Shaft brake disc, in particular for a rail vehicle

A rail vehicle and brake disc technology, applied in the direction of brake discs, brake types, brake components, etc., can solve problems such as unfavorable cost structures, and achieve the effect of avoiding bending stress and optimizing force introduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

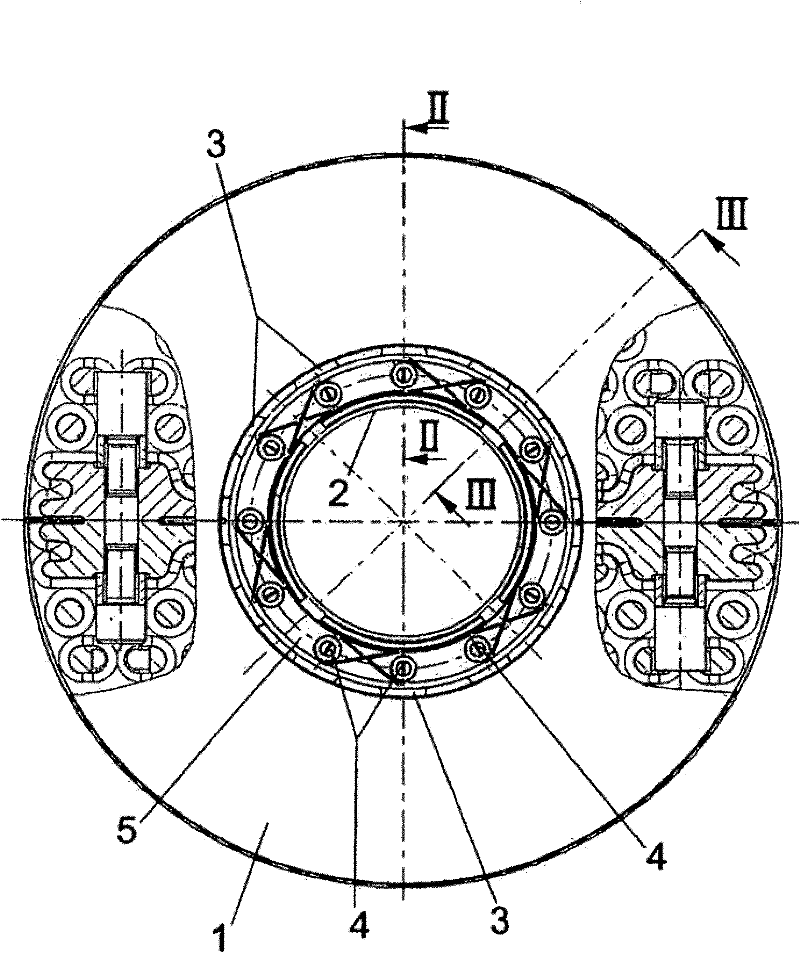

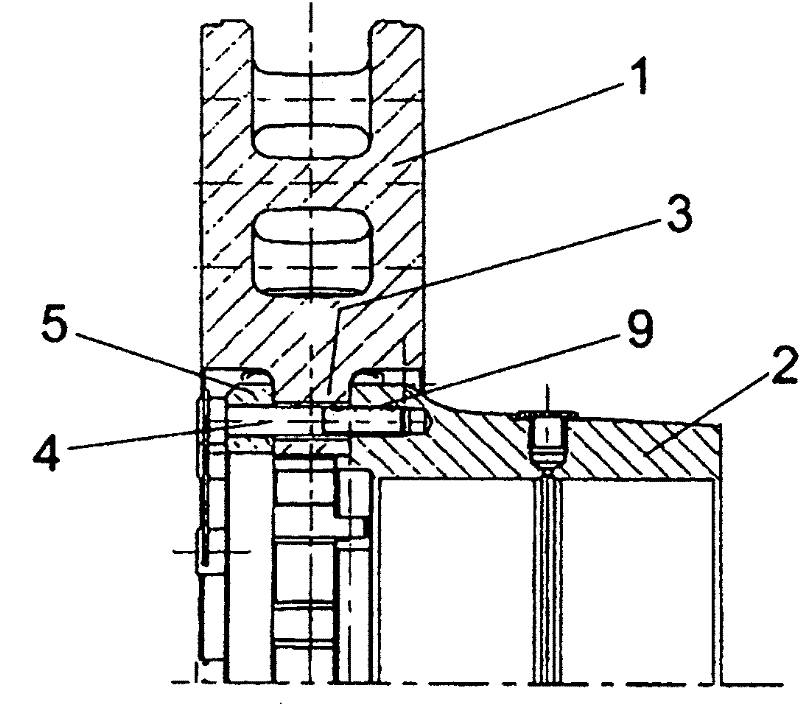

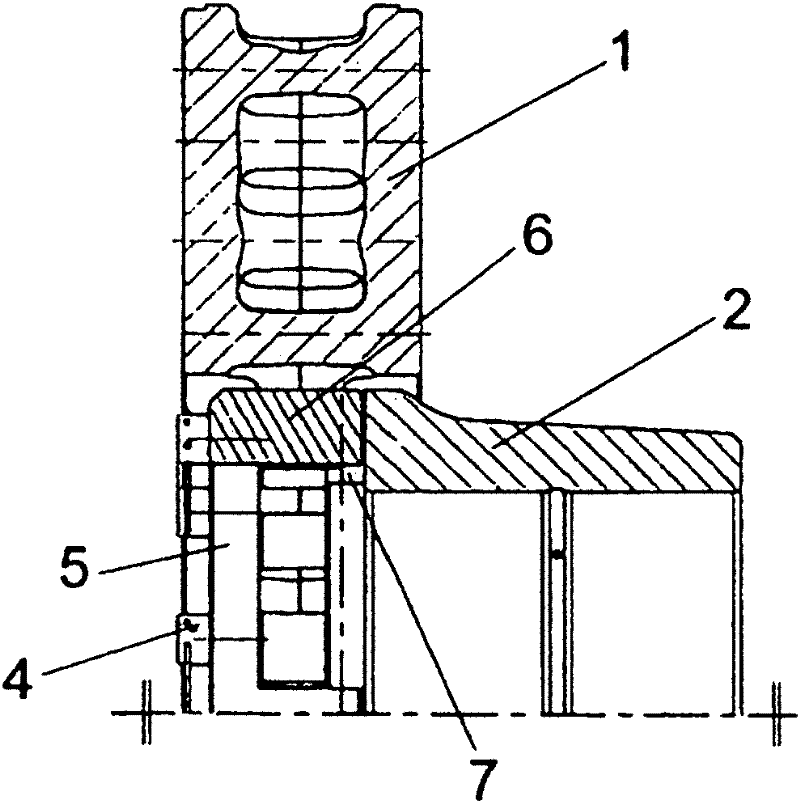

[0026] exist figure 1 A shaft brake disc is shown in , which has a friction ring 1 which is connected to a hub 2 via screws 4 .

[0027] Here, the screws 4 are screwed into threaded holes 9 provided on the end side in the hub 2 , and they are guided with their rods through the through-holes 10 of the friction ring 9 and the through-holes 8 of the tensioning ring 5 ( Figure 4 ), the tensioning ring rests on the connecting flange 3 of the friction ring 1 and more precisely on the side opposite the hub 2 .

[0028] The tensioning ring 5 forms a seat for the screw 4 , ie its head, via which the friction ring 1 is pressed against the hub 2 .

[0029] The connecting flanges 3 of the friction ring 1 are distributed evenly over the inner circumference of the friction ring and extend radially inwards.

[0030] According to the invention, the tensioning ring 5 and the hub 2 engage with each other in a form-fitting manner. For this purpose, the one-piece tensioning ring 5 has four, p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com