Securing element and exhaust gas turbocharger having variable turbine geometry

A technology for fixing components and exhaust gas turbines, applied in the directions of threaded fasteners, connecting components, screws, etc., can solve problems such as expansion of blade flow loss, loss of spiral prestress, damage to blade cascade devices, etc., to improve work reliability and plasticity. The effect of reducing the risk of brittleness and embrittlement and the possibility of failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

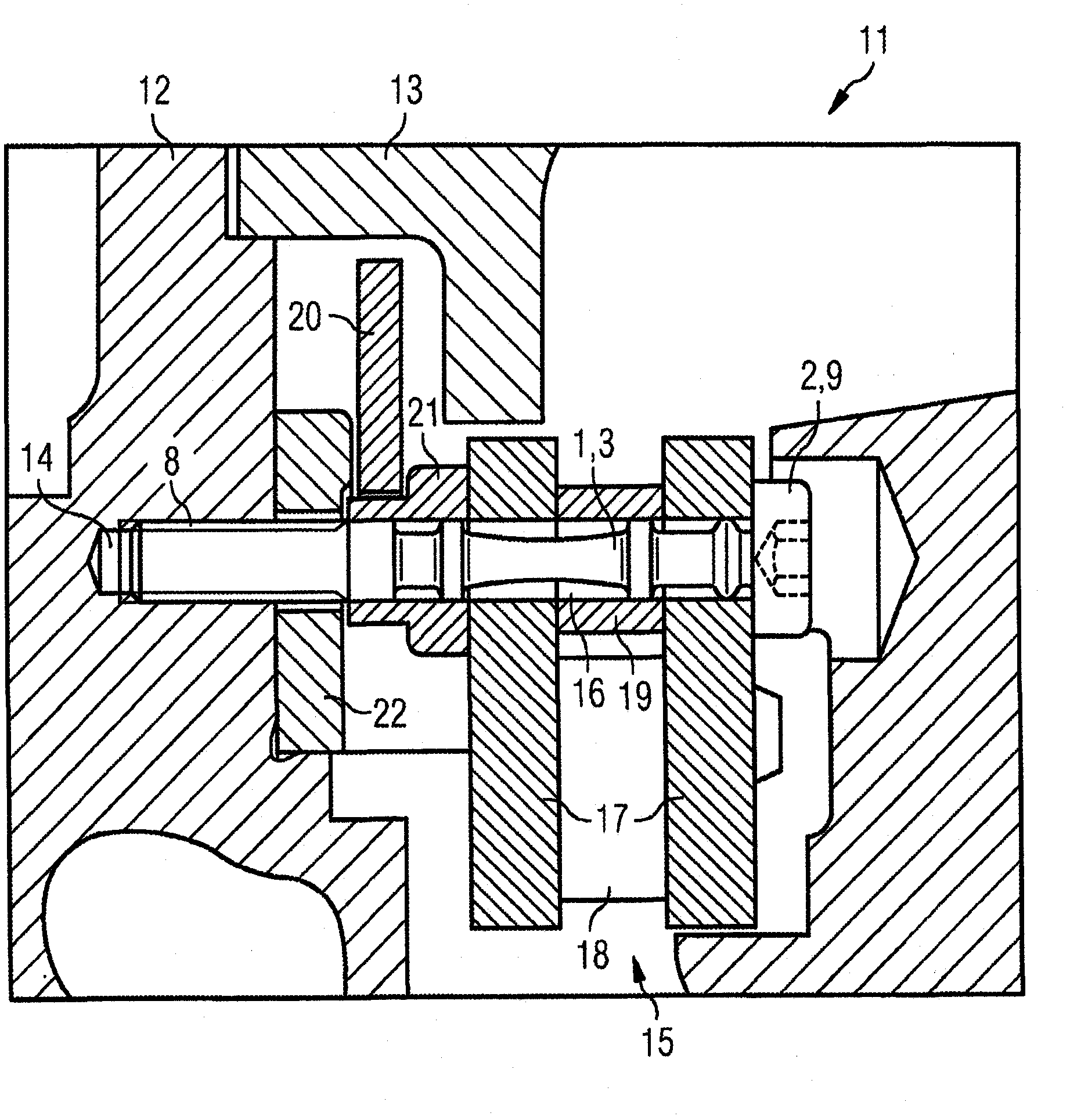

[0042] Identical or functionally equivalent elements are designated by the same reference numerals throughout the drawings, unless otherwise indicated.

