A flame-retardant antibacterial compound containing halloysite and its preparation method

A composite, halloysite nanotube technology, applied in the field of flame retardant and antibacterial composites and their preparation, can solve the problems of insignificant flame retardant effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

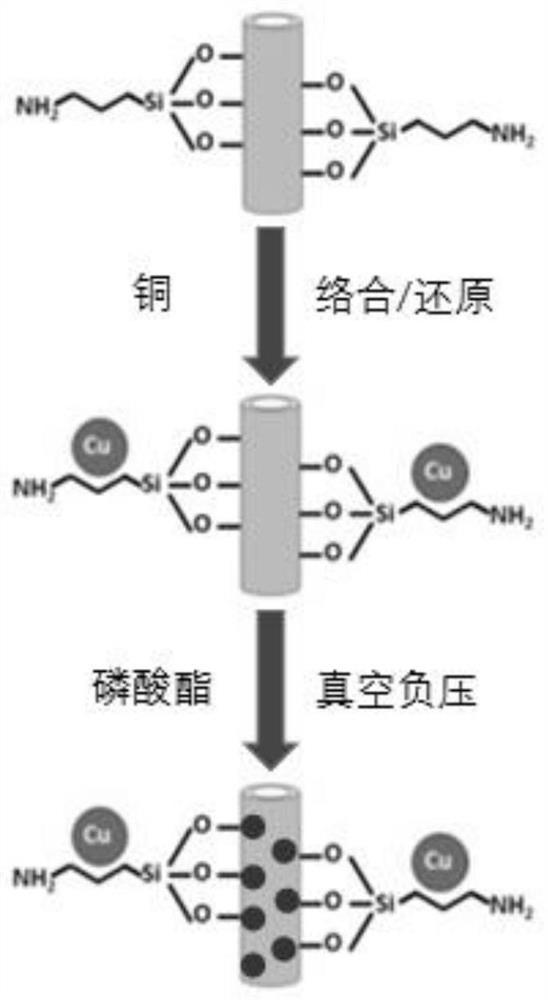

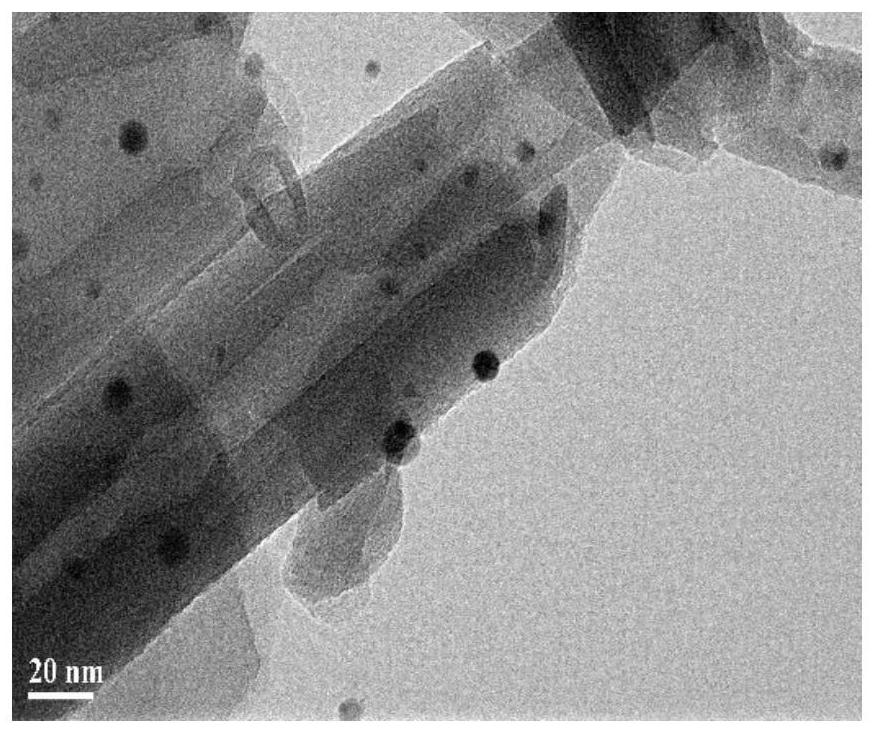

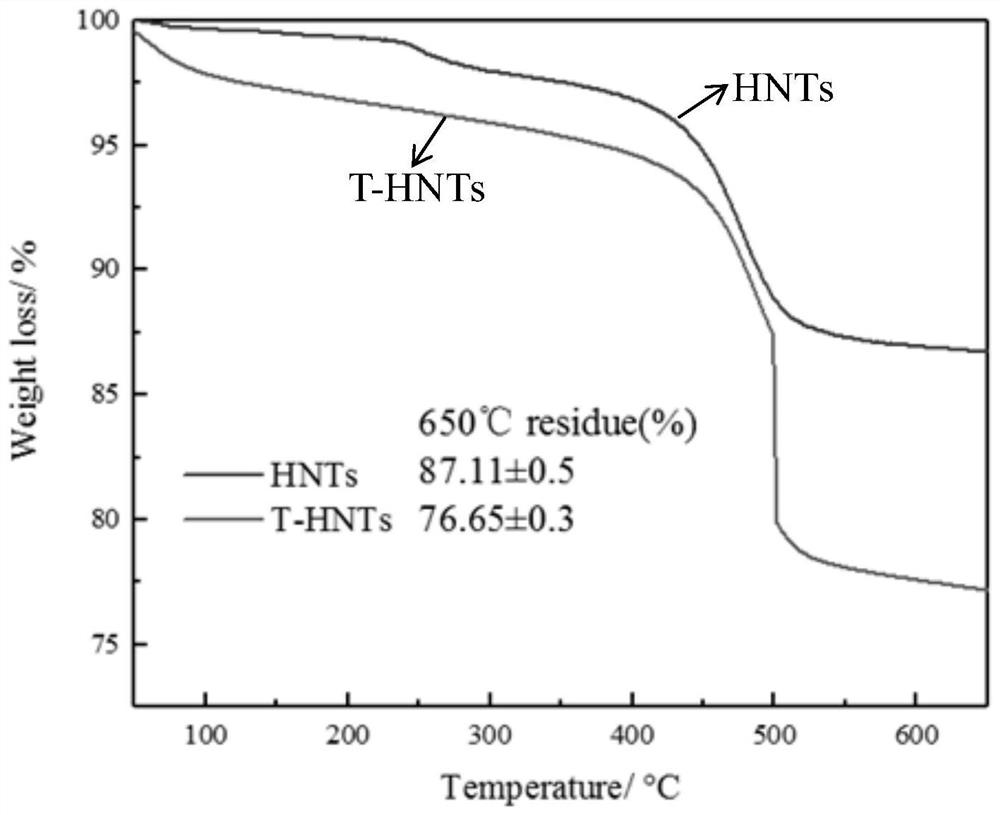

[0072] 1, the preparation of Elonan nanotubes carrying copper-like monument:

[0073] 10 g of Elonin nanotubes were dispersed in 100 ml of toluene, and 10 g of A-1110 coupling agent was added, and 20 min was tested at room temperature, then warmed to 60 ° C, after refluxing and stirring for 4 h, washed twice with toluene. It was dried in vacuo at 80 ° C for 4 h to give modified Elonan nanotubes. 7.5 g of copper chloride was dissolved in 100 ml of water, and 5 g of modified Eloni nanotubes were added, 15 min was tested at room temperature, then warmed to 60 ° C, stirred for 7 h, and washed twice with deionized water. It was dried in vacuo at 80 ° C for 4 h to obtain an endonal nanotube loaded with copper ions. The 4G loaded copper ions were added to 50 ml of deionized water, and the ultrasonic treatment was 15 min, then slowly warmed to 85 ° C, 0.25 g of ascorbic acid, stirred for 2 h, washed with deionized water, at 60 ° C Dry 10 h to get an Elonan nanotube loaded with copper.

[...

Embodiment 2

[0077] 1, the preparation of Elonan nanotubes carrying copper-like monument:

