based composite material comprises the following components in parts by weight: 849-881 parts of cement, 339-425 parts of quartz sand, 215-273 parts of pottery sand, 100-226 parts of fly ash, 30-56 parts of silica fume, 275-295 parts of water, 10-13 parts of water reducing agent, 40-80 parts of steel fiber, 6.5-13 parts of organic fiber and 20-30 parts of epoxy resin. Through material optimization, the durability of a bridge deck paving layer is improved, the overall dead weight is reduced, the cost of a project is simultaneously saved, and the cement-based composite material is suitable for pavement of the larger-span steel box girder bridge decks.

Owner:WUHAN UNIV OF TECH

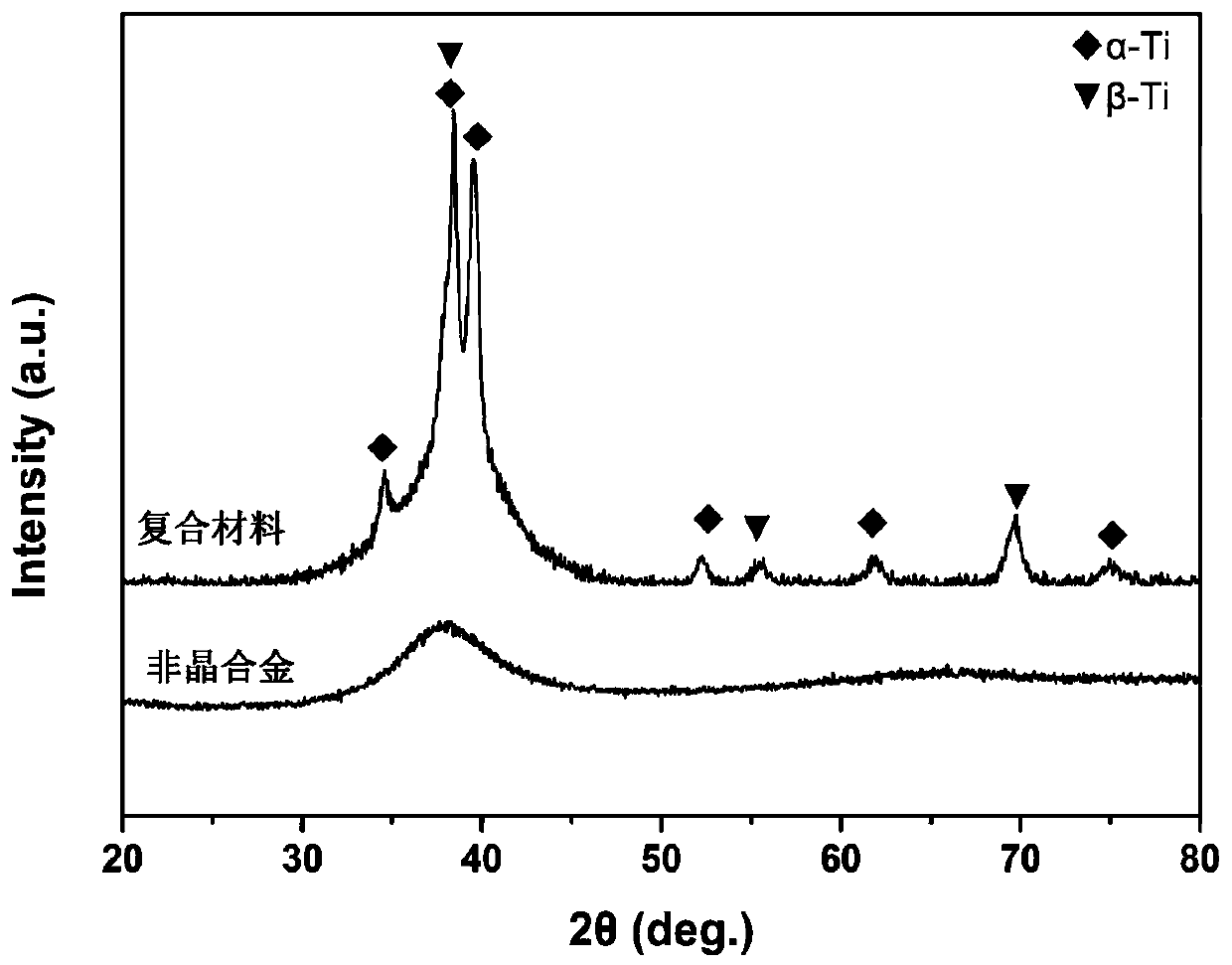

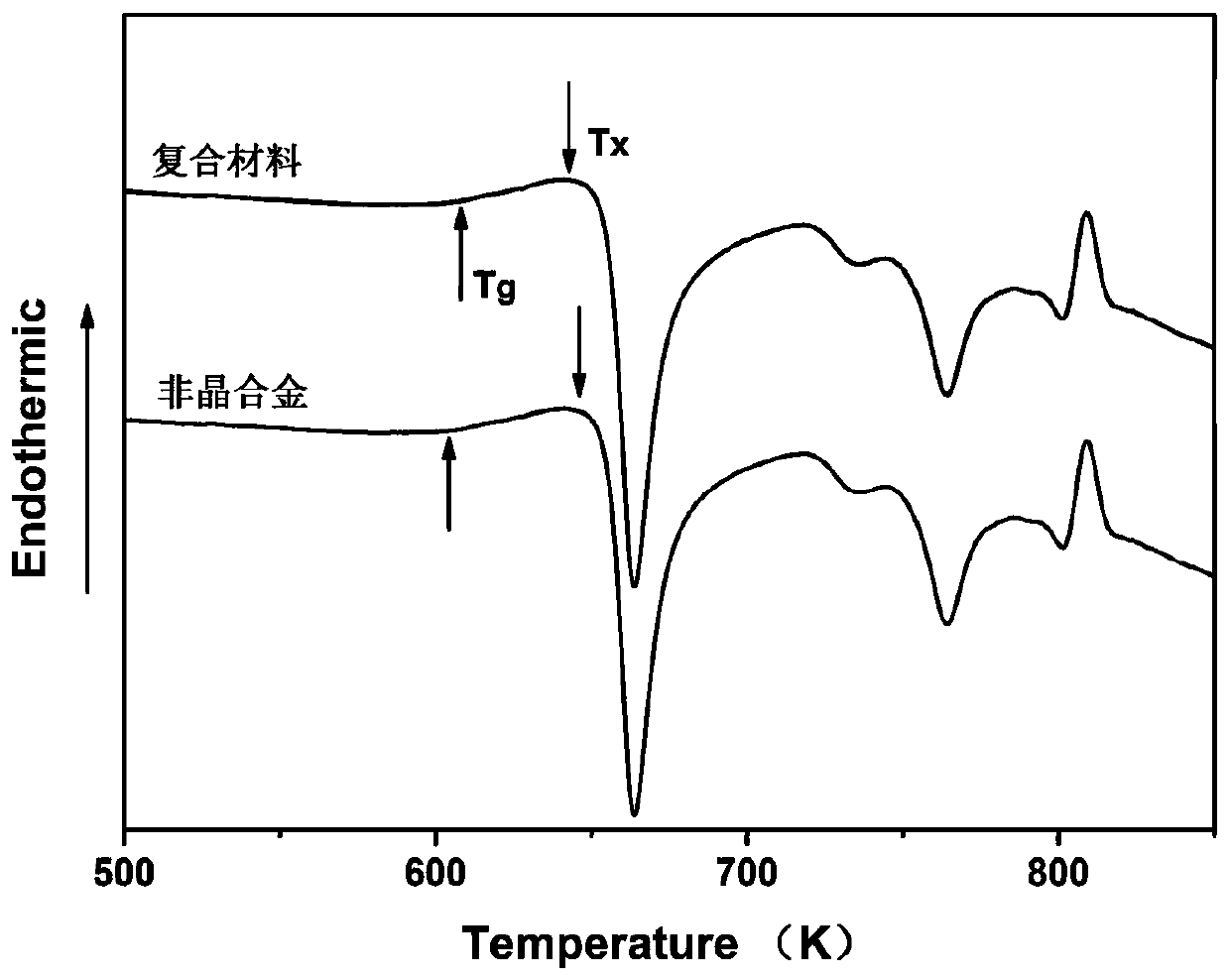

Titanium-based amorphous/titanium alloy layered composite material and preparation method thereof

ActiveCN107953619BFacilitated DiffusionImprove bindingLaminationLamination apparatusAmorphous phaseTitanium

The invention relates to a titanium-based amorphous / titanium alloy layered composite material and a preparation method thereof, belonging to the technical field of metal-based composite materials. Thecomposite material is composed of titanium-based amorphous alloy layers and titanium alloy layers which