A side chain type high temperature proton exchange membrane for fuel cells and its preparation method

A proton exchange membrane, fuel cell technology, applied in fuel cells, circuits, electrical components, etc., can solve the problems of poor membrane toughness, difficult membrane production, peeling of reinforcing fibers and membrane matrix materials, etc., to achieve high proton conductivity and Mechanical properties, effect of great application potential

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

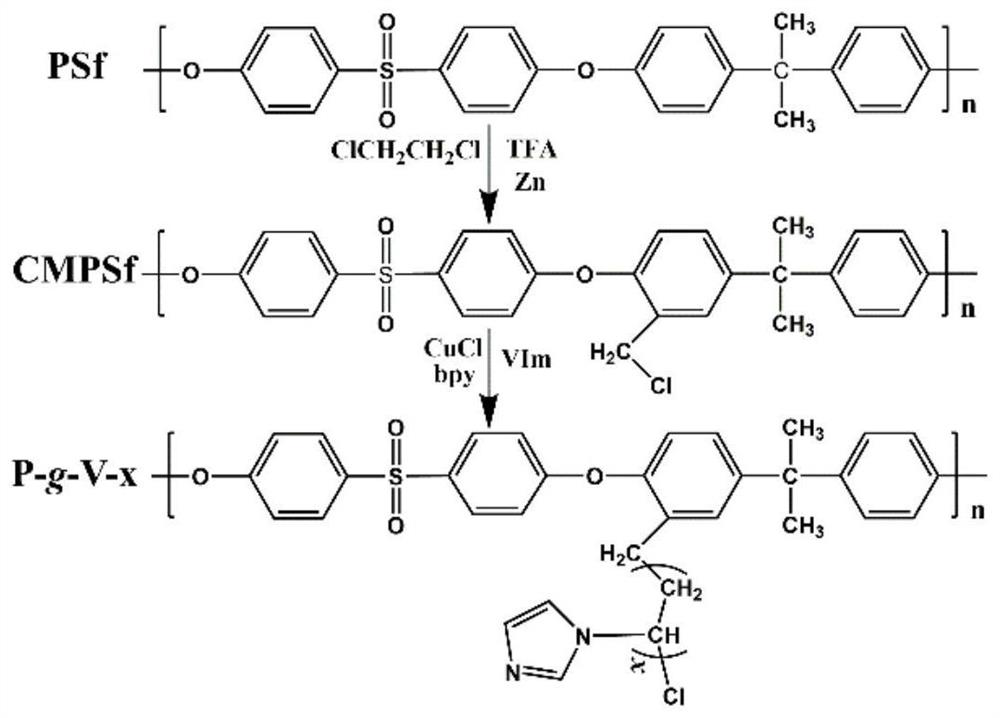

[0034] The preparation method of the present invention mainly includes three steps of synthesis of side chain modified polymer, solution casting membrane and post-protonation treatment, and its preparation process route diagram is as follows: figure 1 As shown, the details are as follows:

[0035] (1) Chloromethylation reaction of polymer

[0036] Dissolving engineering plastic polymers with excellent thermal stability and chemical stability in suitable organic solvents (such as dichloroethane, tetrachloroethane, chloroform) to form a polymer solution to be reacted, the concentration is 5-20wt% , the preferred concentration is 8-15wt%, and the optimum concentration range is 9-12wt%.

[0037] Then add a certain amount of zinc powder and trifluoroacetic acid, usually with a mass ratio of 1:0.5 to 1:3, and the best ratio is: 1:1.2 to 1:1.5.

[0038] The reaction system was stirred at 20-50°C (according to the selected engineering plastics, the reaction temperature should be adj...

