Sheet Holder

A technology for holding devices and thin plates, which is used in auxiliary devices, laser welding equipment, auxiliary welding equipment, etc., to achieve the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

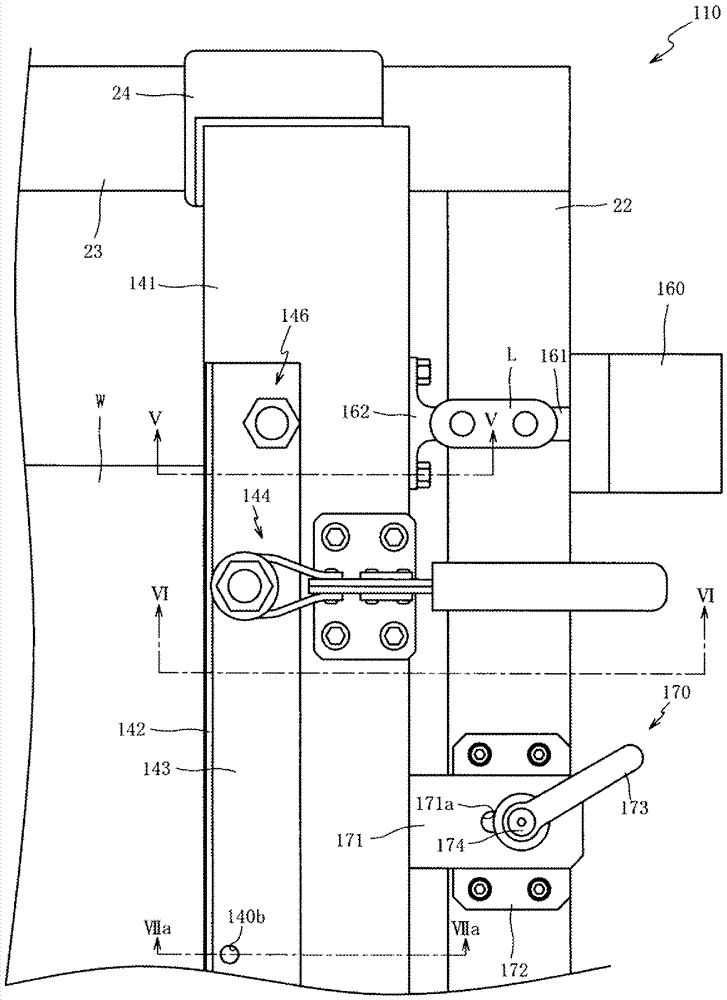

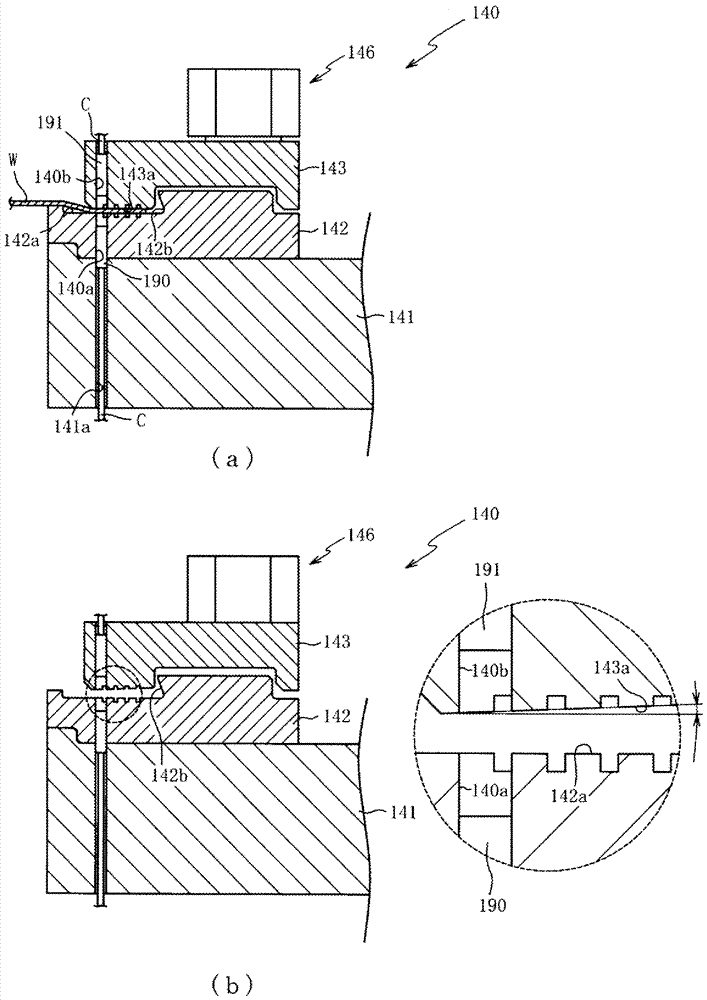

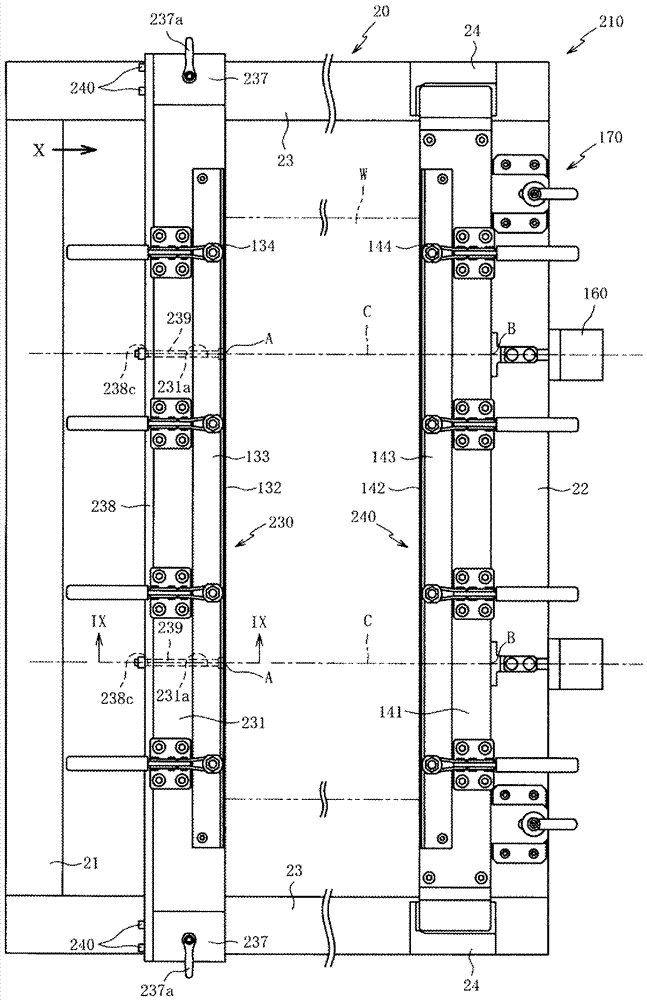

[0036] The best mode for carrying out the present invention will be described below with reference to the drawings. figure 1 It is a front view of the laser processing machine 1 according to the first embodiment of the present invention. Such as figure 1 As shown, the laser processing machine 1 is mainly composed of: a processing head 4 for irradiating a laser beam to a thin plate W to be processed and injecting assist gas; A processing head 4 for irradiating laser light is suspended from the arm 2 via a horizontal moving member 3 . The horizontal moving member 3 is configured to be movable in the Y direction with respect to the arm 2 by the Y-axis driving device 3a, while the machining head 4 is configured to be movable in the X direction with respect to the horizontal moving member 3 by the X-axis driving device 4a. The machining head 4 is driven by the X-axis driving device 3 a and the Y-axis driving device 4 a to move in the XY direction with respect to the arm 2 .

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com