are alternately arranged to form a layered structure. The layered composite material is prepared through an instant liquid connection method which comprises the following steps: alternately laminating selected titanium-based amorphous ribbons and titanium alloy ribbons so as to prepare a preform, then carrying out melting under heating, and carrying out heat-preserving and water-quenching so as to obtain the titanium-based amorphous alloy / titanium alloy layered composite material. Accordingto the invention, the amorphous phase layers and the titanium alloy layers of the composite material are continuously and uniformly distributed in a dimensional space, and through synergistic deformation and mutual strengthening, strength and plasticity of the material are simultaneously and significantly improved. The composite material provided by the invention has the characteristics of excellent mechanical properties, high specific strength and uniform, controllable microstructure, etc., and has broad application prospects.

Owner:沈阳超能新材科技有限公司

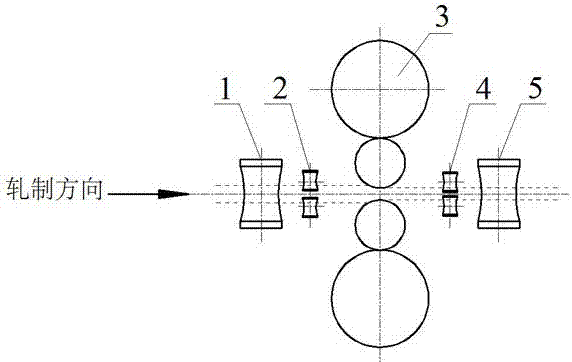

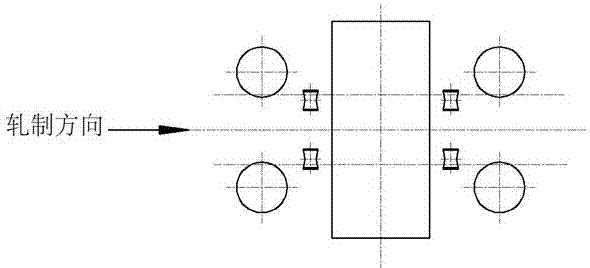

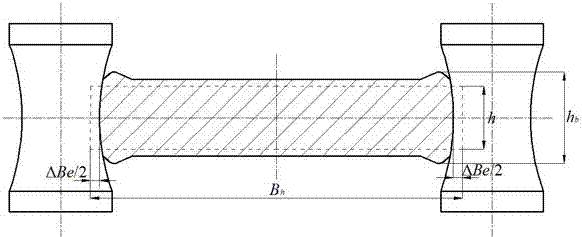

A method for multi-directional pre-deformation rolling of the edge of a wide magnesium alloy thick plate

