Patents

Literature

69results about How to "Avoid bending stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

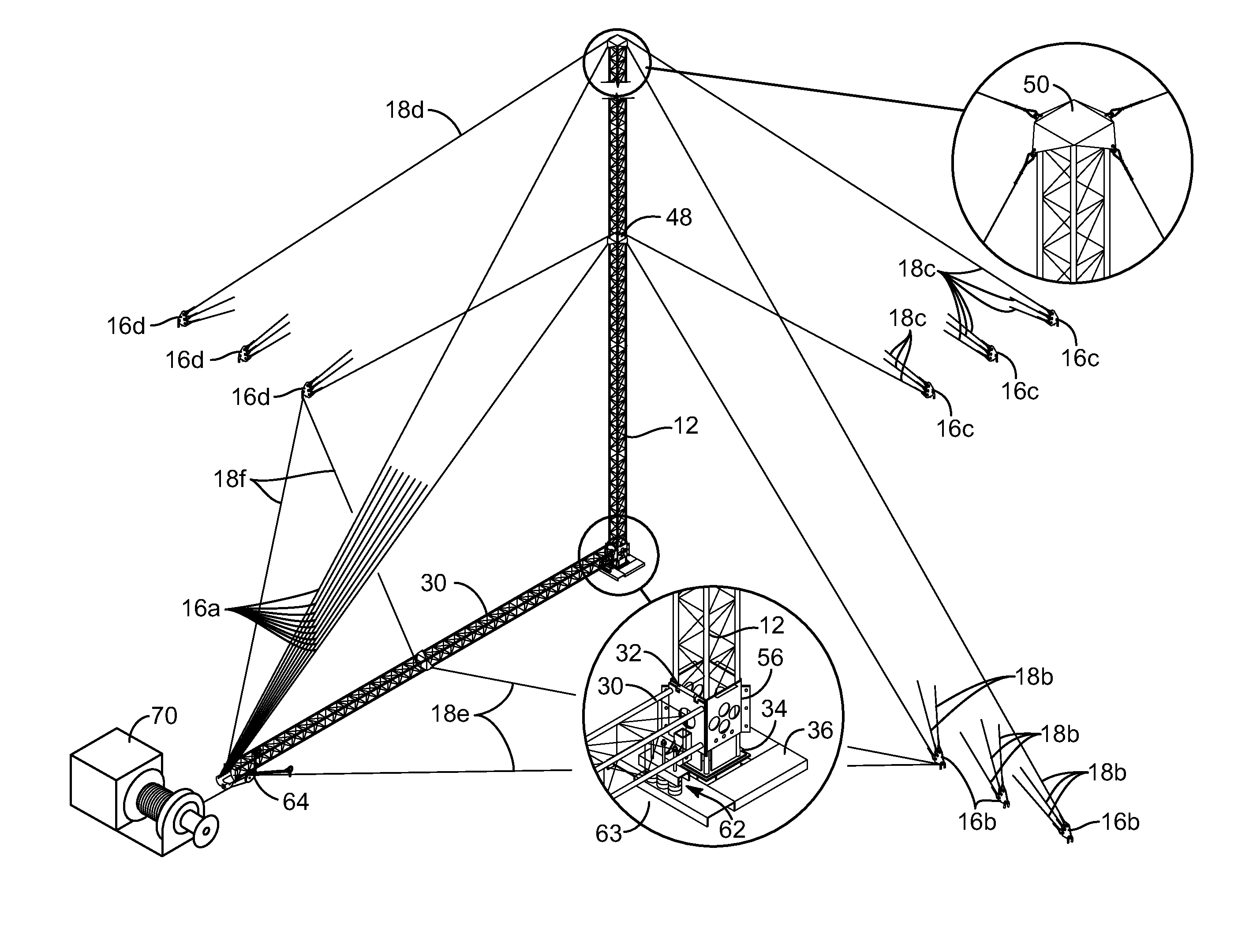

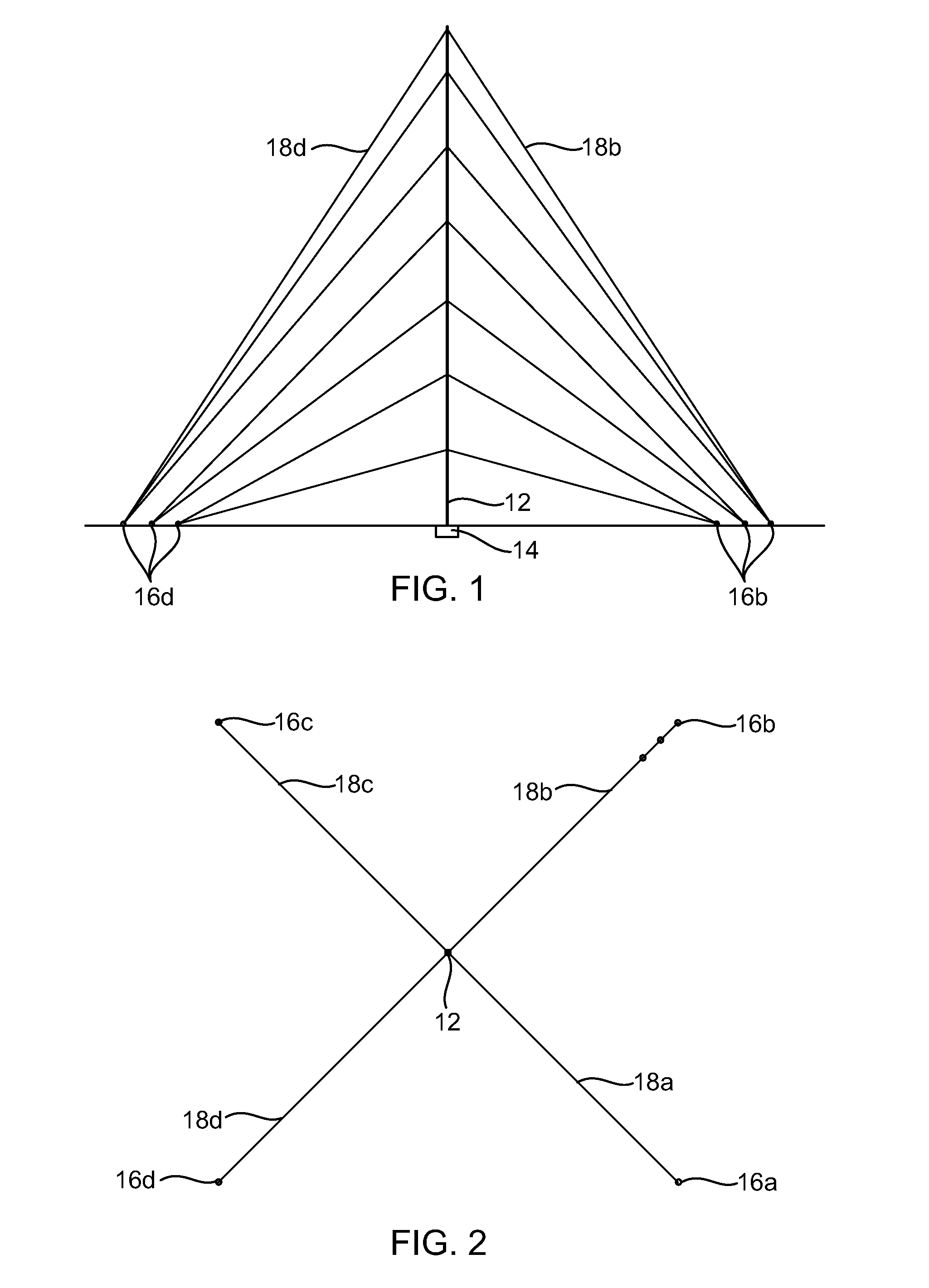

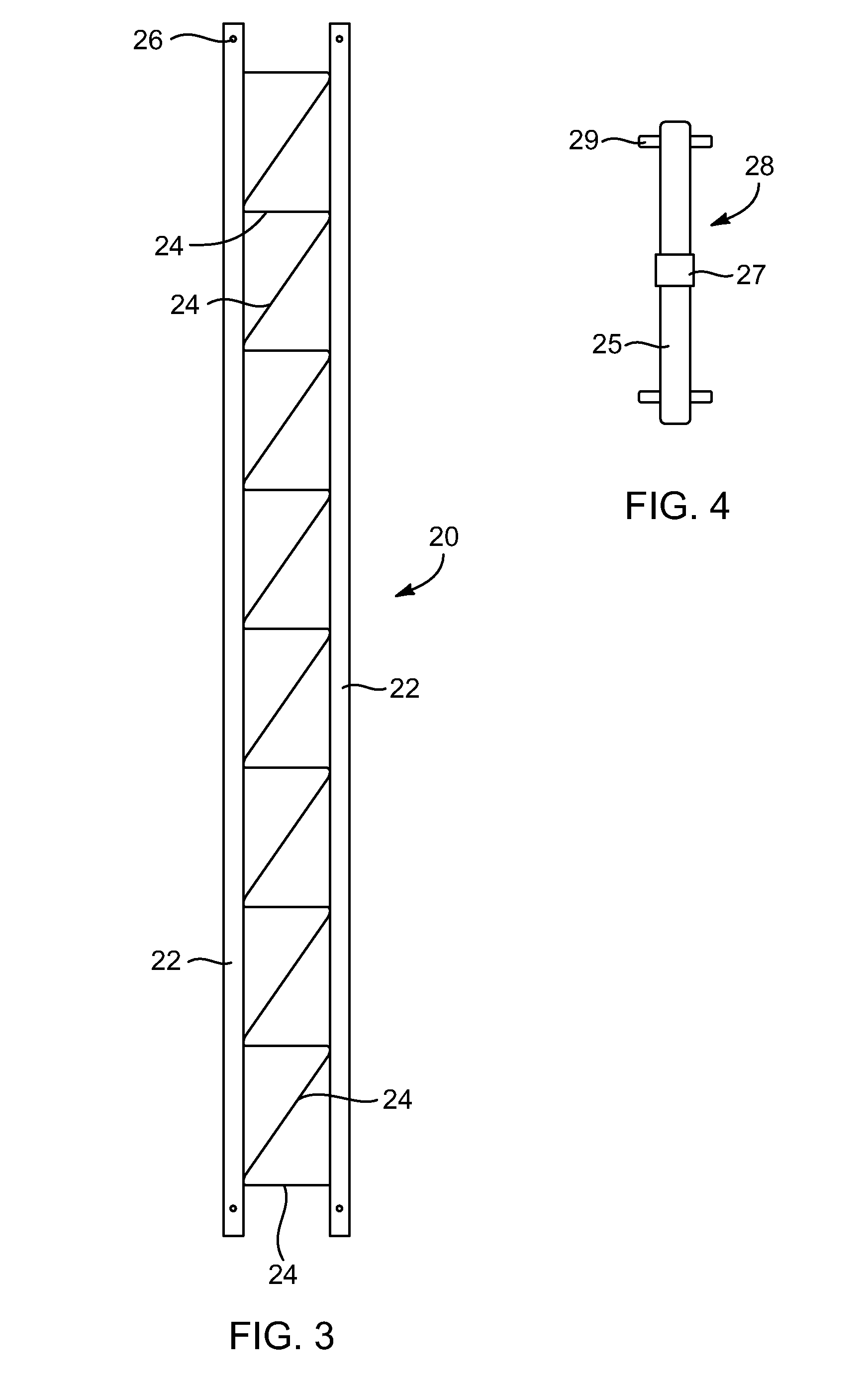

Ultra-light, re-usable, extended-height meteorological tower apparatus and method

InactiveUS20110016804A1Avoid bending stressIncrease the diameterBuilding repairsTowersEngineeringInstrumentation

A method and apparatus for erecting a lightweight, tall (60 to 80 meters or more) tower that may be temporary and re-usable as a mount for meteorological instruments is described including guys balancing lateral and transverse forces while maintaining the tower in tension. Forces on all guy lines maintain the tower stable from a substantially horizontal assembly position to a vertical operational position. A system of gin poles and pivots help maintain registration and alignment while pulling the assembled tower erect.

Owner:HOWARD LONNIE +1

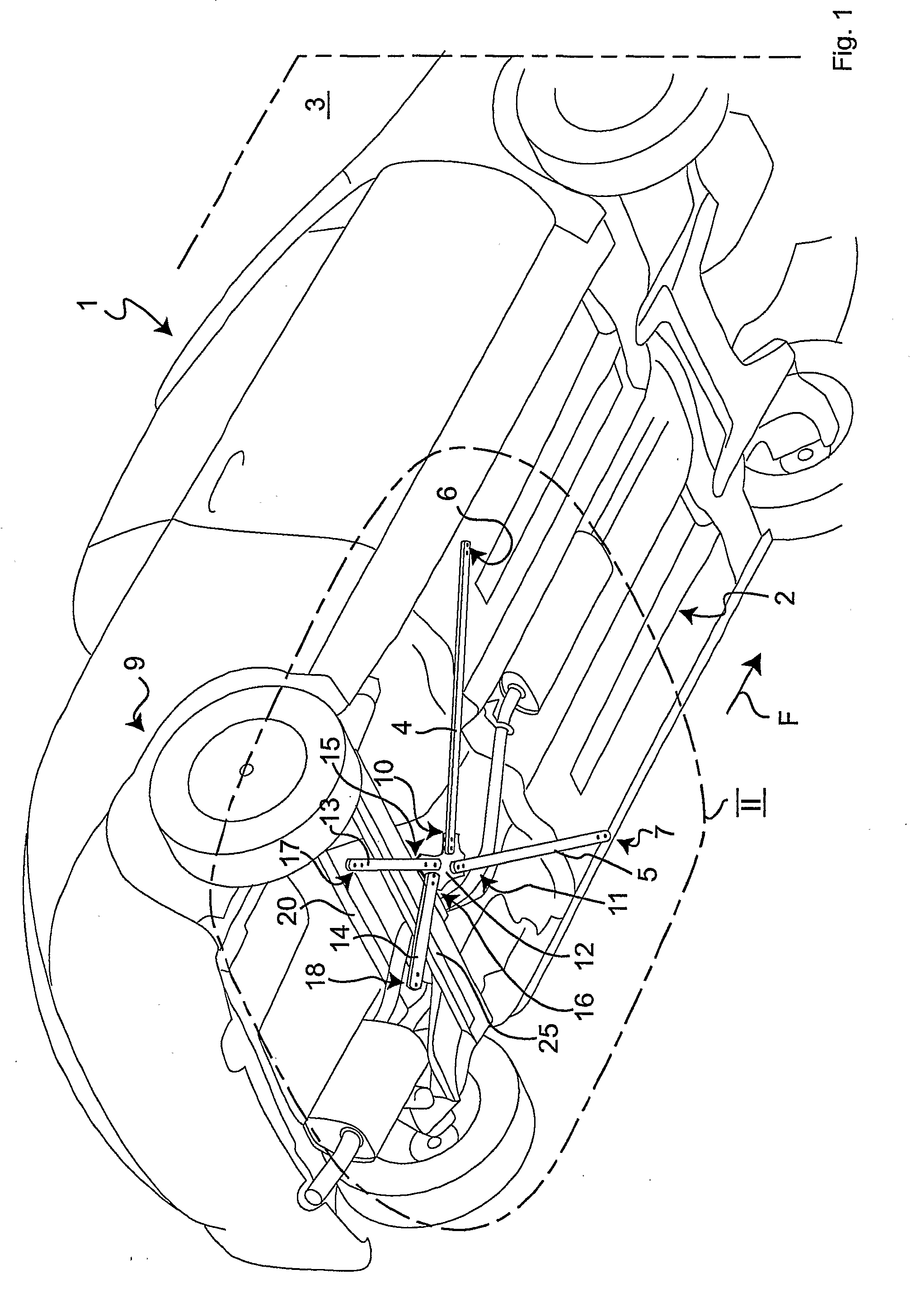

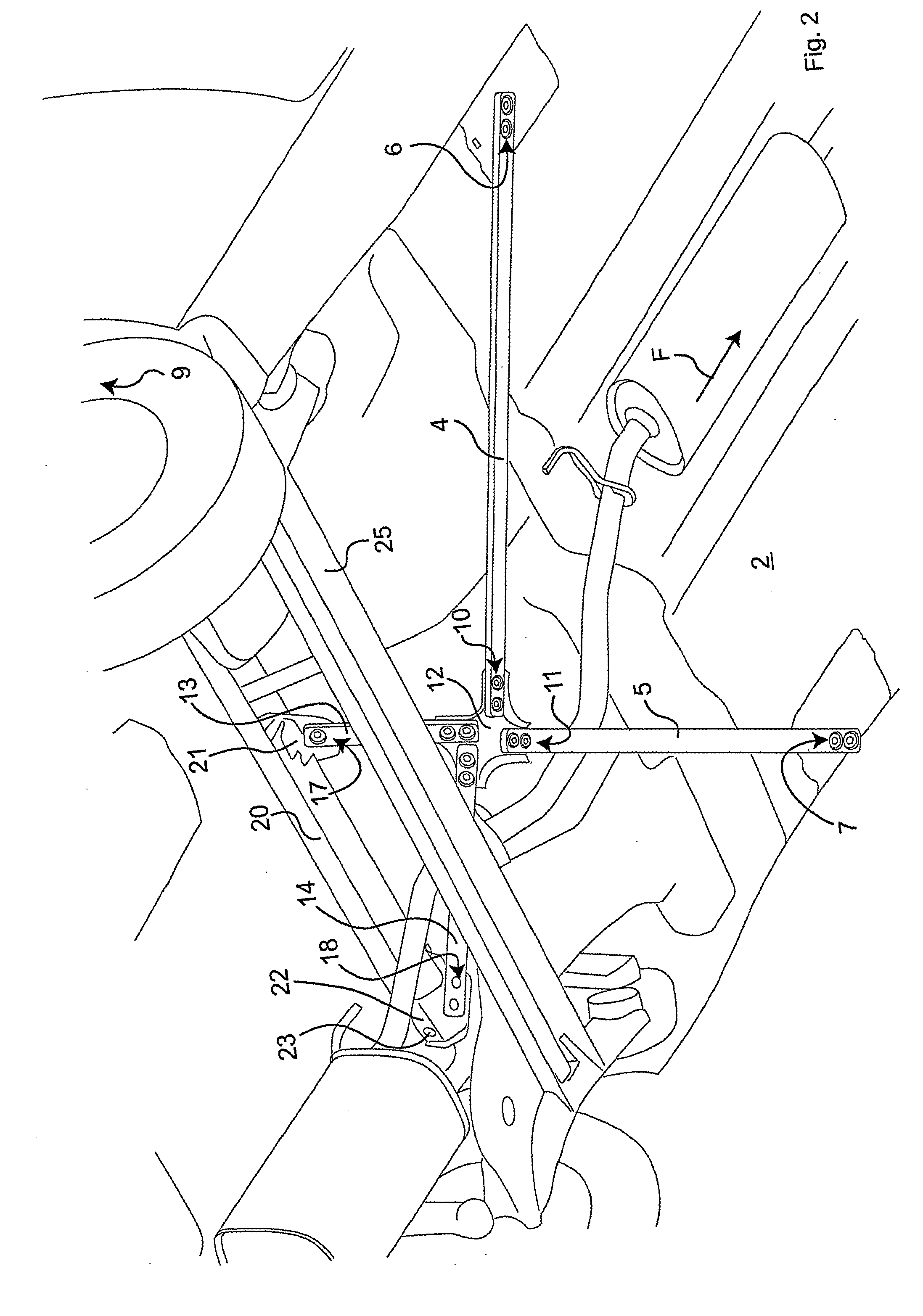

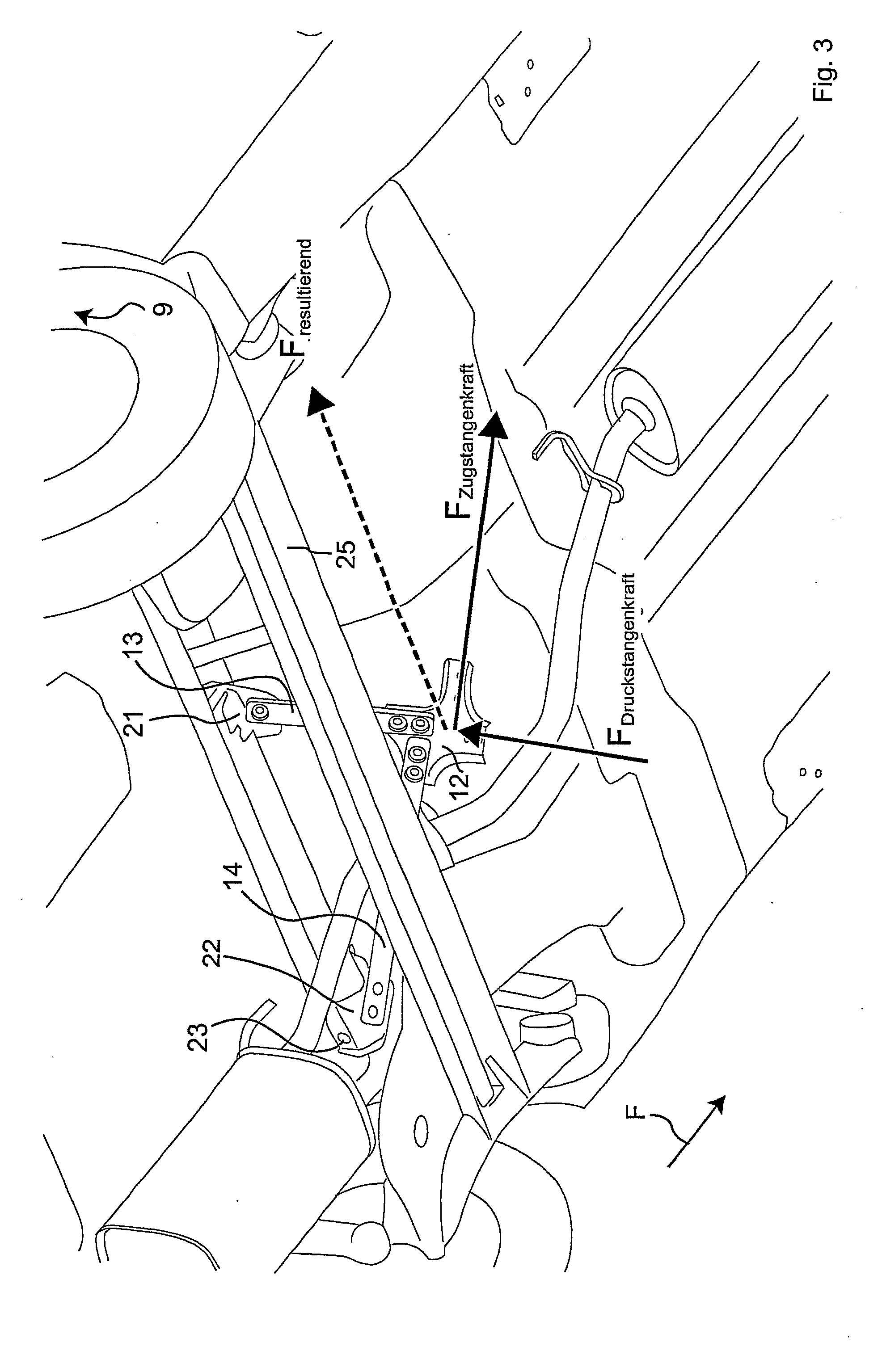

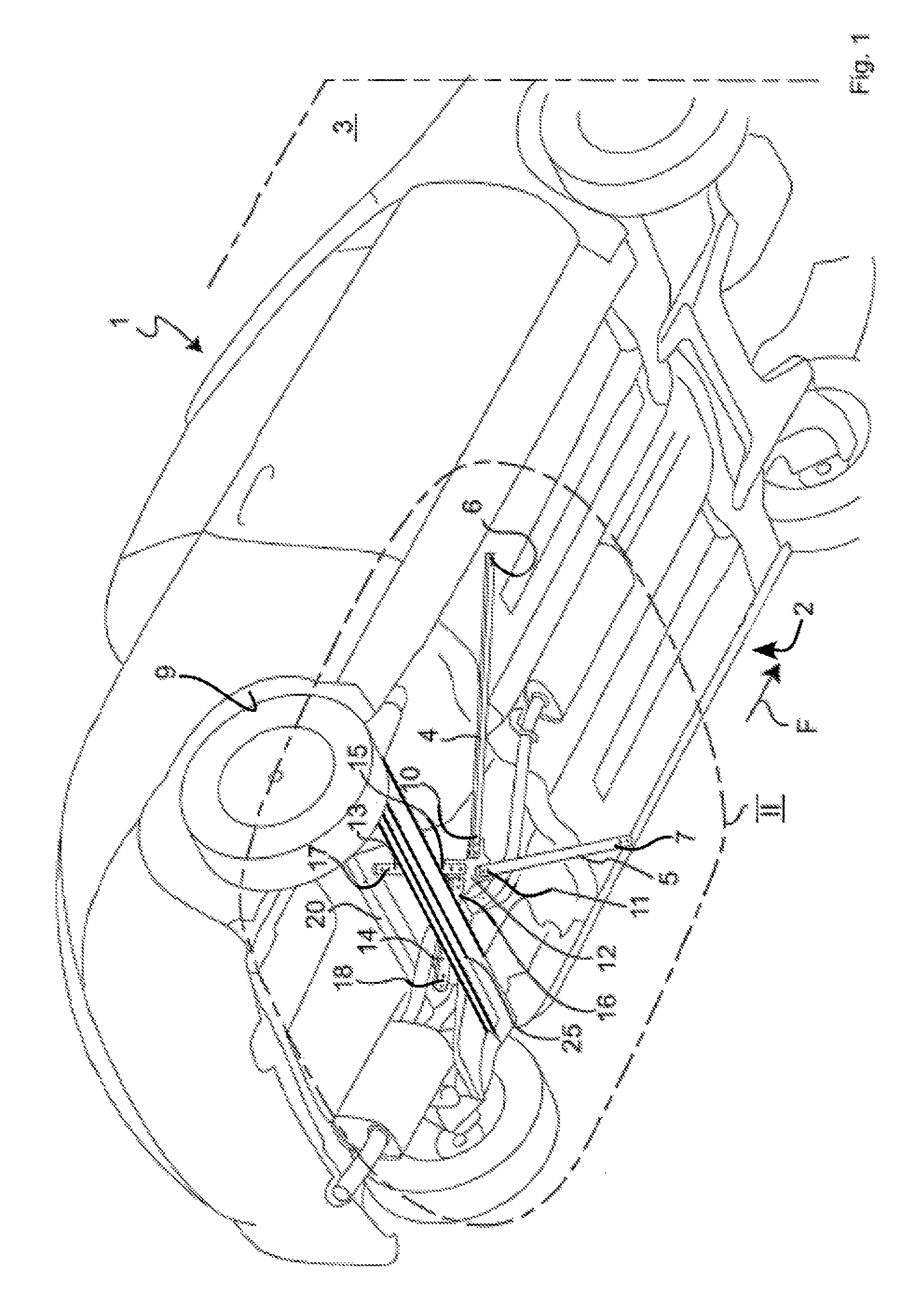

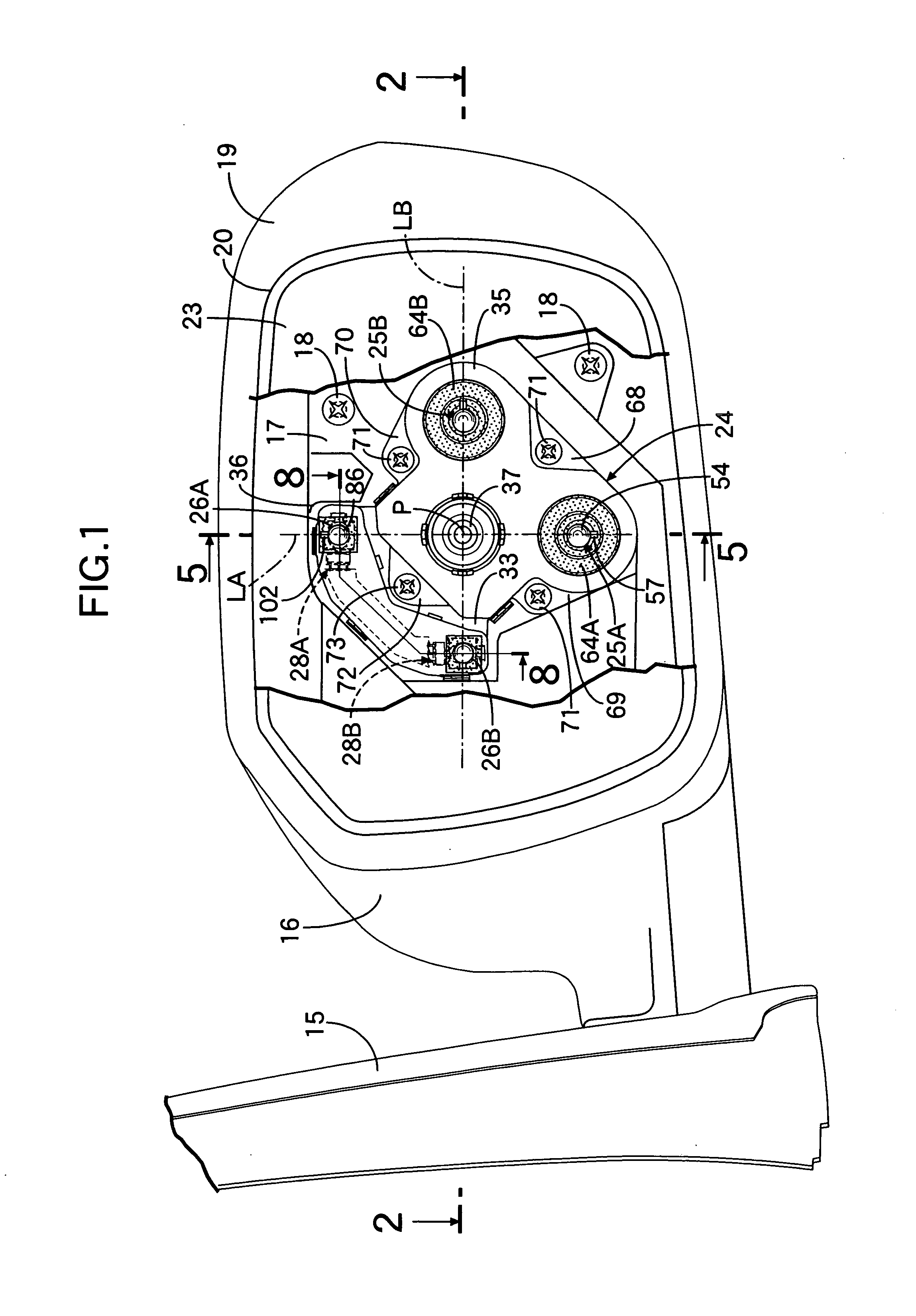

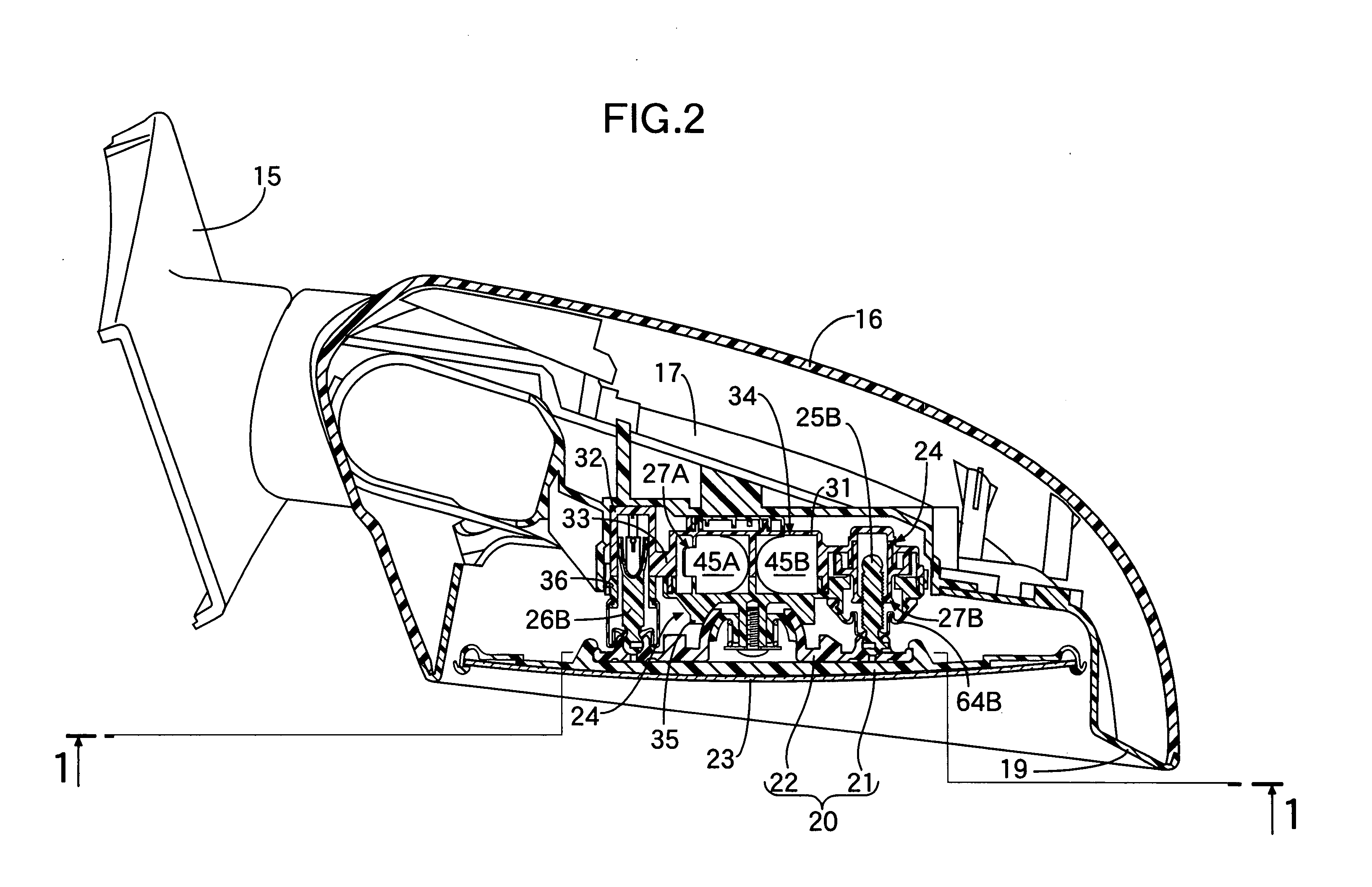

Motor Vehicle

InactiveUS20080231085A1Raise the possibilityAvoid bending stressVehicle seatsUnderstructuresMobile vehicleEngineering

A motor vehicle, especially a cabriolet vehicle, with a motor vehicle chassis is provided to whose underbody area at least two reinforcing struts are allocated, each of which trends from a chassis attachment with a component in the direction of a vertical longitudinal mid-plane. A connection support is provided free under the underbody and with a distance to it, at which support two of these struts are held in close distance to each other with respect to the vehicle transverse direction, as well as two further struts, which from there extend away, in each case, with a component in the direction of the vertical longitudinal mid-plane, wherein the connection support is angled about at least one axis extending transverse to the vehicle between the mountings for the two struts and the mountings for the two further struts.

Owner:VALMET AUTOMOTIVE

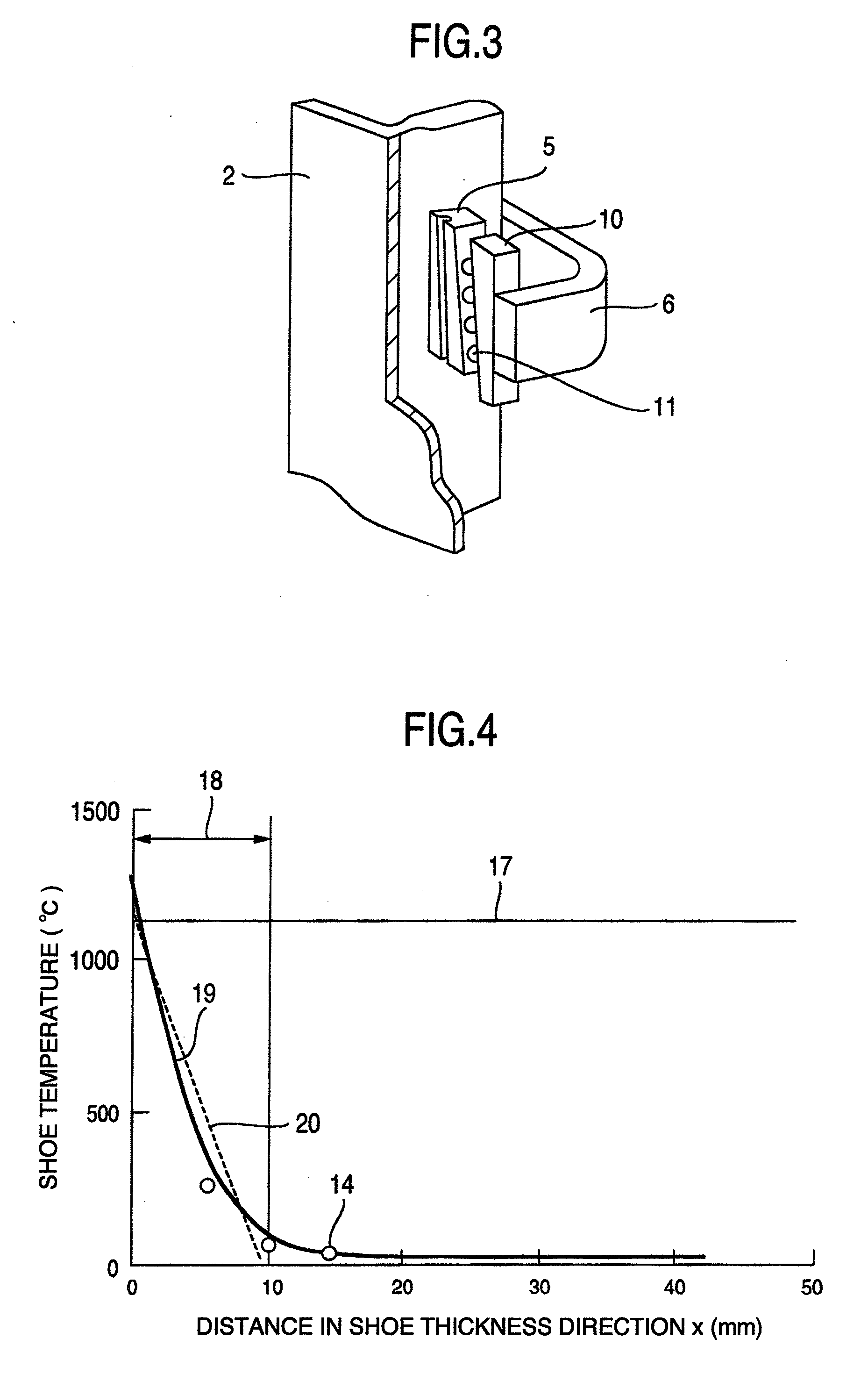

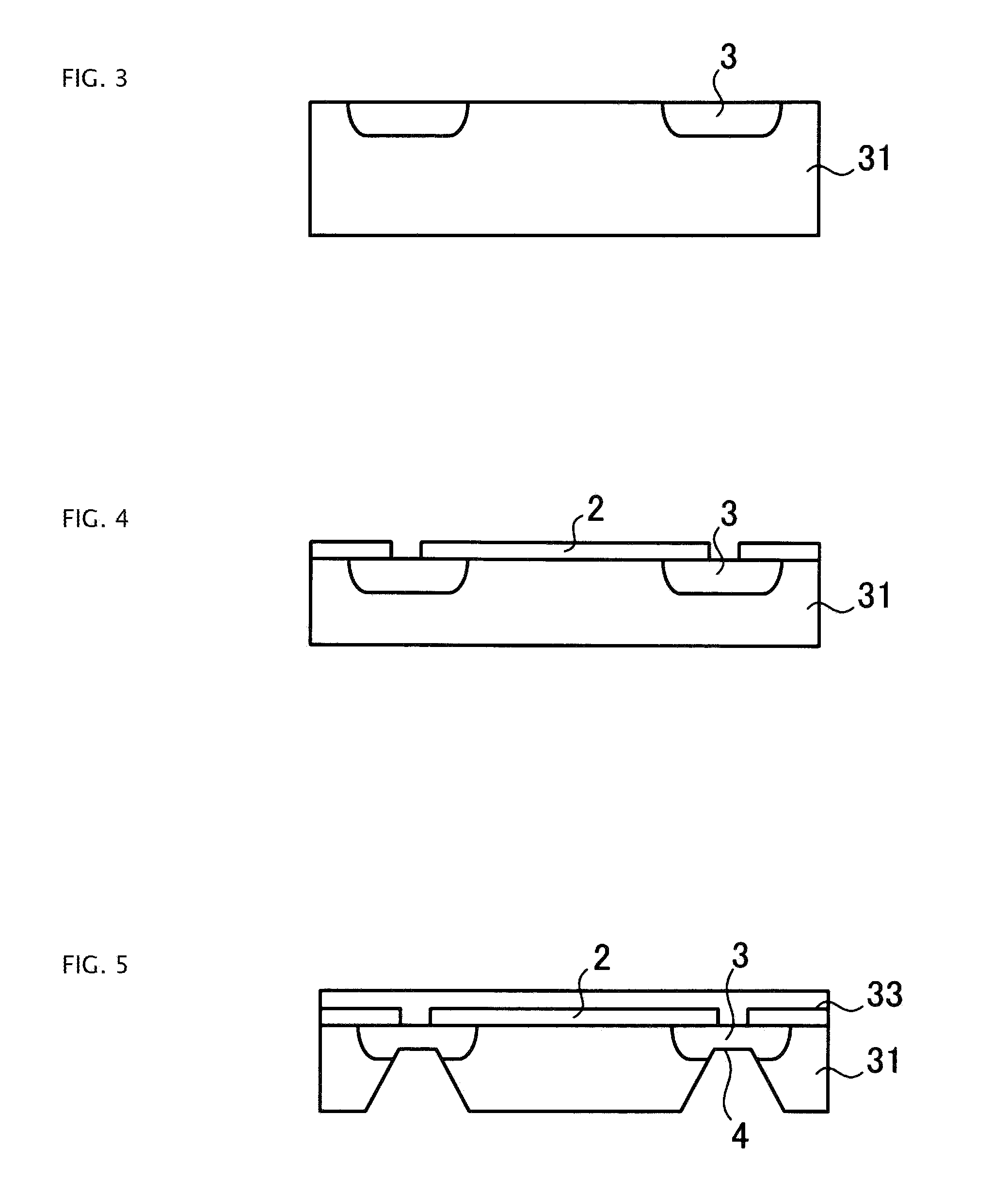

Brake Shoe for Elevator Emergency Stop

The present invention prevents cracking of a brake shoe even when the sliding surface of the brake shoe is heated to a high temperature and provides high reliability. The present invention provides a brake shoe for elevator emergency stop which generates a braking force by pressing brake shoes against a guide rail and making the brake shoes 5 slide to stop an elevator cage in the event of anomalies, including the brake shoes made of a cast iron material having a plurality of grooves 3 formed in a direction substantially perpendicular to the guide rail and gear teeth which constitute a sliding surface with the brake shoes 5 formed as gaps between the grooves, wherein the depth of the grooves is 3 mm or more and not more than 1.7 times the width of the gear teeth.