[0078] 10 g of Elonan nanotubes were dispersed in 100 ml of toluene, and 10 g of KH-602 coupling agent was added, and 20 min was tested at room temperature, then warmed to 60 ° C, after refluxing and stirring for 4 h, was washed twice with toluene. It was dried in vacuo at 80 ° C for 4 h to give modified Elonan nanotubes. 7.5 g of nitrate copper was dissolved in 50 mL of water, and 5 g of modified Eloni nanotubes were added, and 15 min was treated at room temperature, then warmed to 60 ° C, stirred for 6 h, and washed with deionized water twice to the resulting product. It was dried in vacuo at 80 ° C for 4 h to obtain an endonal nanotube loaded with copper ions. The 4G loaded copper ions were added to 50 mL of deionized water, and the ultrasonic treatment was 15 min, then slowly warmed to 85 ° C, 0.25 g of sodium borohydride, stirred for 2 h, washed with deionized water, at 60 It was dried at ° C for 1...

Embodiment 3

[0082] 1, the preparation of Elonan nanotubes carrying copper-like monument:

[0083] 10 g of Elonan nanotubes were dispersed in 100 ml of ethanol, and 5 g of KH-550 coupling agent was added, and 20 min was tested at room temperature, then warmed to 60 ° C, stirring the reaction for 4 h, washed with ethanol twice with ethanol, It was dried in vacuo at 80 ° C for 4 h to give modified Elonan nanotubes. 5 g of copper sulfate was dissolved in 50 mL of water, and 5 g of modified Eloni nanotubes were added, and 15 min was tested at room temperature, then warmed to 60 ° C, stirred for 6 h, and washed with deionized water twice to the resulting product. The vacuum was dried in vacuo at 80 ° C to obtain an endonal nanotube loaded with copper ions. The 4G loaded copper ions were added to 50 ml of deionized water, and the ultrasonic treatment was 15 min, then slowly warmed to 85 ° C, 0.25 g of ascorbic acid, stirred for 2 h, washed with deionized water, at 60 ° C Dry 10 h to get an Elonan na...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| load ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com