ActiveCN104889160BLimit extensionHigh yieldMetal rolling stand detailsRollsPre deformationThick plate

The invention discloses a method and device for multi-directional pre-deformation rolling of the edge of a wide magnesium alloy thick plate. A coordinative rolling method for synchronous application of pressure stress in the directions of the width and the thickness of the plate is adopted. The device comprises a four-high mill, pre-rolling vertical roll / inclined roll combination device and a post-rolling inclined roll / vertical roll combination device. The method for multi-directional pre-deformation rolling of the edge of the wide magnesium alloy thick plate comprises the three steps that (1) edge pre-deformation reciprocating rolling is conducted in the length direction of the magnesium plate; (2) the magnesium plate is rotated by 90 degrees, and broadening reciprocating rolling is conducted; (3) the rolled piece is rotated by 90 degrees again, and lengthening and edge multi-directional compressive deformation combined rolling is conducted so as to form the final thickness. In the rolling process, distribution of the rolling reduction of vertical rolls and inclined rolls and the side pressure angles of the inclined rolls is conducted according to a technological control model. According to the method and device for multi-directional pre-deformation rolling of the edge of the wide magnesium alloy thick plate, due to the fact that multi-roll multi-directional pressure deformation is applied to the edge of the magnesium plate, broadening of the magnesium plate can be limited in the rolling process, a good plate shape can be obtained, the frequency of generation and extension of cracks on the edge is reduced, and the yield of the magnesium alloy plate is improved.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