Owner:HITACHI LTD

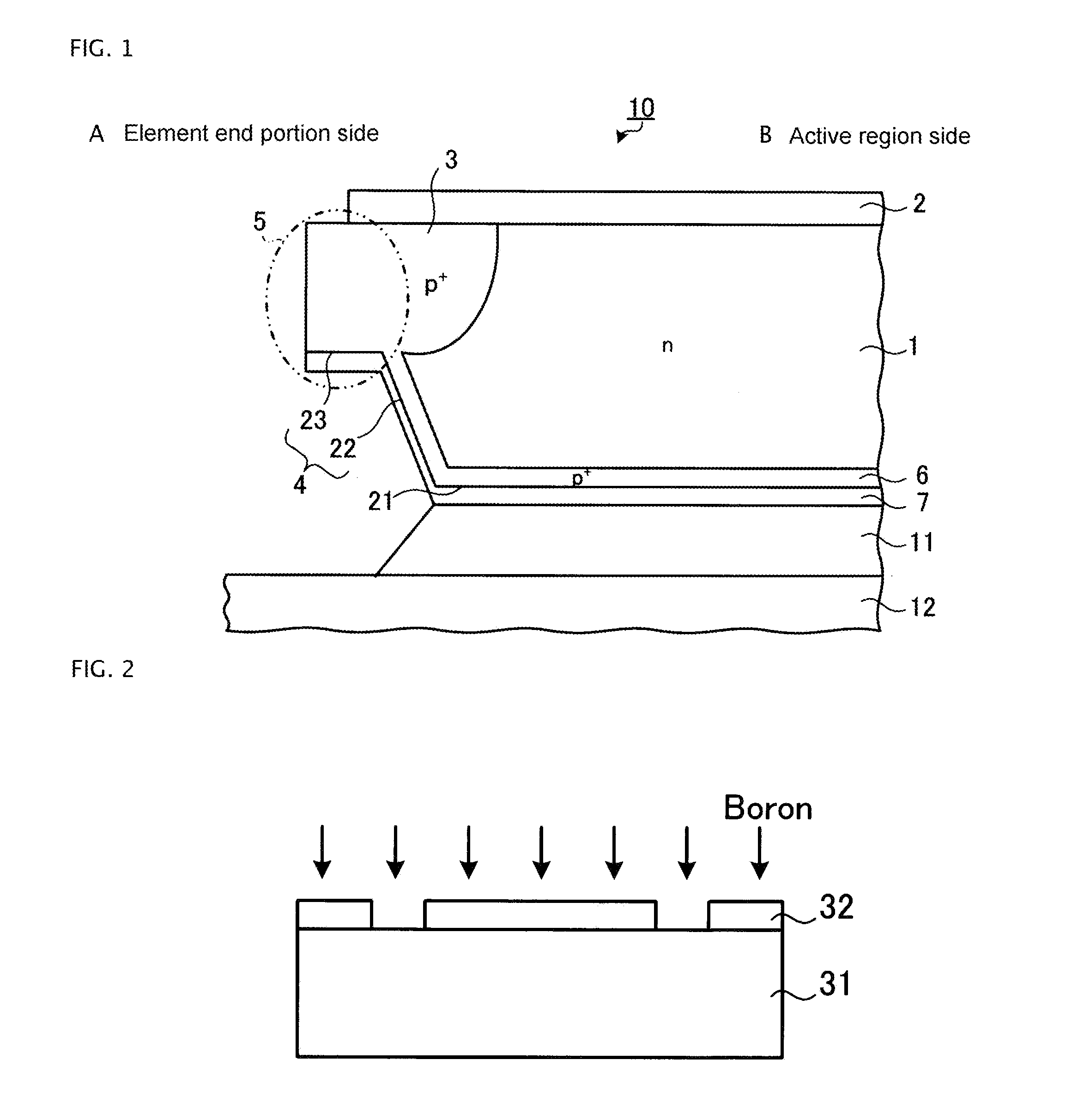

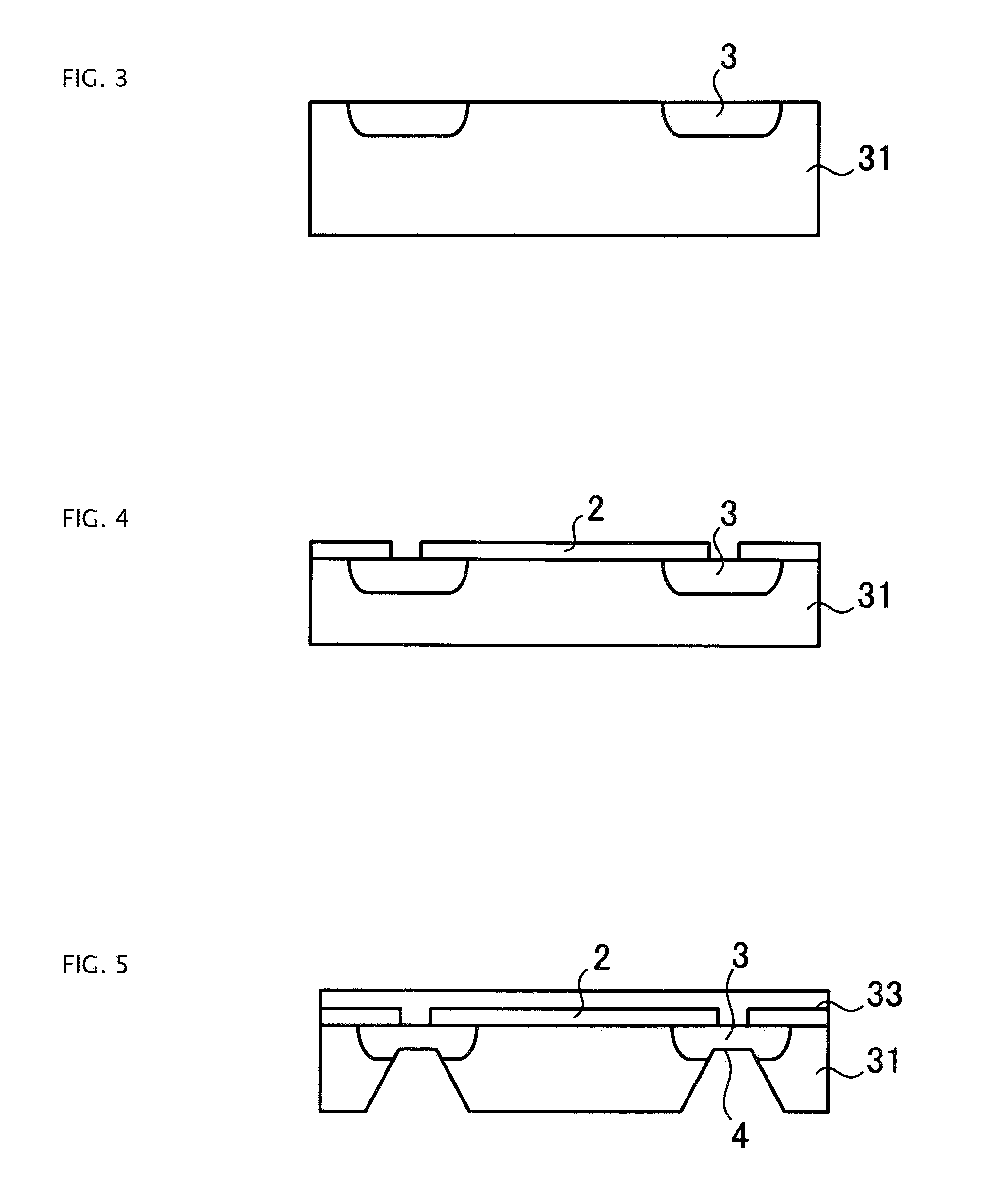

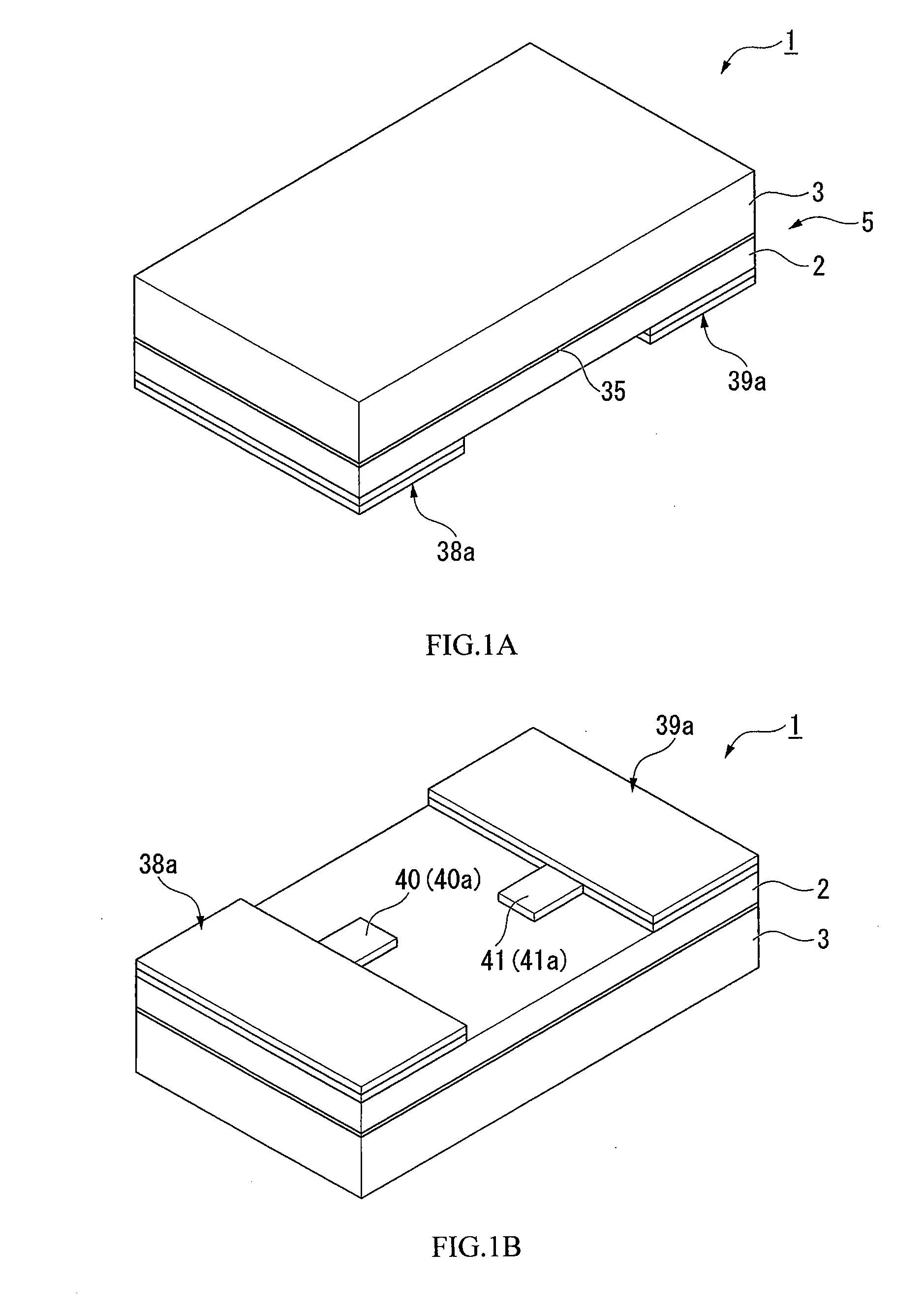

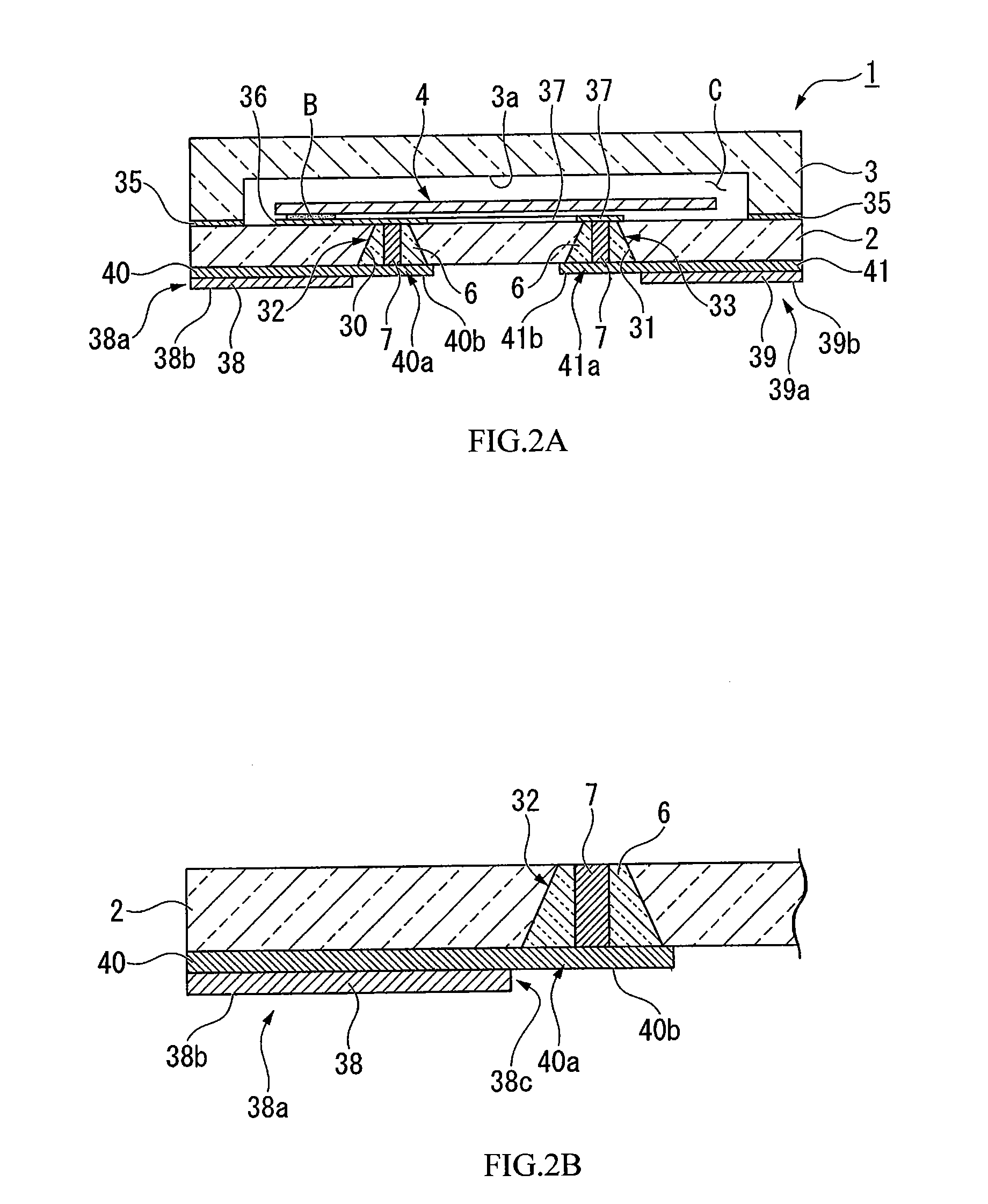

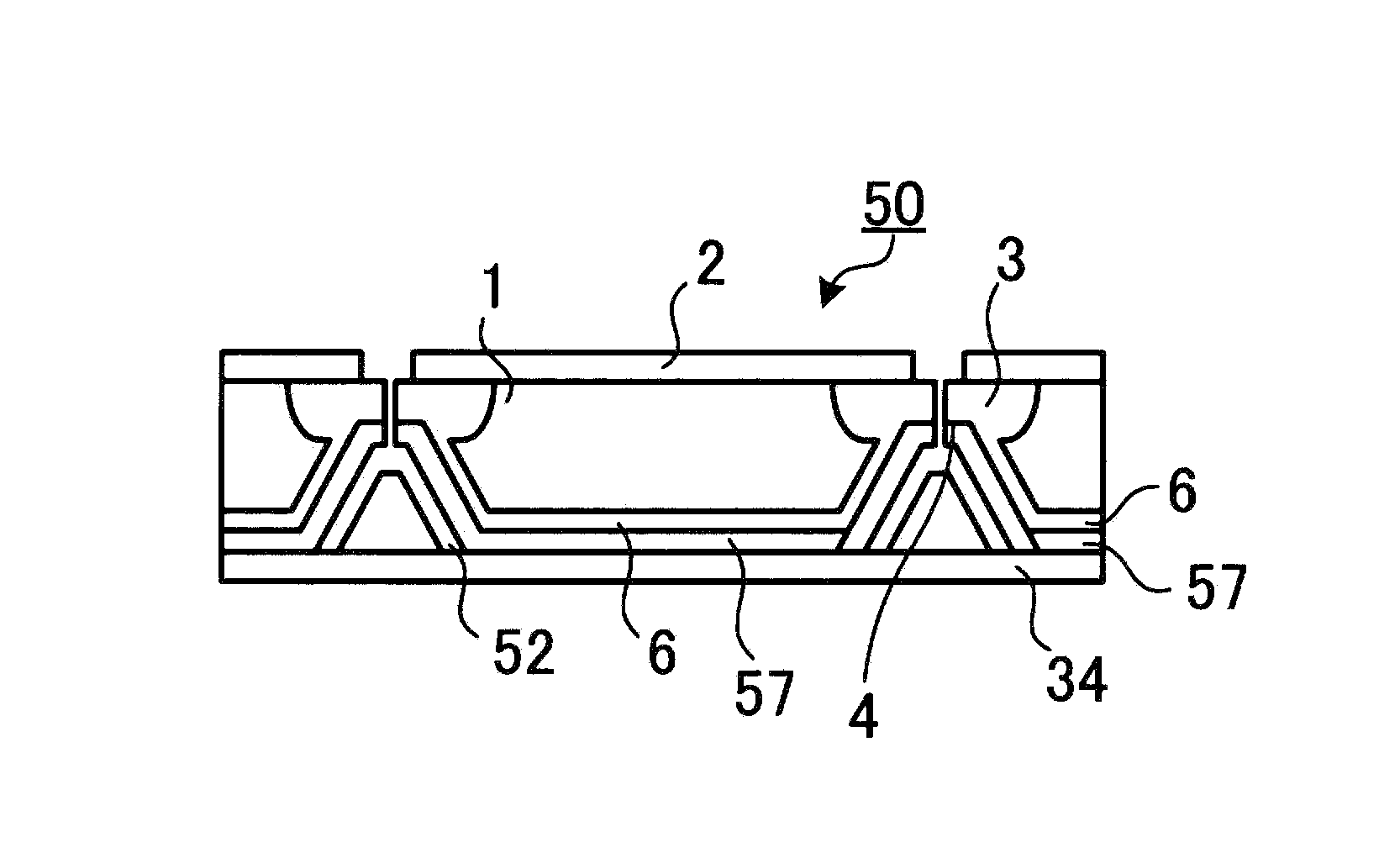

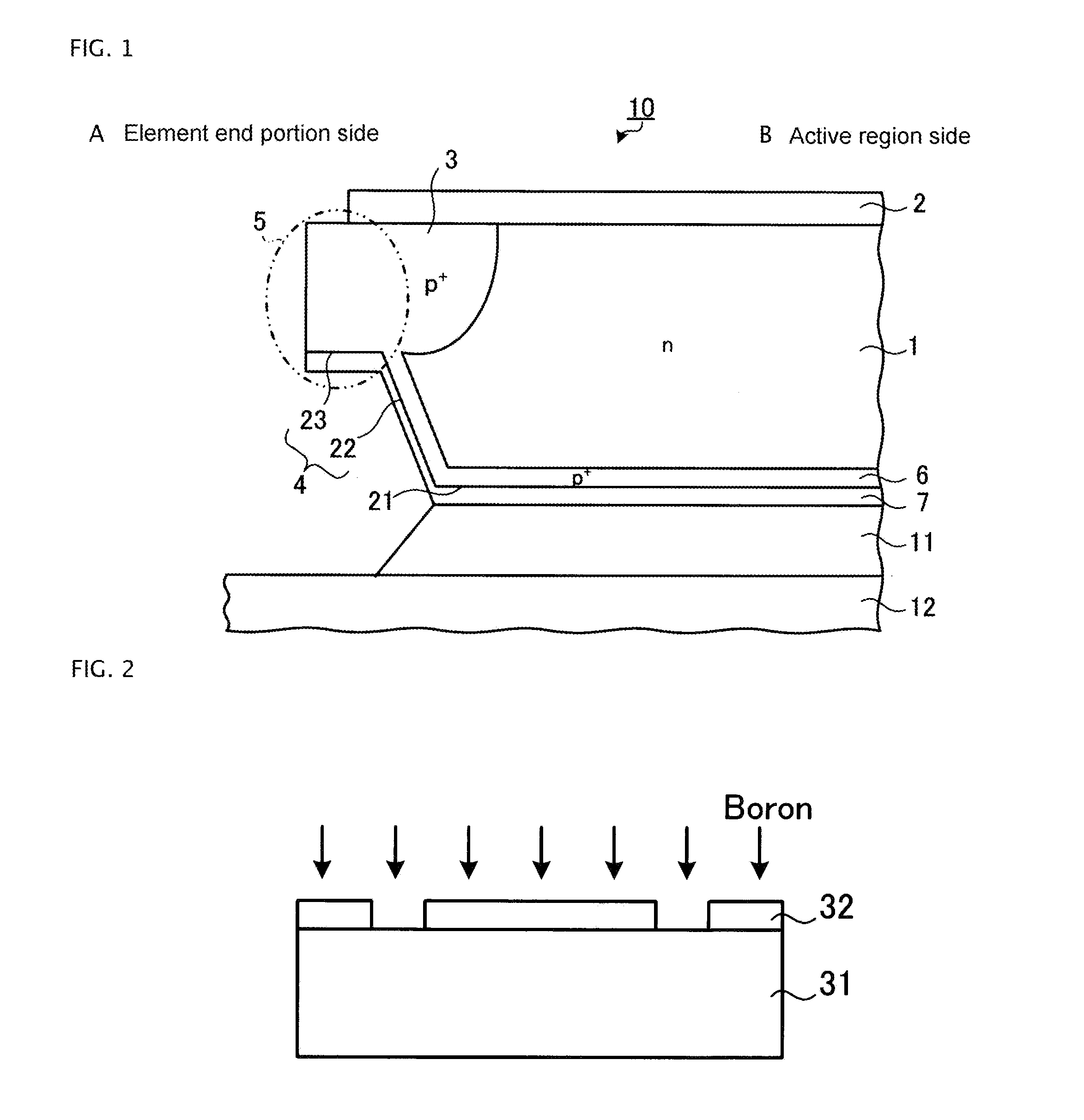

Semiconductor device and semiconductor device manufacturing method

InactiveUS20120313224A1Avoid breakingAvoid chippingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipSemiconductor device fabrication

A semiconductor device and manufacturing method are disclosed which prevent breakage and chipping of a semiconductor chip and improve device characteristics. A separation layer is in a side surface of an element end portion of the chip. An eave portion is formed by a depressed portion in the element end portion. A collector layer on the rear surface of the chip extends to a side wall and bottom surface of the depressed portion, and is connected to the separation layer. A collector electrode is over the whole surface of the collector layer, and is on the side wall of the depressed portion. The thickness of an outermost electrode film is 0.05 μm or less. The collector electrode on the rear surface of the chip is joined onto an insulating substrate via a solder layer, which covers the collector electrode on a flat portion of the rear surface of the semiconductor chip.

Owner:FUJI ELECTRIC CO LTD

Motor vehicle

InactiveUS7891728B2Raise the possibilityAvoid bending stressVehicle seatsUnderstructuresMotorized vehicleMotor vehicle crash

A motor vehicle, especially a cabriolet vehicle, with a motor vehicle chassis is provided to whose underbody area at least two reinforcing struts are allocated, each of which trends from a chassis attachment with a component in the direction of a vertical longitudinal mid-plane. A connection support is provided free under the underbody and with a distance to it, at which support two of these struts are held in close distance to each other with respect to the vehicle transverse direction, as well as two further struts, which from there extend away, in each case, with a component in the direction of the vertical longitudinal mid-plane, wherein the connection support is angled about at least one axis extending transverse to the vehicle between the mountings for the two struts and the mountings for the two further struts.

Owner:VALMET AUTOMOTIVE

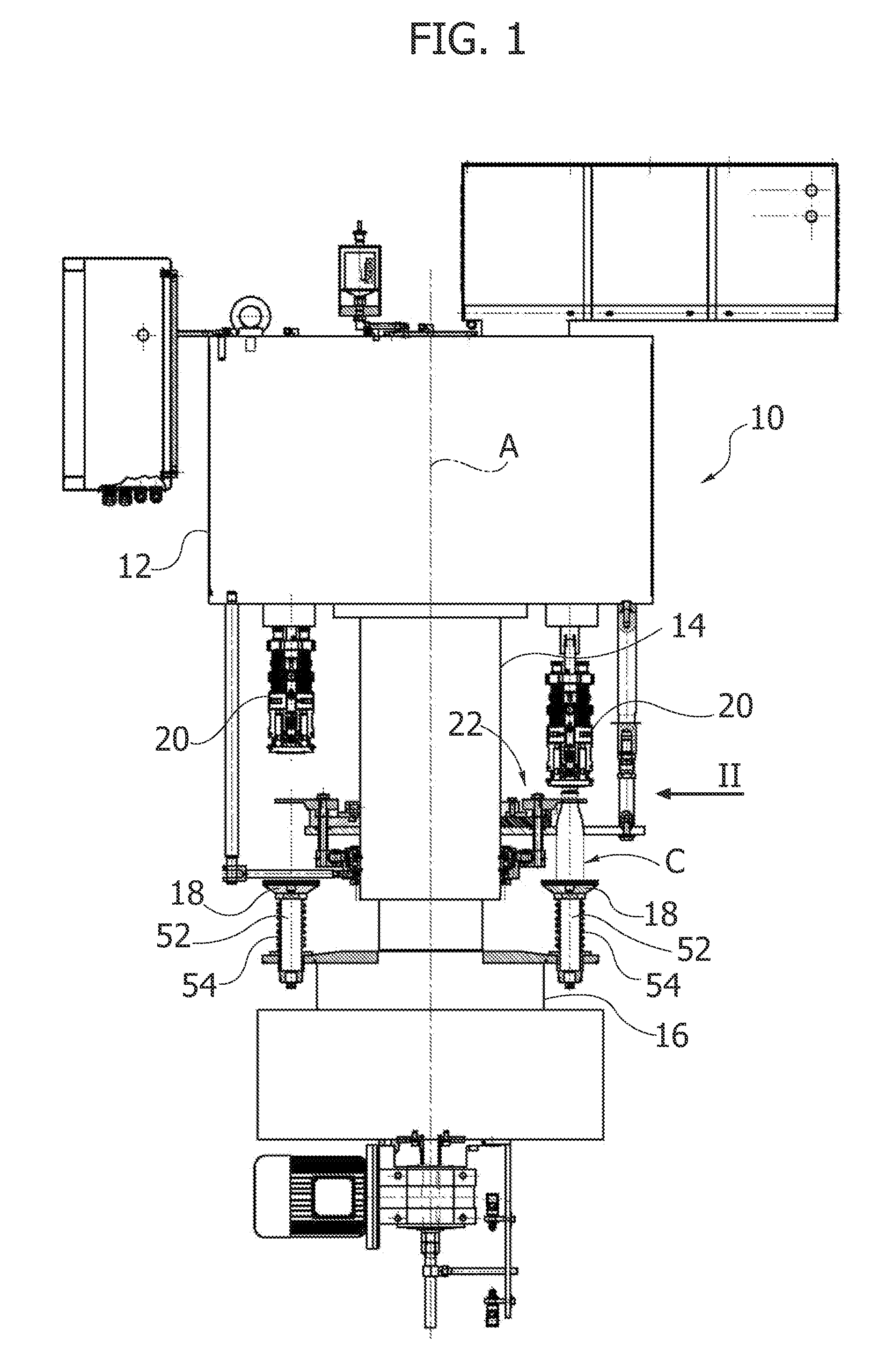

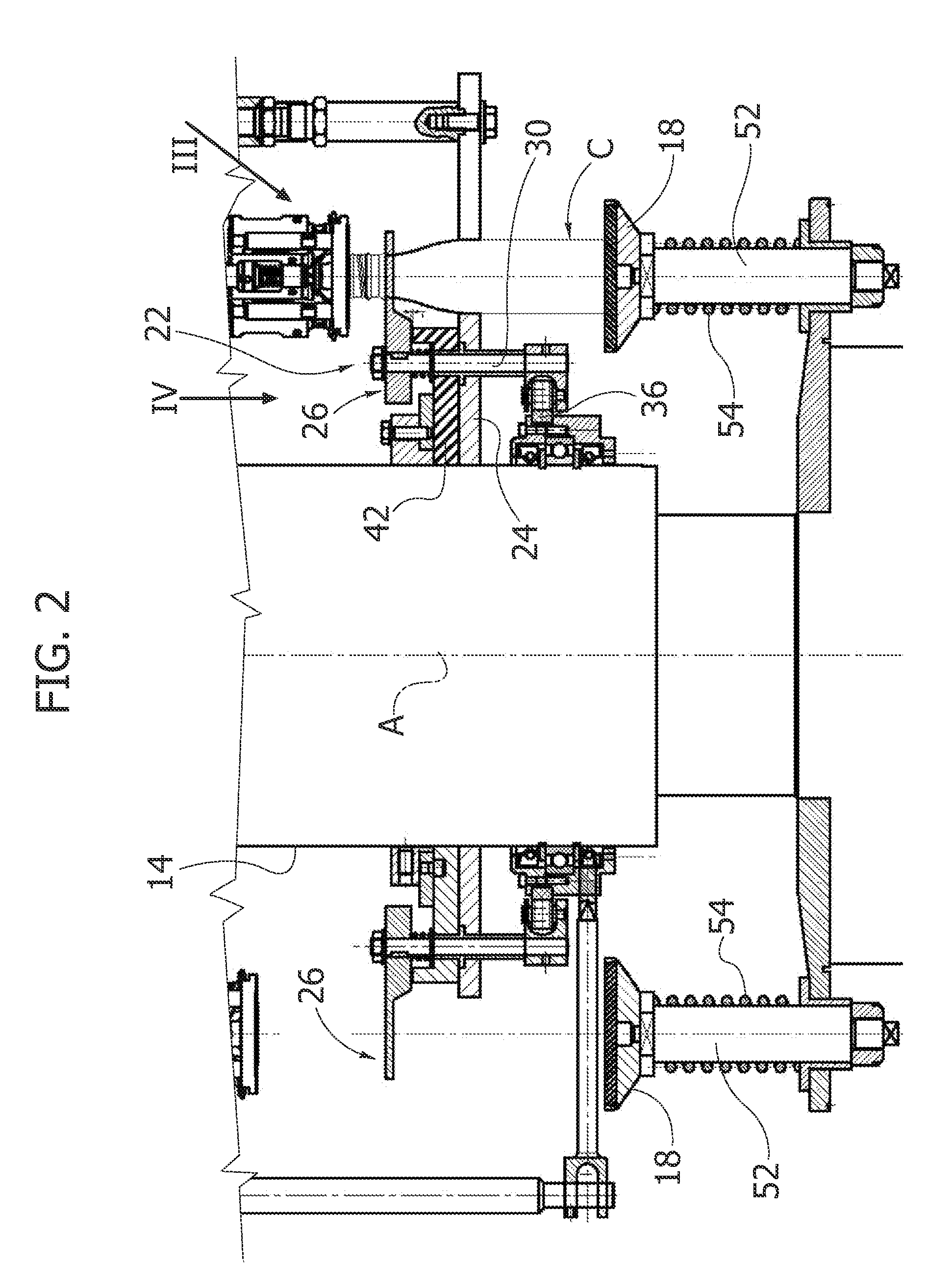

Machine for application of caps on containers such as bottles and the like

InactiveUS20120085068A1Avoid risk of damageRelieve stressCapsThreaded caps applicationAxial forceEngineering

A machine for application of caps on containers such as bottles and the like having a neck with a threaded top end, comprising at least one head for application of caps and at least one gripper designed to grip the neck of the containers during application of the caps. Said at least one gripper is mobile in a vertical direction between a raised position and a lowered position, wherein elastic means are present for pushing the gripper elastically towards the raised position and wherein in the lowered position the gripper rests on a resting plate so that at least part of the axial force applied by said head on the cap is discharged on said resting plate.

