Drum hoop, drum and washing machine

A drum and main body technology, applied in the field of washing machines, can solve problems affecting the safety of users, damage to users' property, damage to washing machines, etc., and achieve the effects of improving operational safety and reliability, prolonging service life, and mitigating impacts

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

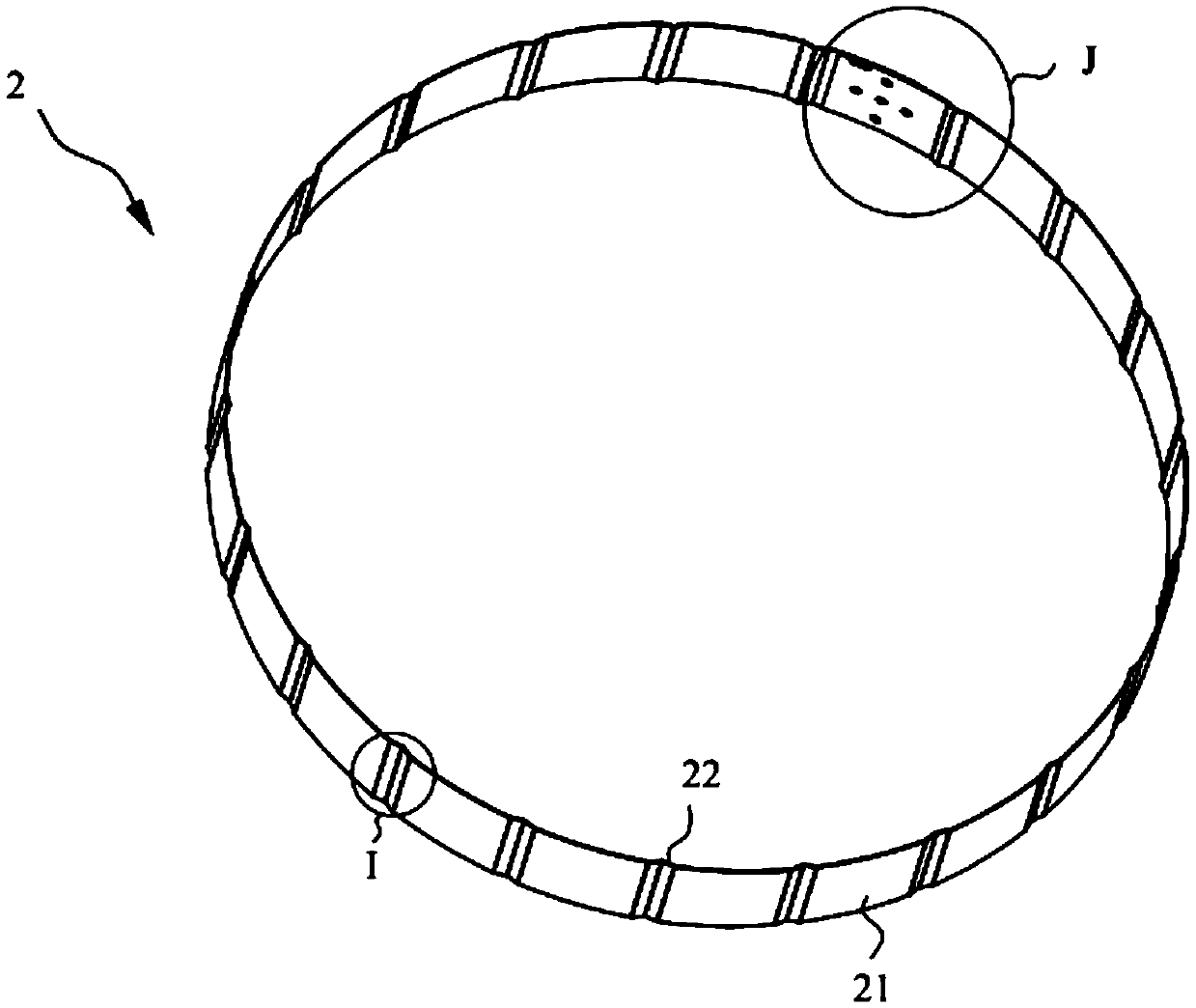

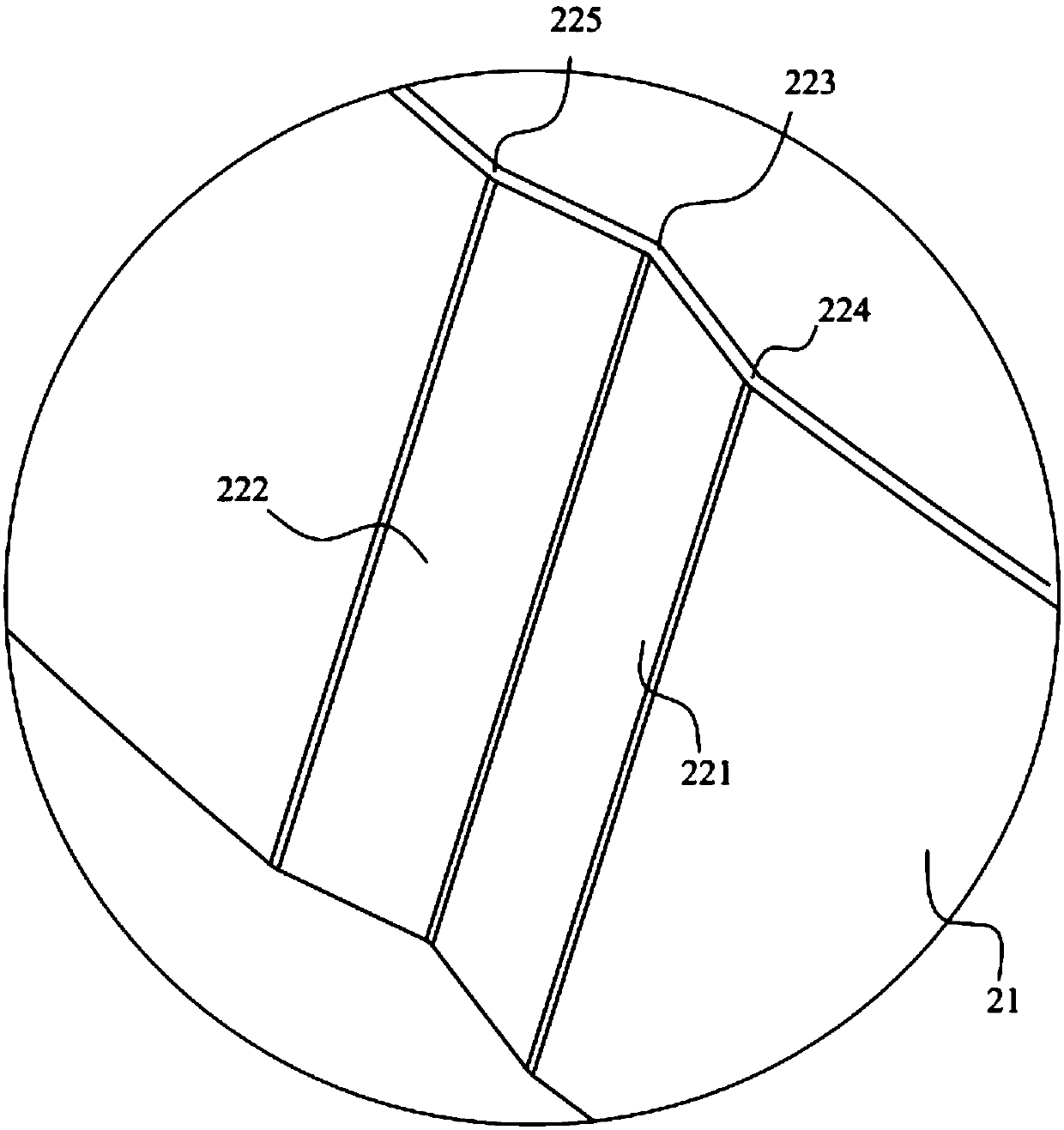

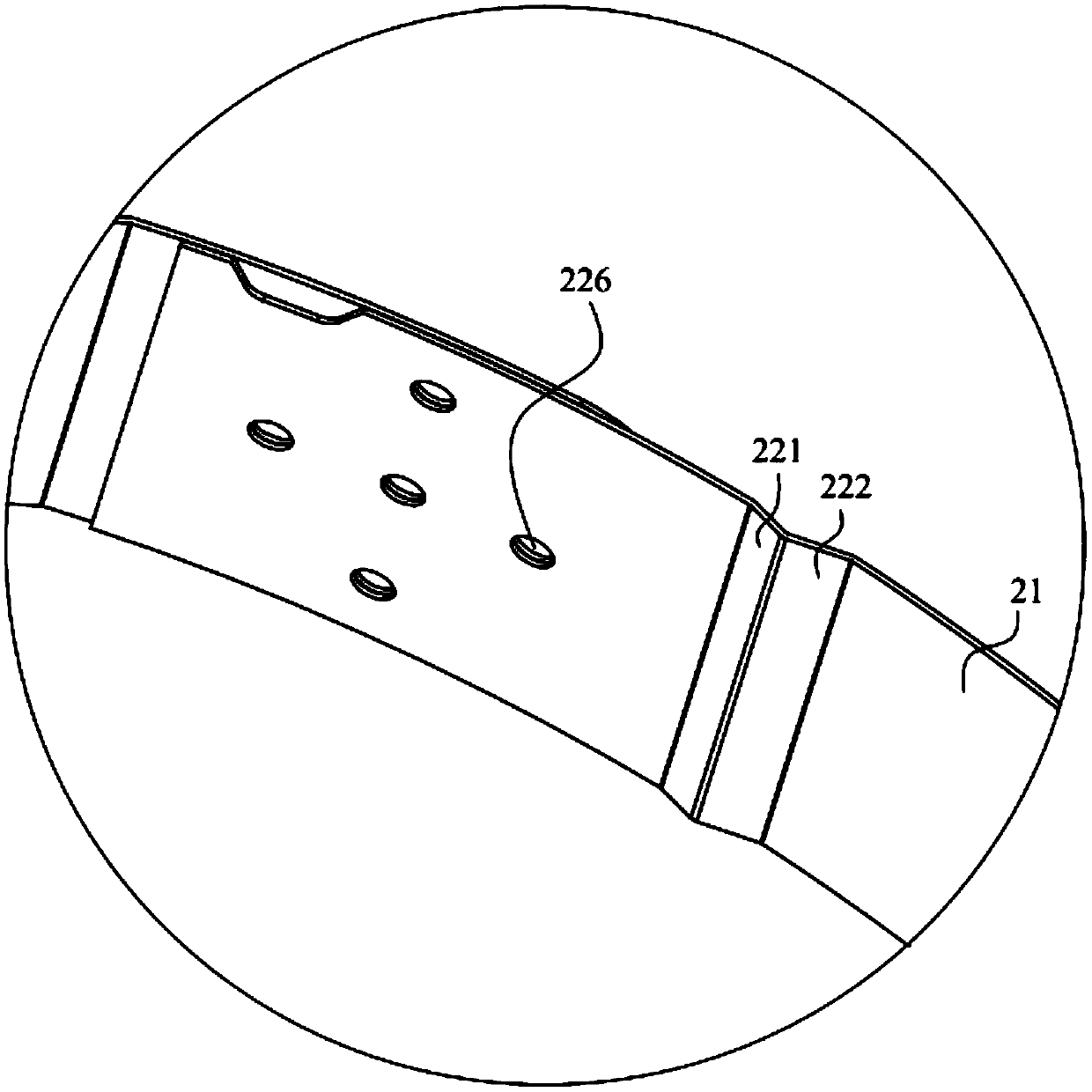

[0035] figure 1 Schematic diagram of the structure of the cylinder hoop 2 provided by the embodiment of the present invention, figure 2 for figure 1 Partial enlarged view of I in the center, such as figure 1 and 2 As shown, this embodiment provides a cylinder hoop 2, which includes a sheet-shaped cylinder hoop body 21. The cylinder