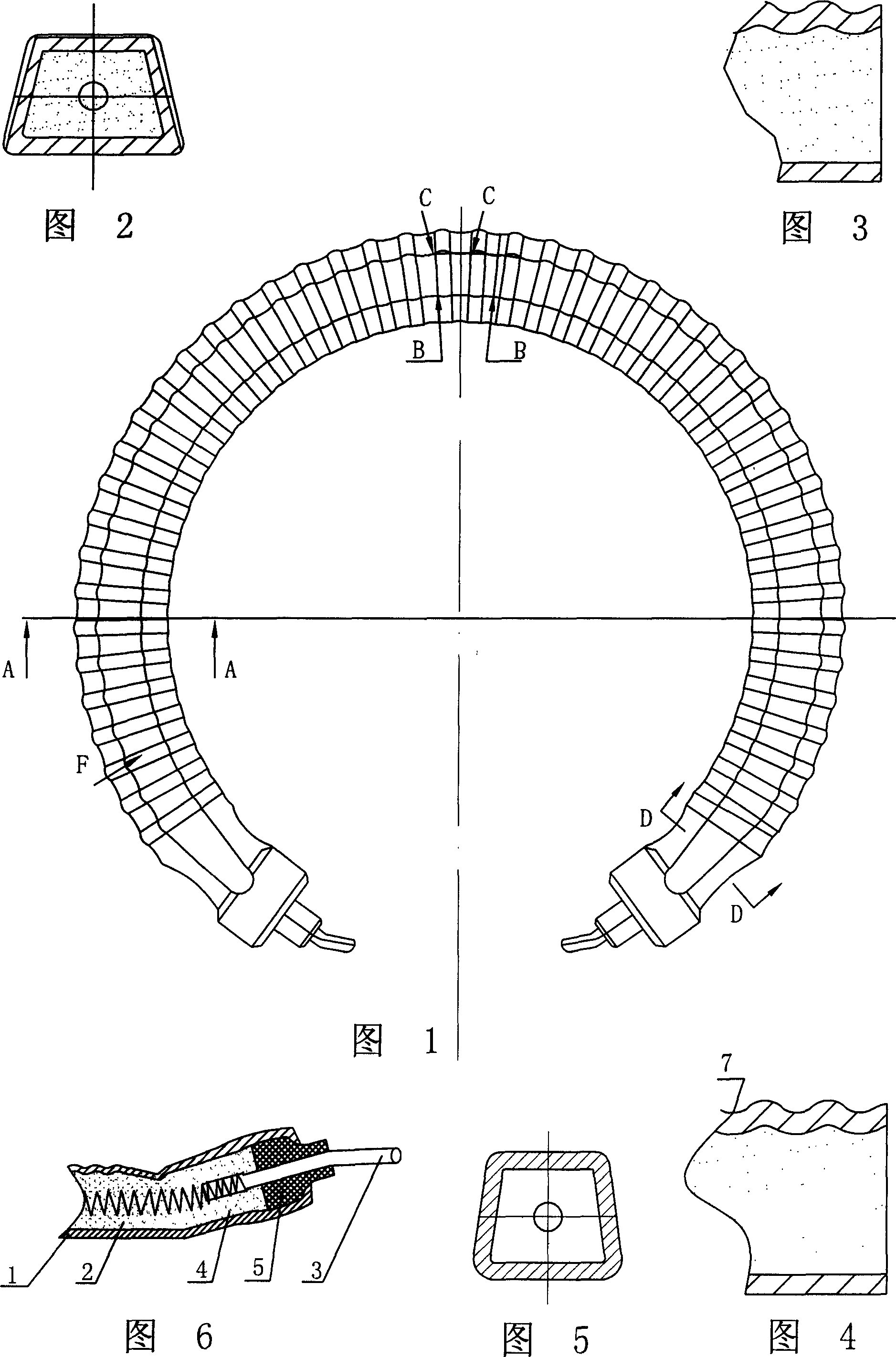

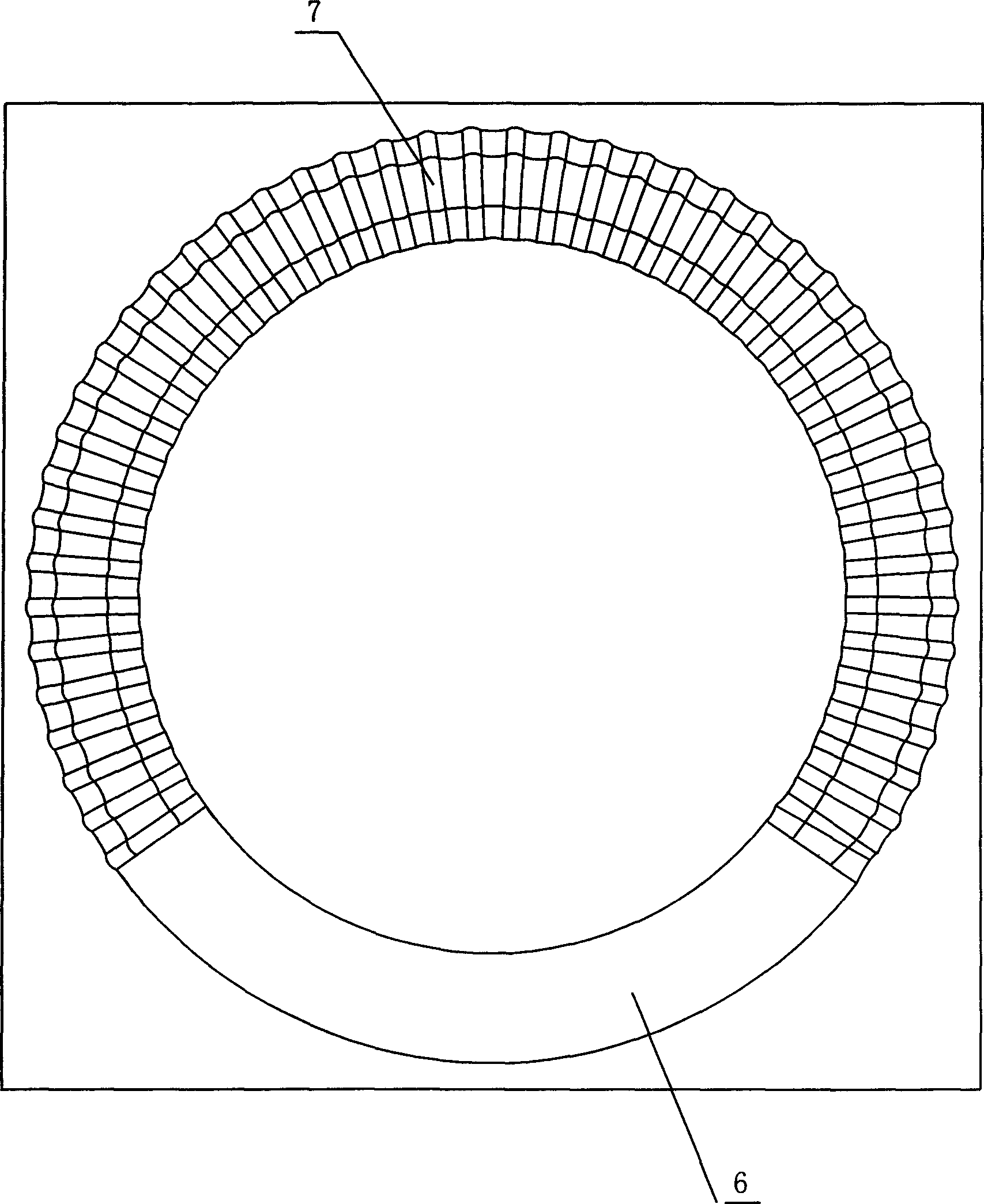

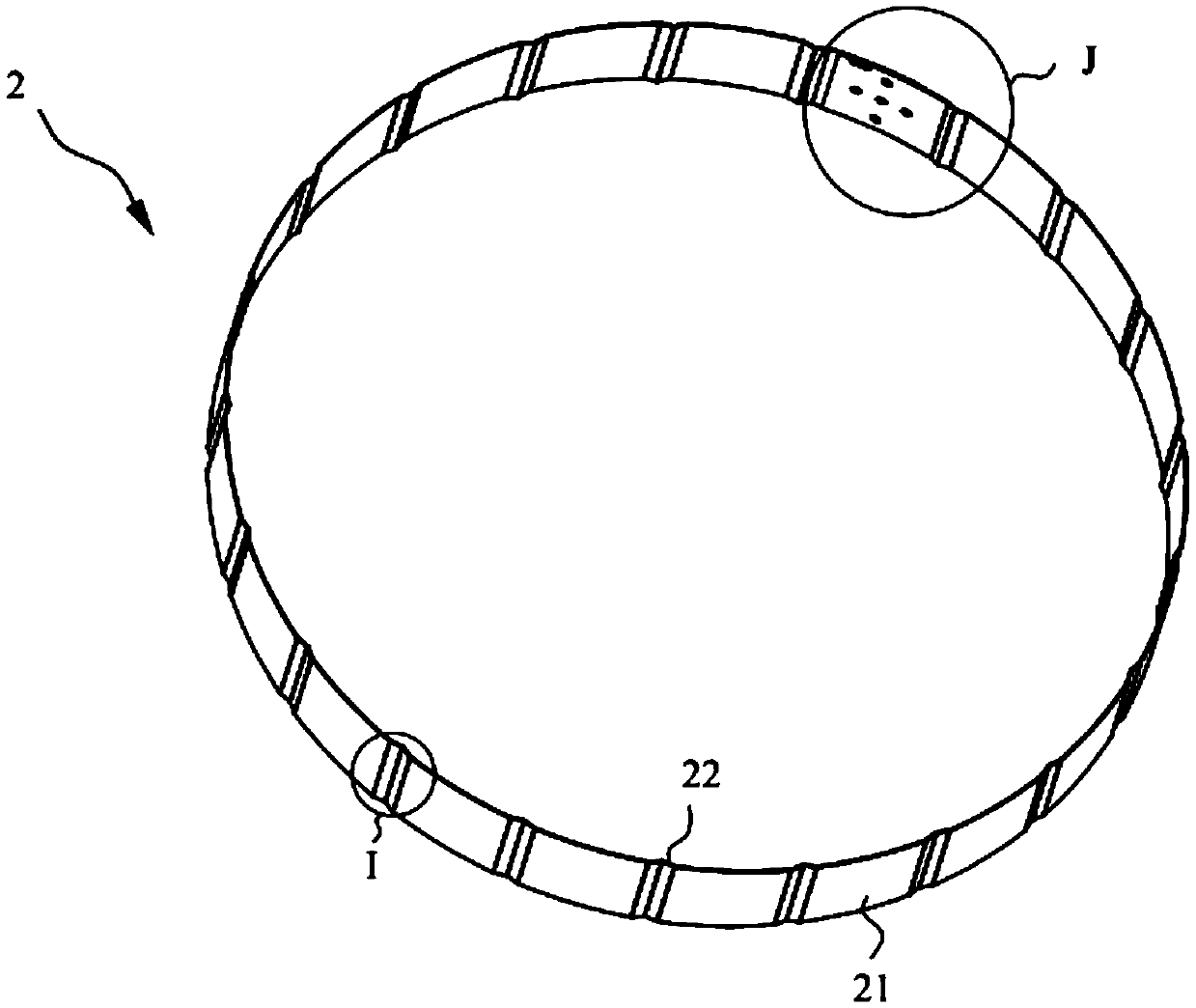

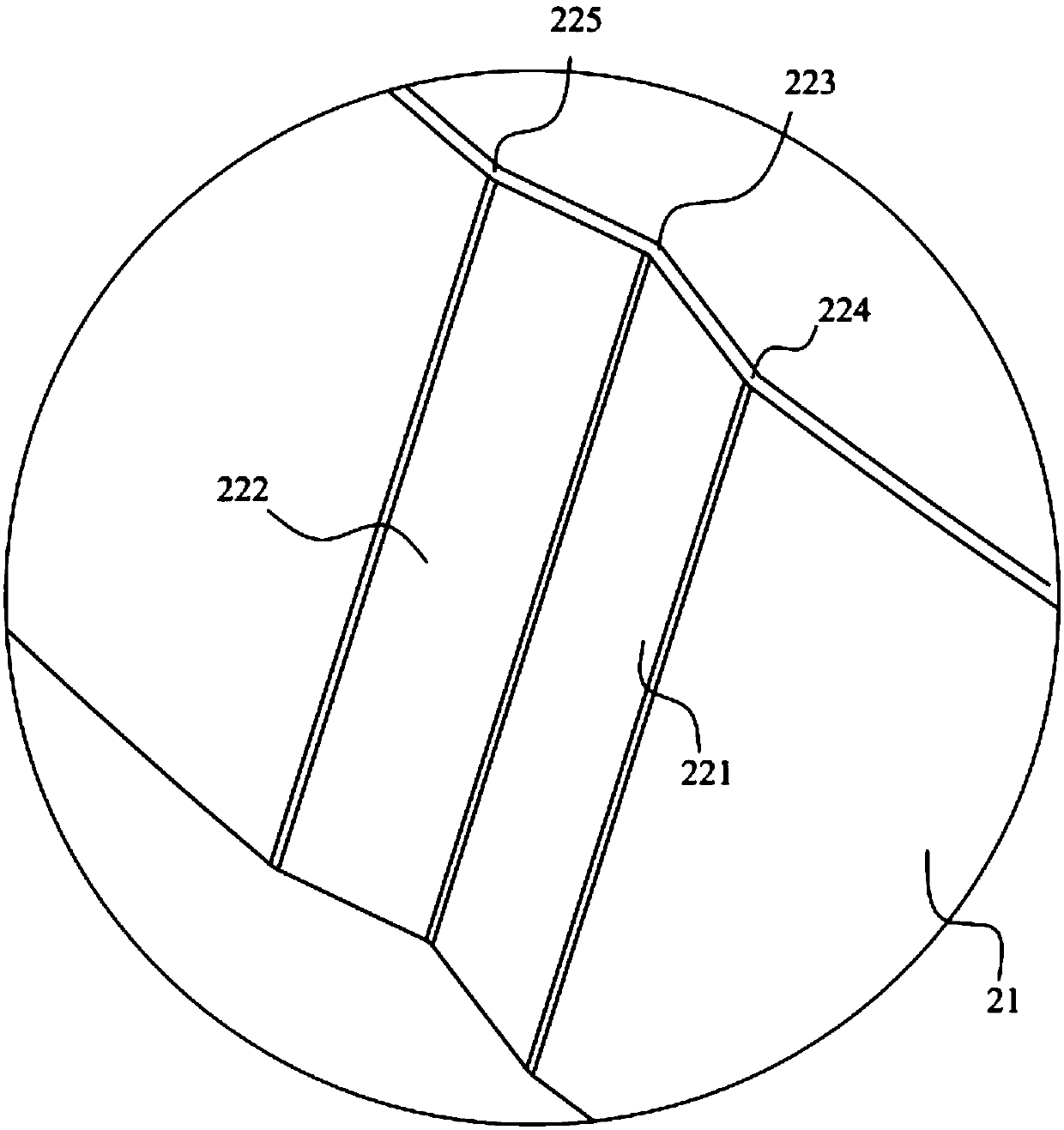

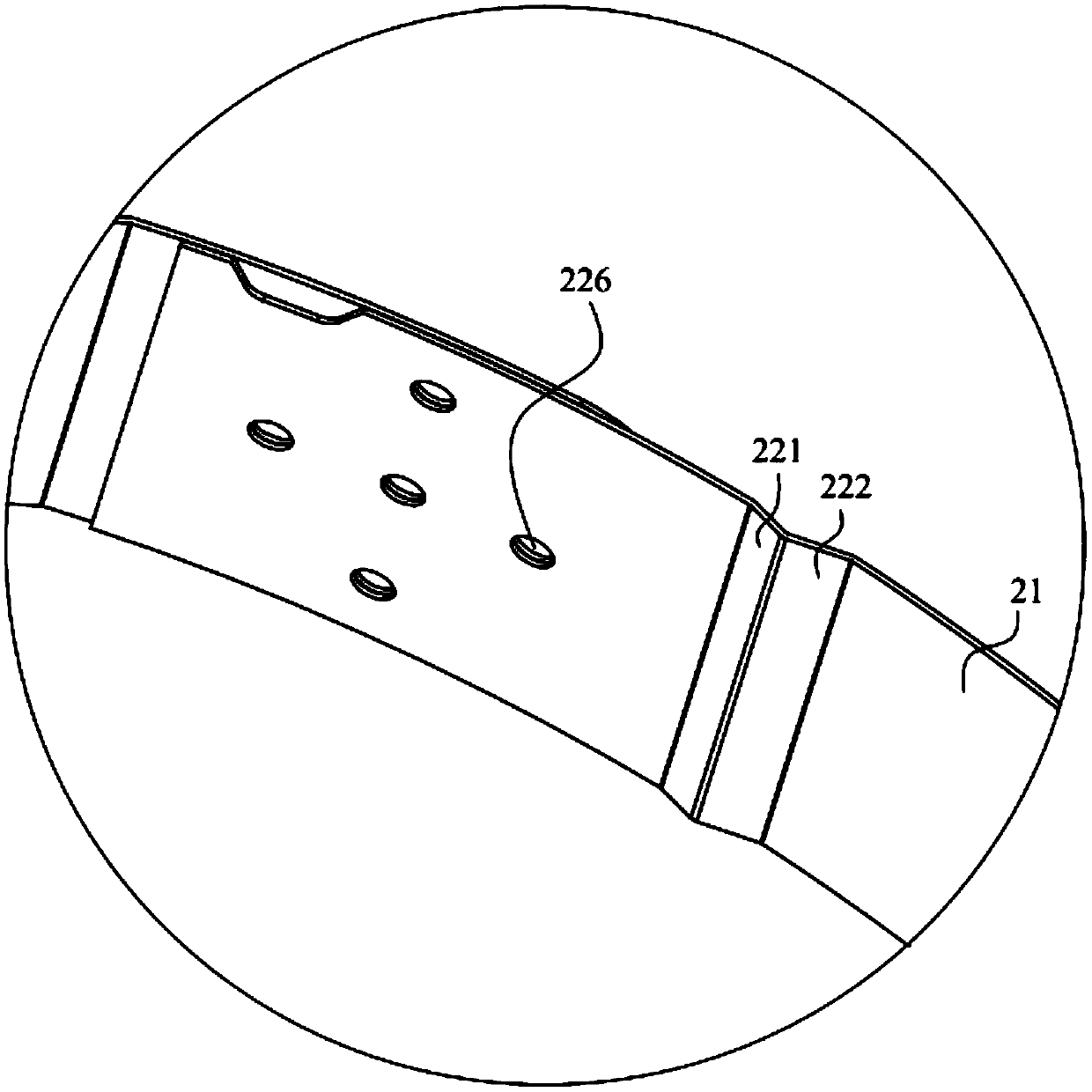

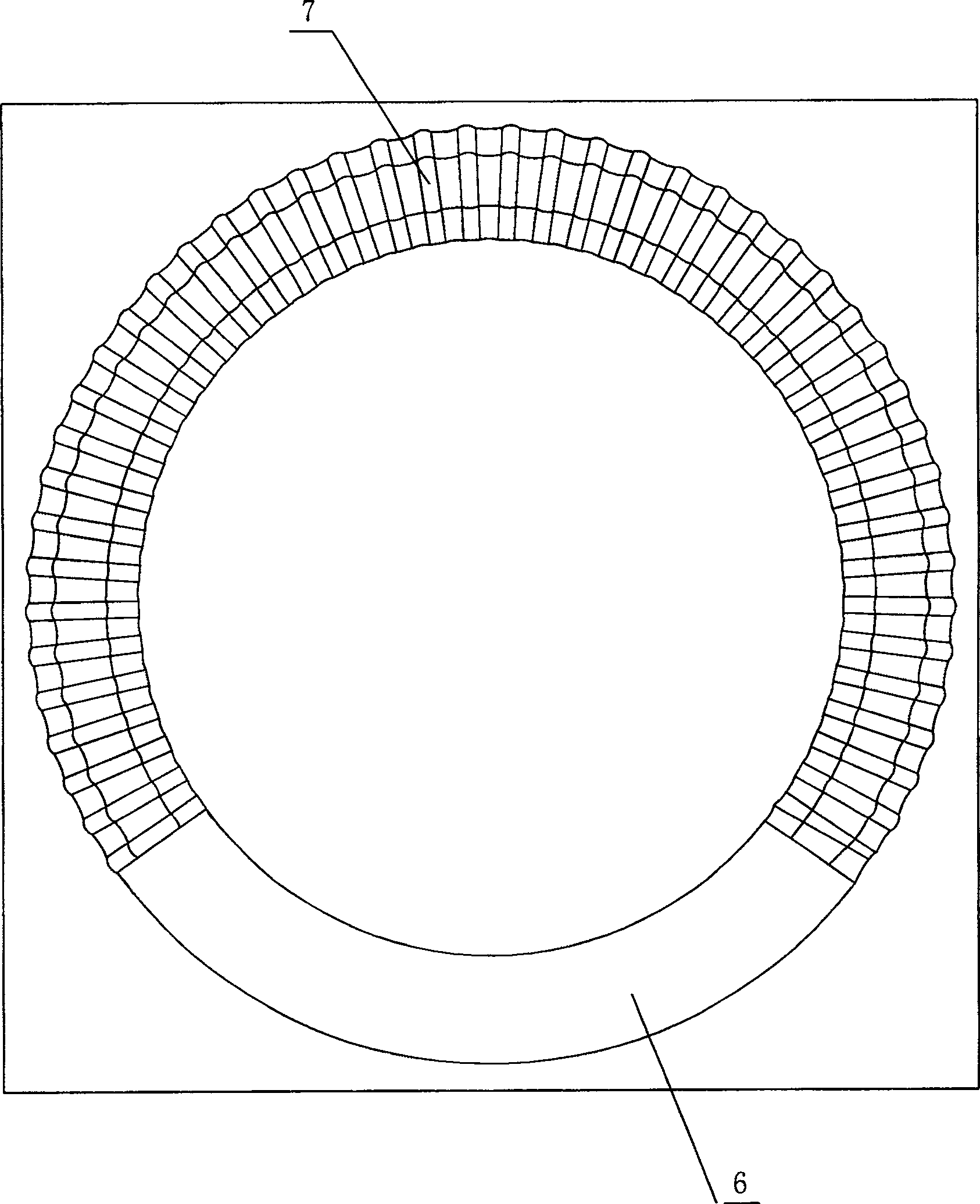

Drum hoop, drum and washing machine

ActiveCN110761035APrevent burstReduce impactOther washing machinesTextiles and paperLaundry washing machineEngineering

The invention belongs to the technical field of washing machines and particularly discloses a drum hoop, a drum and a washing machine. The drum hoop comprises a sheet drum hoop body in a ring shape, the ring outer surface of the drum hoop body is inwardly recessed to form a plurality of projections at intervals along the periphery of the drum hoop body, upper end faces of the projections are flushwith the upper end face of the drum hoop body, and lower end faces of the projections are flush with the lower end face of the drum hoop. The drum comprises a drum body and the drum hoop, and the drum hoop sleeves the outer surface of the drum body and contacts with the outer surface of the drum. The washing machine comprises the drum. The drum hoop, the drum and the washing machine has advantages that structural strength of the drum can be improved, impact resistance of the drum is improved, and safety and reliability of the drum and the washing machine are improved.