Owner:AROL

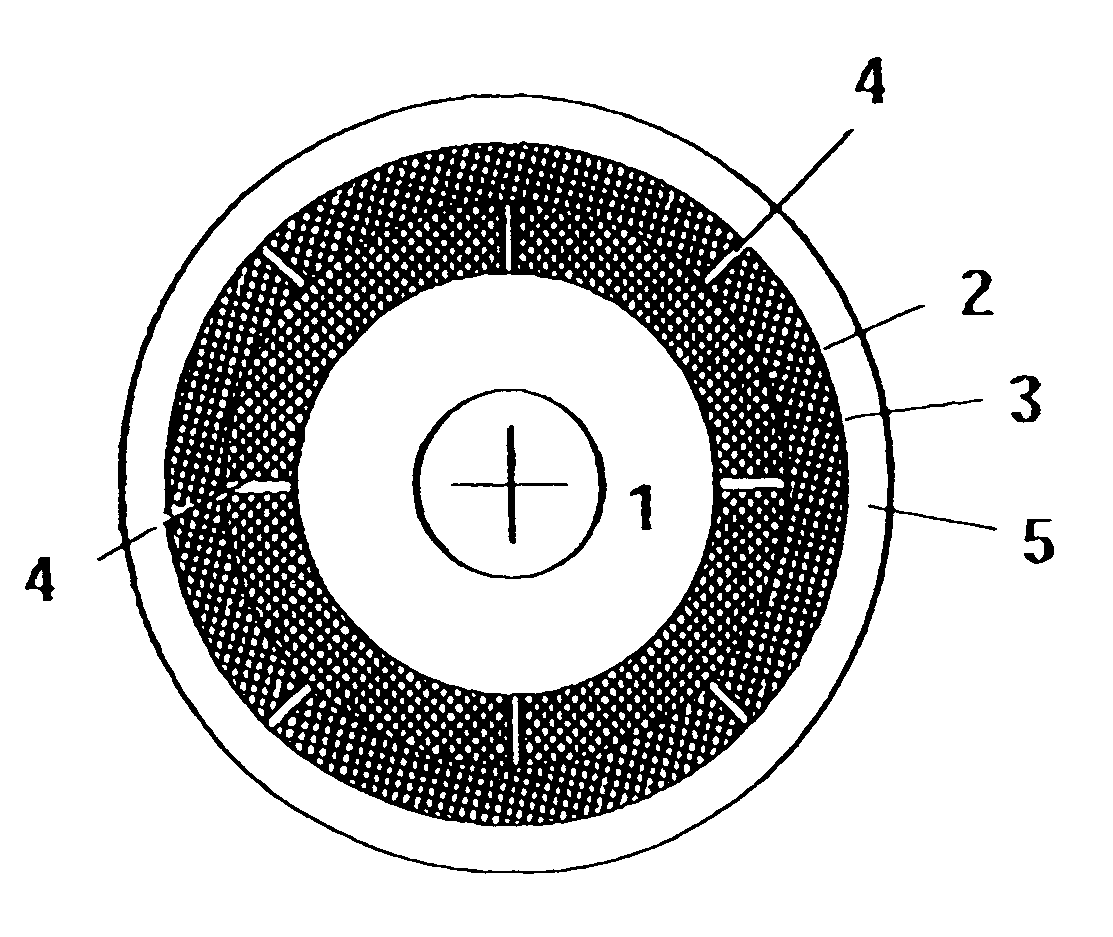

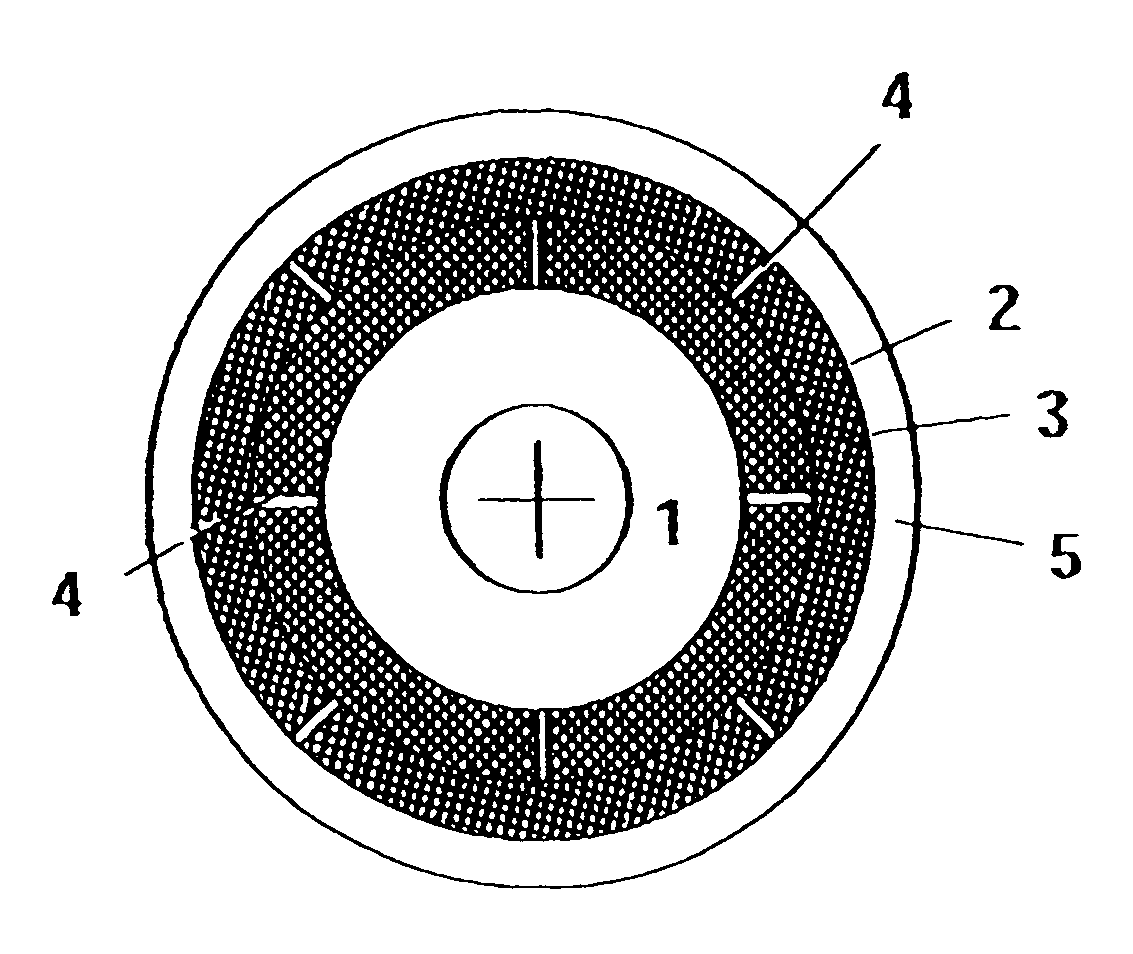

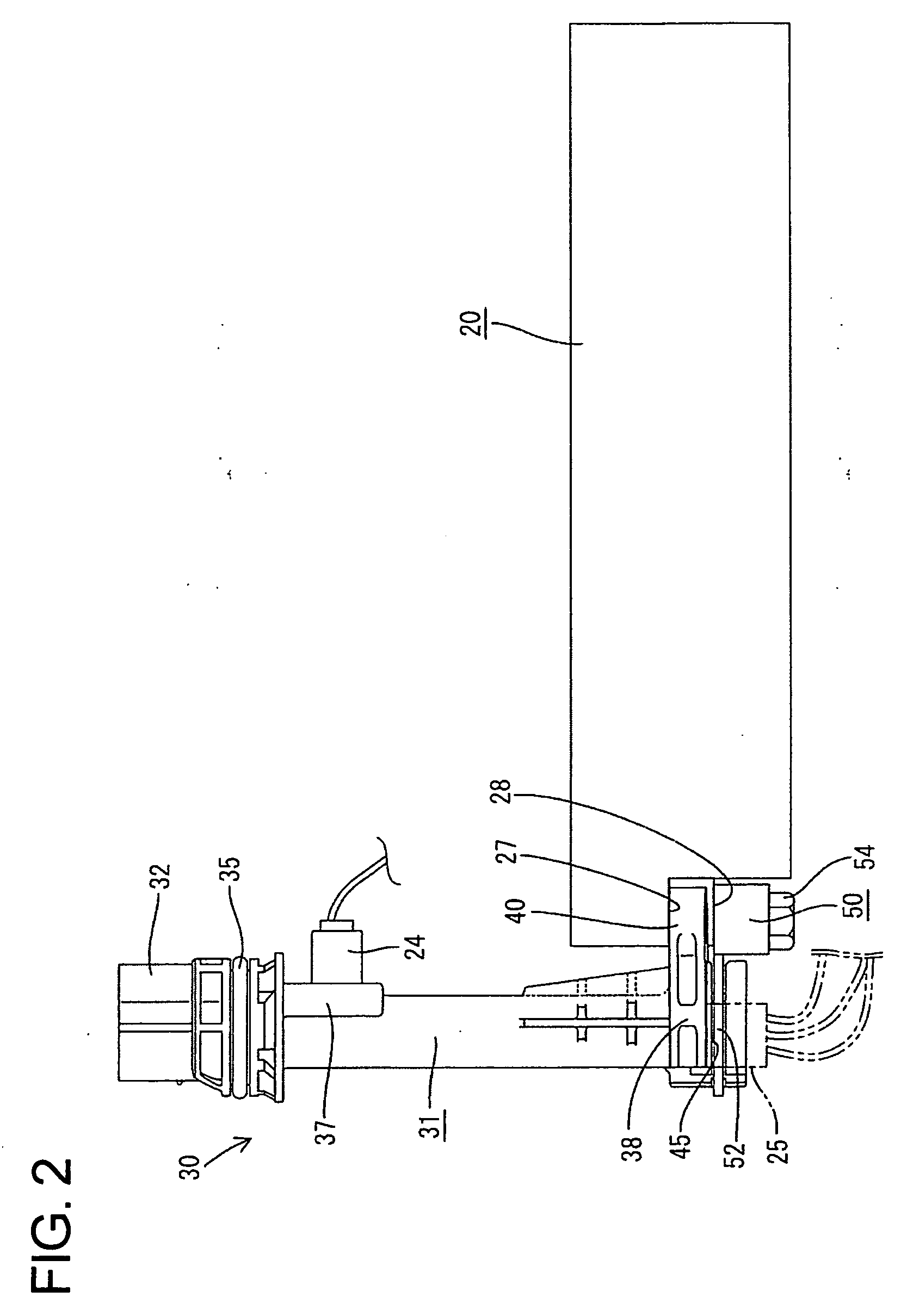

Magnetic bearing element

InactiveUS7872553B2Lower preloading of the binding bandsReduce gapShaftsPermanent magnetsEngineeringMagnetic bearing

The invention relates to a magnetic bearing element having at least one annular permanent magnet (2, 3) that is surrounded by an annular binding band (5), which element is characterized in that the permanent magnet (2, 3) is divided at least one location (4) and spaced apart there.

Owner:FORSCHUNGSZENTRUM JUELICH GMBH

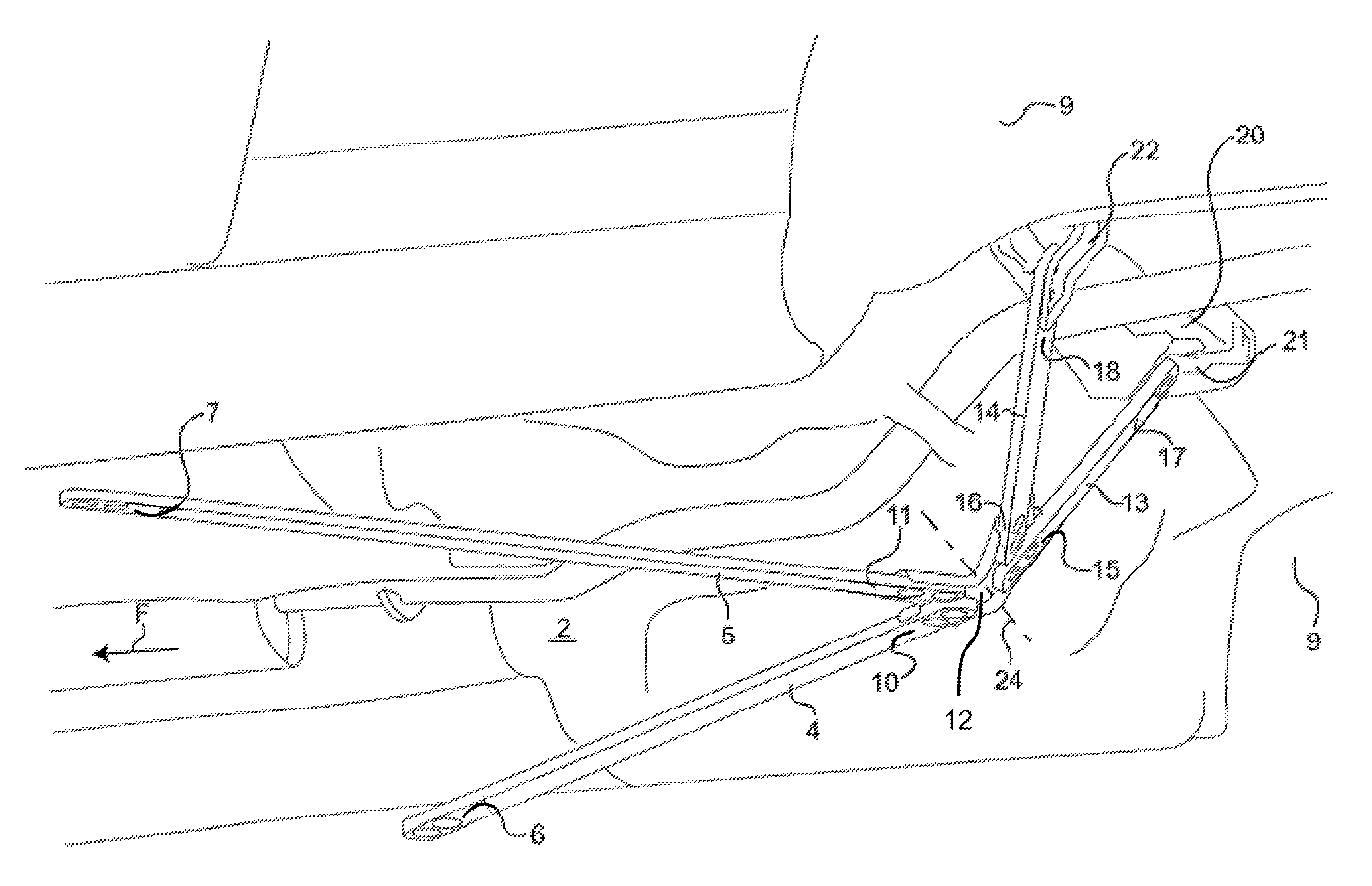

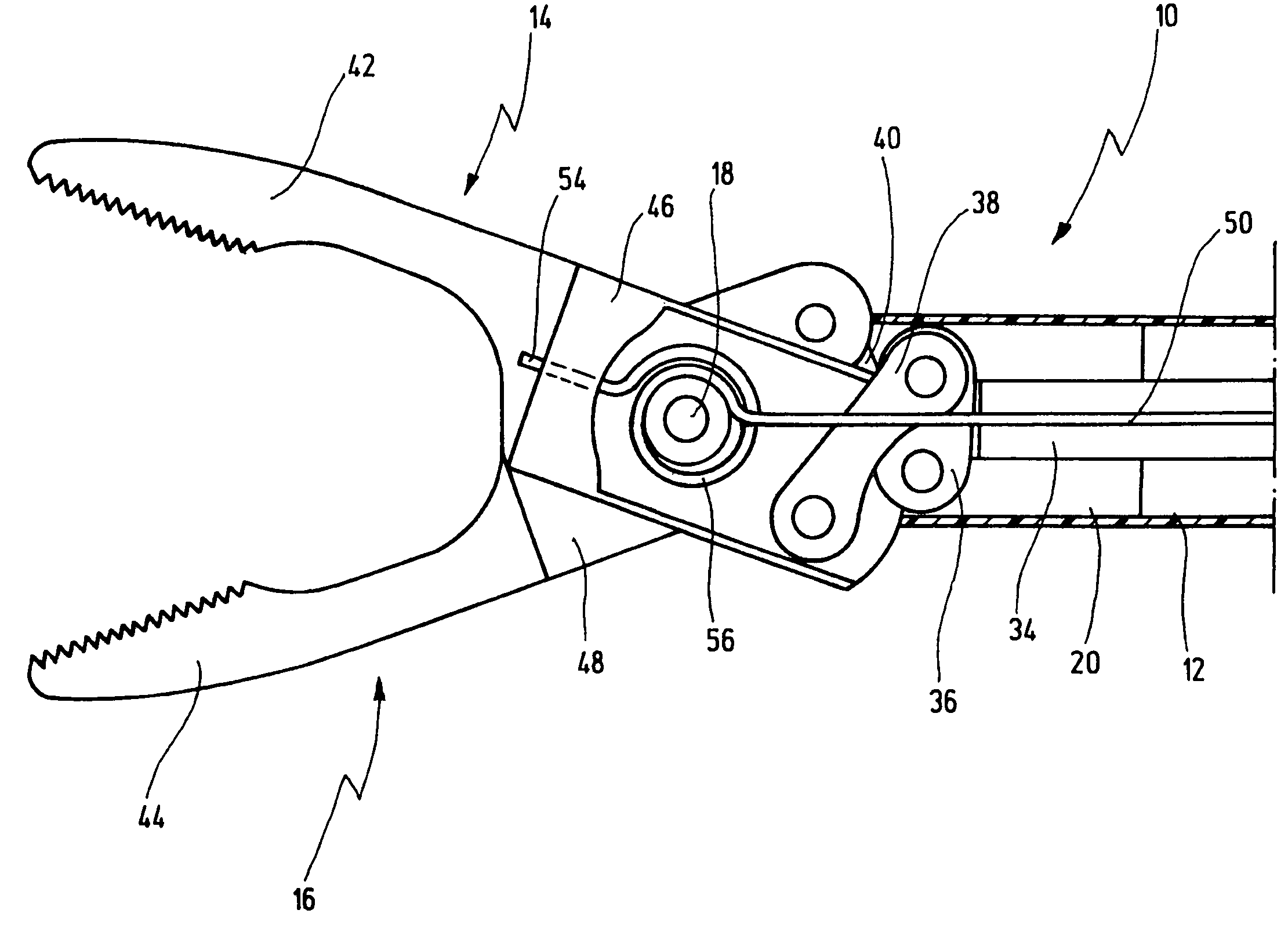

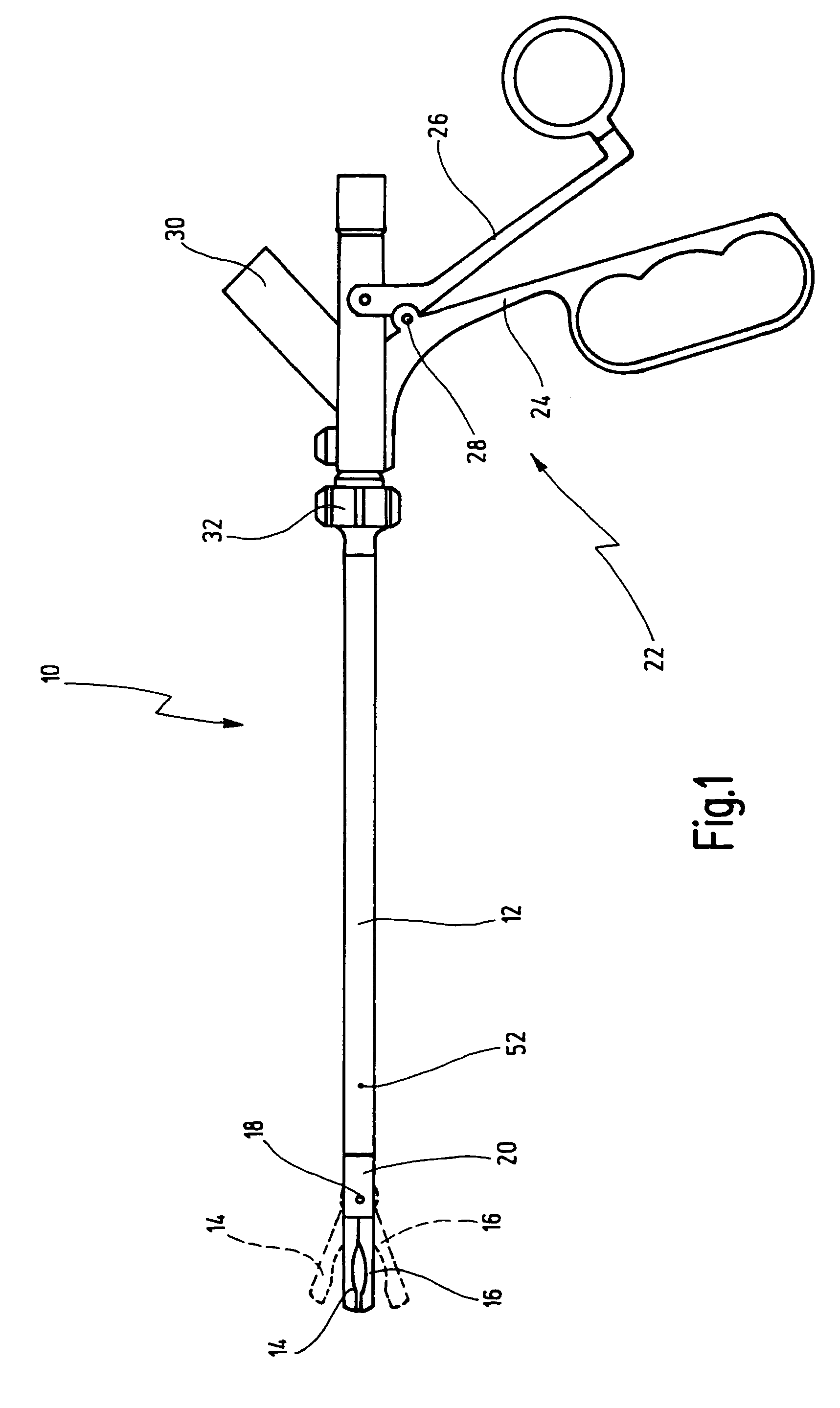

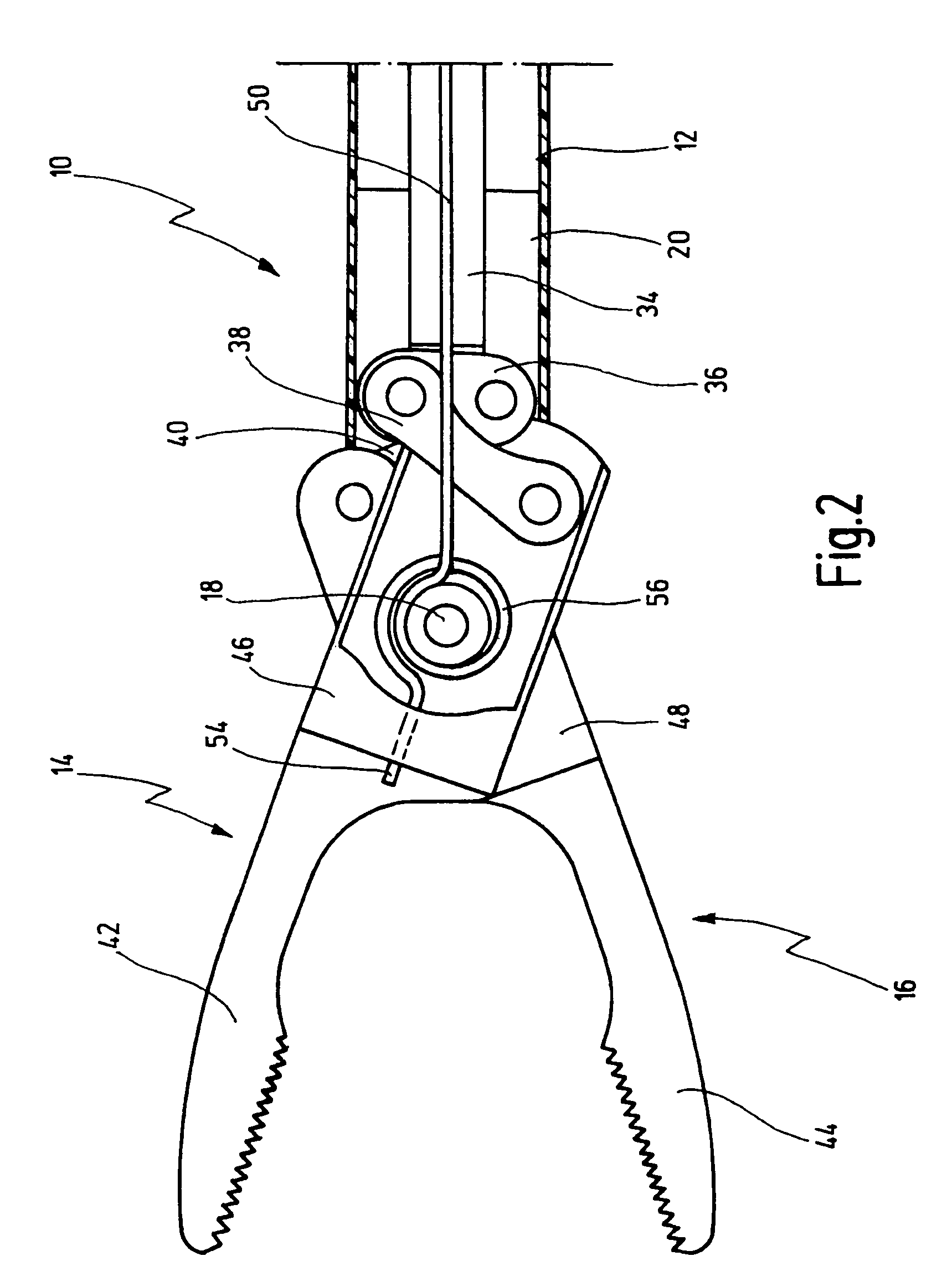

Medical instrument for electrosurgery

ActiveUS7553311B2Avoid bending stressAnimal housingSurgical instruments for heatingElectrosurgeryEngineering

A medical instrument for electrosurgery comprises a tubular shaft having a distal end and a proximal end, at least one jaw part arranged at the distal end of the shaft and movable relative to the tubular shaft about a pivot axis, at least one electrode arranged at the at least one jaw part, and at least one current supply line leading to the at least one electrode and designed as a wire-shaped element, a distal end of which being connected to the at least one electrode, the wire-shaped element being configured as a loop in the region of the pivot axis.

Owner:KARL STORZ GMBH & CO KG

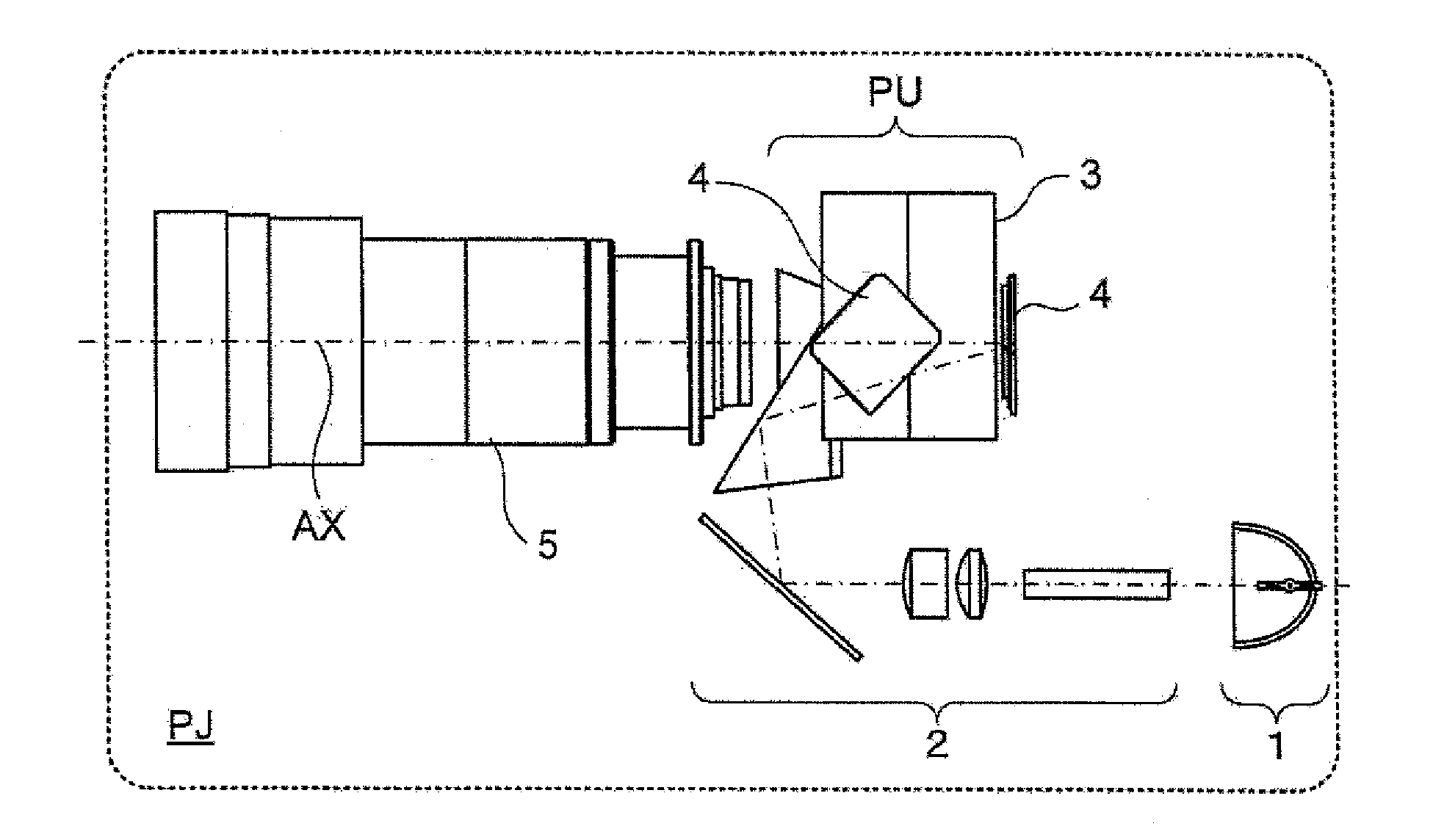

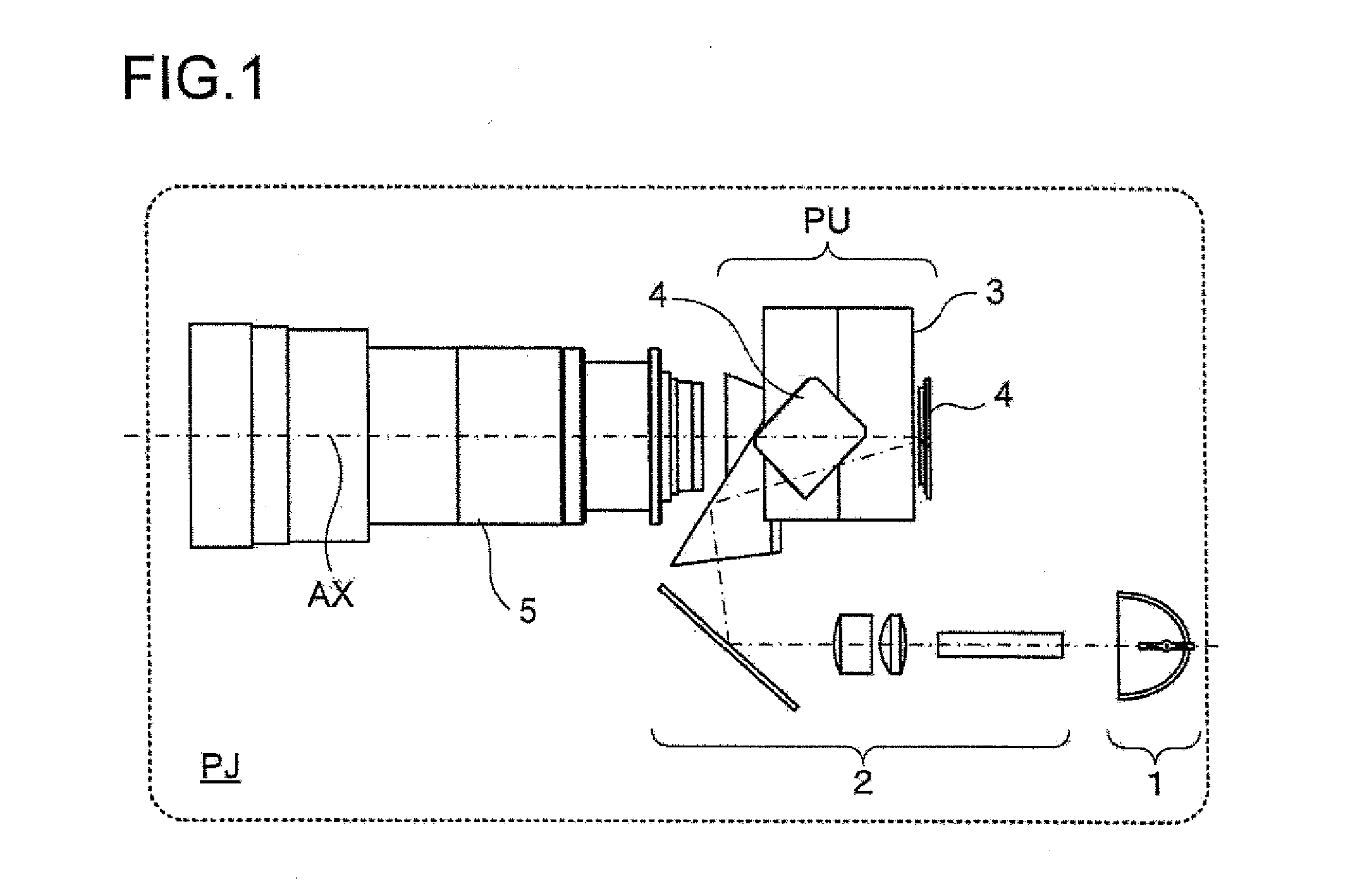

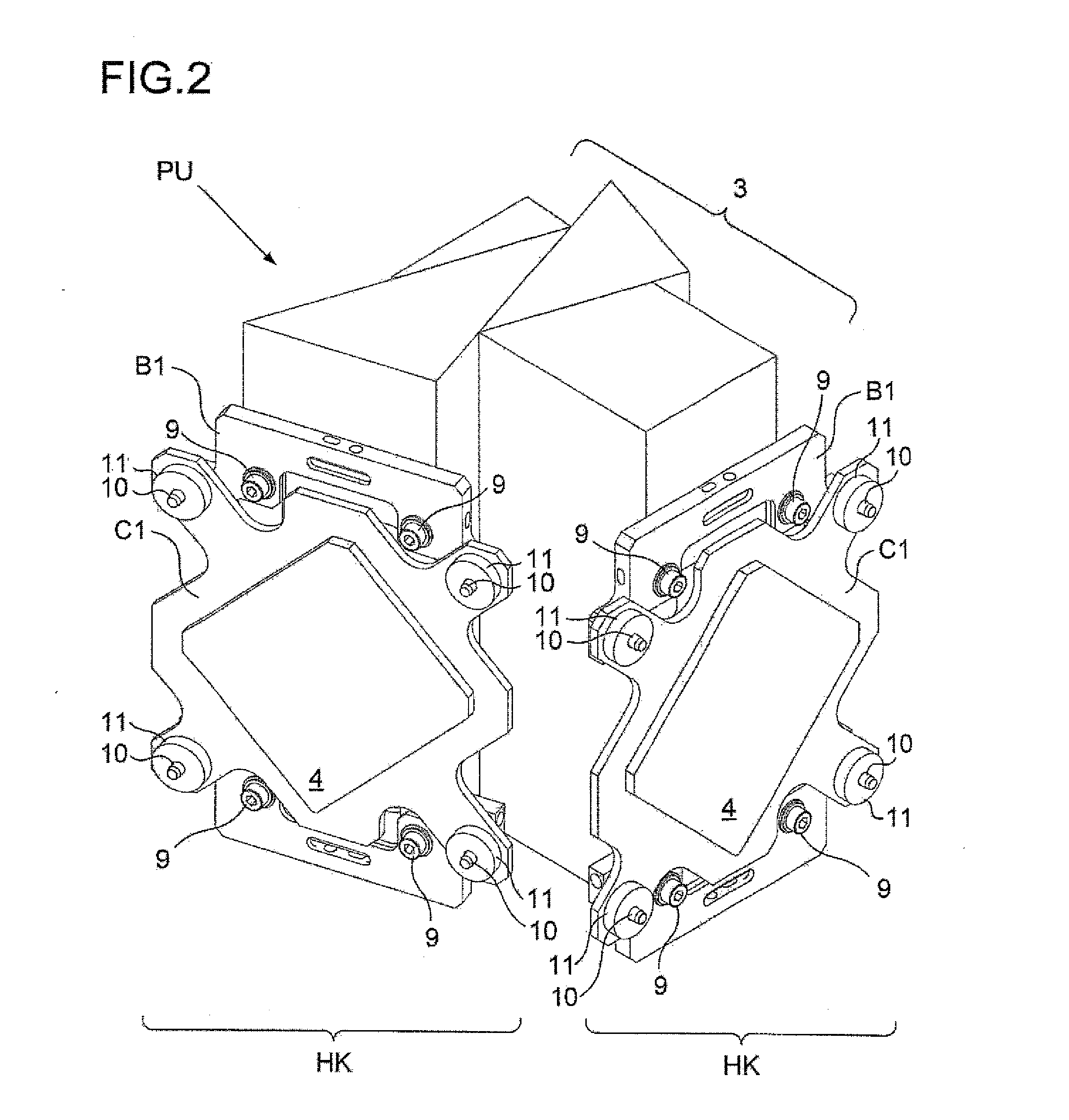

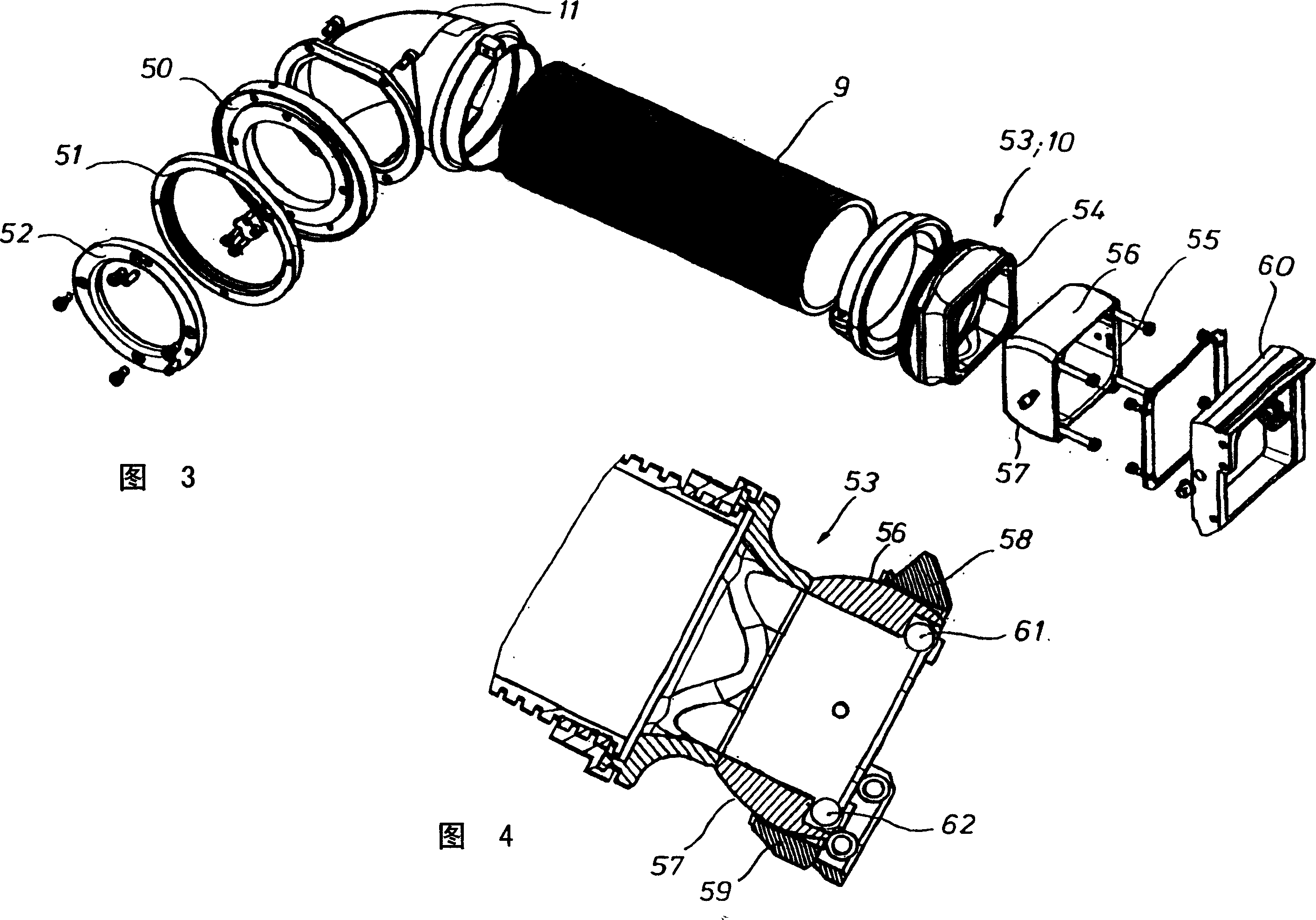

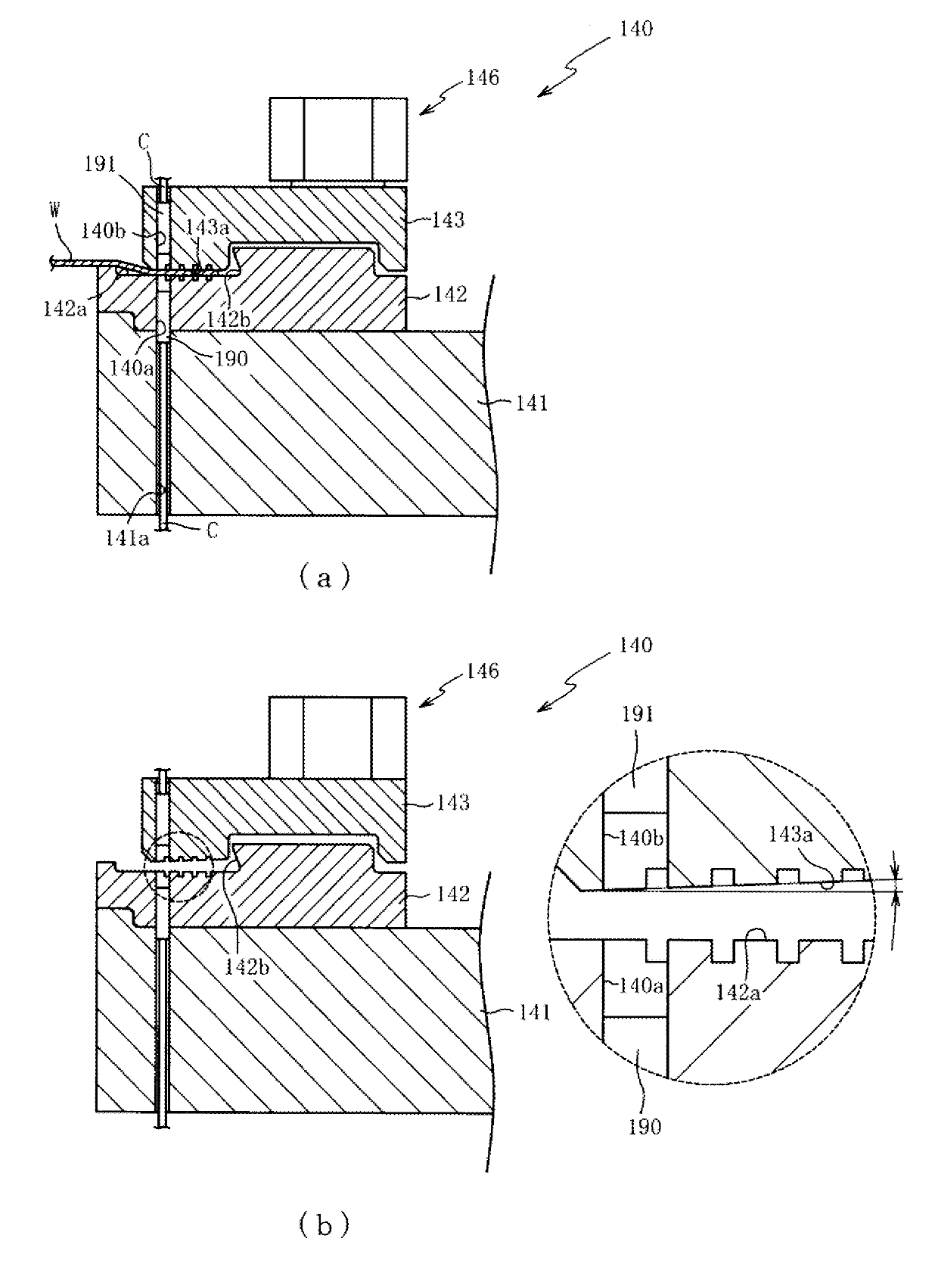

Image display element holding mechanism, prism unit, and projector

A holding mechanism for holding an image display element to a prism includes: a first fixing member fixed to the prism by an adhesive; and a second fixing member, which is fixed to the first fixing member using a screw, and which has the image display element directly or indirectly fixed to the second fixing member. A protruding section is provided at the periphery of a hole to be used for the purpose of fixing using the screw, and at the time of fixing the second fixing member to the first fixing member using the screw, the first fixing member and the second fixing member are directly or indirectly brought into contact with each other at the protruding section such that deformation due to screwing of the screw does not generate within a bonding region of the first fixing member.

