Preparation method of nano-silica and steel fiber reinforced concrete

A nano-silica, reinforced concrete technology, applied in the field of inorganic polymer materials, can solve the problems of insufficient understanding of impact, limited application, lack of attention to maintenance and repair, etc., and achieve good performance results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 Nano silicon dioxide and steel fiber reinforced concrete raw material

[0026] The raw materials for preparing nano silicon dioxide and steel fiber reinforced concrete in the present invention mainly include gravel, river sand, cement, nano SiO 2 , steel fiber, high-efficiency water reducer, fly ash and water, all the technical indicators of the raw materials used meet the requirements. The specific parameters and testing indicators are as follows:

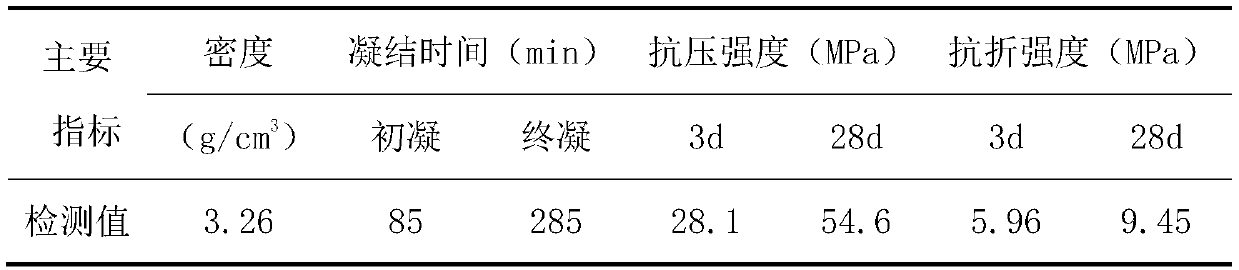

[0027] (1) cement

[0028] The cement used in the experimental study of the present invention is the P.I42.5 rotary kiln portland cement produced by Shandong Lucheng Cement Co., Ltd., and its main technical index detection values are as shown in table 1:

[0029] Table 1 Main technical indicators of cement

[0030]

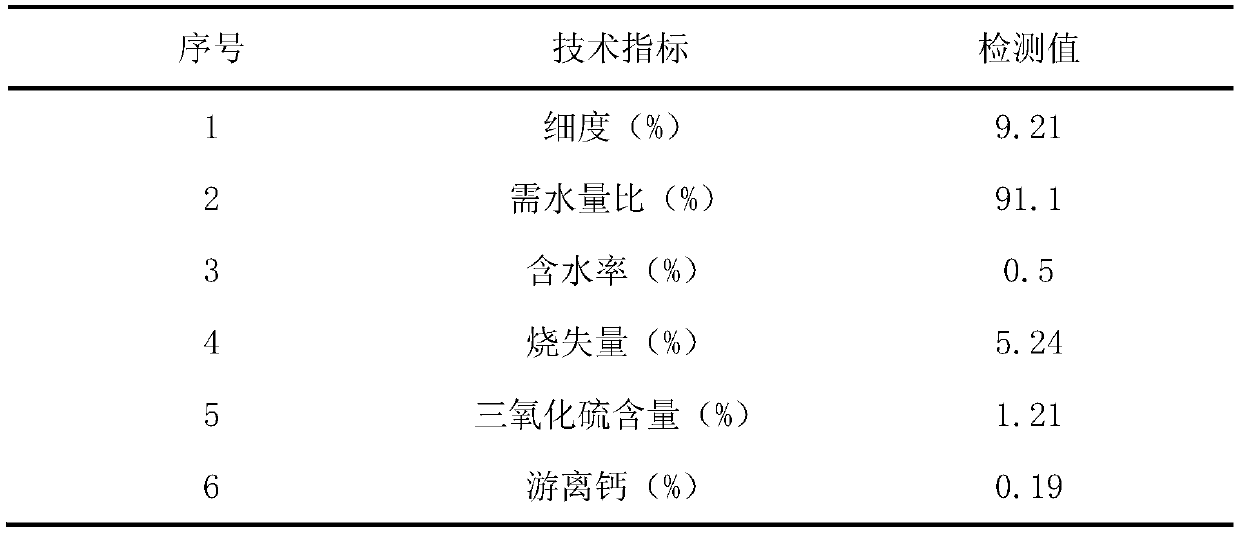

[0031] (2) fly ash

[0032] The fly ash used in the experimental study of the present invention is a first-class fly ash, and each detection index is as shown in table 2:

[0033] Table 2 ...

Embodiment 2

[0061] Embodiment 2 nano-silica and steel fiber reinforced concrete mix design

[0062] The test of the present invention is to add nano-SiO in concrete 2 and steel fiber, to study the influence of the amount of the two on the road performance of concrete, including basic mechanical properties, impact resistance, chloride ion penetration resistance, and frost resistance. According to the research design, choose to fix the water-binder ratio and sand rate, and only change nano-SiO 2 Dosage and steel fiber dosing.

