Windshield wiper strip support, forming method and windshield wiper sheet with windshield wiper strip support

A molding method and wiper strip technology, which is applied in vehicle cleaning, vehicle maintenance, transportation and packaging, and can solve problems such as poor fatigue resistance, low material strength, and difficulty in implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

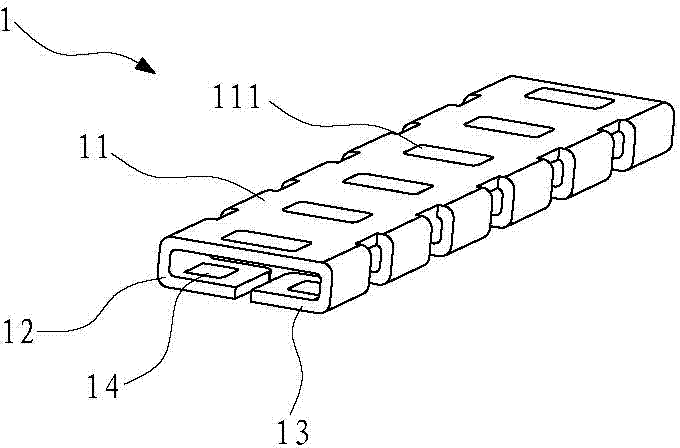

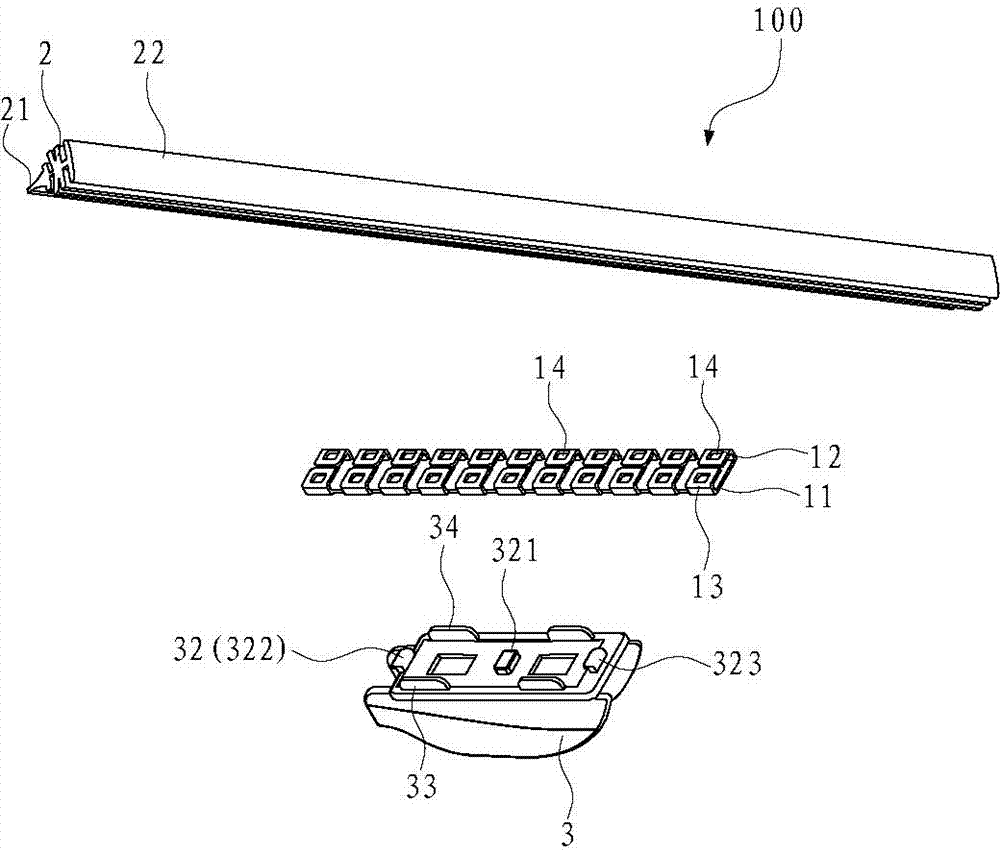

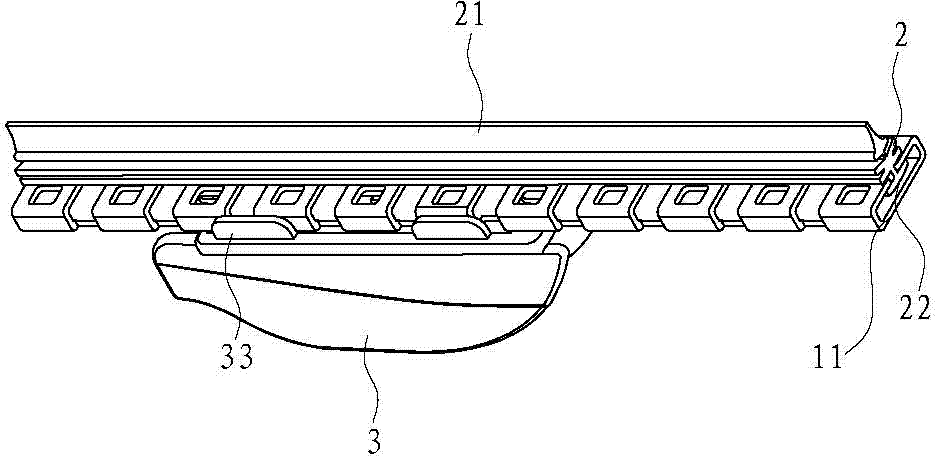

[0060] Such as Figure 1 to Figure 11 As shown, it is the first embodiment of the present invention related to a wiper strip bracket 1, the wiper strip bracket 1 has a back plate 11, a plurality of first ear portions 12 and a plurality of second ear portions 13, the back plate 11 is along the Extending longitudinally, the plurality of first ear portions 12 and the plurality of second ear portions 13 are all connected to the backboard 11, the plurality of first ear portions 12 are arranged at intervals on one lateral side of the backboard 11, and the plurality of second ear portions The ear portions 13 are arranged at intervals on the other lateral side of the back plate 11. The back plate 11, the plurality of first ear portions 12 and the plurality of second ear portions 13 surround and form a longitudinal slot, and the longitudinal slot faces toward the wiper strip 2. Used to accommodate the back strip 22 of the wiper strip 2 , the back plate 11 , the plurality of first ear p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com