Owner:KONICA MINOLTA INC

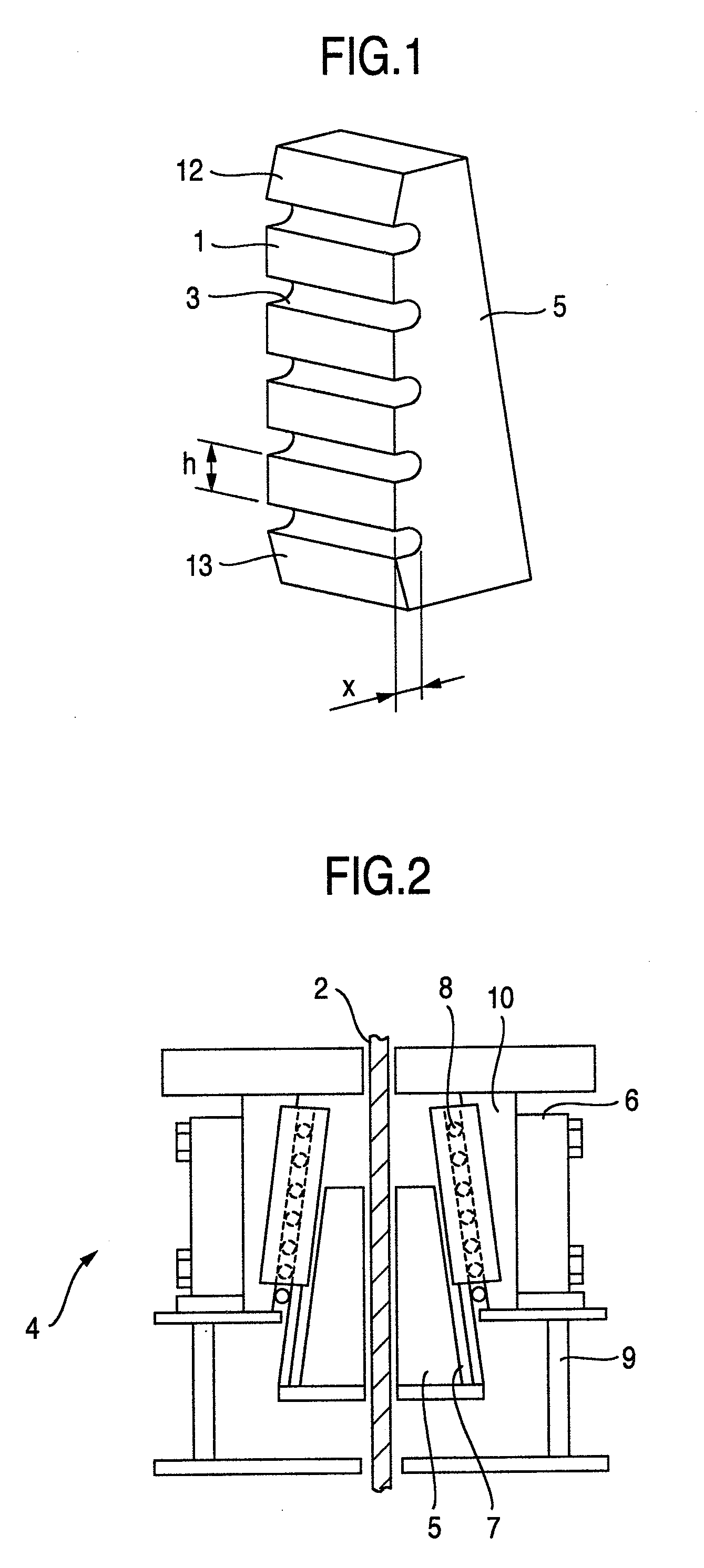

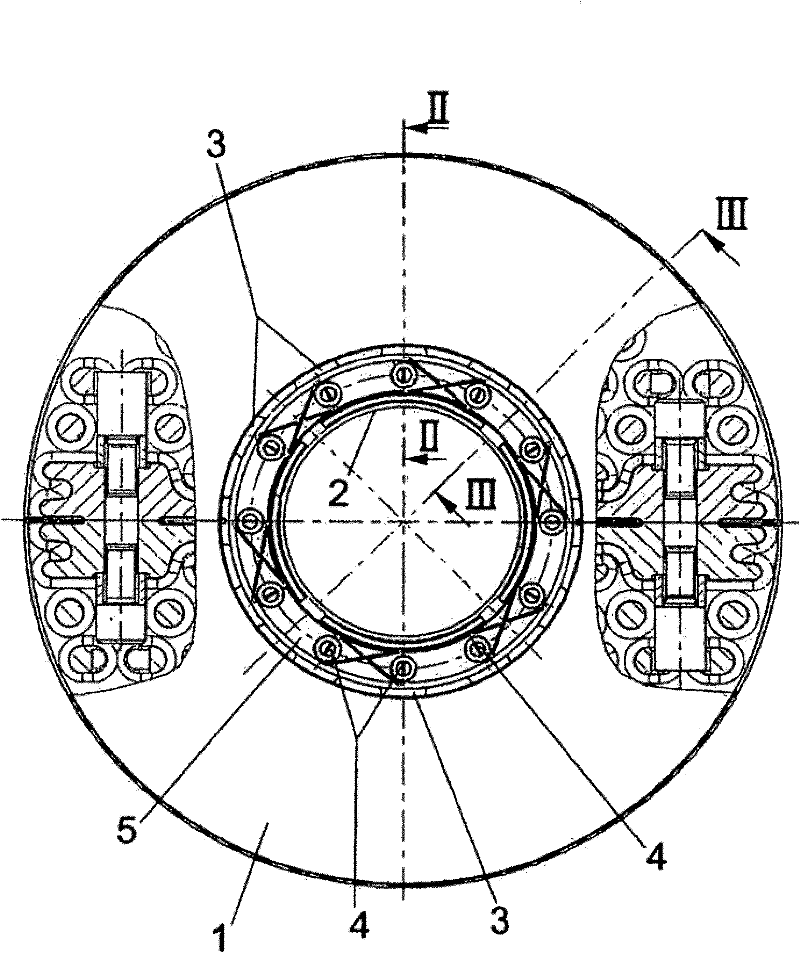

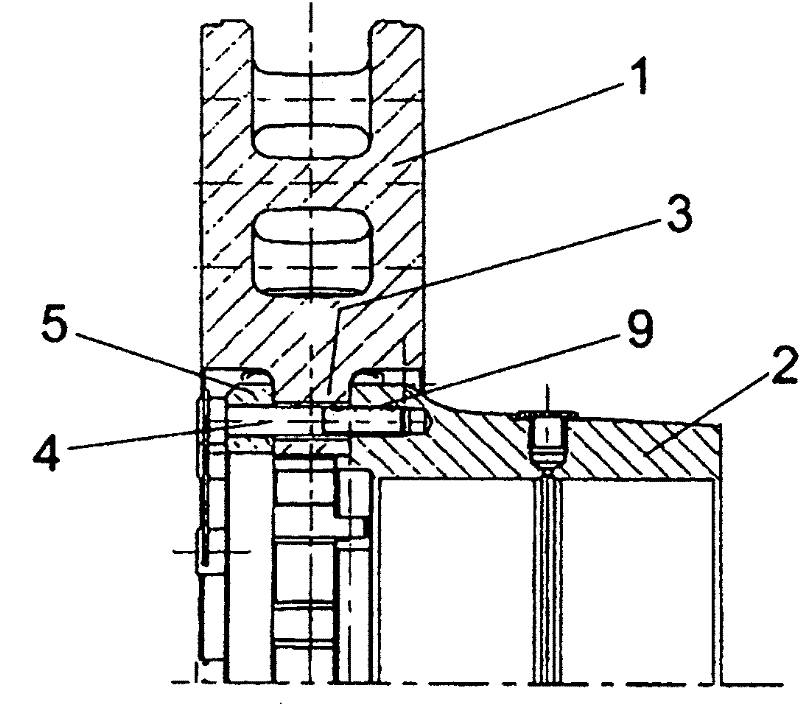

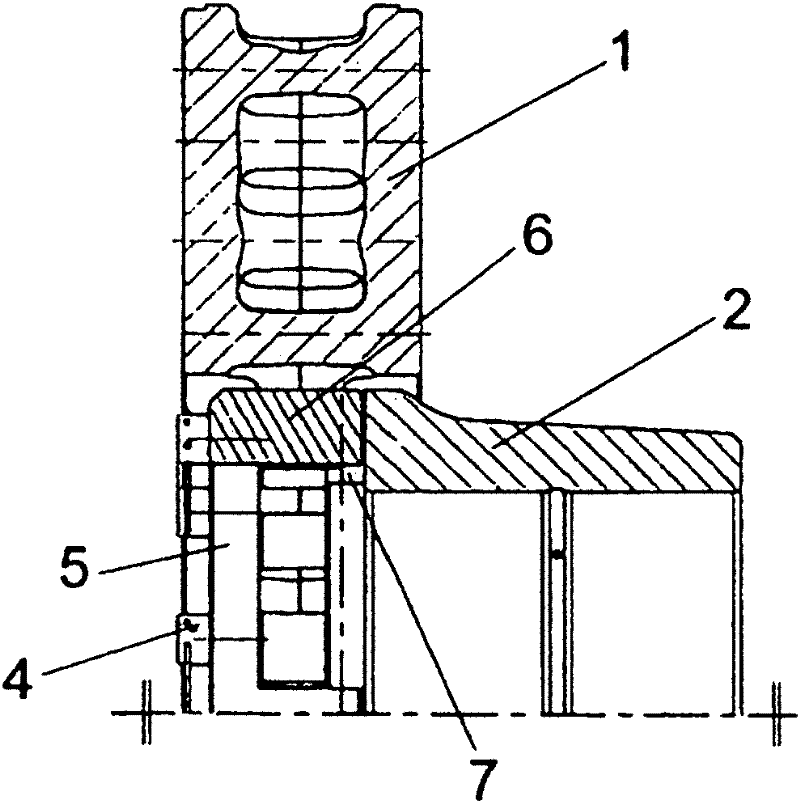

Shaft brake disc, in particular for a rail vehicle

A shaft brake disc, in particular for a rail vehicle, comprising a friction ring (1) fastened to a hub (2) by way of screws (4) that are passed through a clamp ring (5) at the inner periphery of the friction ring (1) that sits against support flanges, said clamp ring forming a backing support for the screws (4), is adapted so that the clamp ring (5) and the hub (2) engage one another in a form-fitted manner.

Owner:KNORR BREMSE SYST FUR SCHIENENFAHRZEUGE GMBH

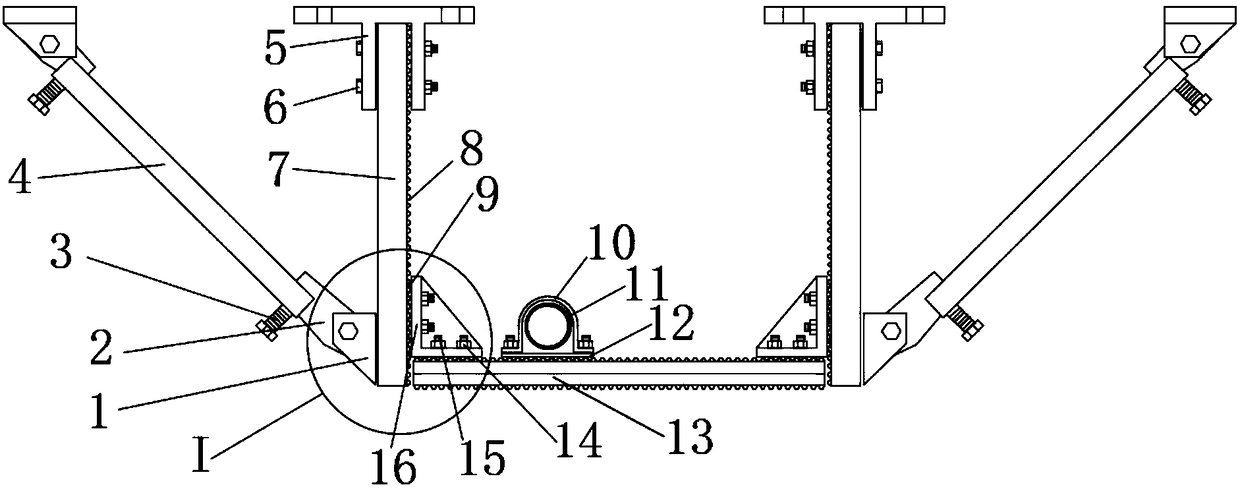

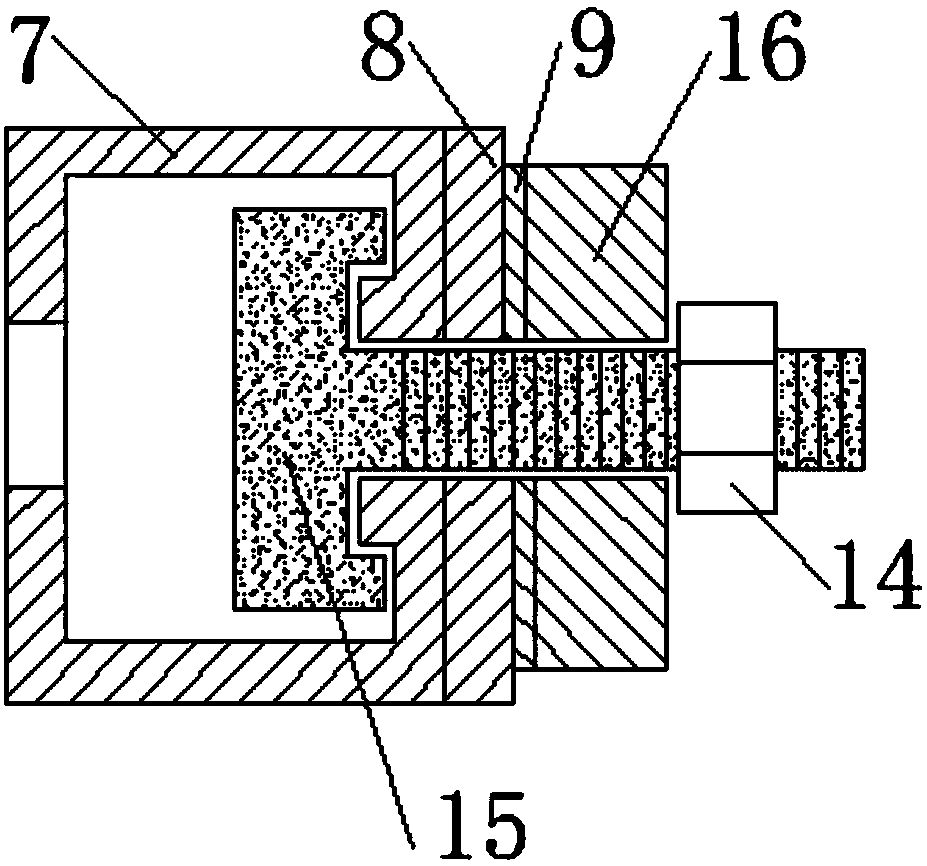

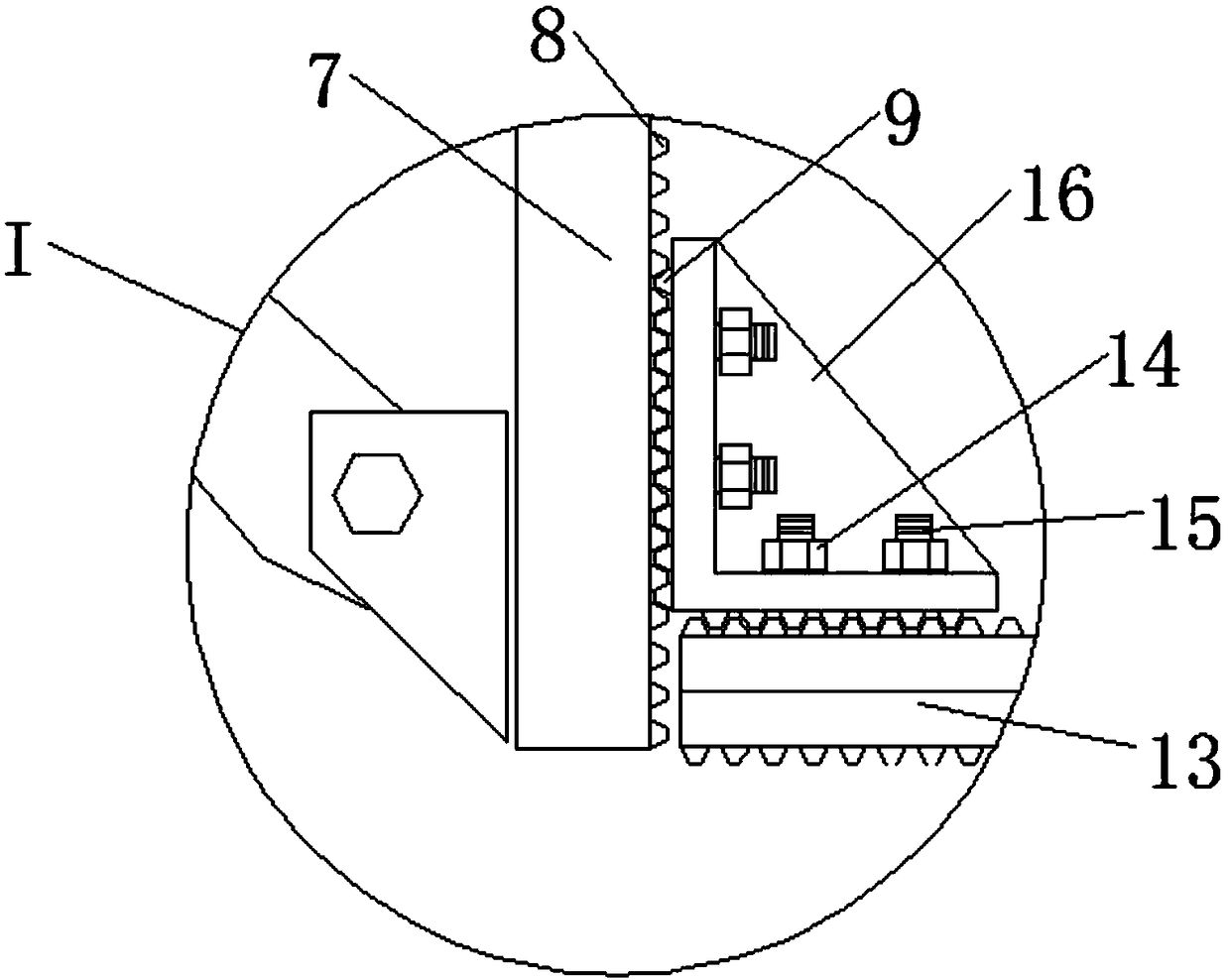

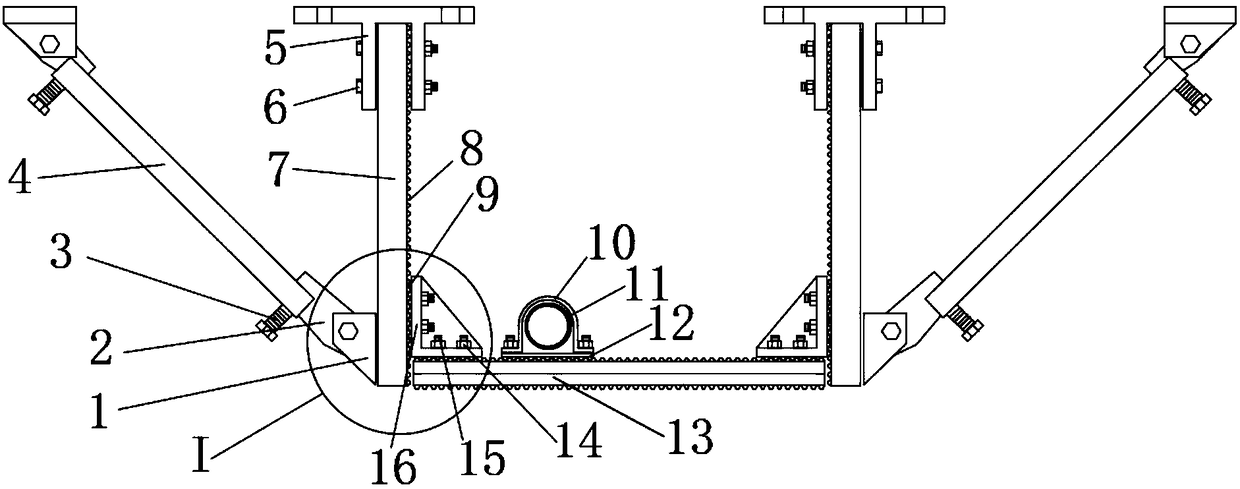

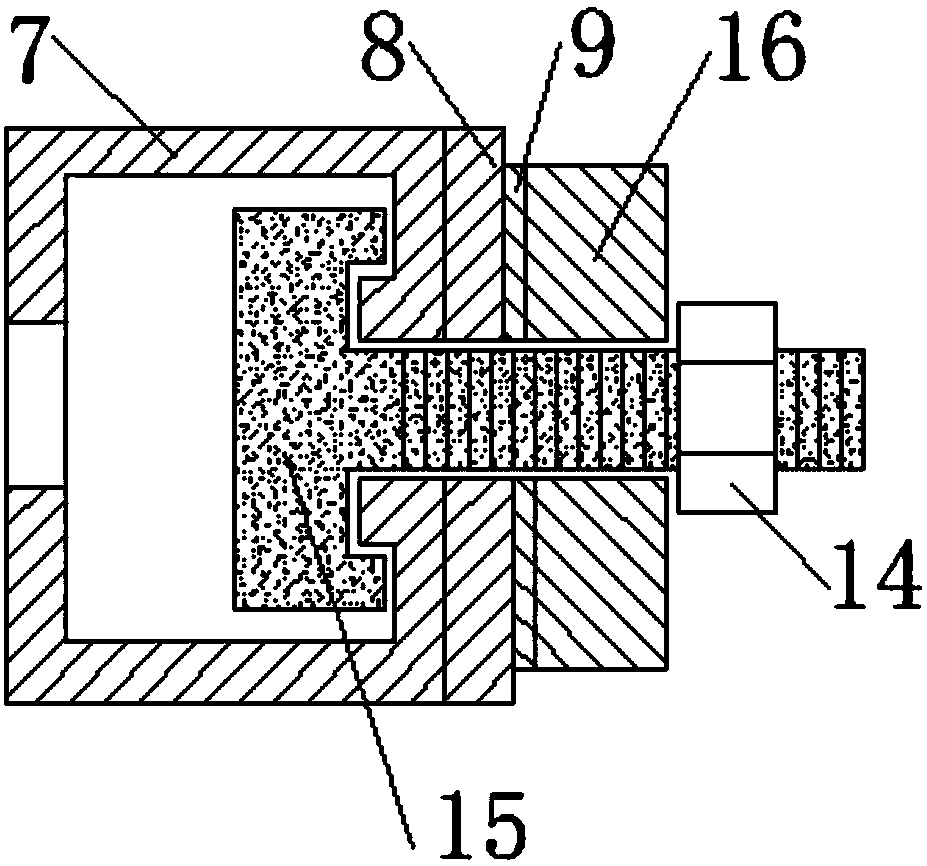

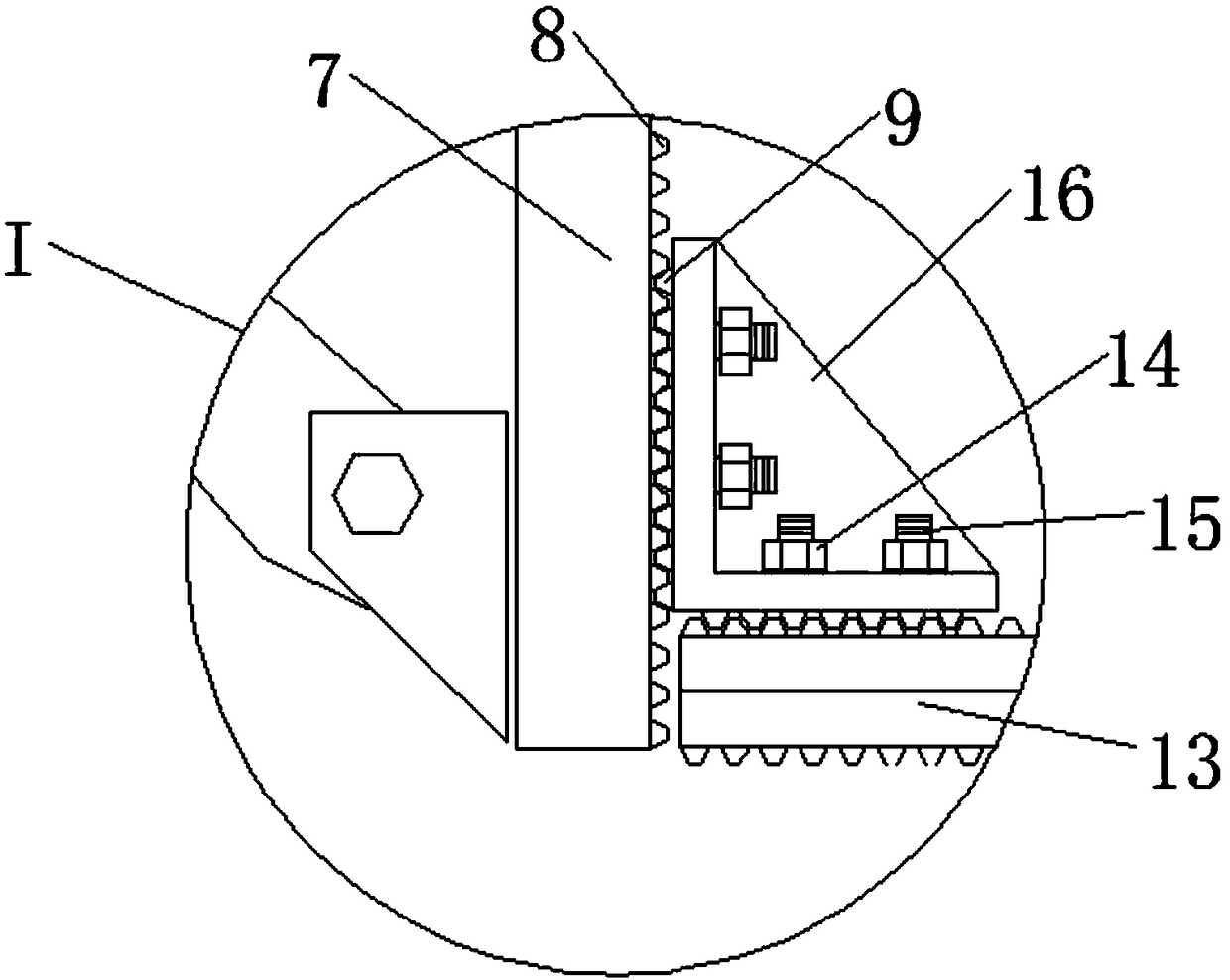

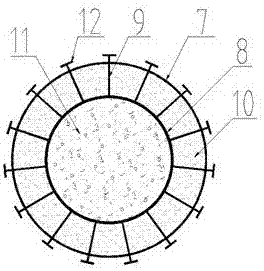

Anti-loose anti-seismic supporting hanging bracket for installing pipeline

InactiveCN108150720APrevent sideways movementGuaranteed locking forcePipe supportsNutsShock resistanceStructural engineering

The invention discloses an anti-loose anti-seismic supporting hanging bracket for installing a pipeline. The anti-loose anti-seismic supporting hanging bracket comprises first channel steel bases, hinges, first screws, channel steel connecting rods, second channel steel bases, anti-loose bolts, single-side channel steel, first racks, second racks, a U-shaped fixing part, a pipeline, a bottom plate, double-spliced channel steel, nuts, second screws and fixing and connecting pieces. The supporting hanging bracket has the advantages of being simple in structure, the first racks and the second racks are arranged so that after the fixing and connecting pieces are installed on the single-face channel steel, locking force between the single-face channel steel and the fixing and connecting piecescan be effectively guaranteed, the fixing and connecting pieces are prevented from laterally moving when being stressed, and therefore shock resistance of the anti-seismic supporting hanging bracket is effectively improved; the first racks are arranged on the side surfaces of the single-face channel steel so that the mutual position between the single-sided steel channel and the fixing and connecting pieces can be continuously adjusted, the double-spliced channel steel on the adjacent anti-seismic supporting hanging bracket can be adjusted to the same horizontal height during installation, andtherefore bending stress is prevented when the pipeline is fixed, and the stability of supporting of the anti-seismic supporting hanging bracket is facilitated; and the anti-loose bolts are arrangedso that the anti-loose performance of the anti-seismic supporting hanging bracket can be greatly improved.