hoop body is in a ring shape, and the annular outer surface of the cylinder hoop body 21 is stamped inwardly to form a protrusion 22. The upper end surface is flush with the upper end surface of the cylinder hoop body 21 , and the lower end surface of the protrusion 22 is flush with the lower end surface of the cylinder hoop body 21 . And there are multiple protrusions 22 , and the plurality of protrusions 22 are arranged at intervals along the circumferential direction of the tube hoop 2 .

[0036] The cylinder collar 2 provided in this embodiment forms a protrusion 22 by recessing the cylinder collar body 21 inwardly. The outer surface of th...

Embodiment 2

[0048] Figure 4 The structure schematic diagram of the drum provided for the embodiment of the present invention, as Figure 4 As shown, this embodiment provides a drum, including a drum body 1, a front end cover 3 and a rear end cover 4, one end of the drum body 1 is connected to the front end cover 3, and the other end of the drum body 1 is connected to the rear end cover 4, the cylinder The outer surface of the hoop body 21 is sheathed with the hoop 2 described in the first embodiment, and the protrusion 22 in the hoop 2 is in contact with the outer surface of the drum body 1 .

[0049] By sheathing the above-mentioned hoop 2 on the outer surface of the drum body 1 , the strength and rigidity of the hoop body 21 can be increased, and the impact resistance of the hoop body 21 can also be improved. When the drum body 1 bursts and other phenomena, the structure of the cylinder hoop 2 makes the cylinder hoop 2 elastically contact with the drum body 1, which can absorb the imp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com