[0063] The test of the present invention is based on the concrete mix ratio design rules, and the design reference concrete compressive strength grade is C45. nano-SiO 2 Replace cement according to the quality of 1%, 2%, 3%, 4%, 5%; keep nano-SiO 2 The dosage is 3%, and the steel fiber is mixed into the concrete according to the ratio of 0.5%, 1.0%, 1.5%, 2.0%, and 2.5% as the volumetric dosage.

[0064] The amount of each material per cubic meter of concrete is...

Embodiment 3

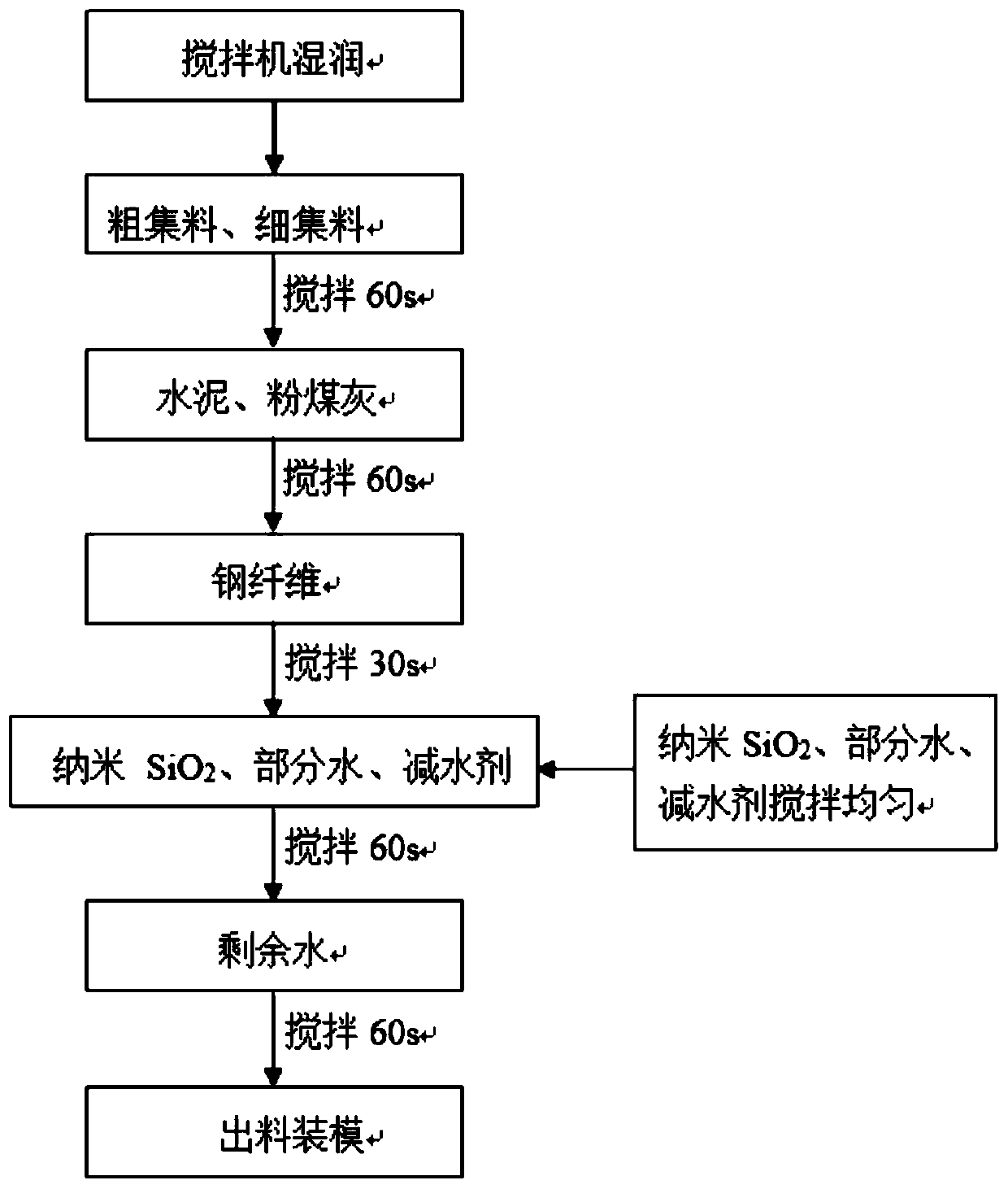

[0069] The preparation technology of embodiment 3 nano silicon dioxide and steel fiber reinforced concrete

[0070] Concrete is made by mixing cement, sand, stone, water, and admixtures in a certain proportion. There are two main reasons that affect its strength and other properties. The first is the quality of raw materials. The raw materials used have been inspected above, and the raw materials used are qualified; the second is the concrete construction technology and process control, which is also the key to the success of the test. Steel fiber and nano-SiO 2 In the process of reinforced concrete preparation, nano-SiO 2 The uniform dispersion of steel and steel fibers is the key point to ensure the quality of concrete, and it is also the basis for concrete to have excellent properties.

[0071] In order to ensure the uniform dispersion of fibers and nanomaterials, it is necessary to select the appropriate incorporation method and sequence. For the steel fiber used in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com