Owner:JIANGSU YIDINGGU ELECTROMECHANICAL TECH CO LTD

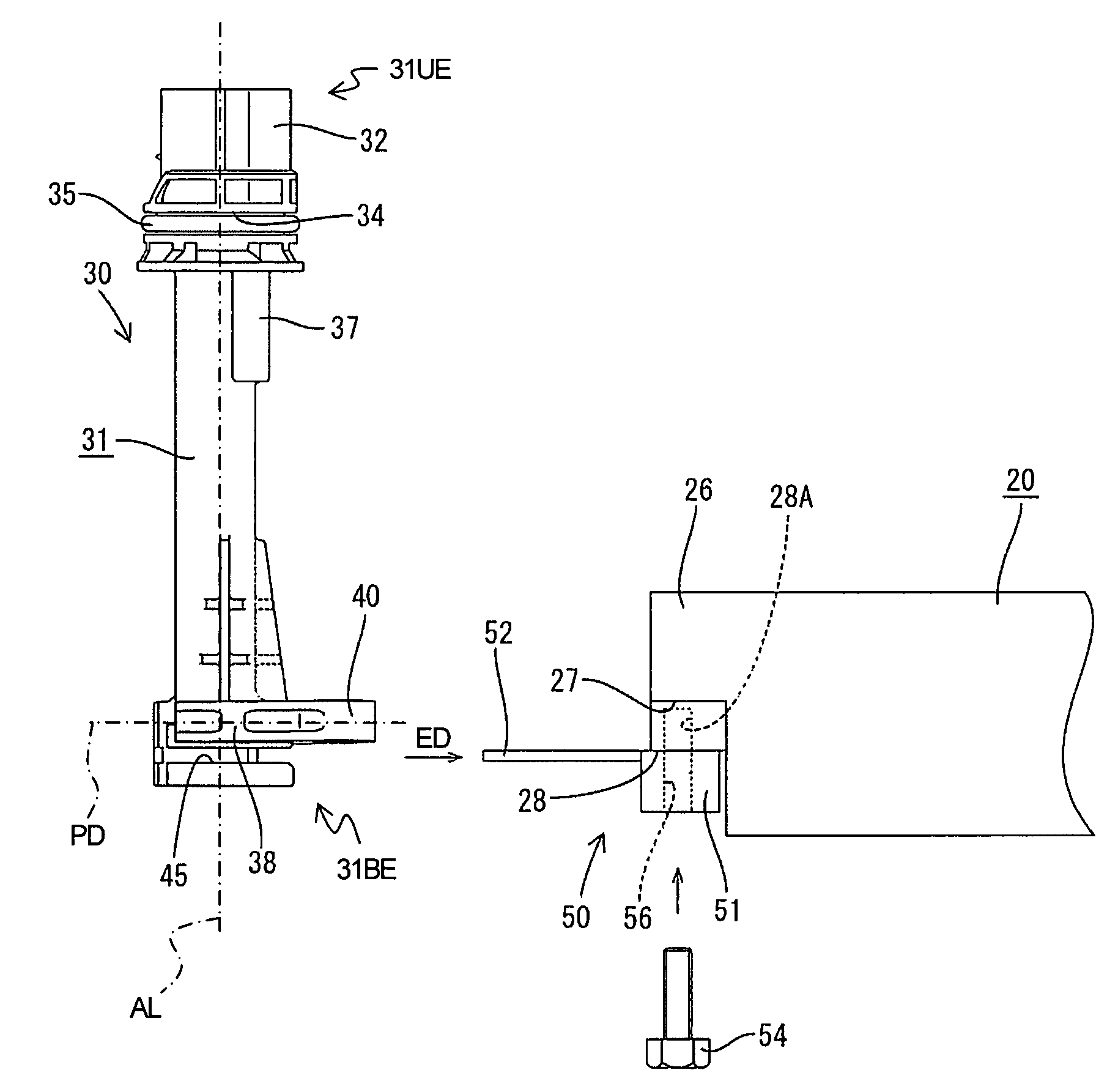

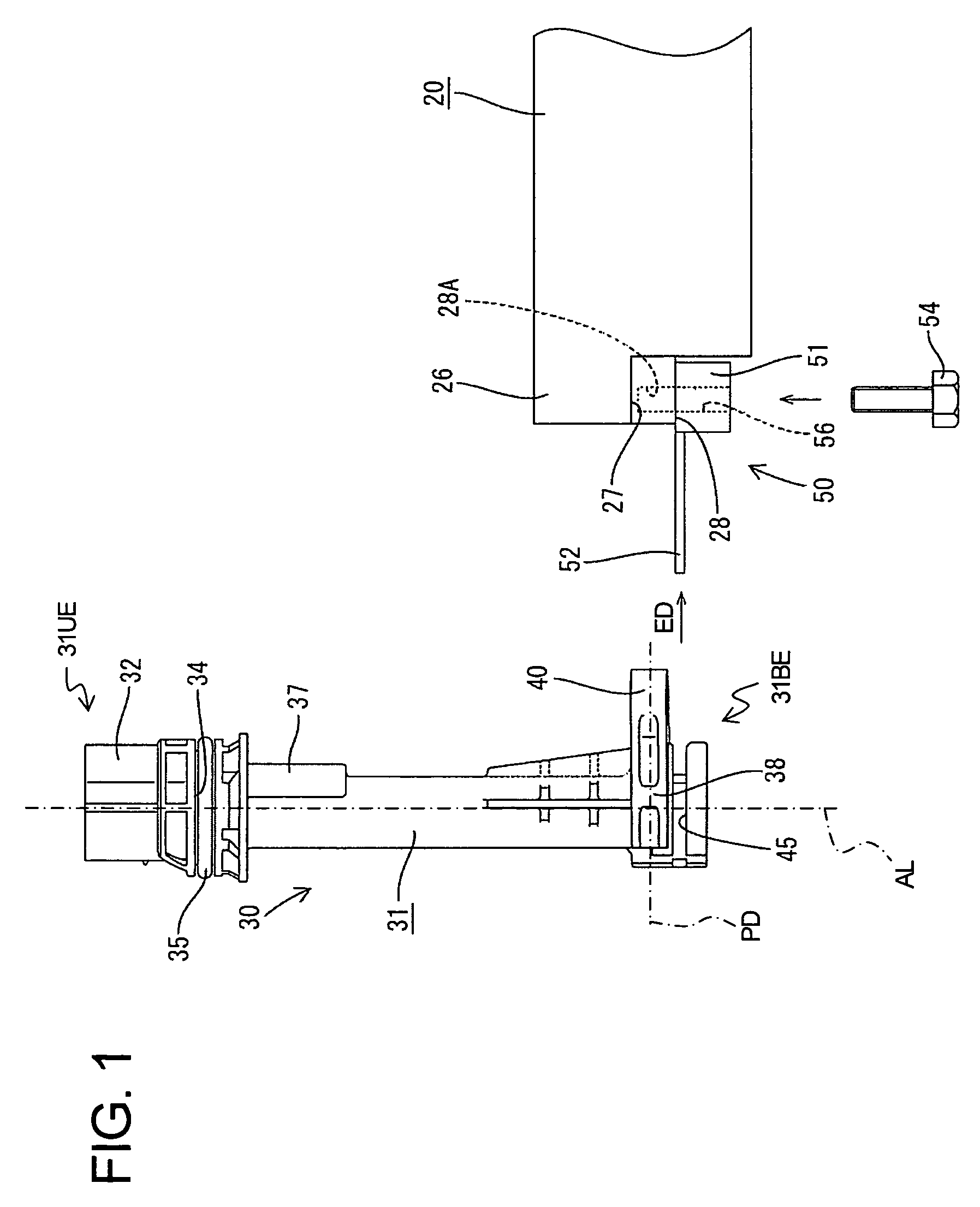

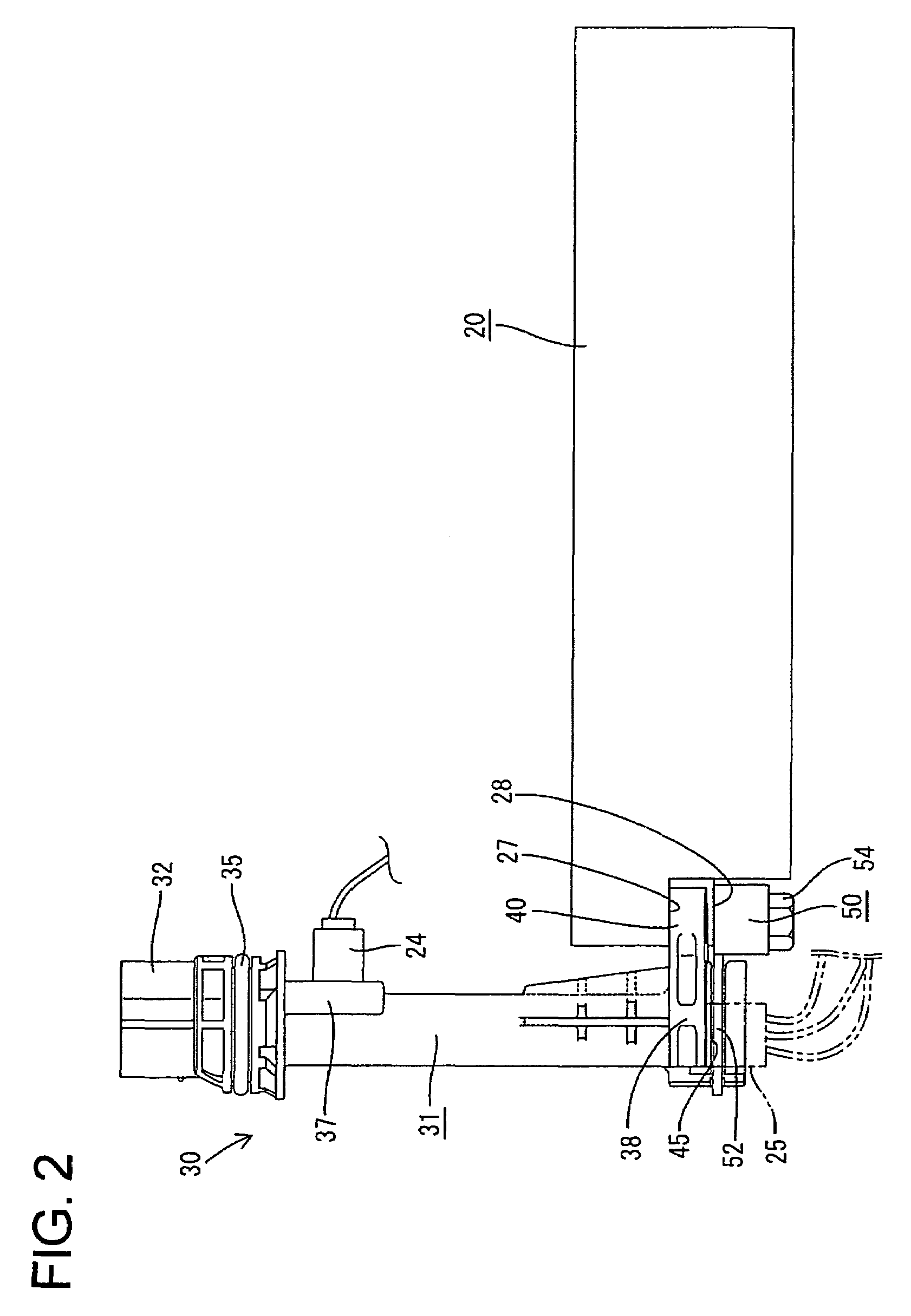

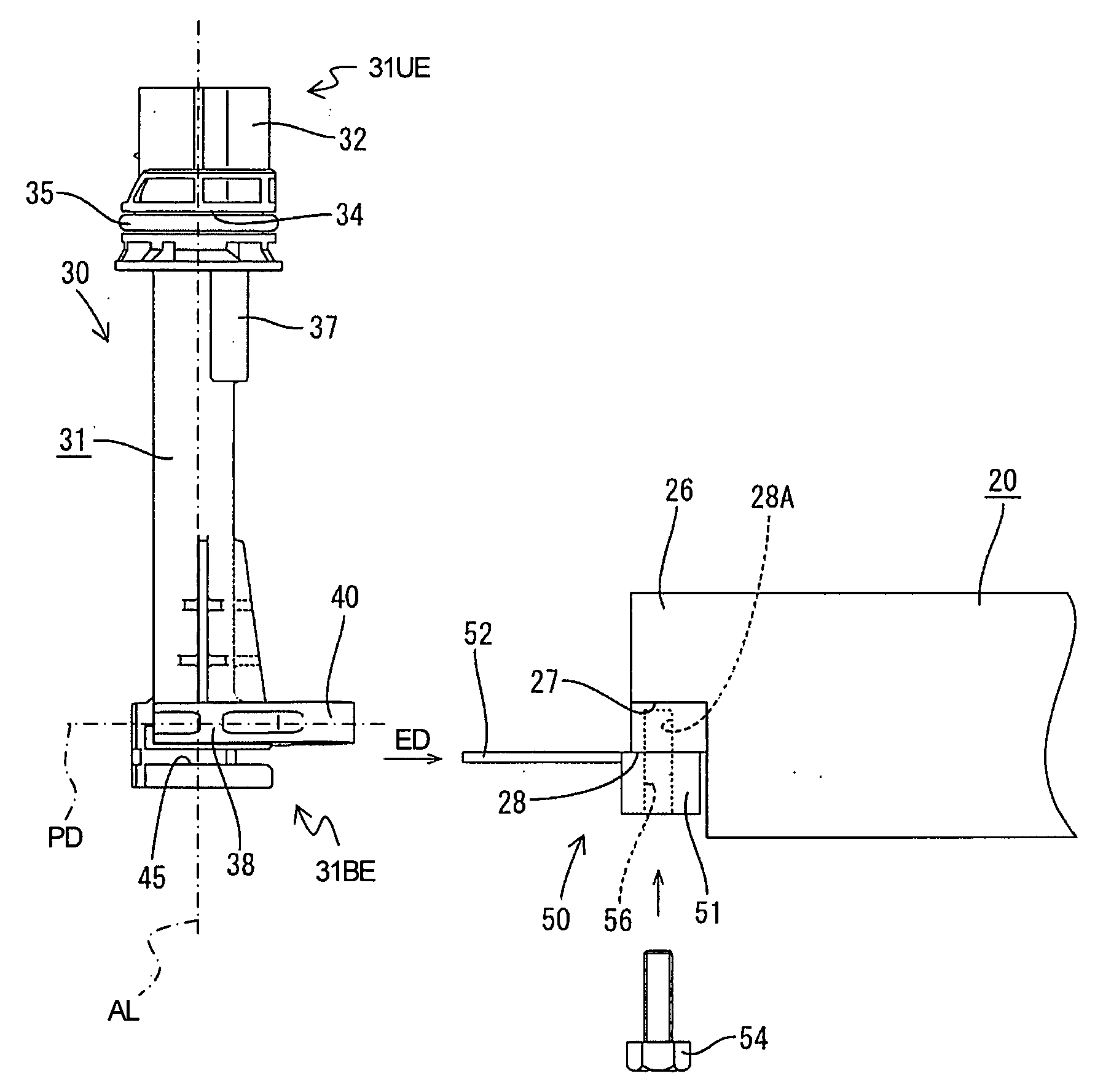

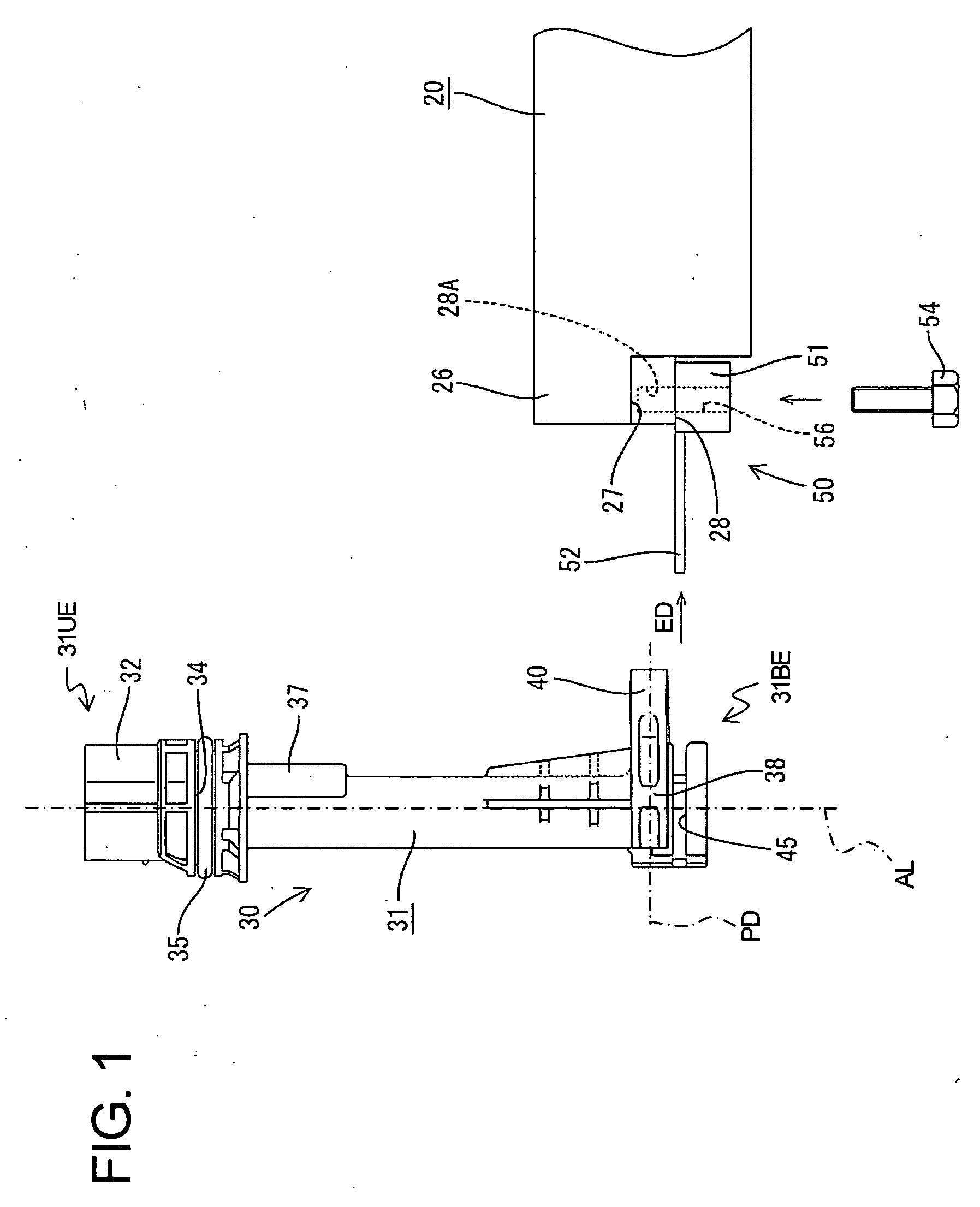

Connector mounting construction and method

ActiveUS7338297B2Avoid bending stressLarge deviationModulation transference balanced arrangementsPrinted circuitsLocking plateBuilding construction

An upper end of a housing (31) is fit into a fitting hole (17) in a lid (12), and a fastenable portion (40) projects horizontally from a bottom end of the housing (31). A bolt (41) is inserted vertically through an insertion hole (42) in the fastenable portion (40) and is screwed into a bolt hole (27A) of a valve body (20) on the lid (12). An engaging groove (45) is formed near the bottom of the housing (31). A U-shaped locking plate (52) projects from the valve body (20) and is inserted into the engaging groove (45) with a clearance that permits movements of the housing (31) along directions intersecting an axis line of the housing (31) while preventing movements of the housing along the axis line. The bolt (41) is insertable into the insertion hole (42) of the fastening portion (40) while defining a clearance.

Owner:SUMITOMO WIRING SYST LTD

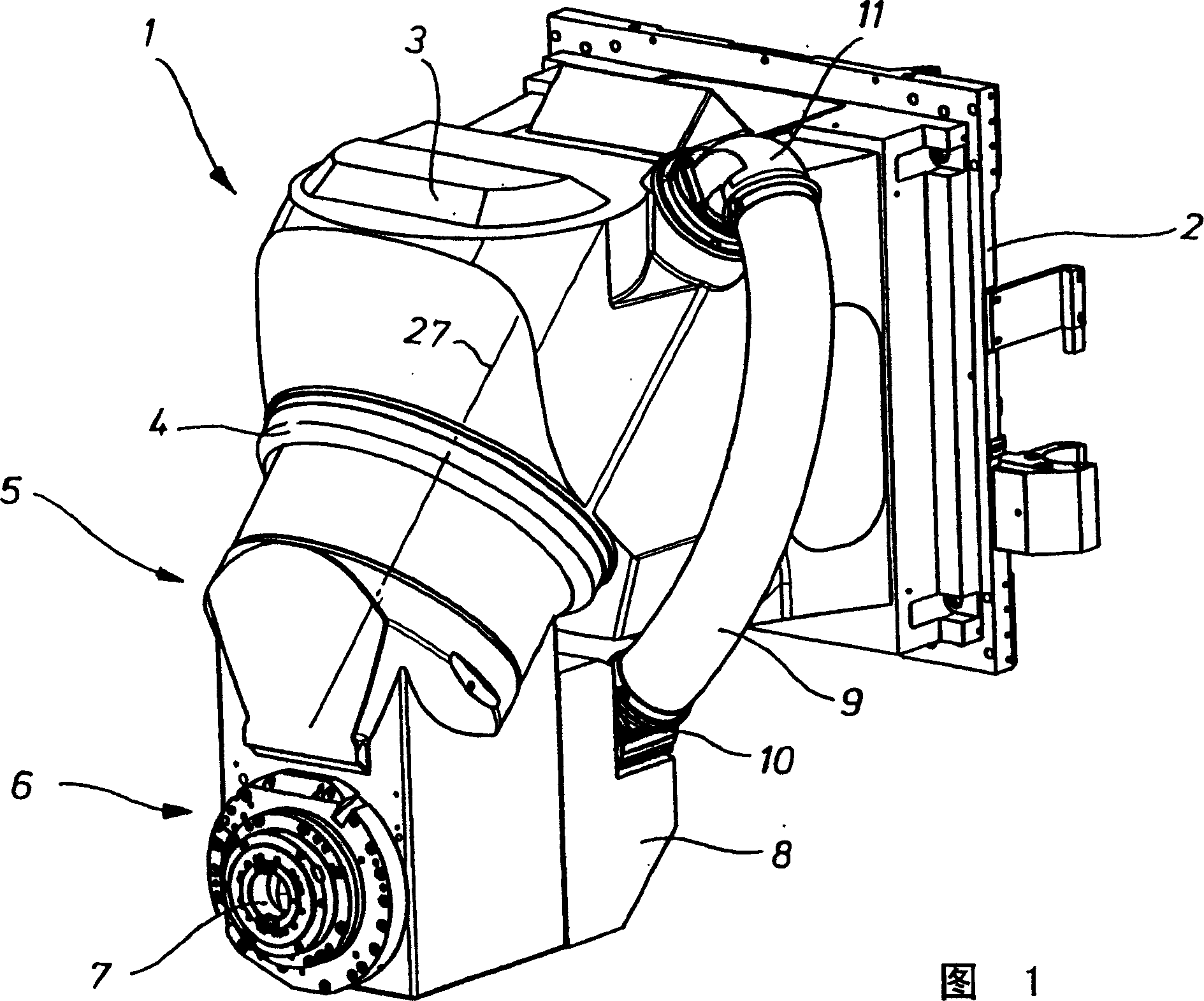

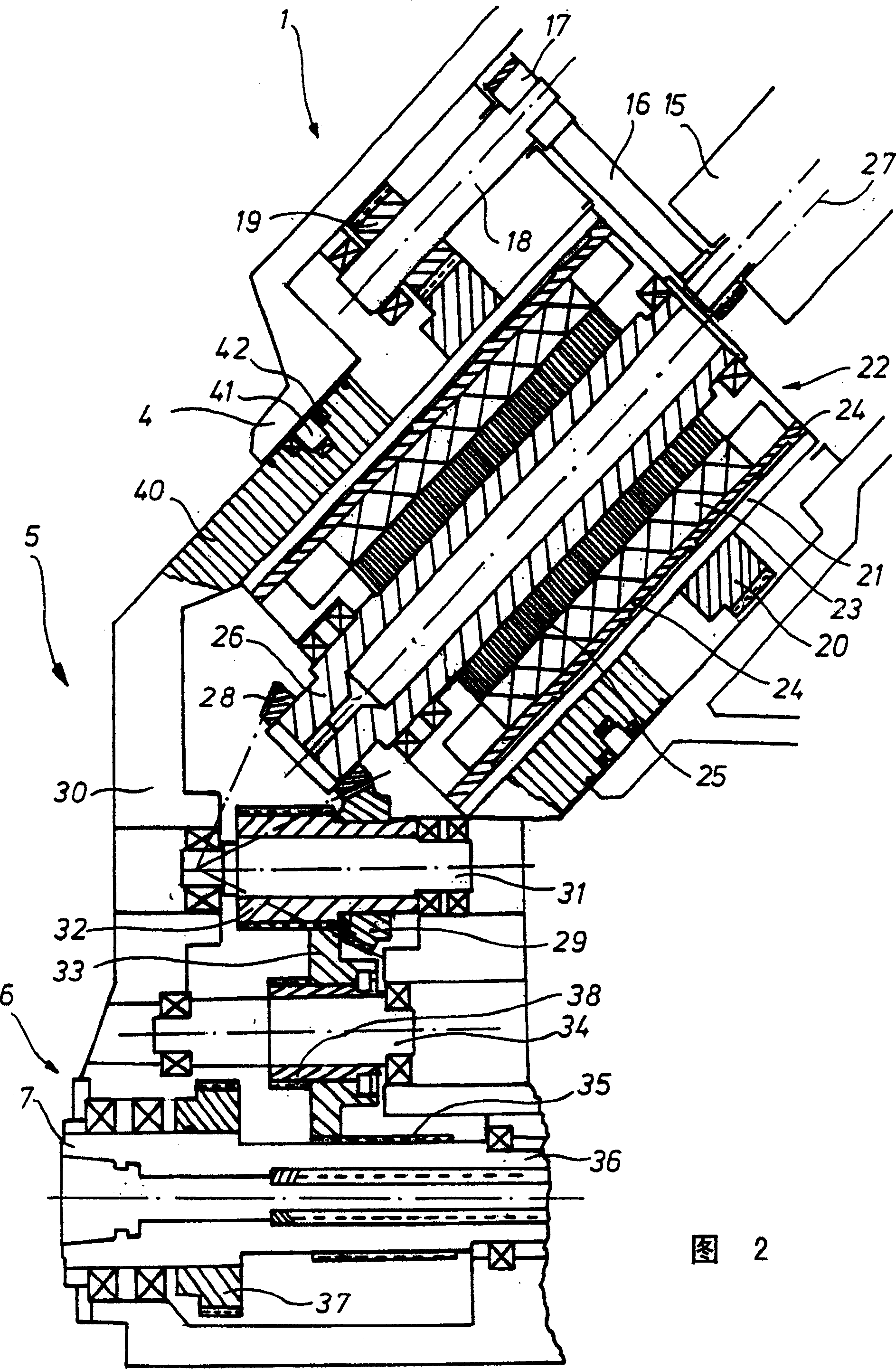

Working unit for programme-controlled milling and boring machines

InactiveCN1500590AIncrease cutting powerPrecise positioningGearboxesToothed gearingsWork unitEngineering

The pivot head (5) includes a cylindrical casing section (40) extending coaxial to the pivot head rotation axis (27) and having a spindle motor (22) secured inside it. The head support (1) includes a casing extension (4) in which the cylindrical casing section is rotatably mounted. The head support can be moved along various coordinate axes and contains a 45 deg. rotation axis extending downwards in the forwards direction. The pivot head is mounted on one of the faces of the head support and is rotatable about the 45 deg. axis via a motor. A spindle head (6) fixed to the pivot head is connected to a spindle (7) extending at an angle of 45 deg. relative to the pivot head rotation axis. The spindle motor extends coaxial to the pivot head rotation axis. An angle gear mechanism (28, 29) for the spindle drive is located inside the pivot head.

Owner:DECKEL MAHO PFRONTEN GMBH

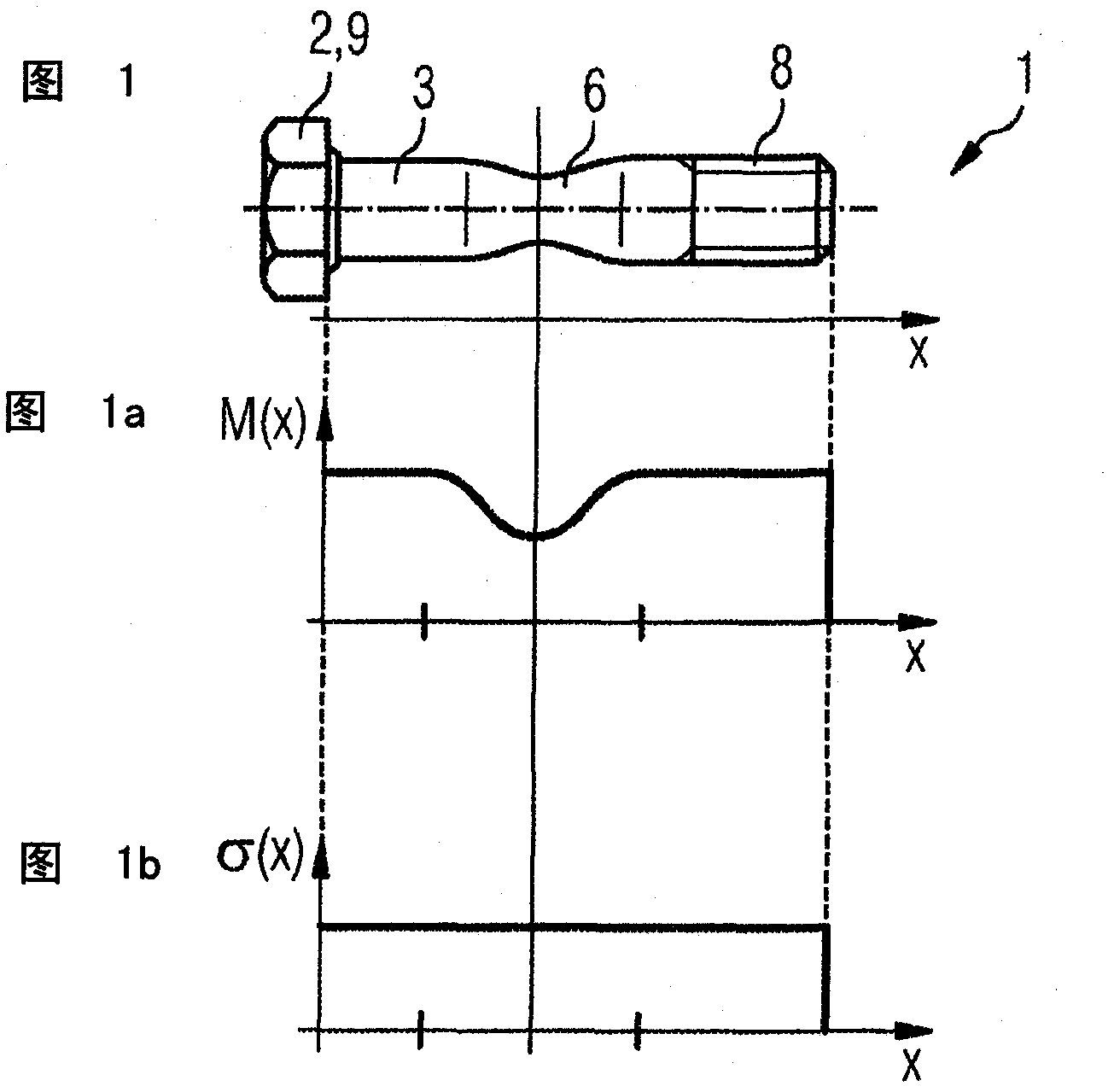

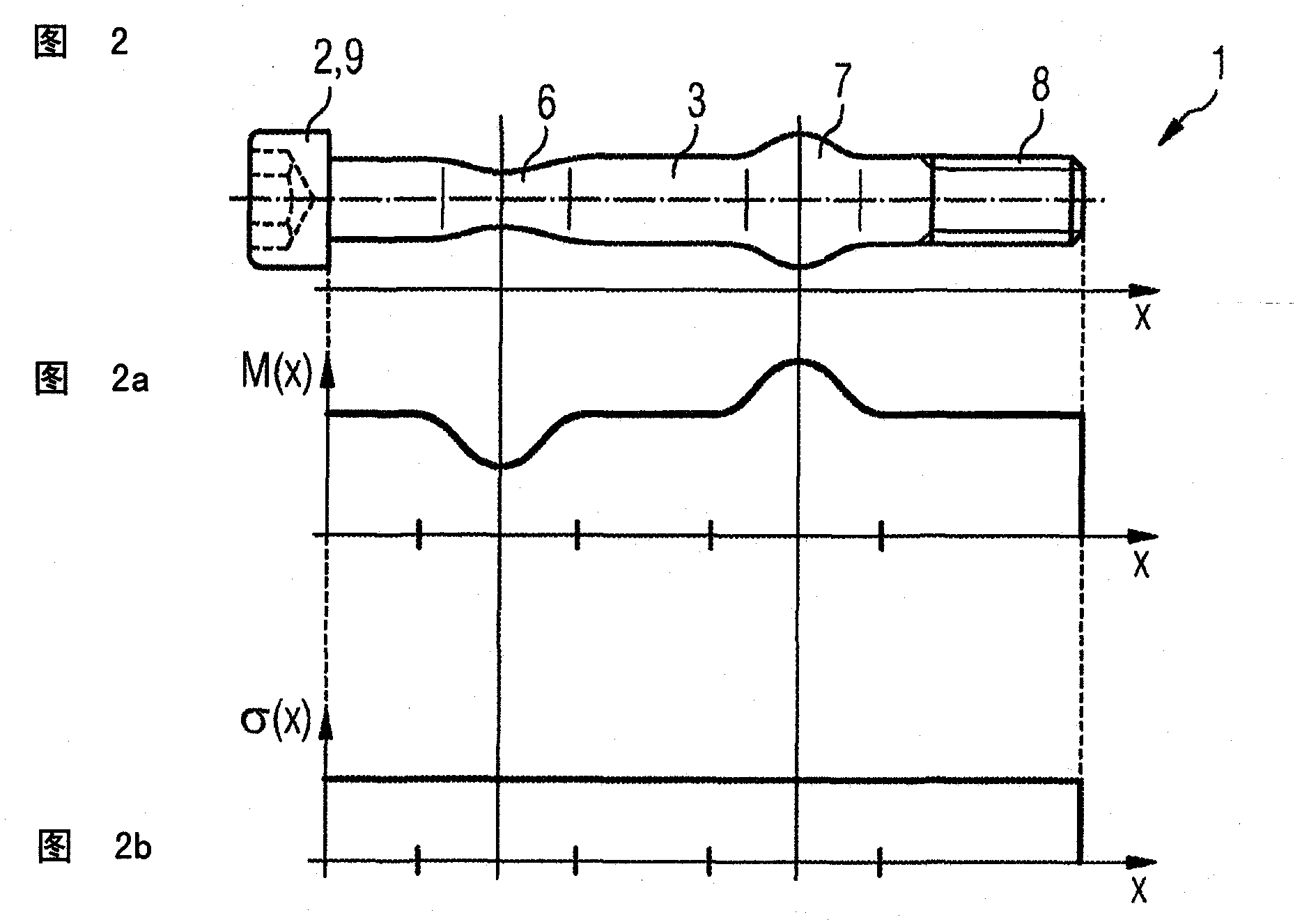

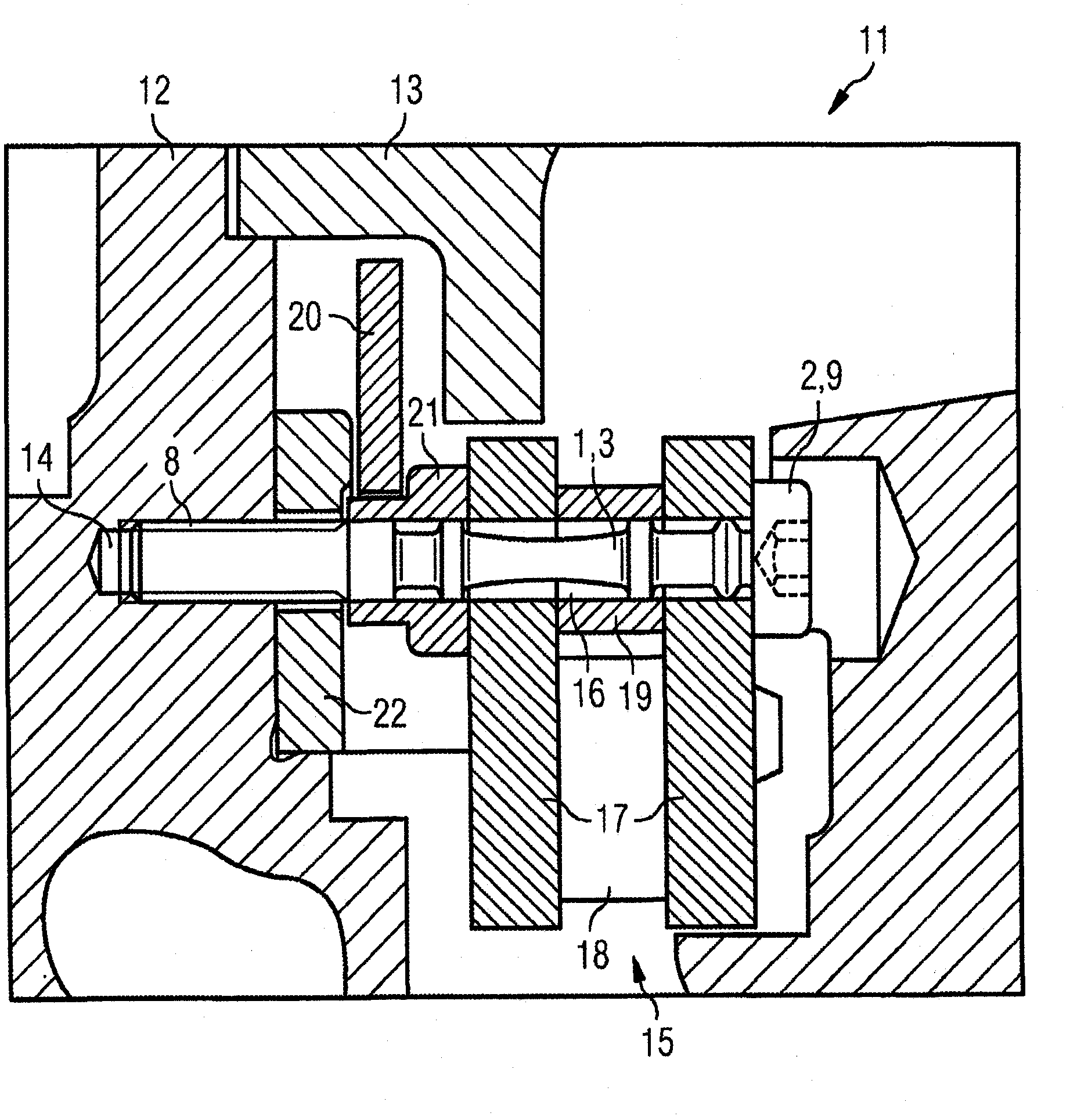

Securing element and exhaust gas turbocharger having variable turbine geometry

The invention relates to a securing element (1) comprising a head section (2), a shank (3), the cross-section of said shank changing in the axial direction such that, by taking into account a qualitative and / or quantitative predetermined bending torque profile in the shank, the cross-section has an essentially uniform bending stress profile in the shank in relation to a securing element with a constant shank cross-section. The invention also relates to an exhaust gas turbocharger (11) having variable turbine geometry in which a VTG-guide vane arrangement (15) comprising at least one securing element (1) of said type is secured to a housing component (12) of the exhaust gas turbocharger.

Owner:CONTINENTAL AUTOMOTIVE GMBH

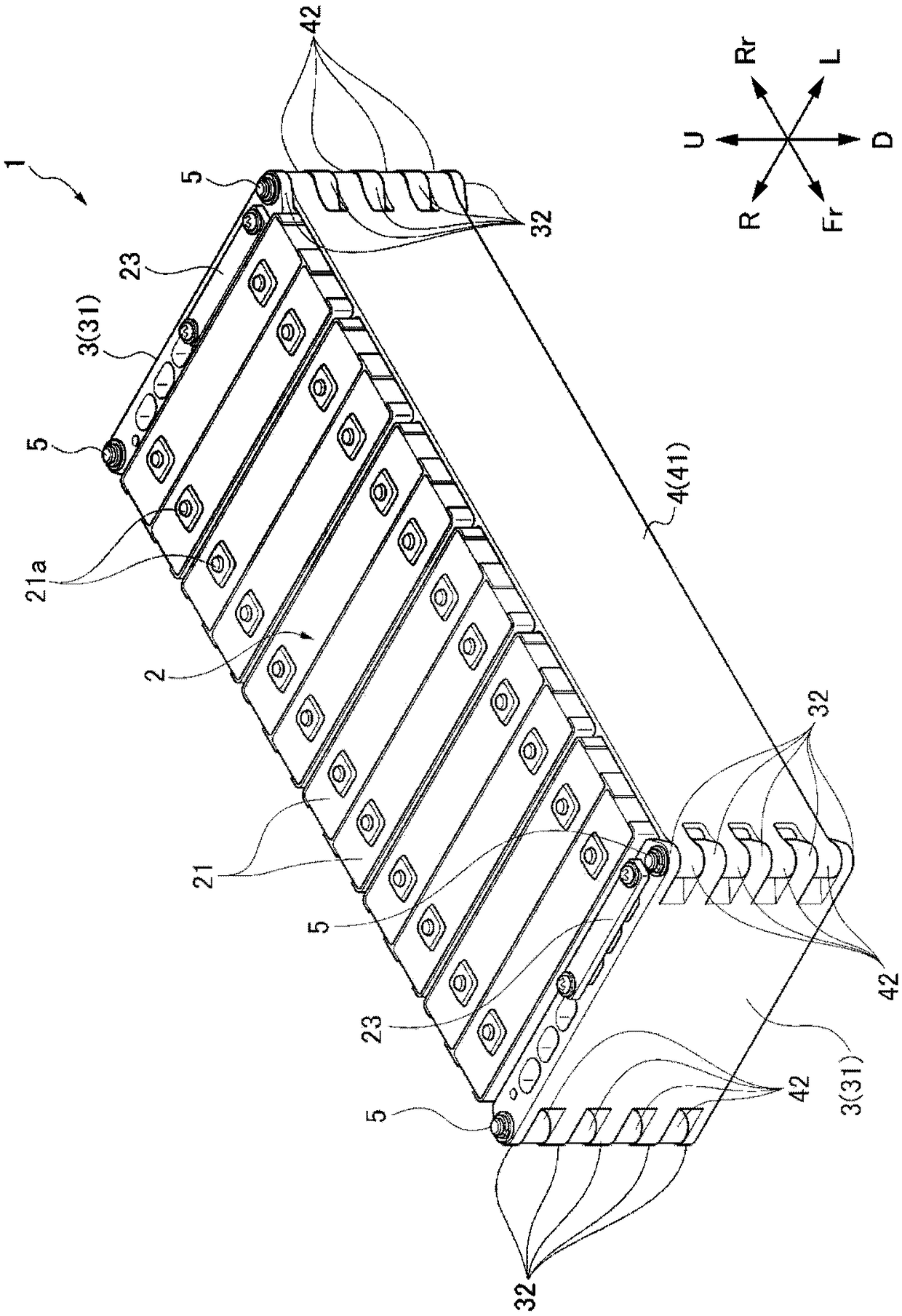

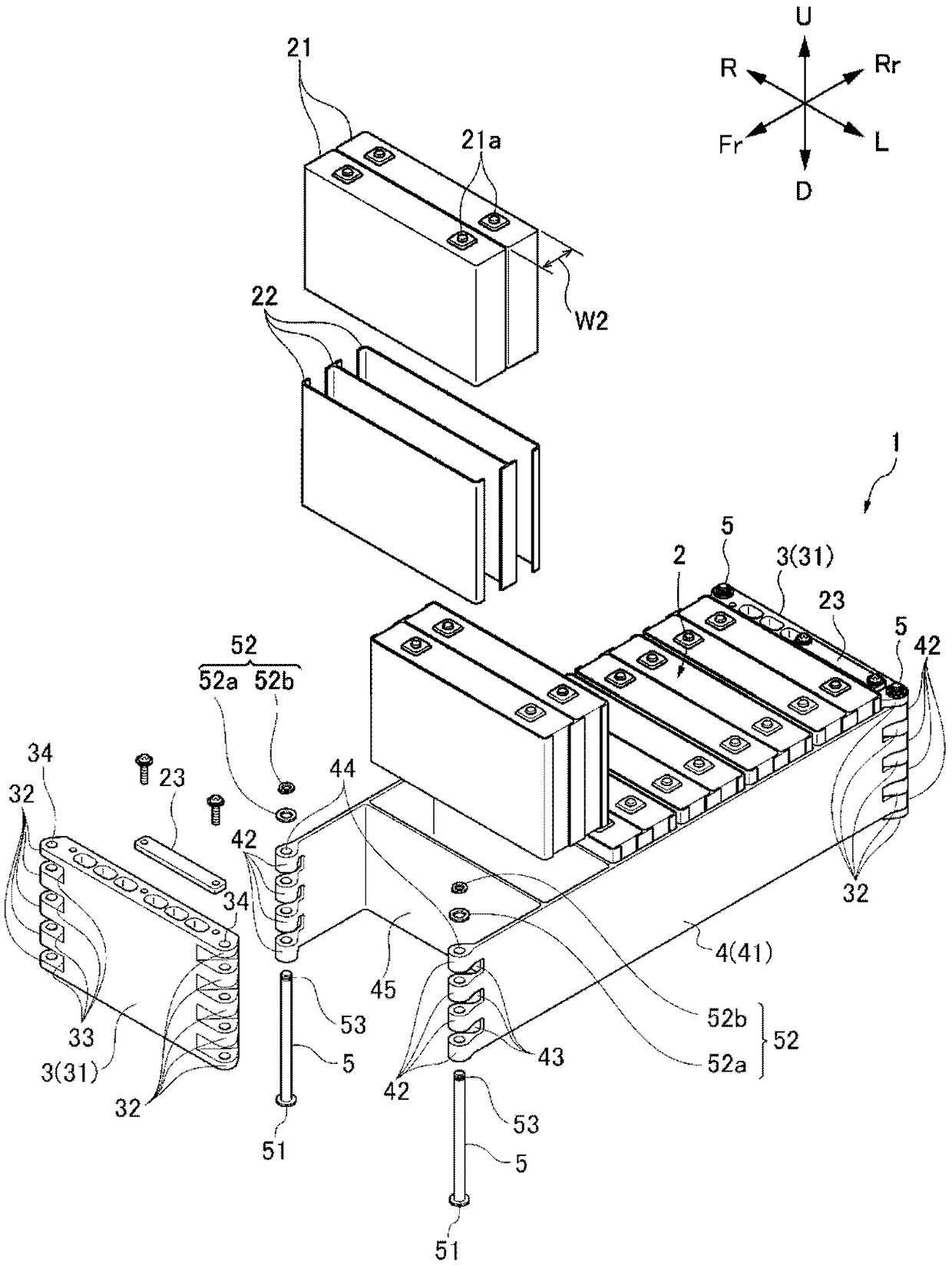

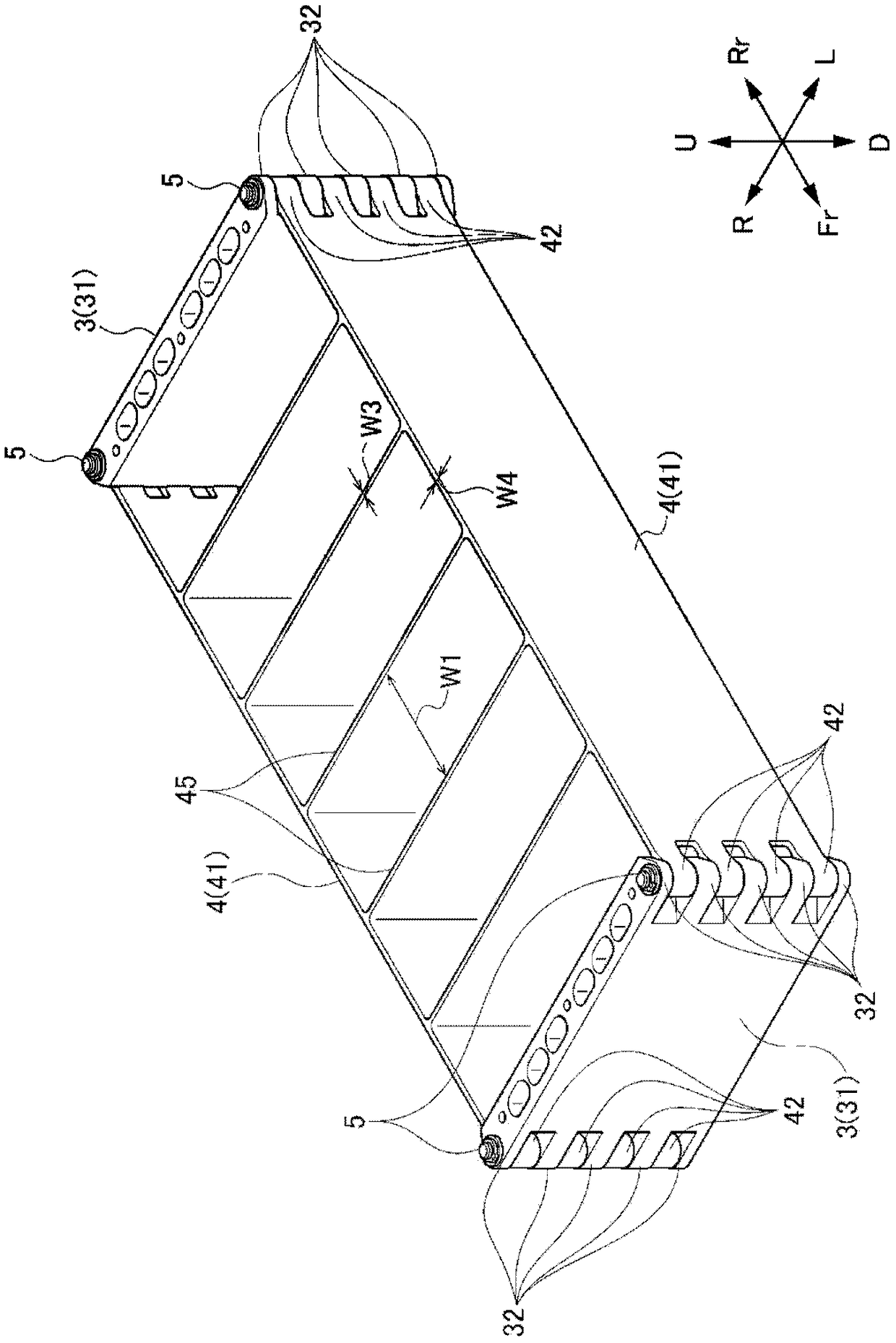

Battery module

ActiveCN109216608AReduce wall thicknessSuppression of bending stressFinal product manufactureSecondary cellsRear quarterEngineering

The invention provides a battery module capable of preventing generation of bending stress of at a connection portion between an end plate and a side plate. The battery module (1) includes: a cell stack body (2) that is constituted by a plurality of cells (21) stacked in a front-rear direction and comprises a front surface, a rear surface, a left surface, a right surface, an upper surface, and a lower surface; a pair of end plates (3) that are disposed on the front surface and the rear surface of the cell stack body (2); and a pair of side frames (4) disposed on the right surface and the leftsurface of the cell stack body (2). An end of the end plate (3) and an end of the side frame (4) have an overlapping portion (R) in which the end of the end plate and the end of the side frame overlapwith each other when viewed from an up-down direction. The overlapping portion (R) has a through hole (34, 44) passing through in the up-down direction. A connection shaft (5) is inserted into the through hole (34, 44).

