Charging room for chemical vapor deposition device

A chemical vapor deposition, loading chamber technology, applied in gaseous chemical plating, electrical components, coatings, etc., can solve problems such as poor process and influence, and achieve the effects of improving productivity, reducing manufacturing, and reducing bending

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] The present invention has been claimed at the Korea Intellectual Property Office by filing Korean Patent Application No. 10-2007-0119236 on November 21, 2007, Korean Patent Application No. 10-2007-0131150 on December 14, 2007, and The advantages of Korean Patent Application No. 10-2008-0027927 filed on March 26, 2008 are disclosed in full as follows.

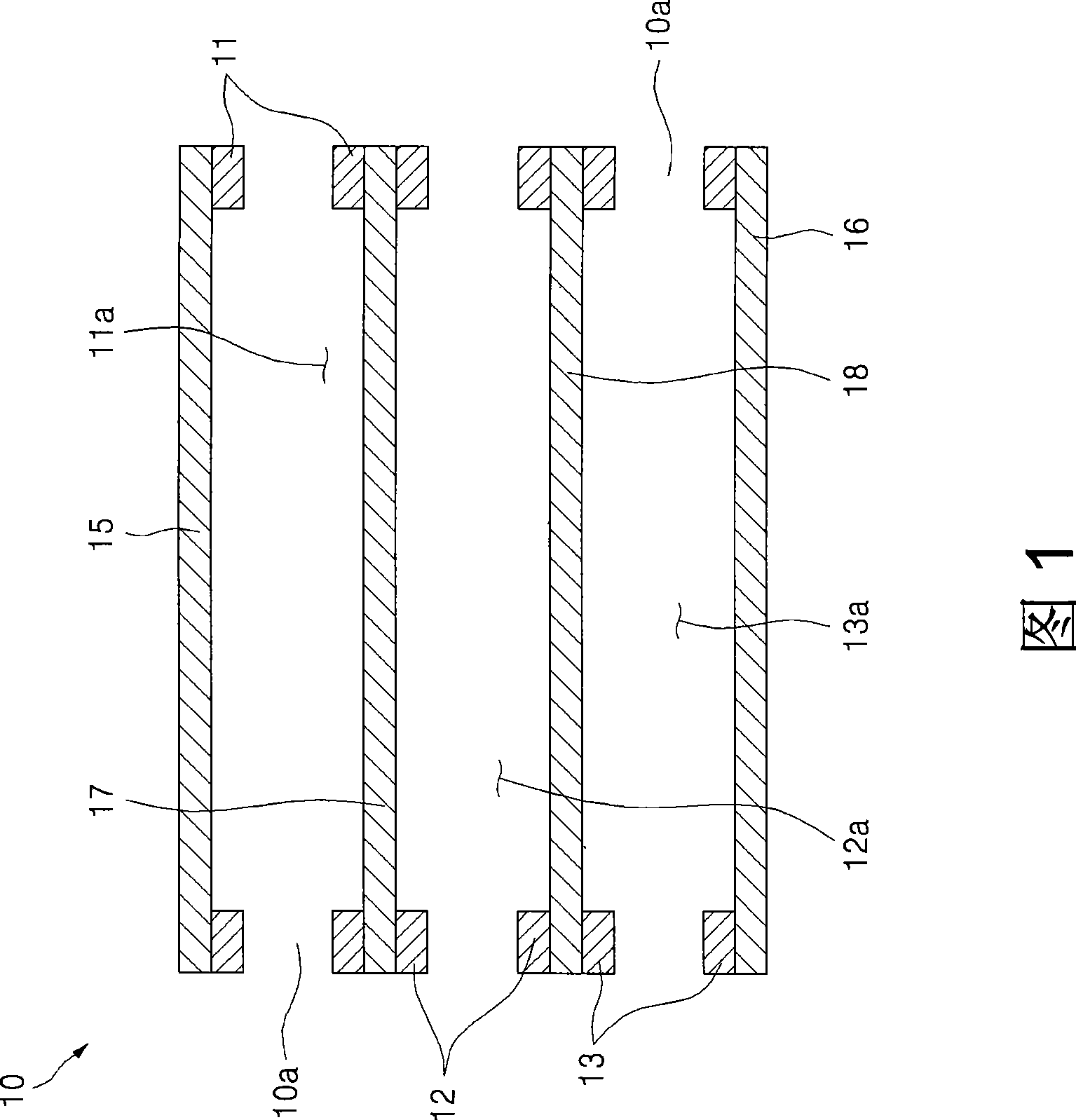

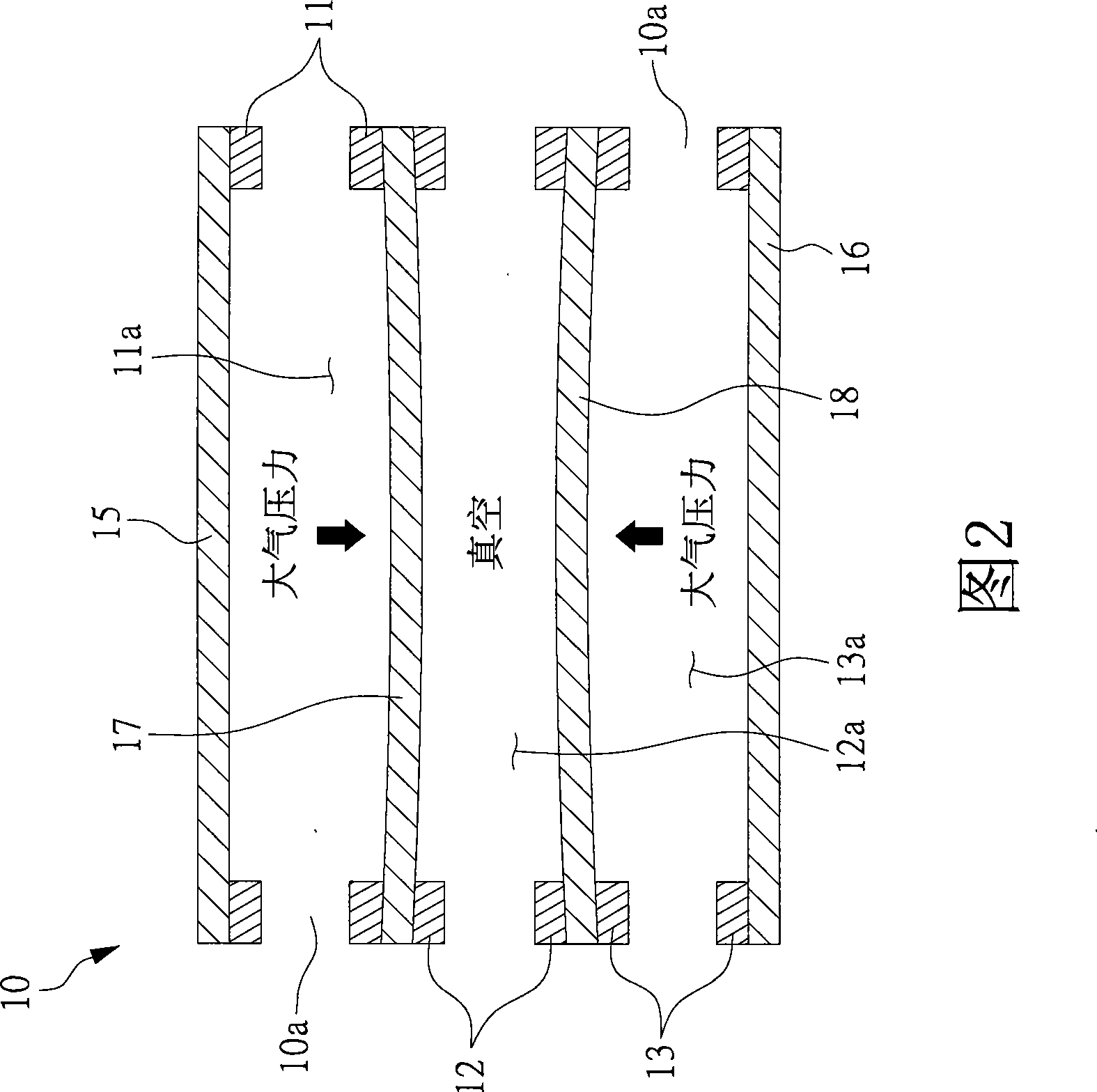

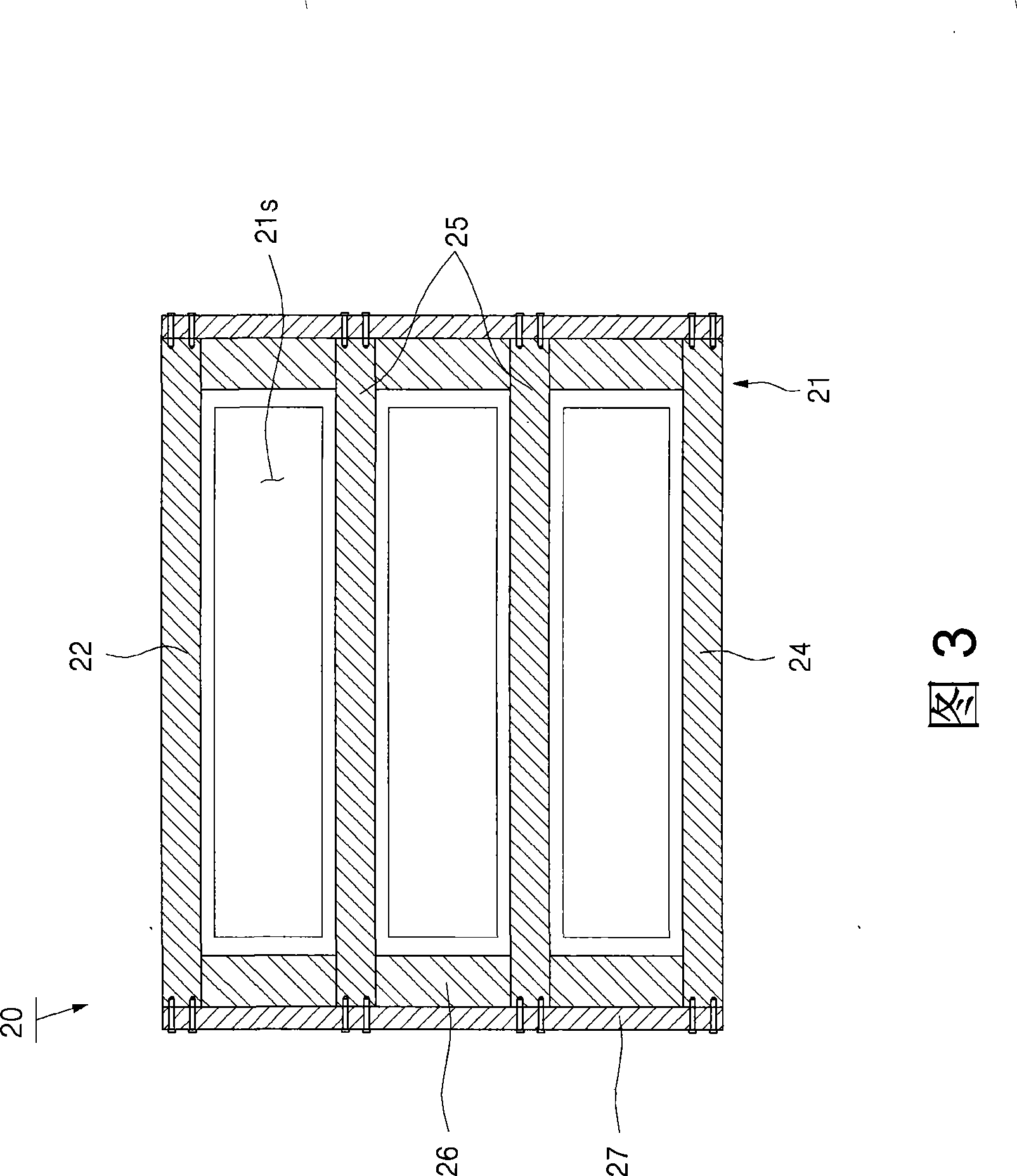

[0048] The accompanying drawings are used to illustrate the embodiments of the present invention, and are cited to gain a sufficient understanding of the present invention and its advantages. Hereinafter, embodiments of the present invention are explained and described in detail with reference to the accompanying drawings. And the same reference element number refers to the same element.

[0049] The following description is for reference. A substrate mentioned below may refer to a flat panel display, including a liquid crystal display (LCD) substrate, a plasma display panel (PDP) substrate and an organic light emitting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com