Owner:QINGDAO HAIER WASHING ELECTRIC APPLIANCES CO LTD +1

Electrothernal tube and its forming method

InactiveCN100525548CAvoid squeezingEvenly compactedHeating element shapesDie bondingSurface structure

The invention belongs to the technical field of electric heaters, and relates to an electric heating tube and a forming method thereof. The invention solves the problem that the existing electric heating tube, when the metal tube is stamped and formed by the stamping die, the metal tube will extend to both ends, resulting in the difficulty of controlling the external dimension and the problem that the insulating powder inside cannot be compacted. The electric heating tube includes insulating powder and resistance wire arranged in the metal pipe, an insulator blocked in the nozzle of the metal pipe and a metal rod arranged in the insulator to keep isolation from the metal pipe and connected to the resistance wire. The metal pipe described above is punched and formed from a metal pipe with a circular cross-section, and its surface has a concave-convex structure and at least one surface is a plane structure. The forming method of the electric heating tube is to place the electric heating tube in the cavity of the A stamping die that is compatible with it, and distribute the raised parts on the surface of the concave cavity, and press the B stamping die and the A stamping die together to make it The surface of the metal tube is concave-convex, and the wall is extended and formed, and the electric heating tube is taken out from the stamping die.

Owner:何伟

Sheet Holder

ActiveCN104175005BAvoid deflectionSimple and fast operationWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a thin plate retaining device capable of arranging a thin plate on an XY platform in an opening mode by simple and convenient operation in a laser machine. A first frame material (21) and a second frame material (22) are fixedly arranged on the XY platform (11), and are spaced from each other by a given distance. A first part (130) is arranged between the first frame material (21) and the second frame material (22), and one end of a thin plate (W) is clamped by the first part (130). A second part (140) is formed by relatively moving from a direction away from the first part (130), and is arranged between the first frame material (21) and the second frame material (22) along the second frame material (22), and the other end of the thin plate (W) is clamped by the second part (22). The ends of multiple connecting rods (L) which are formed in a swinging way are connected with the corresponding multiple parts of the second part (22), and the other ends of the connecting rods (L) are connected with a cylinder (160). The thin plate (W) can be arranged on the XY platform (11) by the simple and convenient operation that force is applied to the second frame material (22) by the second part (140).

Owner:SUMITOMO HEAVY IND LTD

Pressure sensor, preparation method thereof and pressure detection system

PendingCN113686467AIncrease overload pressureIncrease pressure rangeForce measurementFluid pressure measurement using capacitance variationPhysicsComposite material

The invention provides a pressure sensor, a preparation method thereof and a pressure detection system. The pressure sensor comprises a first electrode layer, a second electrode layer, a first elastic dielectric layer and an anti-rolling structure, wherein the first elastic dielectric layer is located between the first electrode layer and the second electrode layer, and the first elastic dielectric layer has a first tensile modulus; and the anti-rolling structure is configured to limit the extension deformation of the first elastic dielectric layer in the direction perpendicular to the pressure when the first elastic dielectric layer is subjected to the pressure. According to the pressure sensor, the extension deformation of the elastic dielectric layers in the XY plane direction is limited by the anti-rolling structure, so that the elastic compression limits of the elastic dielectric layers in the Z-axis direction are increased, and the purposes of improving the overload pressure of the pressure sensor and increasing the range are achieved.