Owner:HONDA MOTOR CO LTD

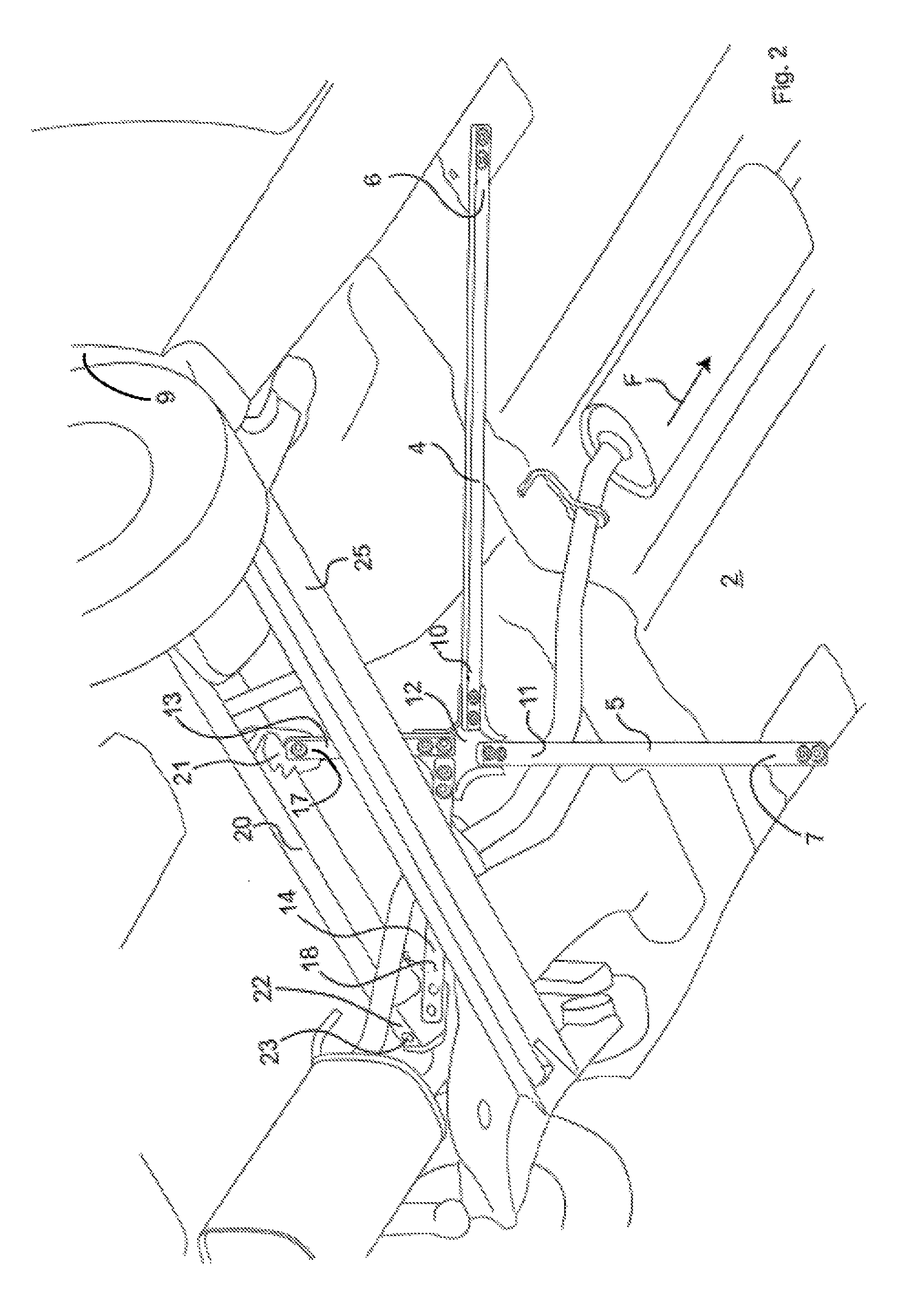

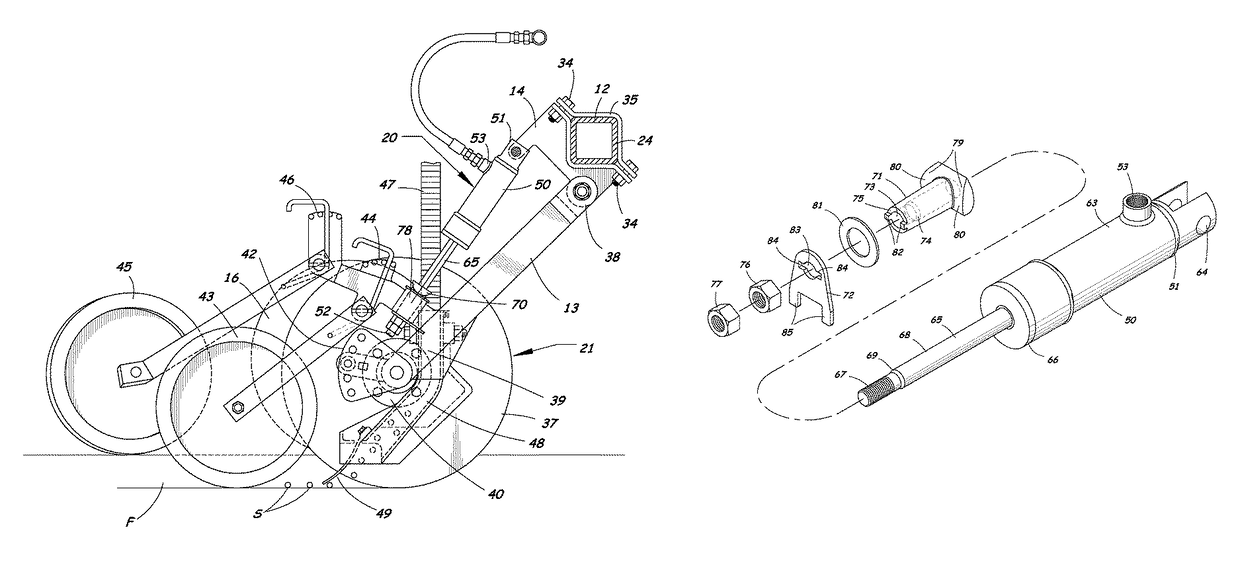

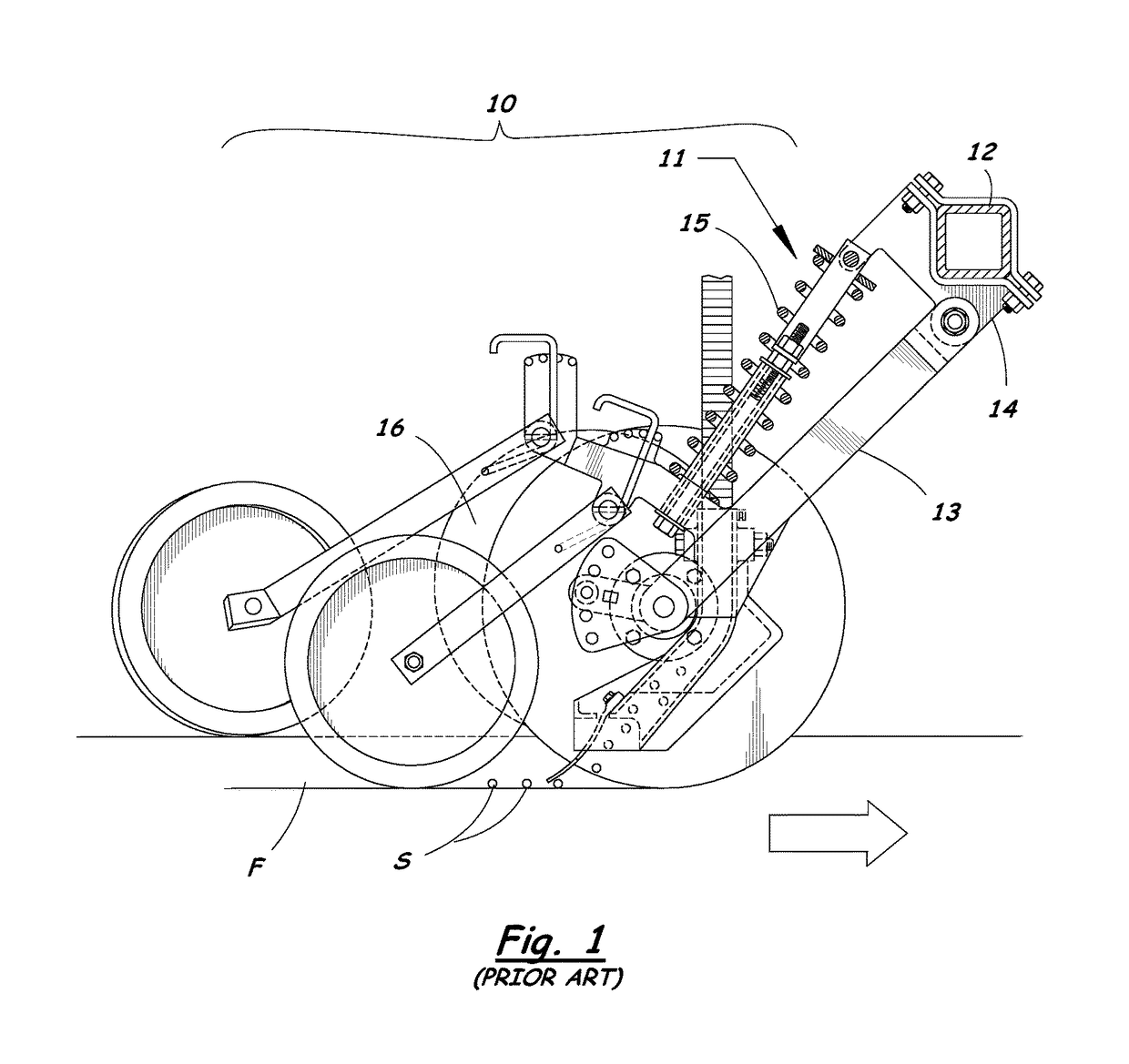

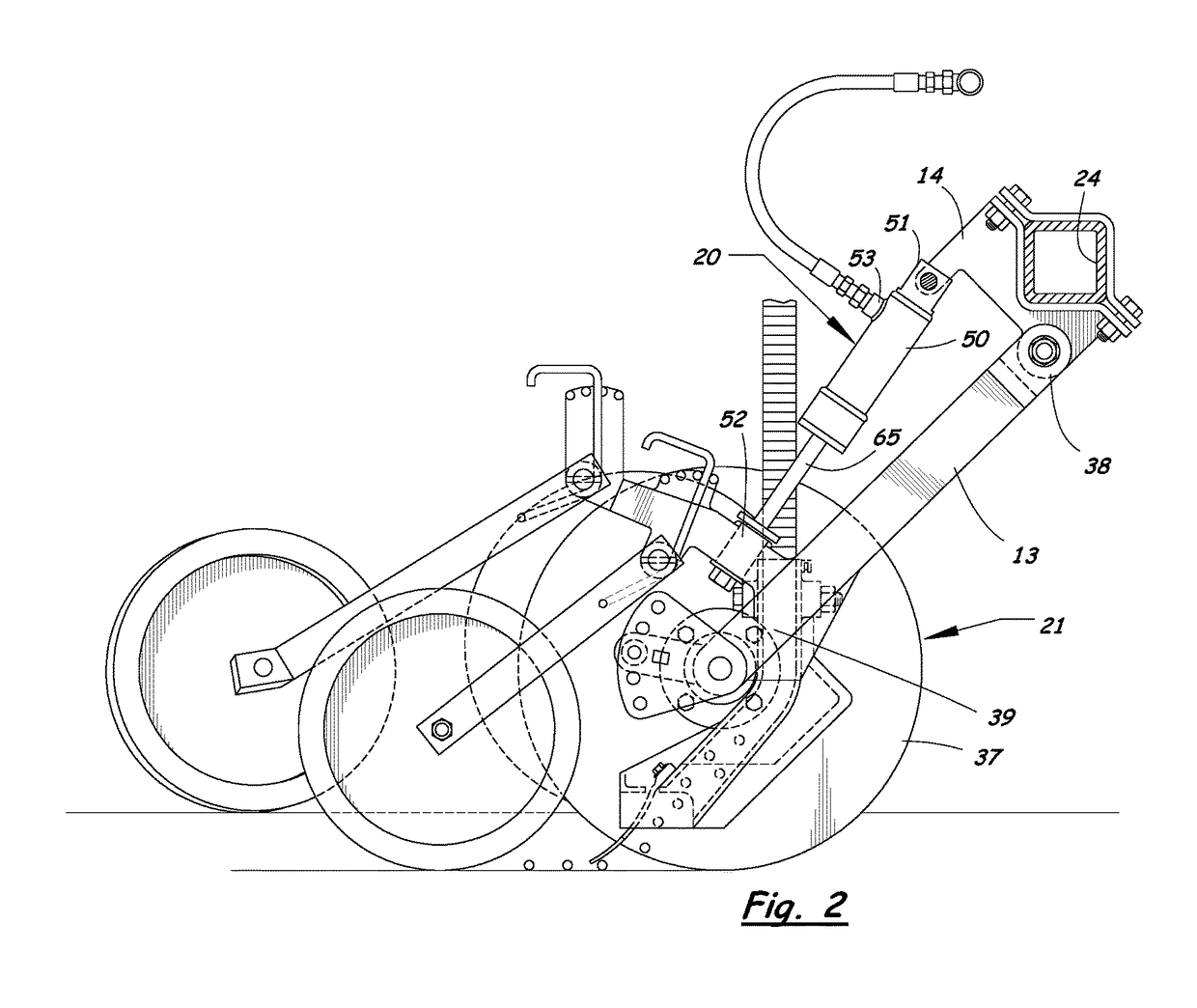

Mounting structure for down-pressure system for opener assembly of agricultural implement

ActiveUS9930822B2Stress minimizationExtended range of motionAgricultural machinesPlantingControl theoryLinear actuator

A down-pressure system for an agricultural implement has a linear actuator connected between a frame assembly and an opener assembly. A mounting structure for connecting the linear actuator to the opener assembly includes a bushing and an alignment member attached to the linear actuator. The bushing has protrusions extending transversely from opposite sides of a longitudinal axis of the linear actuator. Each protrusion has a curved engagement surface for engaging a flat surface on the opener assembly to prevent bending stresses on the linear actuator when the opener assembly is raised and lowered. The alignment member is arranged to lock the bushing into a predetermined rotational position about a longitudinal axis of the linear actuator relative to the opener assembly. The alignment member comprises a first structure that mates with a corresponding structure on the bushing, and a second structure that engages opposite sides of the opener assembly.

Owner:DOWNS EMILIE

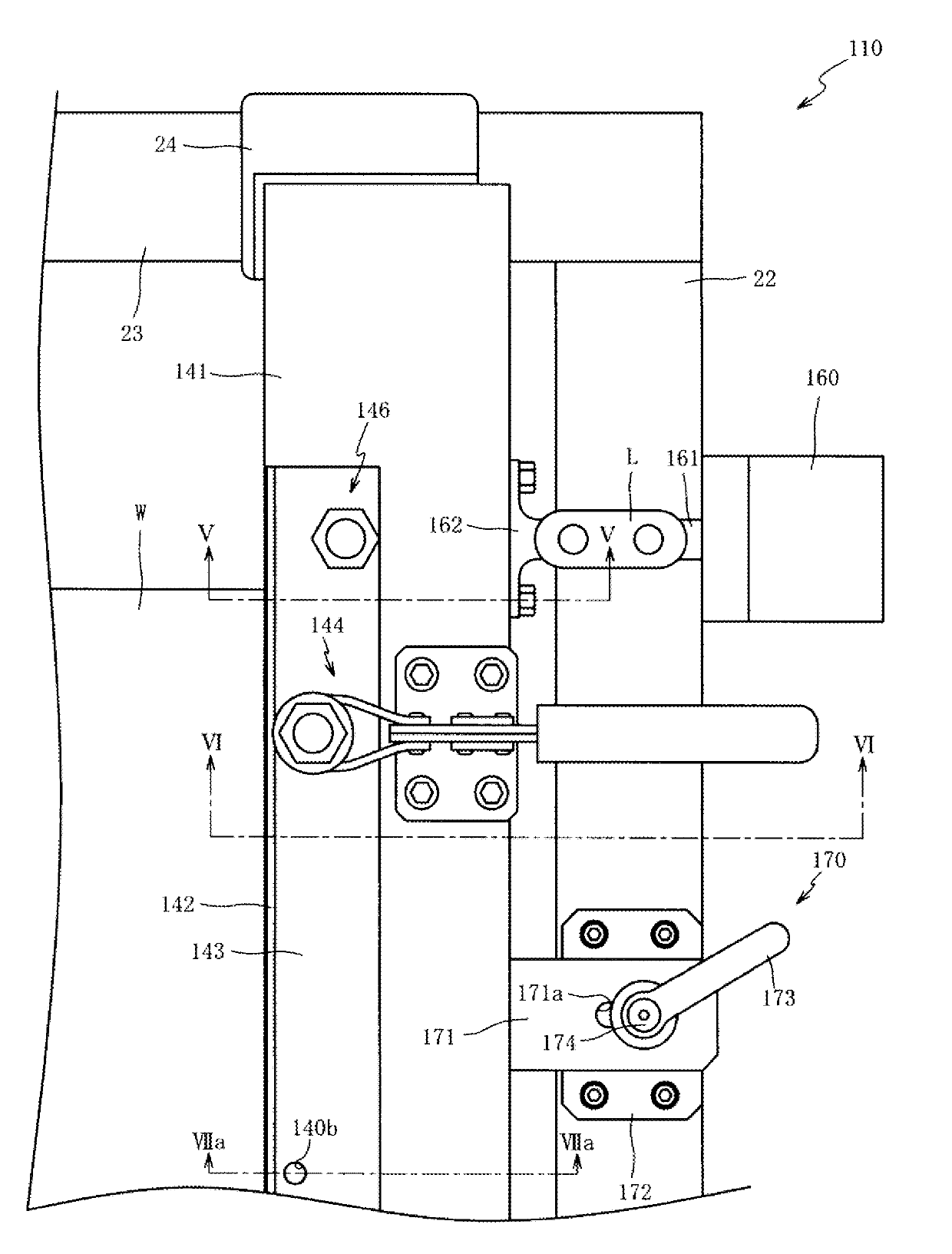

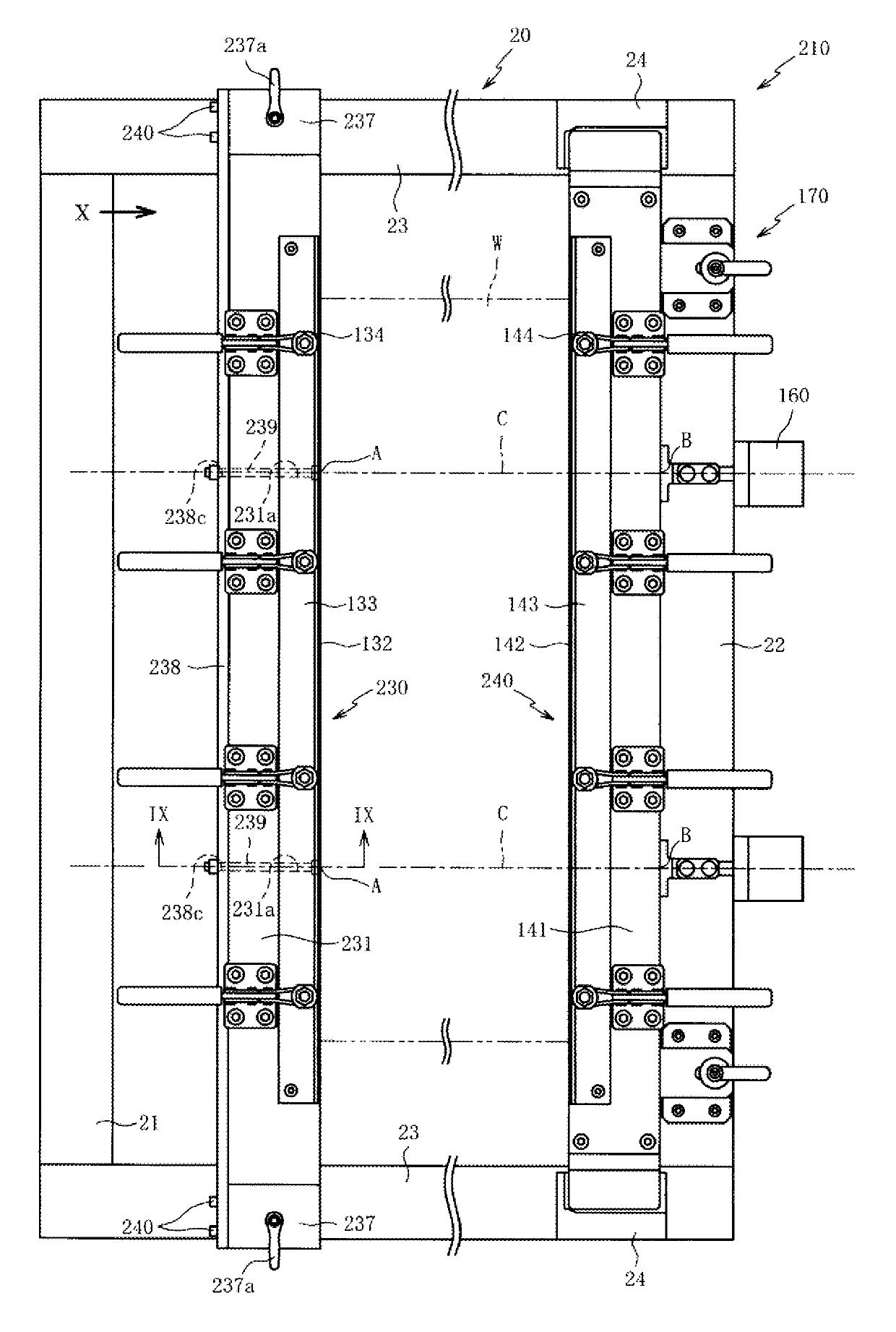

Thin plate retaining device

ActiveCN104175005ASimple and fast operationAvoid deflectionWelding/cutting auxillary devicesAuxillary welding devicesEngineeringMechanical engineering

The invention provides a thin plate retaining device capable of arranging a thin plate on an XY platform in an opening mode by simple and convenient operation in a laser machine. A first frame material (21) and a second frame material (22) are fixedly arranged on the XY platform (11), and are spaced from each other by a given distance. A first part (130) is arranged between the first frame material (21) and the second frame material (22), and one end of a thin plate (W) is clamped by the first part (130). A second part (140) is formed by relatively moving from a direction away from the first part (130), and is arranged between the first frame material (21) and the second frame material (22) along the second frame material (22), and the other end of the thin plate (W) is clamped by the second part (22). The ends of multiple connecting rods (L) which are formed in a swinging way are connected with the corresponding multiple parts of the second part (22), and the other ends of the connecting rods (L) are connected with a cylinder (160). The thin plate (W) can be arranged on the XY platform (11) by the simple and convenient operation that force is applied to the second frame material (22) by the second part (140).

Owner:SUMITOMO HEAVY IND LTD

Anti-shock supporting and hanging frame used for installing pipeline

InactiveCN108167537APrevent sideways movementGuaranteed locking forcePipe supportsPipe elementsEngineeringMechanical engineering

The invention discloses an anti-shock supporting and hanging frame used for installing a pipeline. The anti-shock supporting and hanging frame comprises a first channel steel base, a hinge, a first screw, a channel steel connecting rod, a second channel steel base, a bolt, single-face channel steel, a first rack, a second rack, a U-shaped fixing part, the pipeline, a bottom plate, double-splicingchannel steel, a nut, a second screw and a fixing connecting part. The anti-shock supporting and hanging frame is simple in structure, by arranging the first rack and the second rack, after the fixingconnecting part is installed on the single-face channel steel, the locking force degree between the single-face channel steel and the fixing connecting part can be effectively ensured, the fixing connecting part is prevented from moving laterally when stressed, and the anti-shock performance of anti-shock supports is effectively improved. The first rack is arranged on the side face of the single-face channel steel, the mutual position between the single-face channel steel and the fixing connecting part can be adjusted continuously, in the installing process, the double-splicing channel steelon the adjacent anti-shock support can be adjusted to the same horizontal height beneficially, bending stress is prevented from being generated when the pipeline is fixed, and supporting stability ofthe anti-shock supporting and hanging frame is benefitted.

Owner:JIANGSU YIDINGGU ELECTROMECHANICAL TECH CO LTD

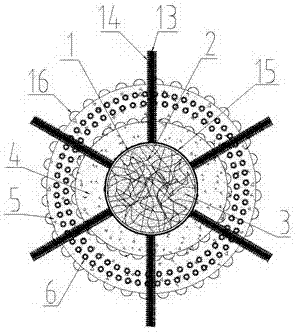

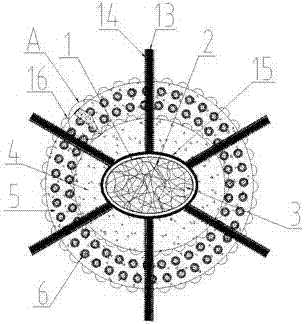

Building anti-seismic ball mixed into concrete

ActiveCN107345454AAvoid bending stressIncrease surface tensionProtective buildings/sheltersShock proofingSelf-healingFiber

The invention discloses a building anti-seismic ball mixed into concrete. The building anti-seismic ball comprises a steel core ball, wherein the steel core ball is filled with steel wires and a binder; the steel wires are disorderly connected to the inside of the steel core ball; the binder contains a carbon fiber; an outer layer of the steel core ball is connected with a first concrete layer; the first concrete layer comprises rubber particles and asphalt; the outer layer of the first concrete layer is connected with a second concrete layer; the second concrete layer contains a self-healing ball; the self-healing ball comprises a steel outer ball layer and a steel inner ball layer; the inner ball layer is provided with a connecting rod; the outer ball layer is connected with the inner ball layer through the connecting rod; and one end of the connecting rod is connected with the outer side of the inner ball layer and the other end of the connecting rod penetrates through the outer ball layer. Improvement of the elasticity of the concrete can be achieved, the energy generated when vibration is absorbed can be absorbed, the building anti-seismic effect can be strengthened, and meanwhile, cracks in the concrete can be repaired.

Owner:枣庄交运新型建材科技有限公司

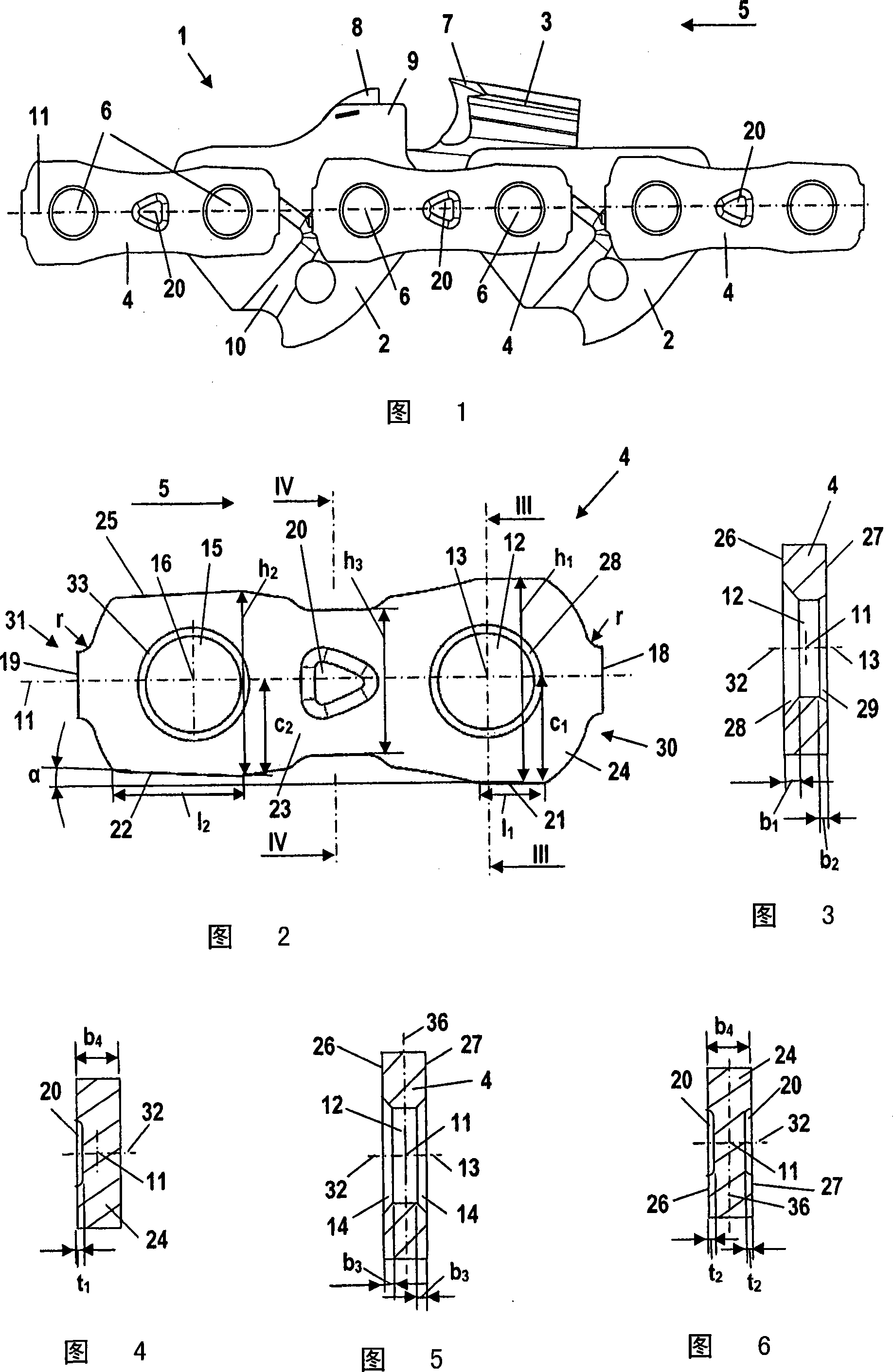

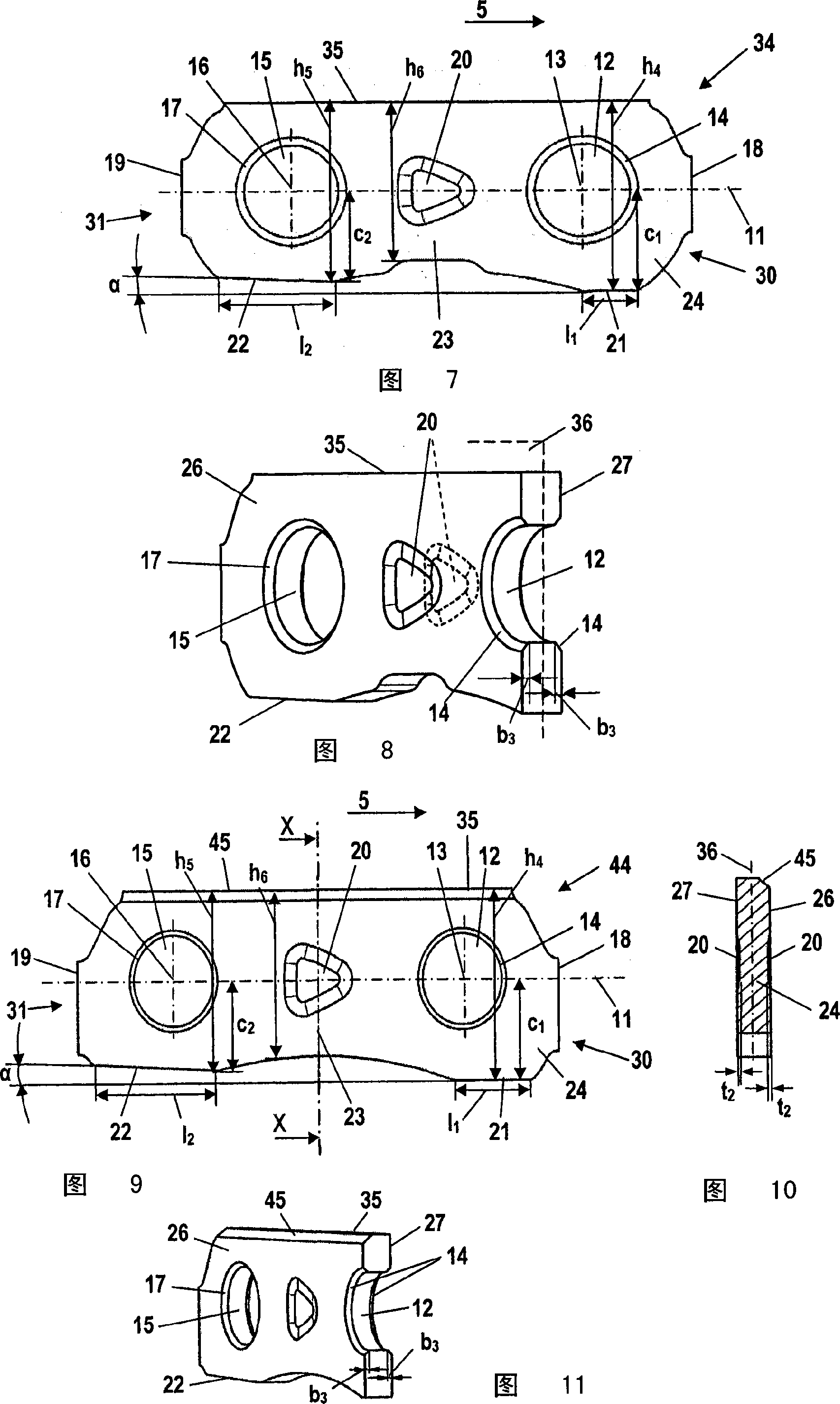

Connecting chain link for saw chain

A connecting link ( 4, 34 ) for a saw chain ( 1 ) of a motor-driven chain saw has an areal base body ( 24 ) which has two rivet openings ( 12, 15 ). The connecting link ( 4, 34, 44 ) has a longitudinal center axis ( 11 ) which intersects the axes ( 13, 16 ) of rivet openings ( 12, 15 ) and runs in the base body ( 24 ). The functional regions of the connecting links ( 4, 34, 44 ) are mirror symmetrical to planes ( 32, 36 ), which contain the longitudinal center axis ( 11 ), and are unsymmetrical to each plane perpendicular to the longitudinal center axis ( 11 ). In this way, the connecting link ( 4, 34, 44 ) can be arranged on both longitudinal sides of the saw chain ( 1 ).