Embodiment 1

[0048] Polysulfone (PSf) is selected as the high molecular polymer, and its chloromethylation process is as follows:

[0049] Polysulfone, which has excellent thermal stability and chemical stability, was dissolved in dichloroethane at a concentration of 10 wt%. Then add zinc powder and trifluoroacetic acid, the mass ratio of the two is 1:0.5. After the reaction system was stirred at 35°C for 0.5 hours, 25 mL of chloromethyl ether was added dropwise, and the reaction was continued for 0.5 hours after the dropwise addition was completed. The reaction mixture after the reaction was poured into a precipitant for precipitation, and then filtered sequentially. After washing and drying, a polymer containing chloromethylation is obtained. The degree of chloroformation of polysulfone is obtained from the ratio of the integral of methylene hydrogen on the benzyl group to the integral of benzene ring hydrogen on the main chain in the nuclear magnetic spectrum, and the selected degree o...

Embodiment 2

[0056] Polyphenylsulfone is selected as the polymer, and its chloromethylation process is as follows:

[0057] Polyphenylsulfone, which has excellent thermal and chemical stability, was dissolved in chloroform in a concentration range of 13 wt%. Then add zinc powder and trifluoroacetic acid, the mass ratio of the two is 1:1. After the reaction system was stirred at 45°C for 1.1 hours, 35 mL of chloromethyl ether was added dropwise, and the reaction was continued for 1 hour after the dropwise addition was completed. The reaction mixture after the reaction was poured into a precipitant for precipitation, and then filtered sequentially. After washing and drying, a polymer containing chloromethylation is obtained. The degree of chloroformation of polyphenylsulfone is obtained according to the ratio of the integral of methylene hydrogen on the benzyl group to the integral of benzene ring hydrogen on the main chain in the nuclear magnetic spectrum, and the selected degree of chloro...

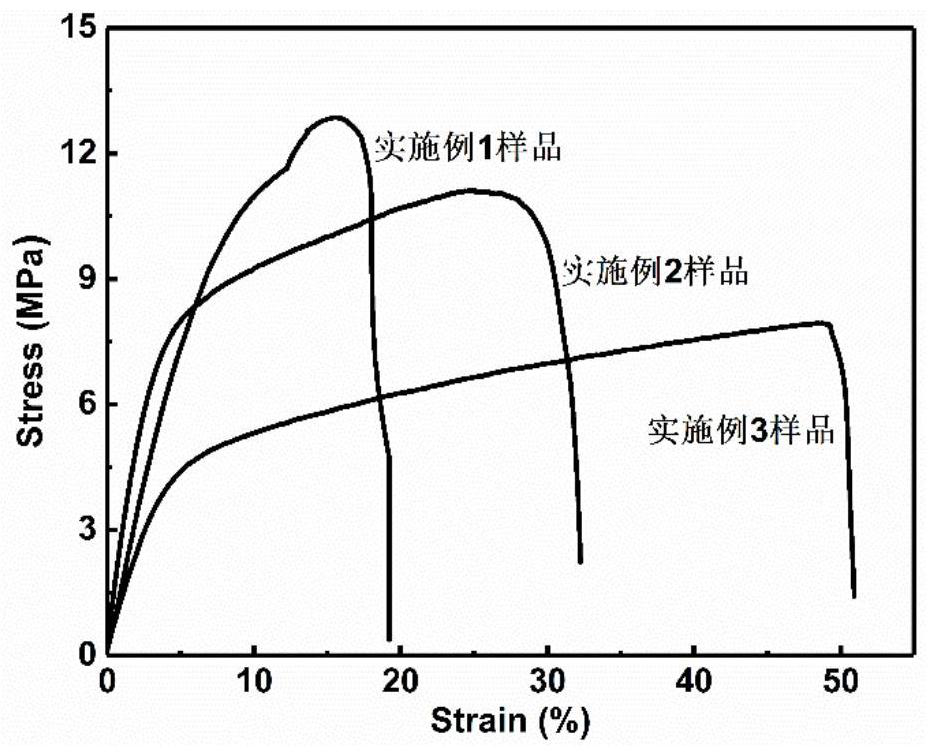

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com