Owner:成都蕊感微电子有限公司

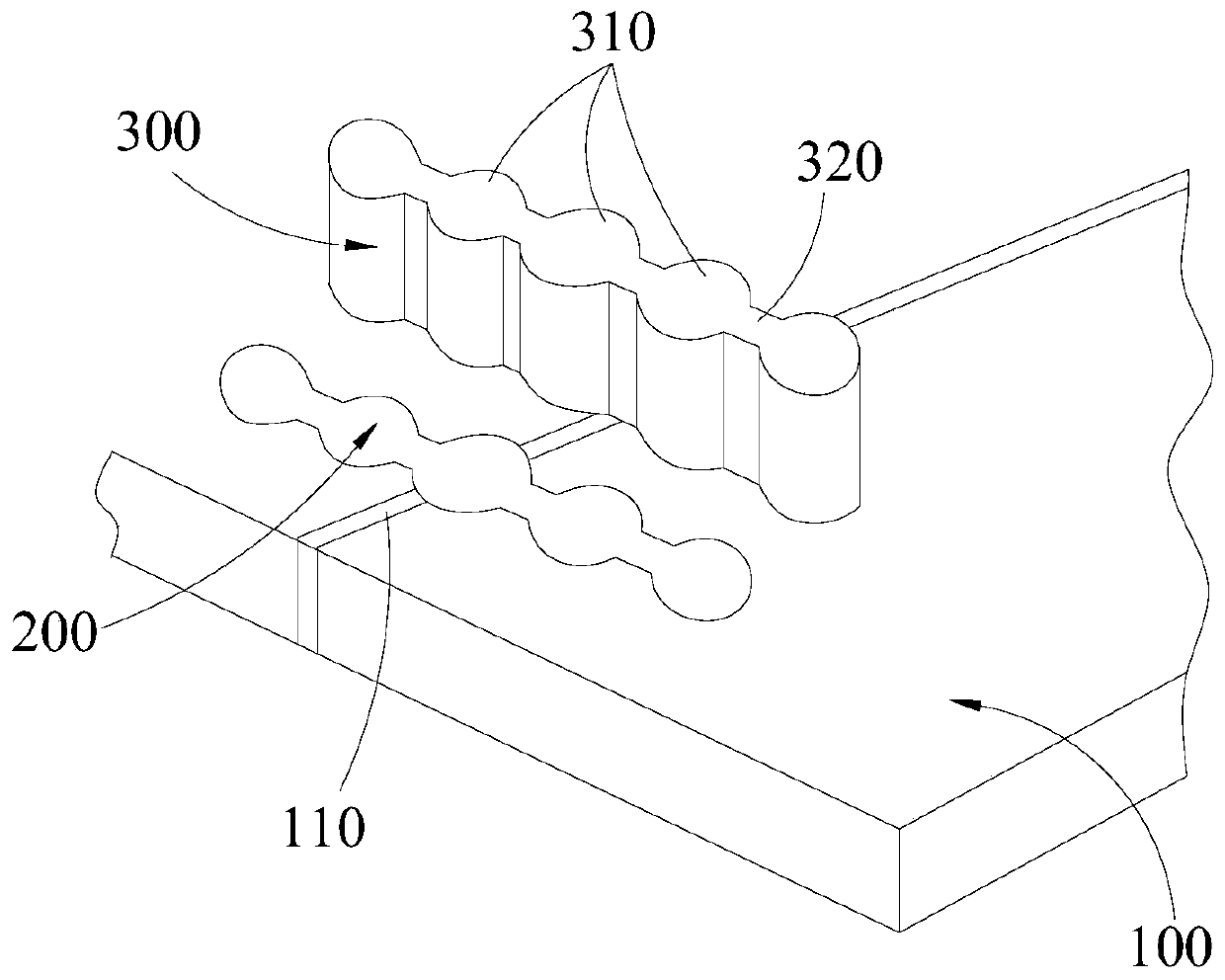

Crack Repair Structure and Repair Method of Emergency Diesel Engine Body in PWR Nuclear Power Plant

ActiveCN108838616BLimit extensionSupplemental Strength LossStress concentrationPressurized water reactor

The invention belongs to the technical field of internal combustion engines, and aims at providing a pressurized water reactor nuclear power station emergency diesel engine body crack repairing structure and method. The repairing structure comprises slotted hole sets and connecting pieces, the slotted hole sets passing through a crack are arranged on an engine body in a manner of extending in thedirection vertical to the crack, wave keys are inlaid into the slotted hole sets, in the manner, the mechanical connecting manner is used for quickly and conveniently tightening the crack, expansion of the crack is limited, and the engine body strength loss generated after cracking is supplemented in time; and when the extension strength needed by the engine body is large, at least one row of slotted hole sets is arranged, a plurality of sealing holes are formed in the two sides of each slotted hole set along the crack, sealing screw pieces are inserted into corresponding sealing holes and aremade to abut against each other, the crack is accordingly sealed, and stress concentration on the crack face is eliminated. The repairing structure and the corresponding repairing method solve the technical problem that crack defects of a diesel engine block are difficult to repair through repair welding, the structure is simple and reliable, and crack repairing is convenient, quick and better ineffect.

Owner:LINGDONG NUCLEAR POWER +4

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com