Owner:ANDREAS STIHL AG & CO KG

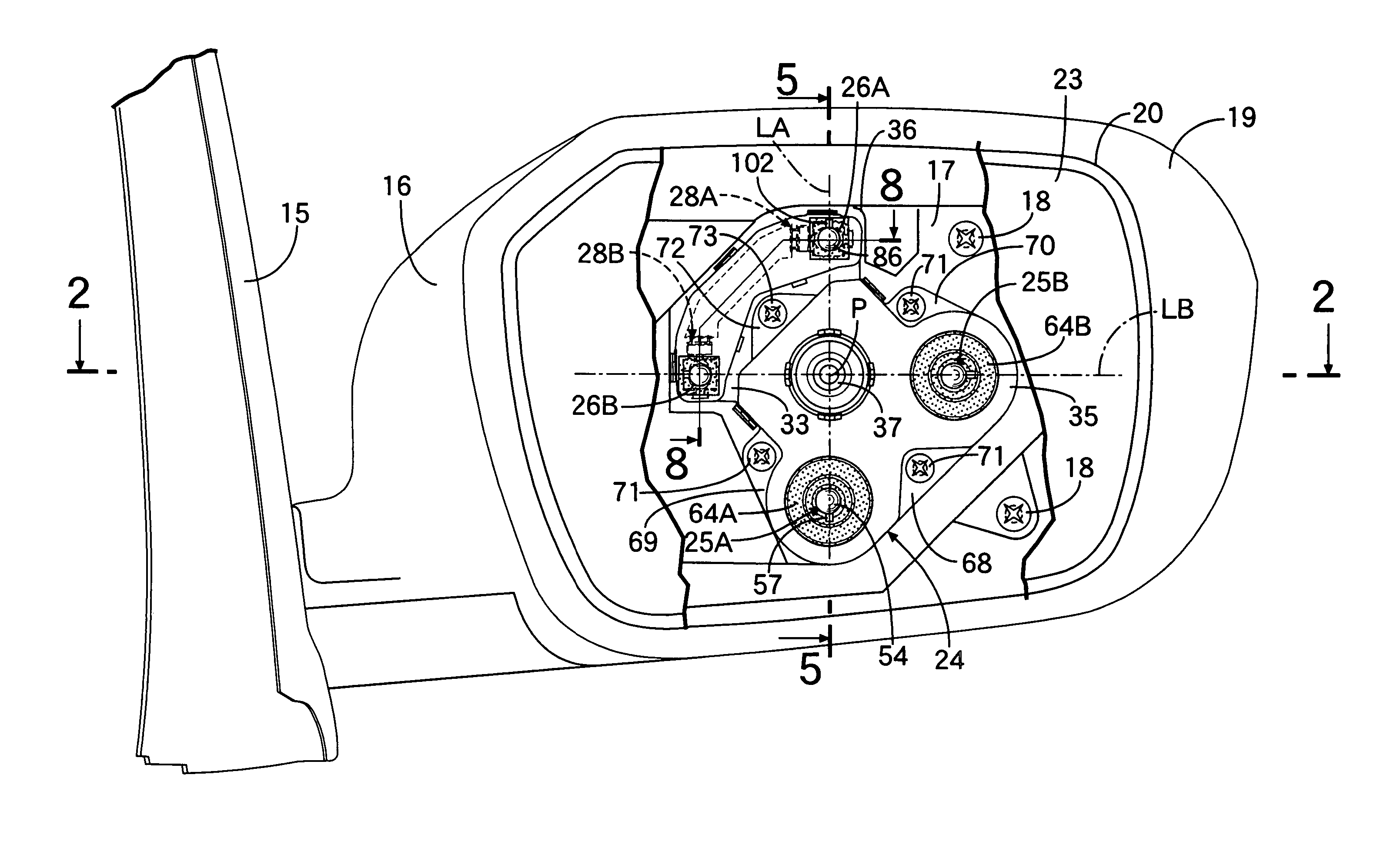

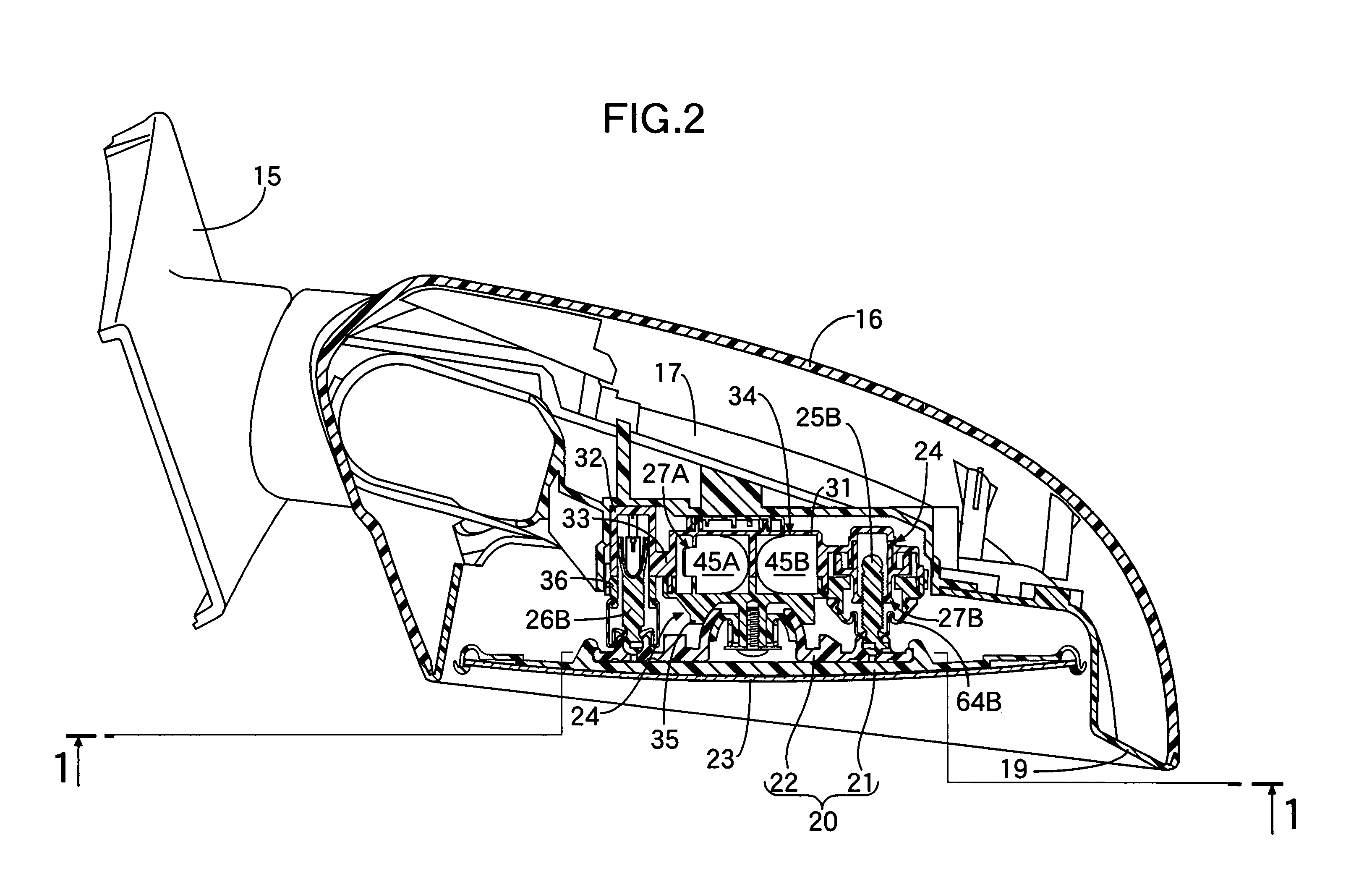

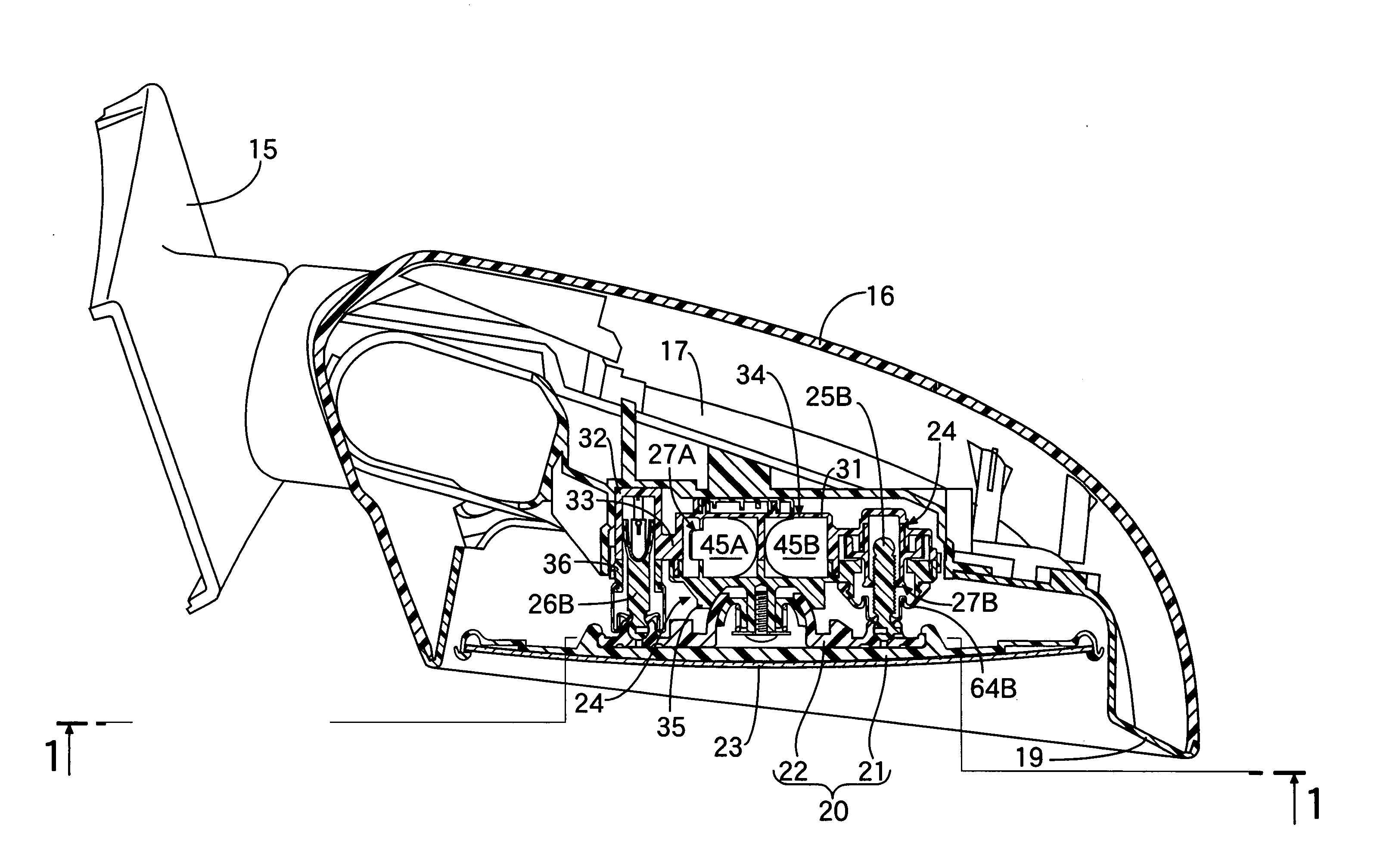

Vehicular mirror having tilt angle detection rod with swing axis

InactiveUS7354170B2Improve accuracyImprove sensor accuracyPicture framesDomestic mirrorsDrive shaftEngineering

In a vehicular mirror device, one end part of an operating shaft disposed on a side opposite to a drive shaft relative to a fulcrum of a mirror holder is swivelably coupled to the mirror holder, and a detection rod of a sensor is coupled to the operating shaft, which is slidably inserted into a guide hole provided in a fixed support member, so that it detects a swing angle of the mirror holder according to an axial position of the operating shaft. The operating shaft is inserted into the guide hole while being supported on the support member so that it can swing around an axis perpendicular to a plane containing a straight line linking a part of the drive shaft that couples the drive shaft to the mirror holder, the fulcrum of the mirror holder, and a part of the operating shaft that couples the operating shaft to the mirror holder. The detection rod, which has an axis coaxial with the swing axis of the operating shaft, is coupled to the operating shaft so that the operating shaft can swing around the swing axis. Thus, the swing angle of the mirror holder can be detected with a high accuracy.

Owner:HONDA LOCK MFG CO LTD

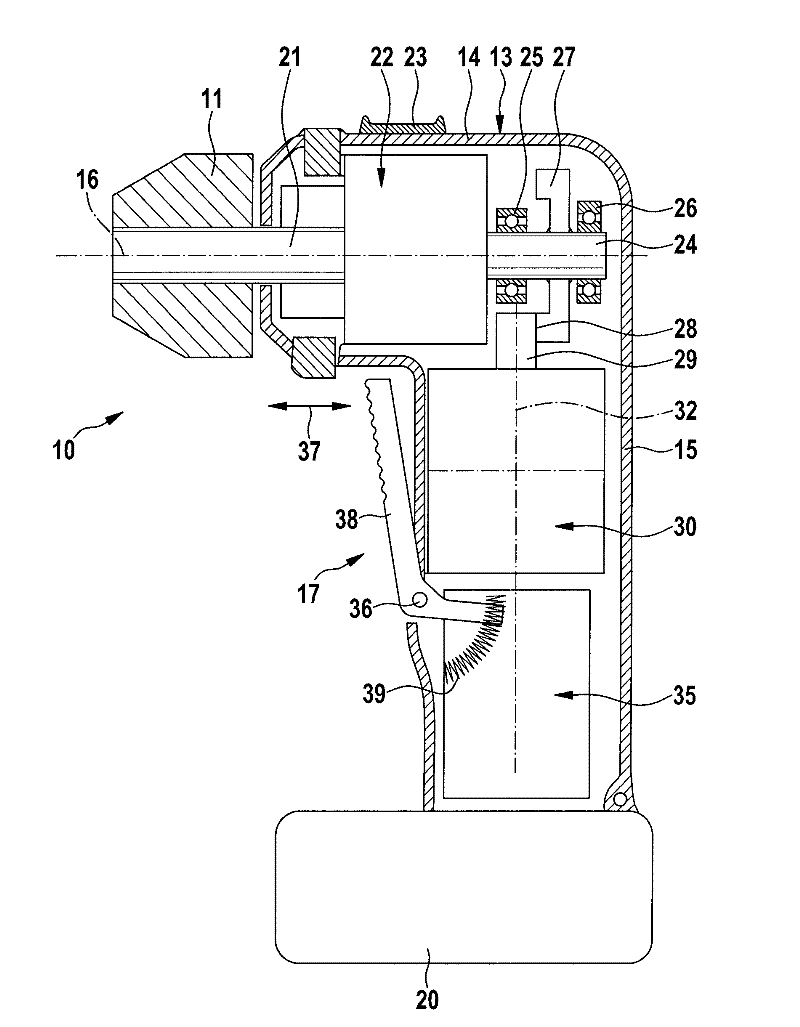

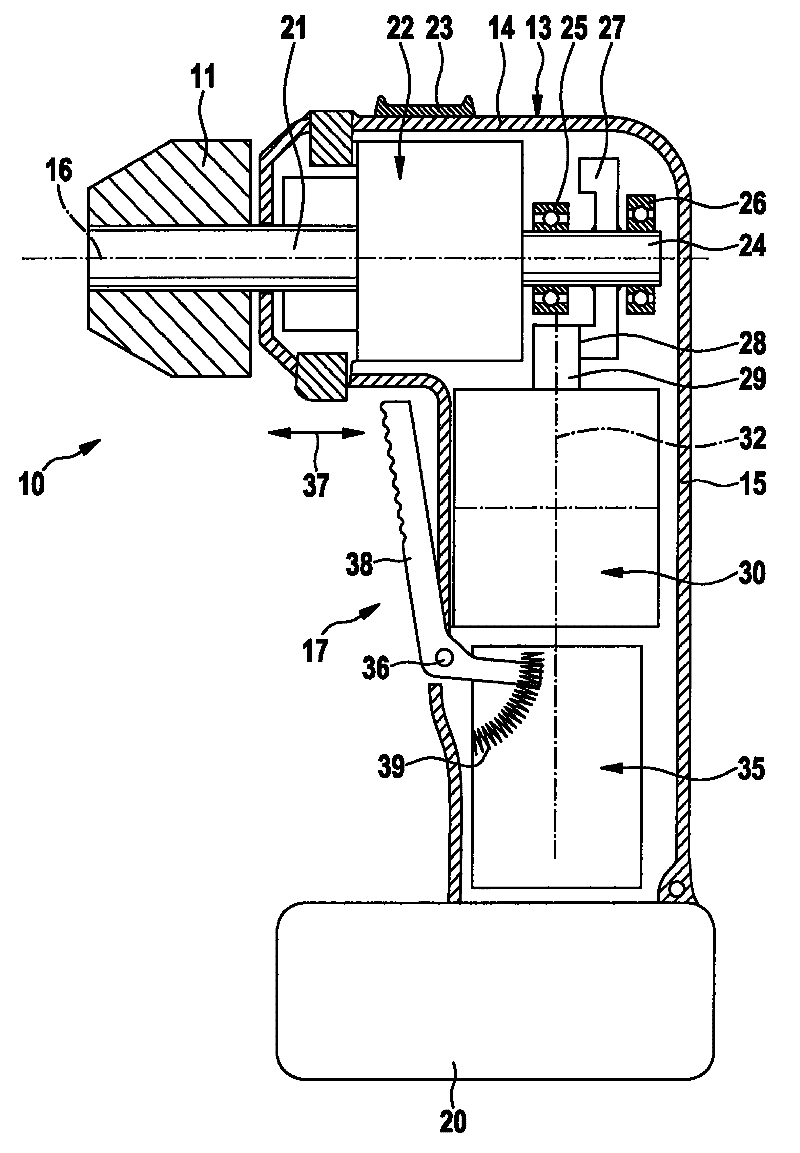

Handheld power tool, in particular power drill or power screwdriver

InactiveCN102554886ARealize electrical couplingGood and easy to operatePortable power-driven toolsPortable drilling machinesEngineeringDrive motor

A handheld power tool, in particular, a power drill or a power screwdriver is disclosed. The handheld power tool includes a housing which includes a first region for a tool holder and a second region which serves as a handle. The tool holder is coupled to a drive motor by a gear mechanism. Both the drive motor and a switching device for operating the drive motor is arranged in the second region of the housing. Provision is made for the drive motor to be arranged in the second region of the housing on the side which faces the gear mechanism.

Owner:ROBERT BOSCH GMBH

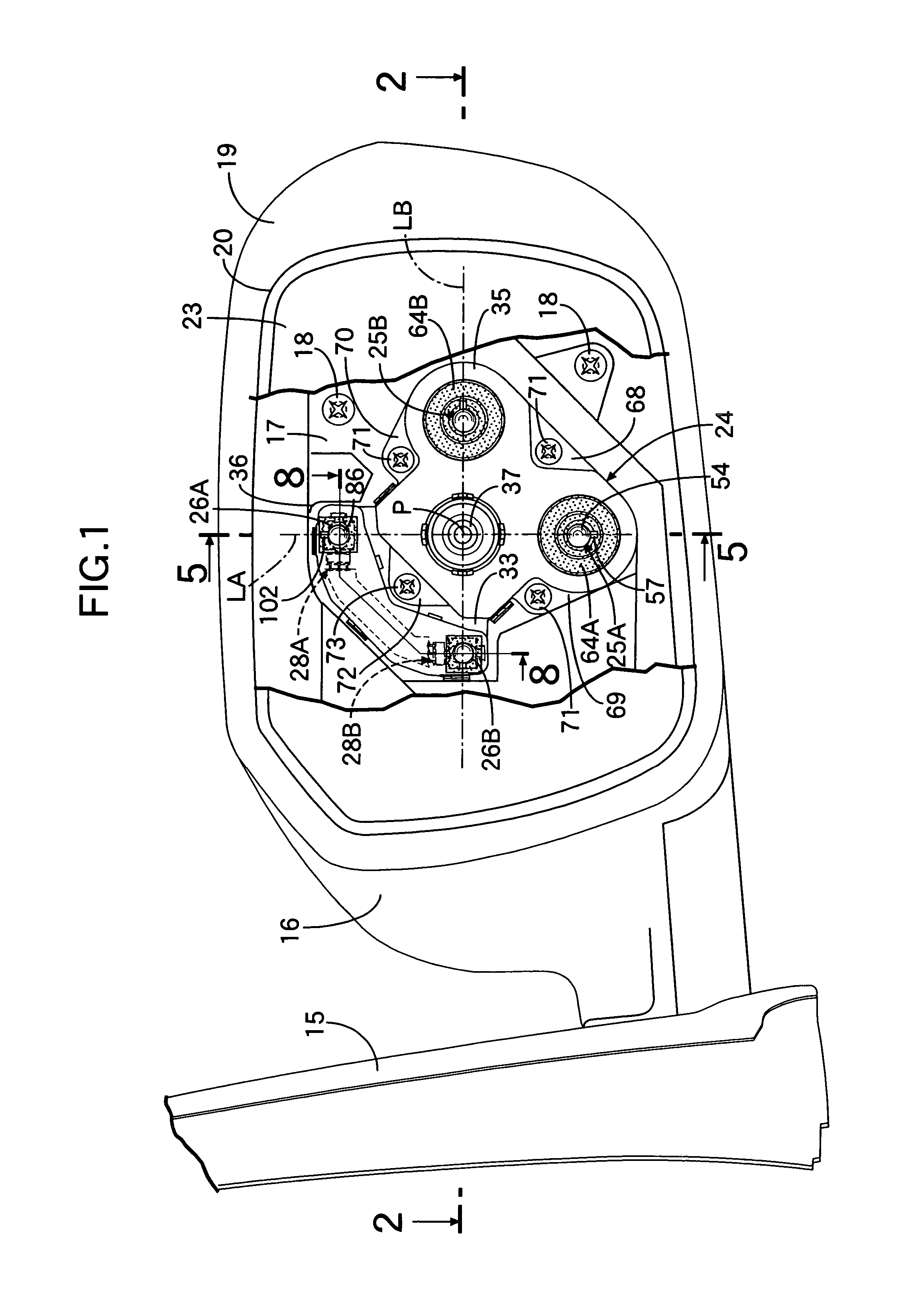

Vehicular mirror device

InactiveUS20060181793A1High accuracyImprove accuracyPicture framesDomestic mirrorsRear-view mirrorEngineering

In a vehicular mirror device, one end part of an operating shaft disposed on a side opposite to a drive shaft relative to a fulcrum of a mirror holder is swivelably coupled to the mirror holder, and a detection rod of a sensor is coupled to the operating shaft, which is slidably inserted into a guide hole provided in a fixed support member, so that it detects a swing angle of the mirror holder according to an axial position of the operating shaft. The operating shaft is inserted into the guide hole while being supported on the support member so that it can swing around an axis perpendicular to a plane containing a straight line linking a part of the drive shaft that couples the drive shaft to the mirror holder, the fulcrum of the mirror holder, and a part of the operating shaft that couples the operating shaft to the mirror holder. The detection rod, which has an axis coaxial with the swing axis of the operating shaft, is coupled to the operating shaft so that the operating shaft can swing around the swing axis. Thus, the swing angle of the mirror holder can be detected with a high accuracy.

Owner:HONDA LOCK MFG CO LTD

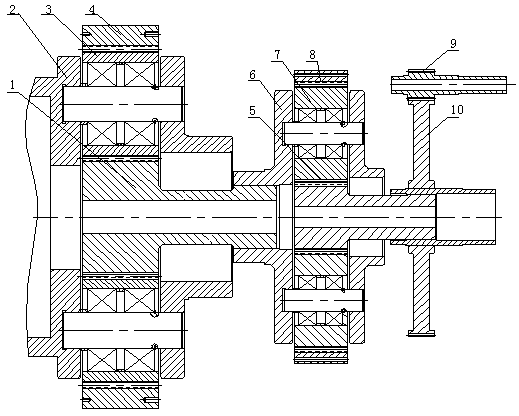

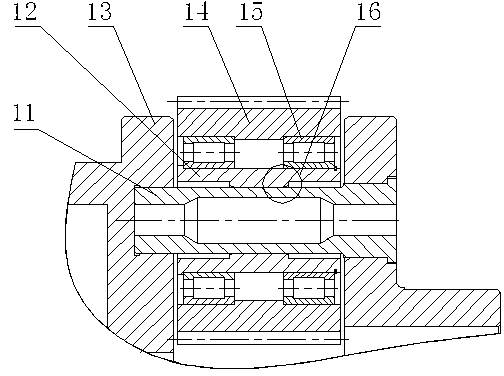

Flexible planet gear transmission mechanism of wind power gear box

InactiveCN103343810AChange in support stiffnessReasonable flexibilityEngine fuctionsGearingGear wheelEngineering

The invention discloses a flexible planet gear transmission mechanism of a wind power gear box. The flexible planet gear transmission mechanism of the wind power gear box comprises a shaft pin (11), a planet gear support (13), a planet gear (14) and a planet gear bearing (15), wherein the shaft pin (11) is installed on the planet gear support (13), the planet gear (14) is installed on the shaft pin (11) through the planet gear bearing (15), the shaft pin (11) is a hollow shaft, a shaft sleeve (12) is installed between the shaft pin (11) and the planet gear bearing (15), and an inner step (16) is arranged in the middle of the shaft sleeve (12). The flexible planet gear transmission mechanism of the wind power gear box has the advantages that in the situation that wind load changes, reasonable elastic deformation of the shaft pin can be kept, the service life of an engaging tooth is prolonged, normal engagement of a planet gear engaging tooth pair can be kept, and stability of transmission of the planet gear can be improved.

Owner:CHONGQING UNIV

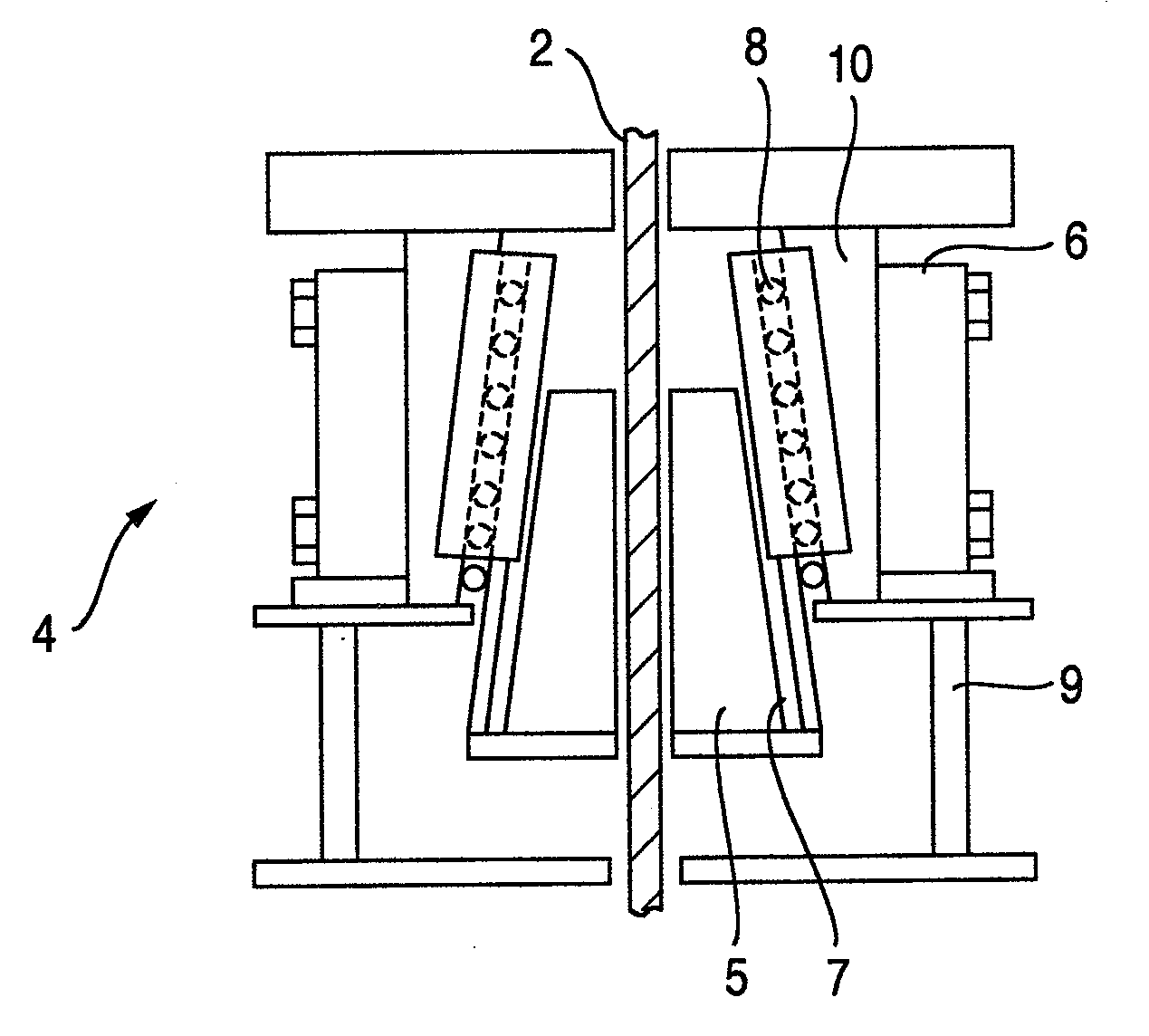

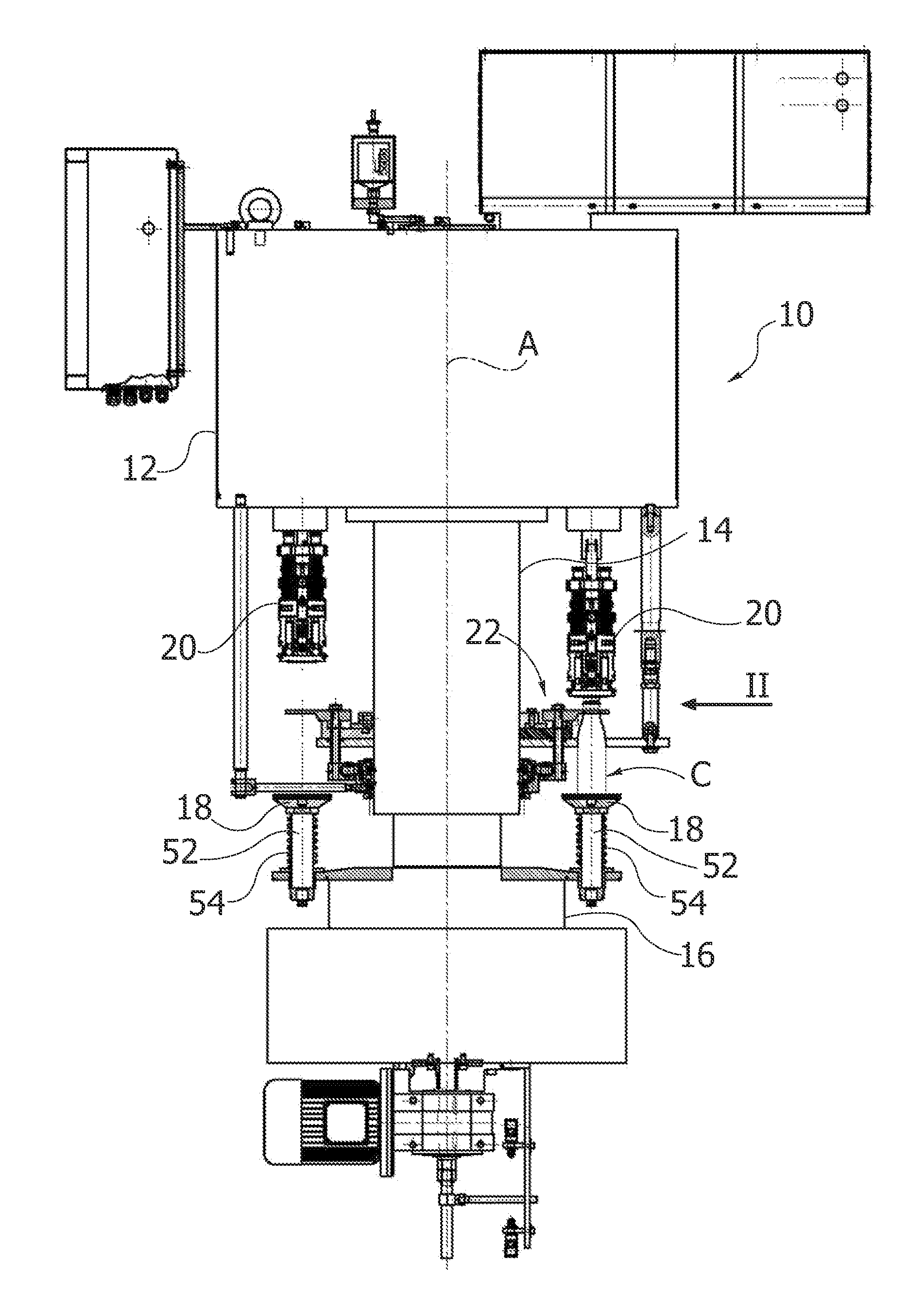

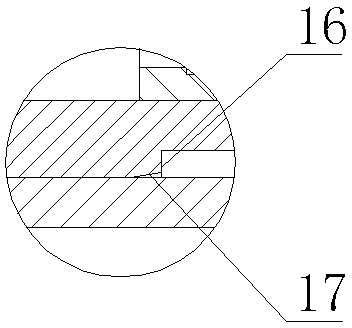

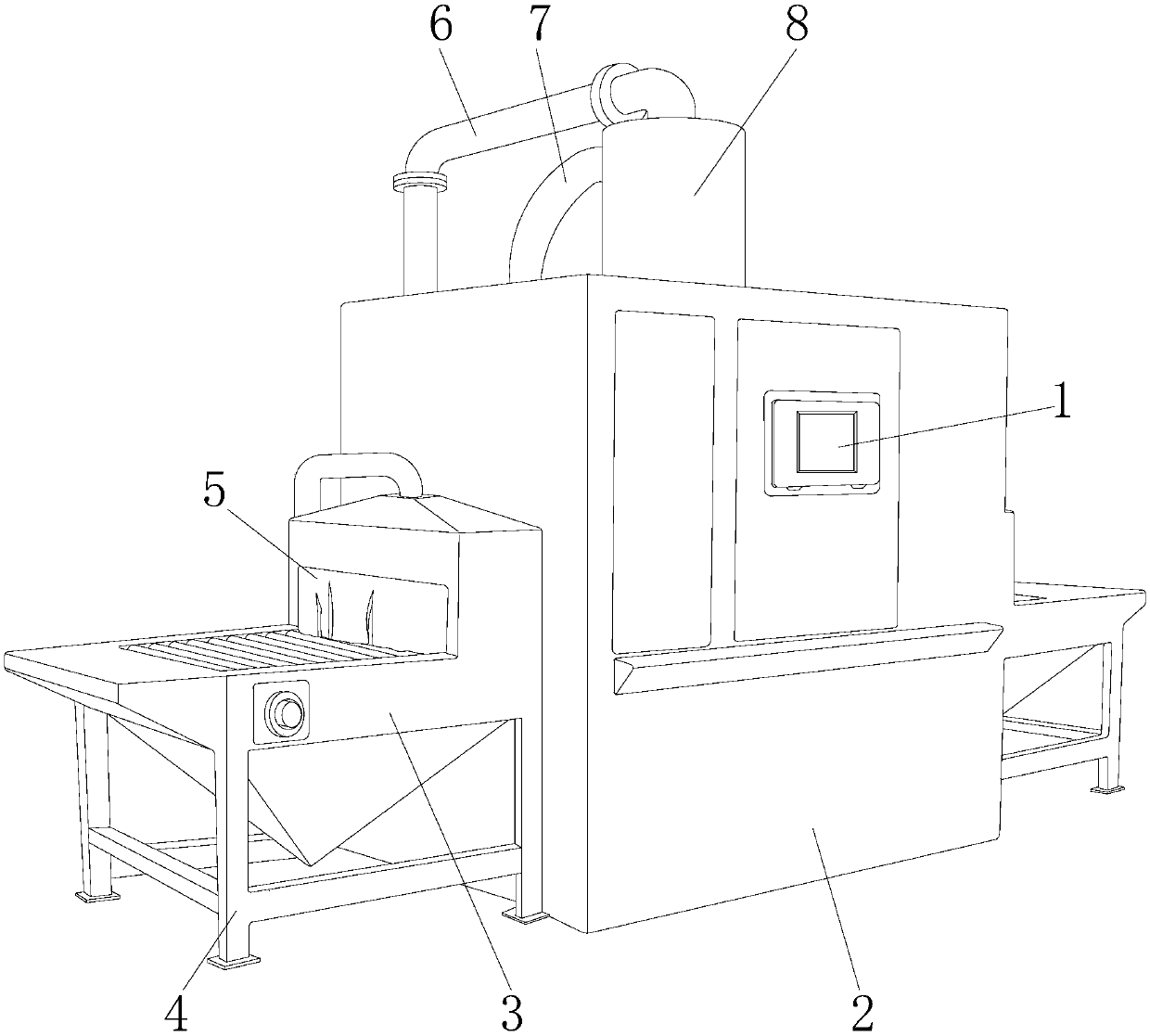

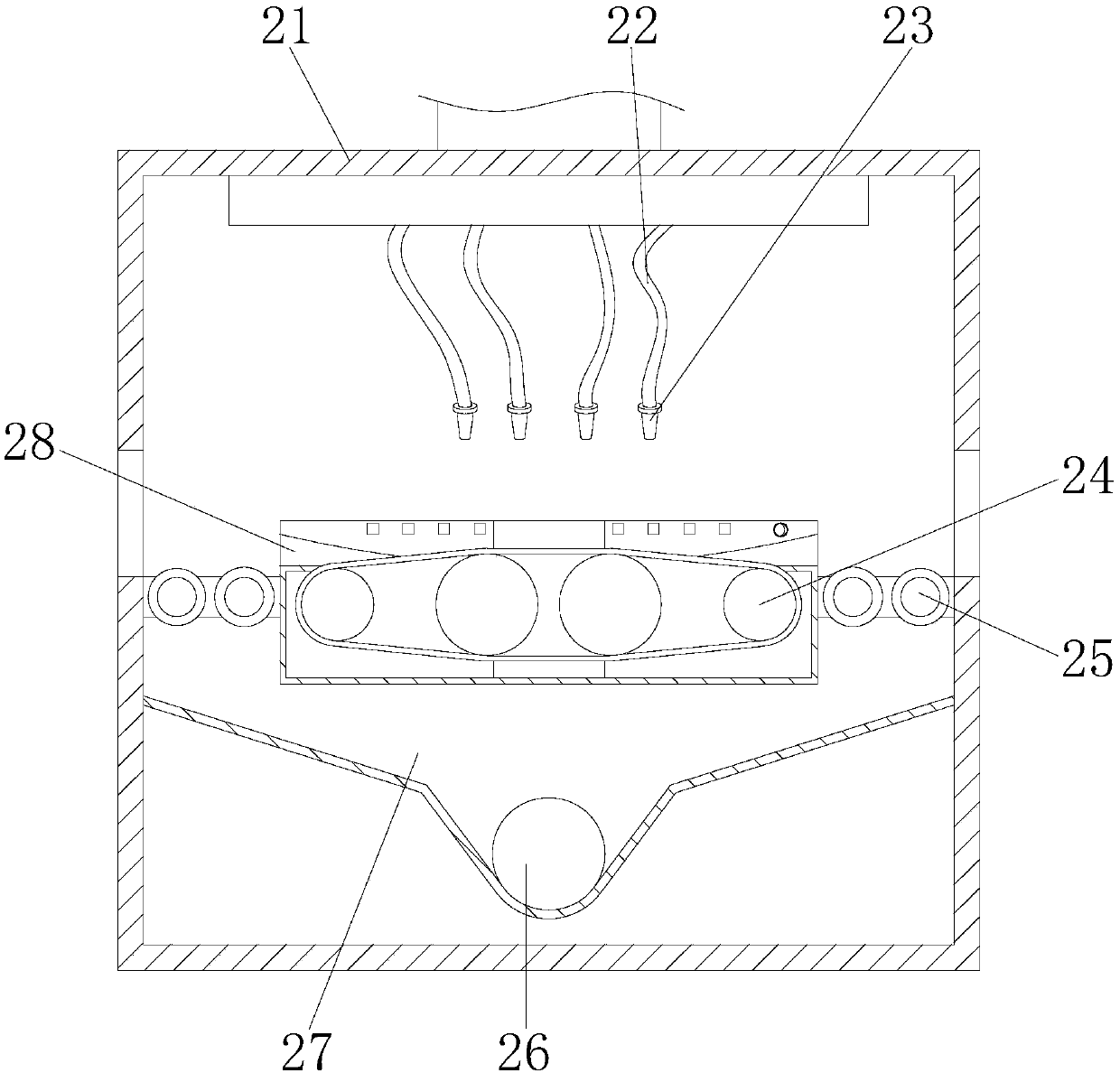

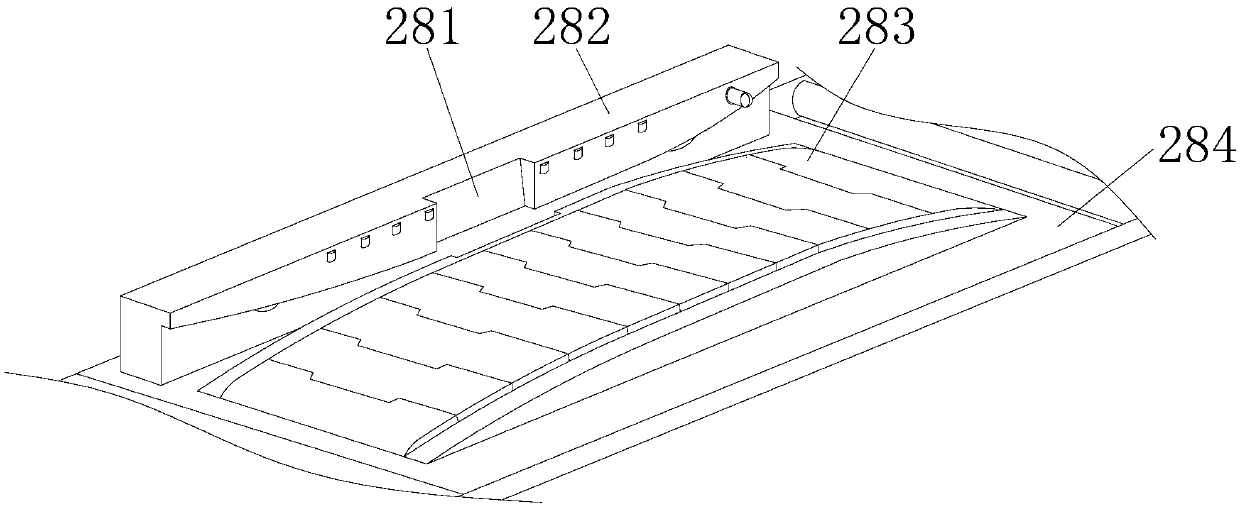

Double-sided sand-blasting machine for bending stress resistance of stainless steel sheet

ActiveCN109571281AStress conditions are the sameAvoid bending stressAbrasive machine appurtenancesAbrasive blasting machinesStress conditionsSand blasting

The invention discloses a double-sided sand-blasting machine for bending stress resistance of a stainless steel sheet. The double-sided sand-blasting machine structurally comprises an observation window, a sand-blasting box, a conveying frame, supporting legs, a dustproof curtain, a gravel conveying pipe, an air drawing pipe and a sand-blasting cylinder. The observation window is installed on thefront side of the sand-blasting box in an inlaid mode and connected with the sand-blasting box through a hinge, the sand-blasting box is located below the front end of the gravel conveying pipe, and the conveying frame is fixedly installed on the side surface of the sand-blasting box in an inlaid mode and communicates with the sandblasting box. Compared with the prior art, the special shape of a state limiting conversion block and the height difference between chain plate side edge protective blocks are utilized to erect the sheet, an upper single-inclined-face elastic jacking column and a lower single-inclined-face jacking top column which are provided with elastic elements push and abut against the sheet, and the sheet is placed flatly without damaging the sheet, so that the double-sidedsand-blasting machine can perform sand blasting on the two surfaces of the sheet simultaneously in the sheet transportation process, the stress conditions of the two surfaces are completely the same,the occurrence of bending stress is avoided, and the working efficiency of the double-sided sand-blasting machine is improved.