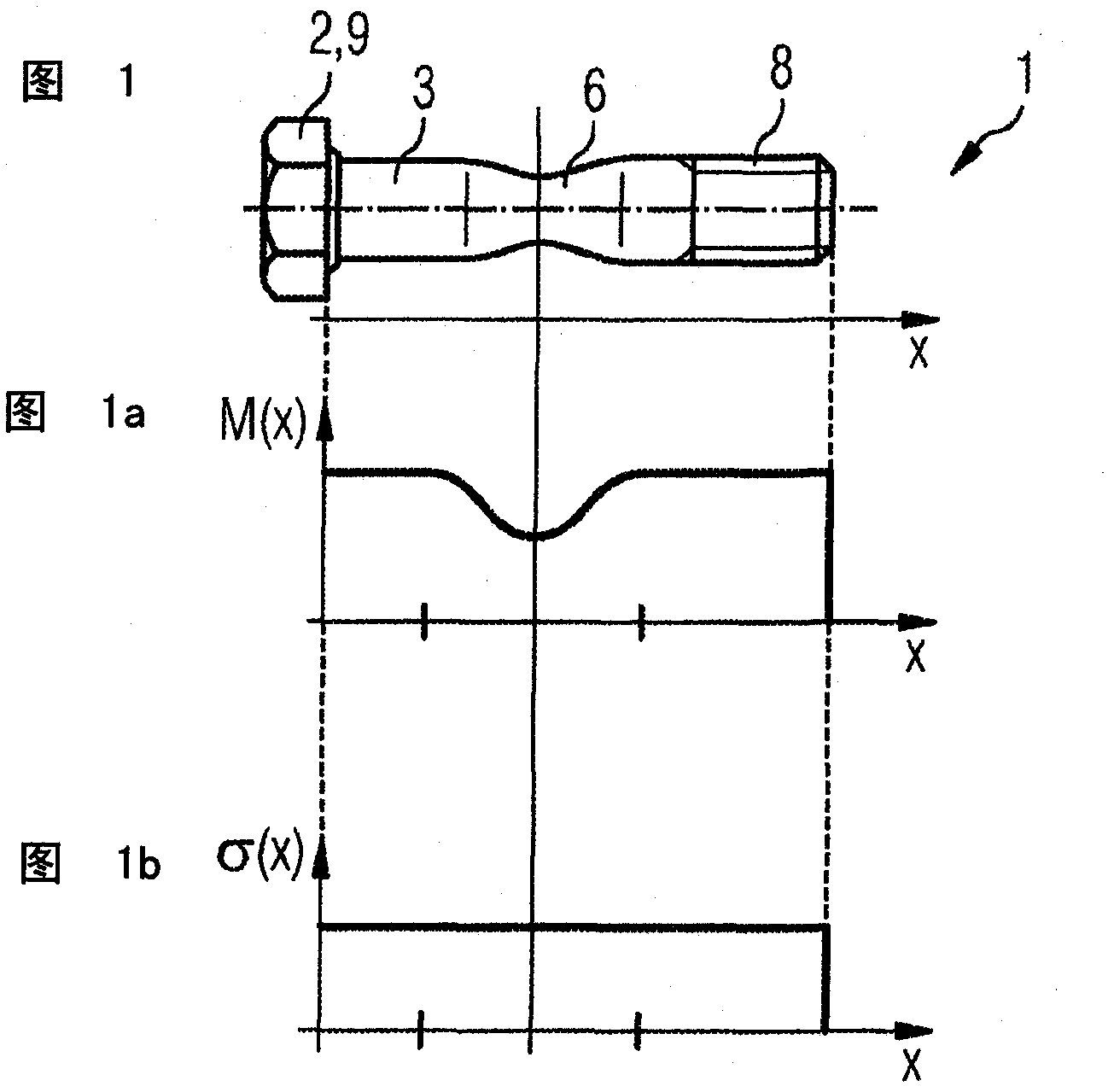

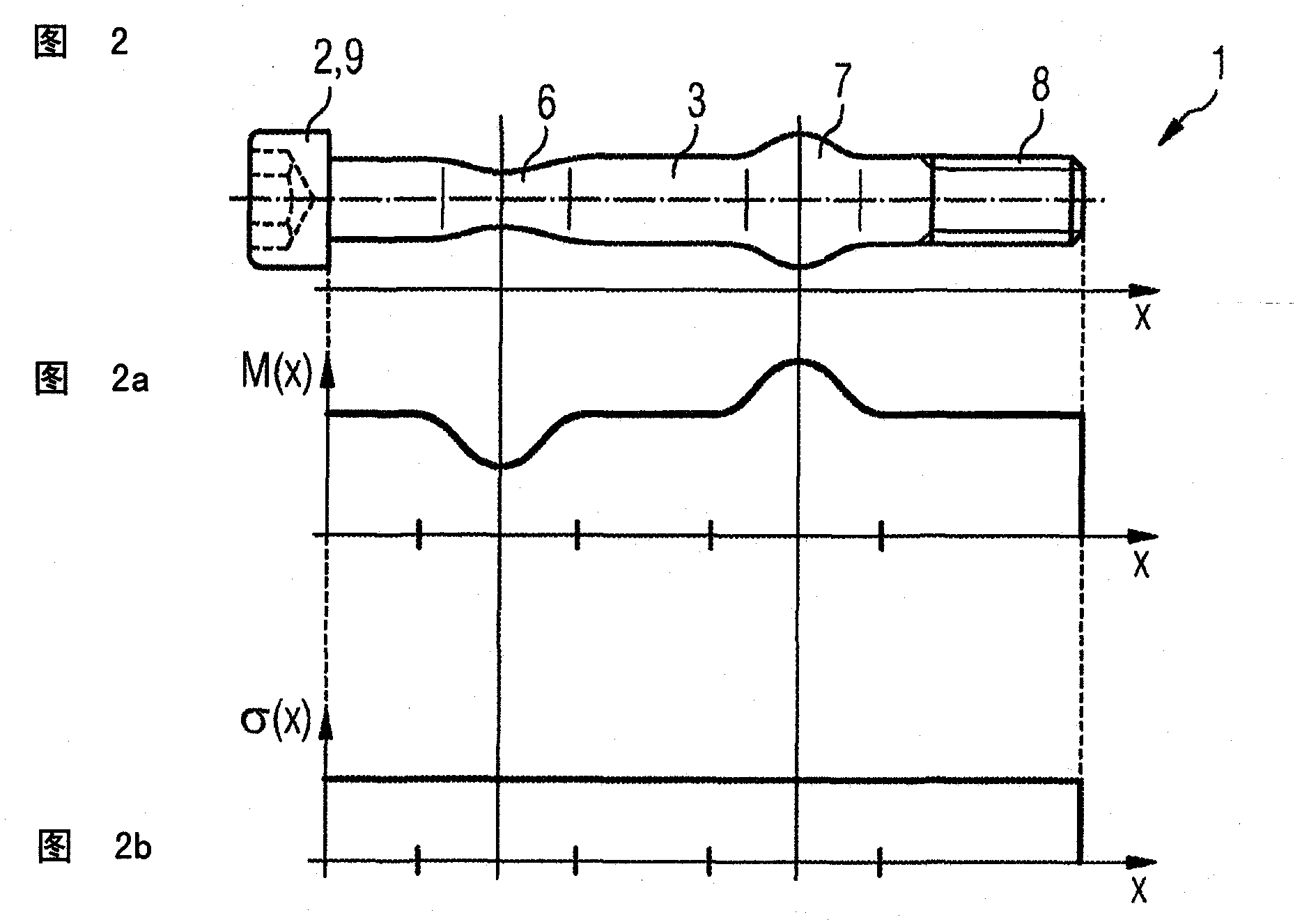

[0043] figure 1 It is a side view of a first embodiment of the fixing element 1 of the present invention. The fixing element 1 has a head 2 and a shaft 3 . The head 2 is designed here as a screw head 9 integrally formed on the fastening element. On the side opposite the head 2 , the shaft 3 of the fastening element 1 has a thread 8 . The rod 3 of the fixing element 1 has, for example, a local taper 6 .

[0044] Figure 1a is a view of the bending moment distribution M(x) in a first embodiment of the fixing element according to the invention. The bending moment distribution M(x) is a function of the bar 3 ordinate x.

[0045] Figure 1b is a view of the bending stress distribution σ(x) in a first embodiment of the fixing element 1 according to the invention. The bending stress distribution σ(x) is a function of the bar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com