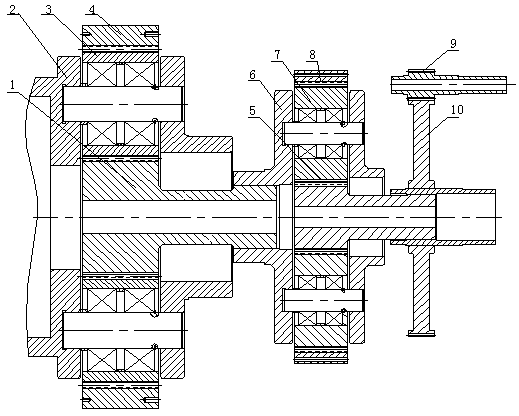

Flexible planet gear transmission mechanism of wind power gear box

A technology of gear transmission mechanism and wind power gearbox, which is applied to transmission parts, belts/chains/gears, mechanical equipment, etc. It can solve the problem that the planetary gear shaft cannot produce elastic deformation, cannot maintain normal meshing of meshing teeth, and affects system reliability. To achieve the effect of improving load sharing performance, avoiding processing quality defects and increasing bending stress, and maintaining normal meshing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

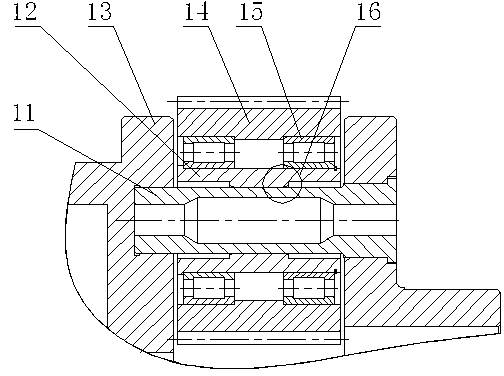

[0019] Such as figure 2 Shown, the present invention comprises axle pin 11, planetary wheel support 13, planetary wheel 14 and planetary wheel bearing 15, axle pin 11 is installed on the planetary wheel support 13, and planetary wheel 14 is installed on the axle pin 11 by planetary wheel bearing 15, so The shaft pin 11 is a hollow shaft, and a shaft sleeve 12 is installed between the shaft pin 11 and the planet wheel bearing 15, and an inner step 16 is provided in the middle of the shaft sleeve 12 .

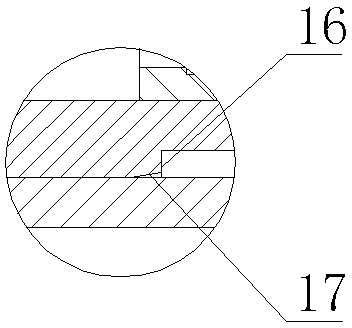

[0020] Such as image 3 As shown, the two ends of the inner step 16 of the shaft sleeve 12 are provided with a tapered surface 17, and the tapered surface 17 makes the diameter of the two ends of the stepped ring surface larger, and when the shaft pin 11 is bent and deformed greatly, the contact area is increased. Large, the unit load is reduced, and the furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com