Owner:嘉兴市华染新能源有限公司

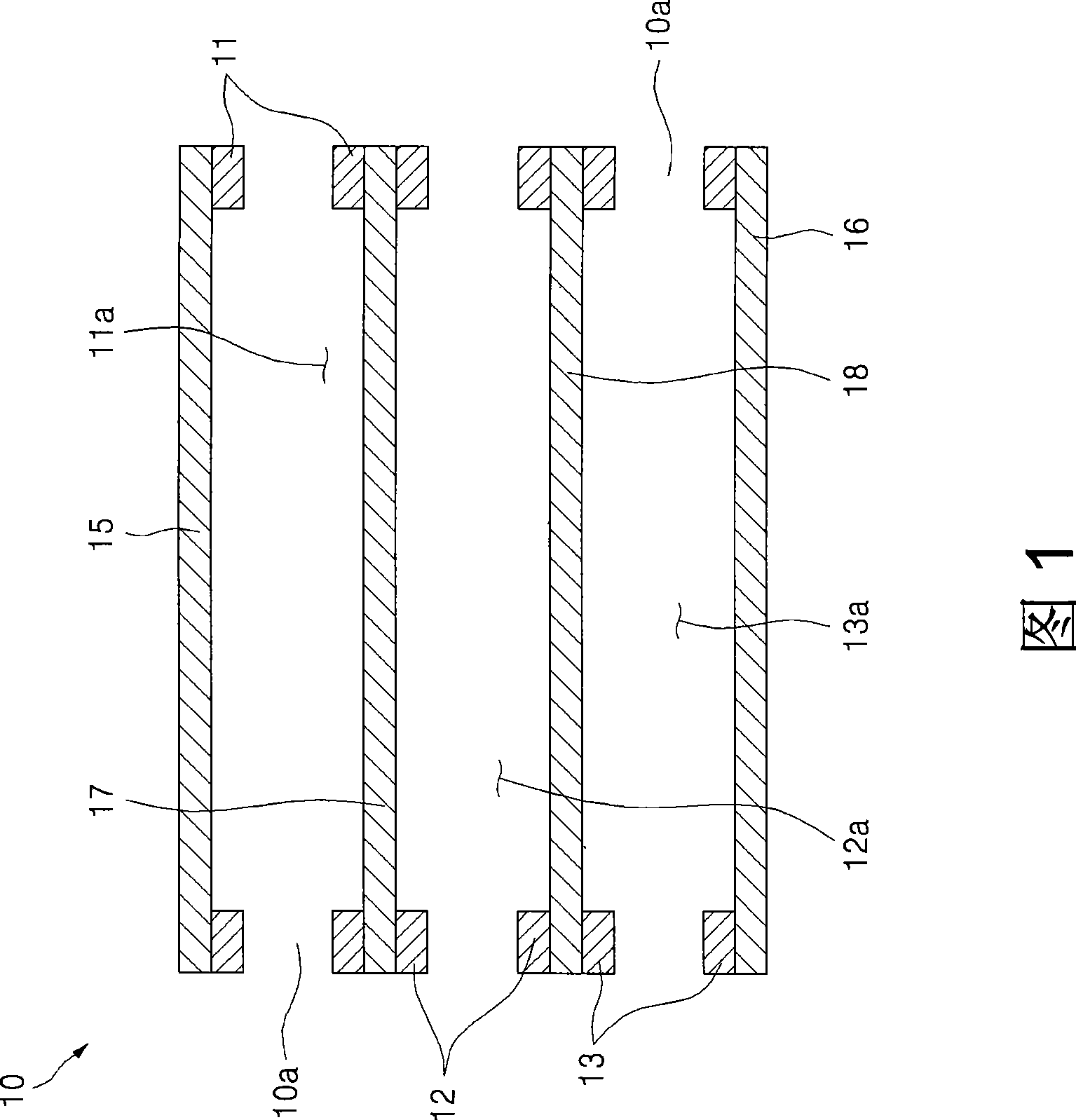

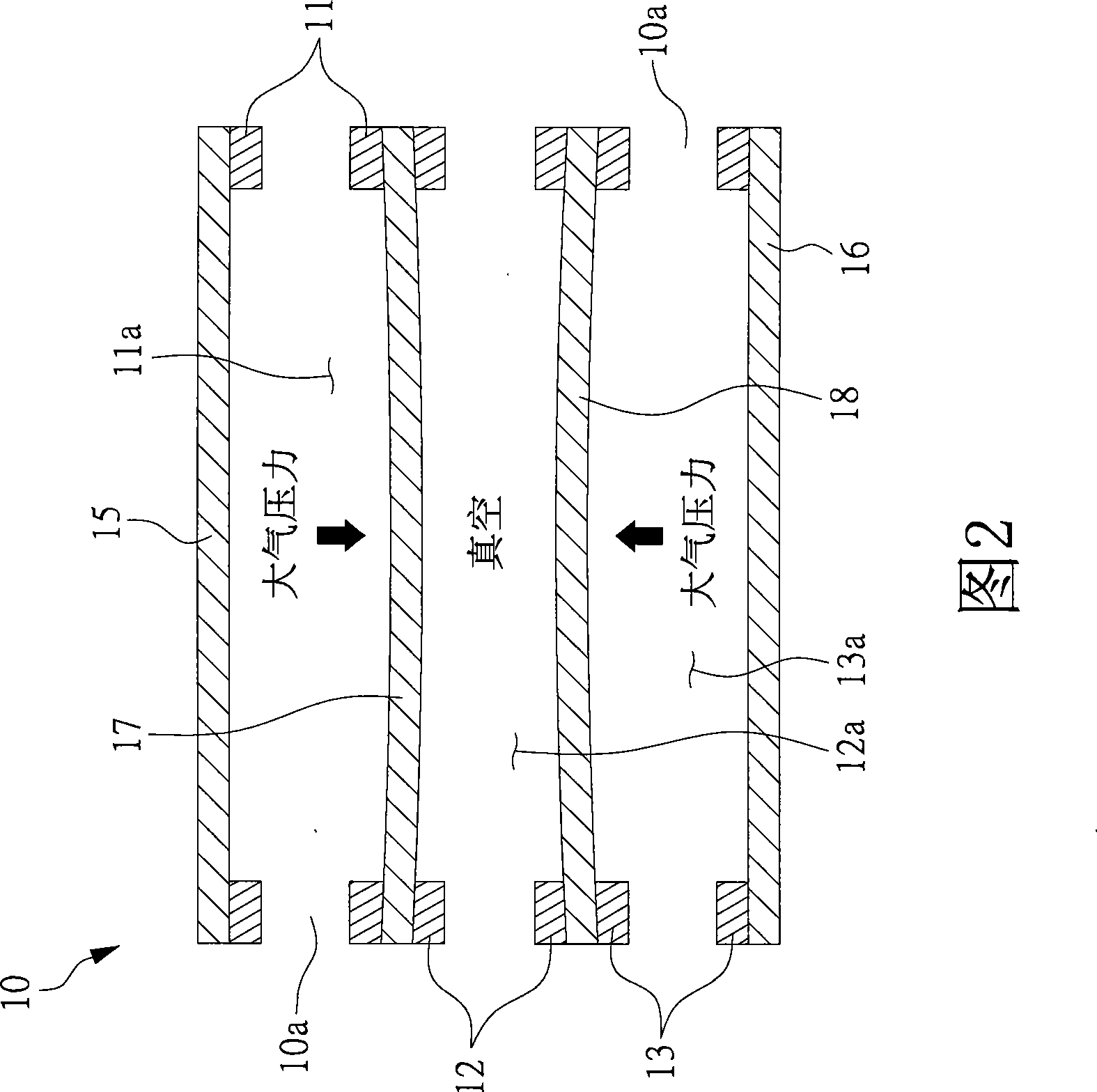

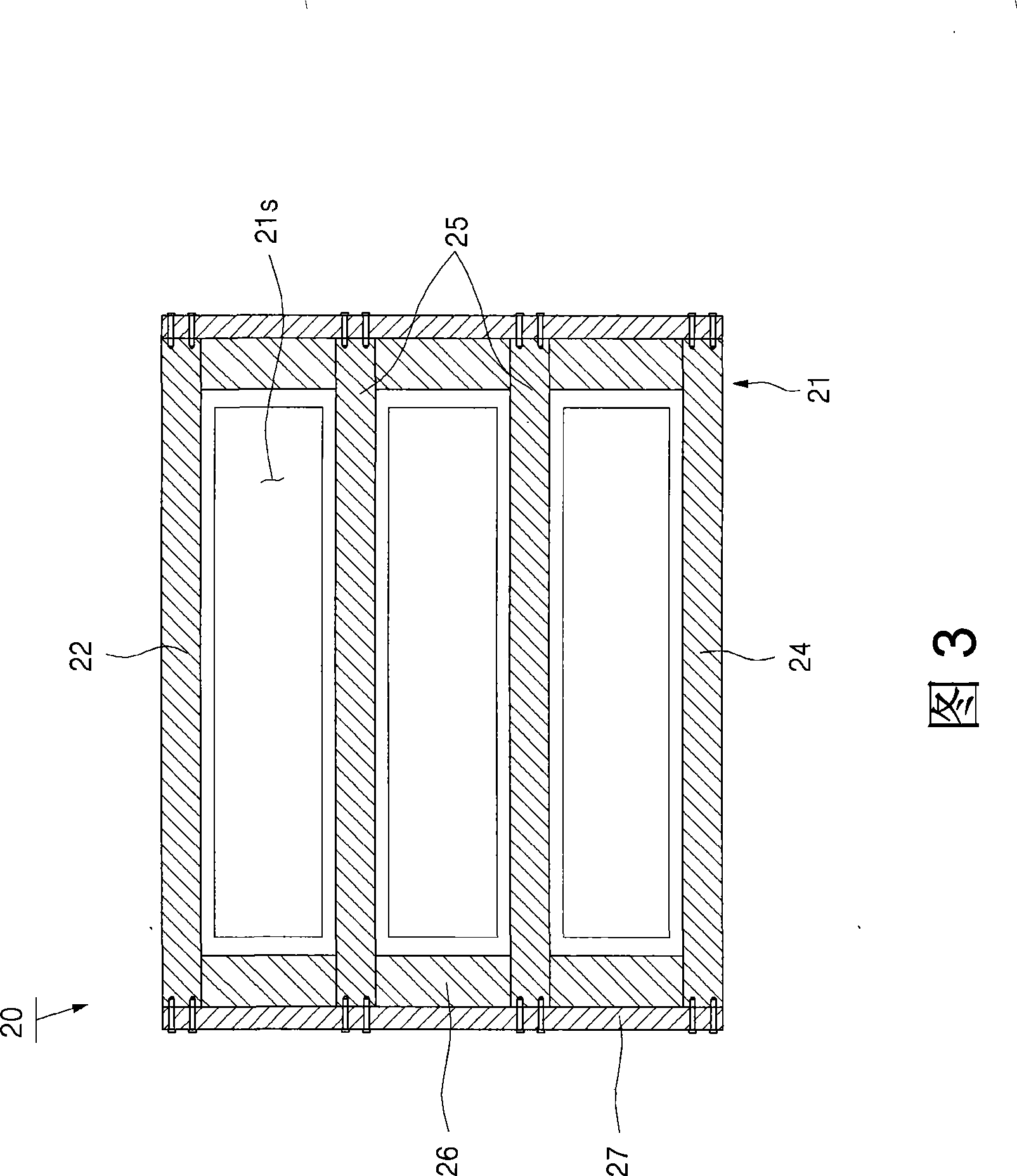

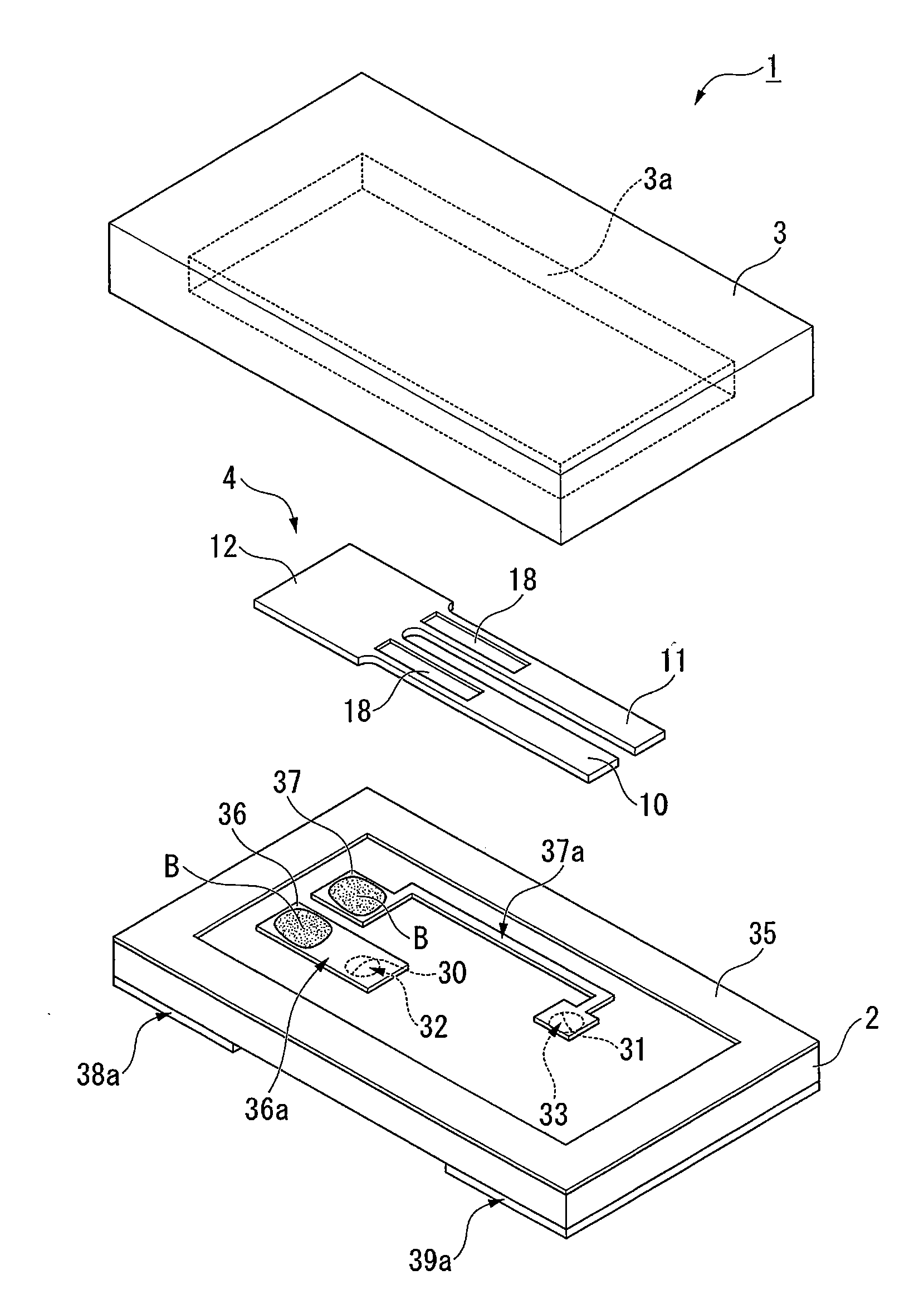

Charging room for chemical vapor deposition device

InactiveCN101440483AHigh strengthAvoid bending stressSemiconductor/solid-state device manufacturingChemical vapor deposition coatingGas phaseEngineering

The invention relates to a load chamber for chemical vapor deposition, comprising a cavity body having plural single-group chambers containing a substrate therein and plural grooves for inputting and outputting the substrate formed at one side surface and the other side surface in relation to the single-group chamber; and at least one reinforcing plate at least connected to one side surface and the other side surface of the chamber body having grooves. The strength of the chamber body is reinforced to avoid a bending stress generated as a result of pressure difference between the single-group chambers.

Owner:SFA ENG CORP

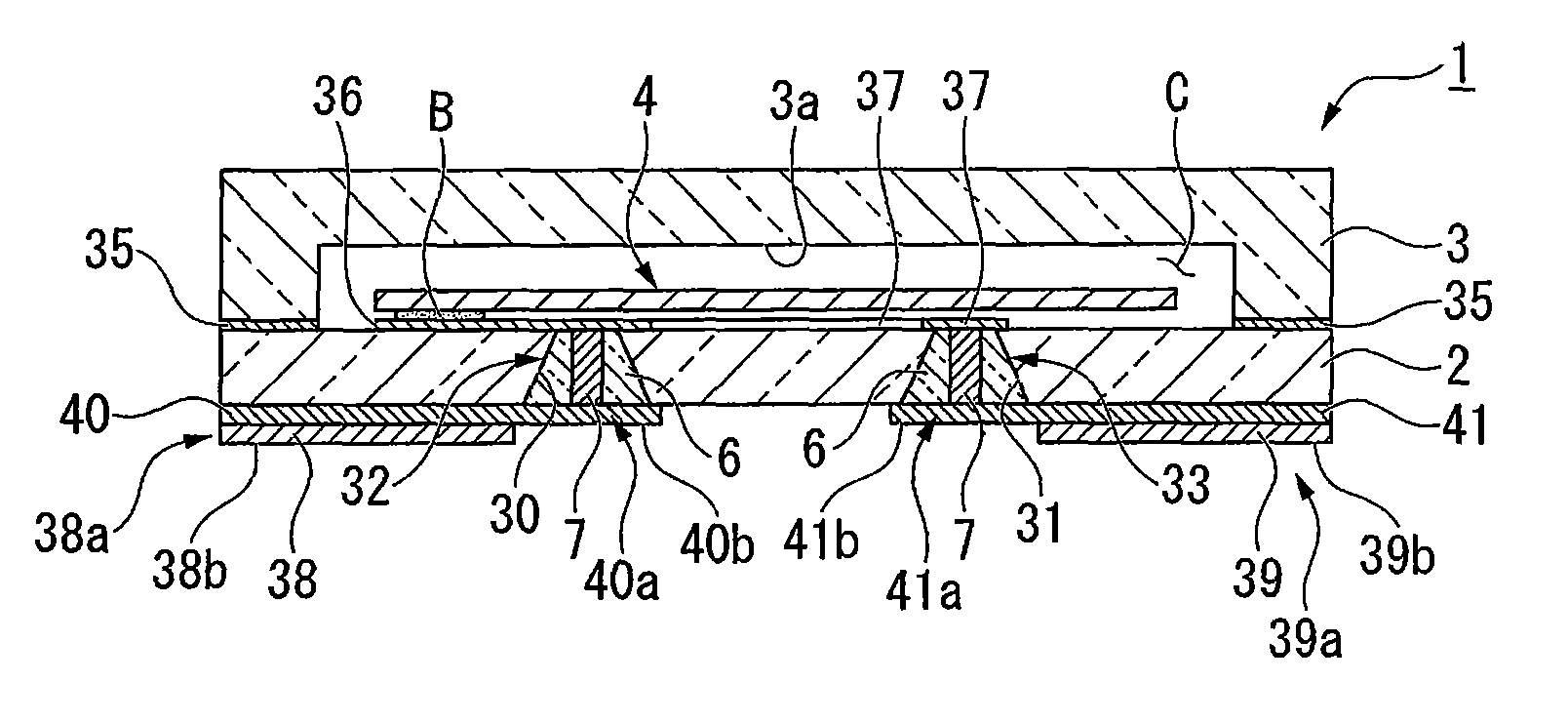

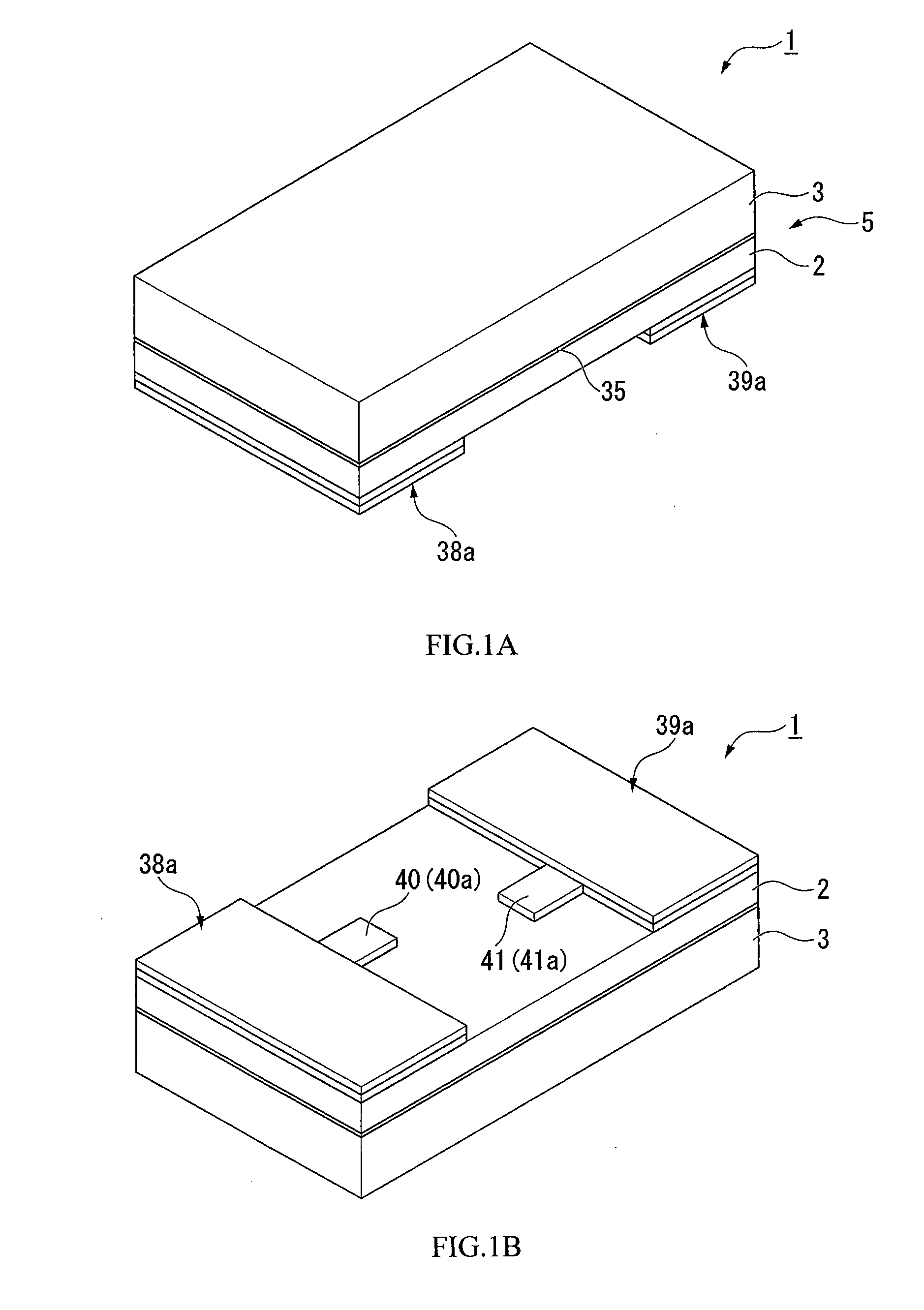

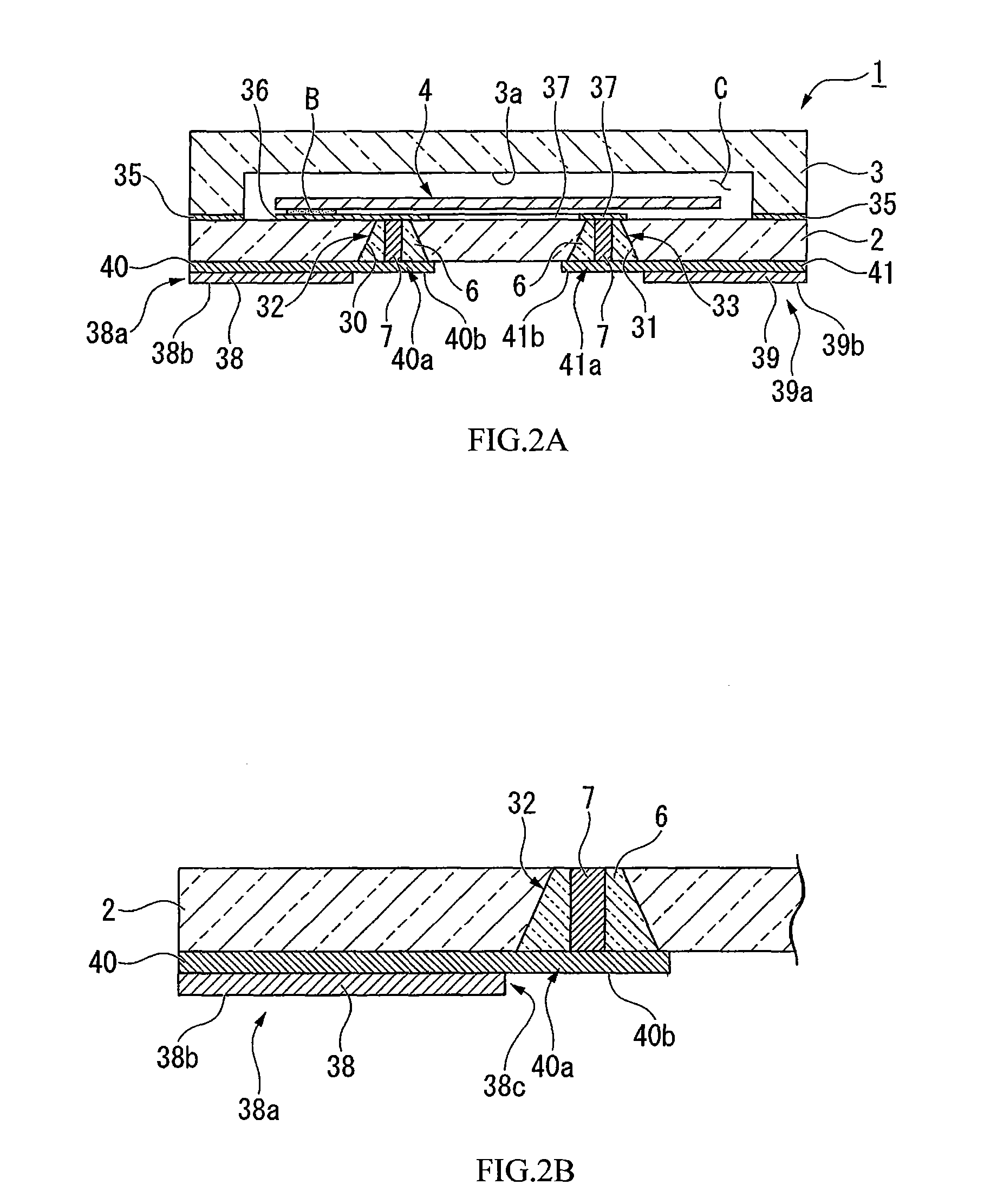

Piezoelectric vibrator, piezoelectric vibrator mounting body, and piezoelectric vibrator manufacturing method

InactiveUS20110285250A1High affinityReduce resistancePiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesPiezoelectric actuatorsPiezoelectric generator

This piezoelectric vibrator is provided with a package that is structured to include a first substrate and a second substrate that are bonded to each other such that a cavity is formed therebetween, an internal electrode portion that is formed on the first substrate and housed in the cavity, a piezoelectric vibrating reed that is sealed in the cavity and also is electrically connected to the internal electrode portion in the cavity, an external electrode portion that is formed on an external surface of the first substrate, a through electrode portion that is disposed so as not to be overlapped by the external electrode portion in a thickness direction of the first substrate, while one end of the through electrode portion is electrically connected to the internal electrode portion and another end of the through electrode portion is formed on the external surface of the first substrate while penetrating through the first substrate, and a routing wiring portion that electrically connects the through electrode portion and the external electrode portion.

Owner:SII CRYSTAL TECH

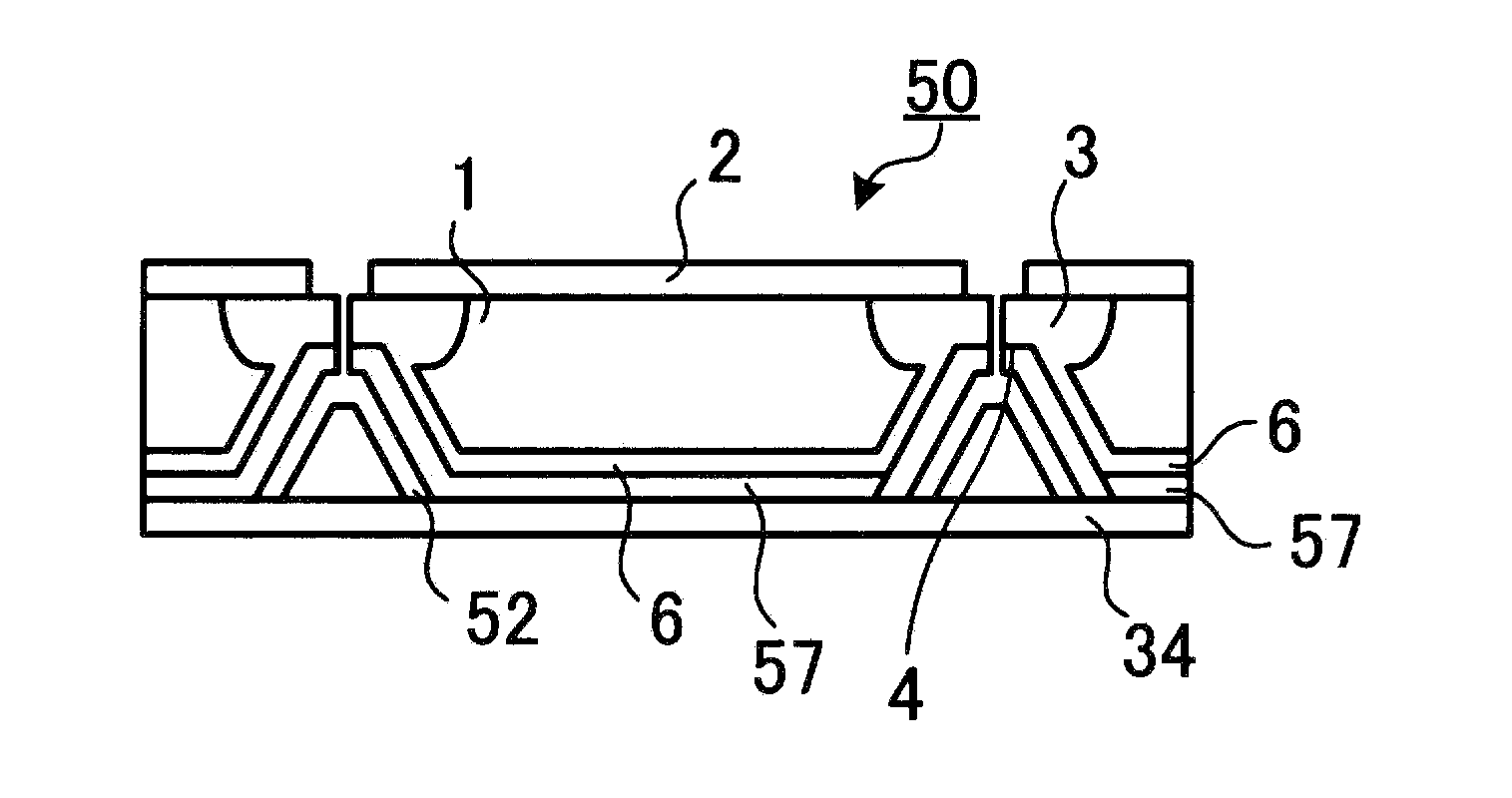

Semiconductor device

InactiveUS8598688B2Avoid breakingAvoid chippingSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor chipSemiconductor device modeling

A semiconductor device and manufacturing method are disclosed which prevent breakage and chipping of a semiconductor chip and improve device characteristics. A separation layer is in a side surface of an element end portion of the chip. An eave portion is formed by a depressed portion in the element end portion. A collector layer on the rear surface of the chip extends to a side wall and bottom surface of the depressed portion, and is connected to the separation layer. A collector electrode is over the whole surface of the collector layer, and is on the side wall of the depressed portion. The thickness of an outermost electrode film is 0.05 μm or less. The collector electrode on the rear surface of the chip is joined onto an insulating substrate via a solder layer, which covers the collector electrode on a flat portion of the rear surface of the semiconductor chip.

Owner:FUJI ELECTRIC CO LTD

Connector mounting construction and method

ActiveUS20070123072A1Prevent movementAvoid bending stressModulation transference balanced arrangementsPrinted circuitsEngineeringVALVE PORT

An upper end of a housing (31) is fit into a fitting hole (17) in a lid (12), and a fastenable portion (40) projects horizontally from a bottom end of the housing (31). A bolt (41) is inserted vertically through an insertion hole (42) in the fastenable portion (40) and is screwed into a bolt hole (27A) of a valve body (20) on the lid (12). An engaging groove (45) is formed near the bottom of the housing (31). A U-shaped locking plate (52) projects from the valve body (20) and is inserted into the engaging groove (45) with a clearance that permits movements of the housing (31) along directions intersecting an axis line of the housing (31) while preventing movements of the housing along the axis line. The bolt (41) is insertable into the insertion hole (42) of the fastening portion (40) while defining a clearance.

Owner:SUMITOMO WIRING SYST LTD

Piezoelectric vibrator, piezoelectric vibrator mounting body, and piezoelectric vibrator manufacturing method

InactiveUS8415862B2Avoid crackingReliable electrical connectionPiezoelectric/electrostrictive device manufacture/assemblyPiezoelectric/electrostriction/magnetostriction machinesElectrical and Electronics engineeringElectrode

This piezoelectric vibrator is provided with a package that is structured to include a first substrate and a second substrate that are bonded to each other such that a cavity is formed therebetween, an internal electrode portion that is formed on the first substrate and housed in the cavity, a piezoelectric vibrating reed that is sealed in the cavity and also is electrically connected to the internal electrode portion in the cavity, an external electrode portion that is formed on an external surface of the first substrate, a through electrode portion that is disposed so as not to be overlapped by the external electrode portion in a thickness direction of the first substrate, while one end of the through electrode portion is electrically connected to the internal electrode portion and another end of the through electrode portion is formed on the external surface of the first substrate while penetrating through the first substrate, and a routing wiring portion that electrically connects the through electrode portion and the external electrode portion.

Owner:SII CRYSTAL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com