Working unit for programme-controlled milling and boring machines

A technology of power head, drilling and milling machine, applied in the field of power head, can solve the problem of high cost of positioning and swing head technology, and achieve the effect of high cutting power

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

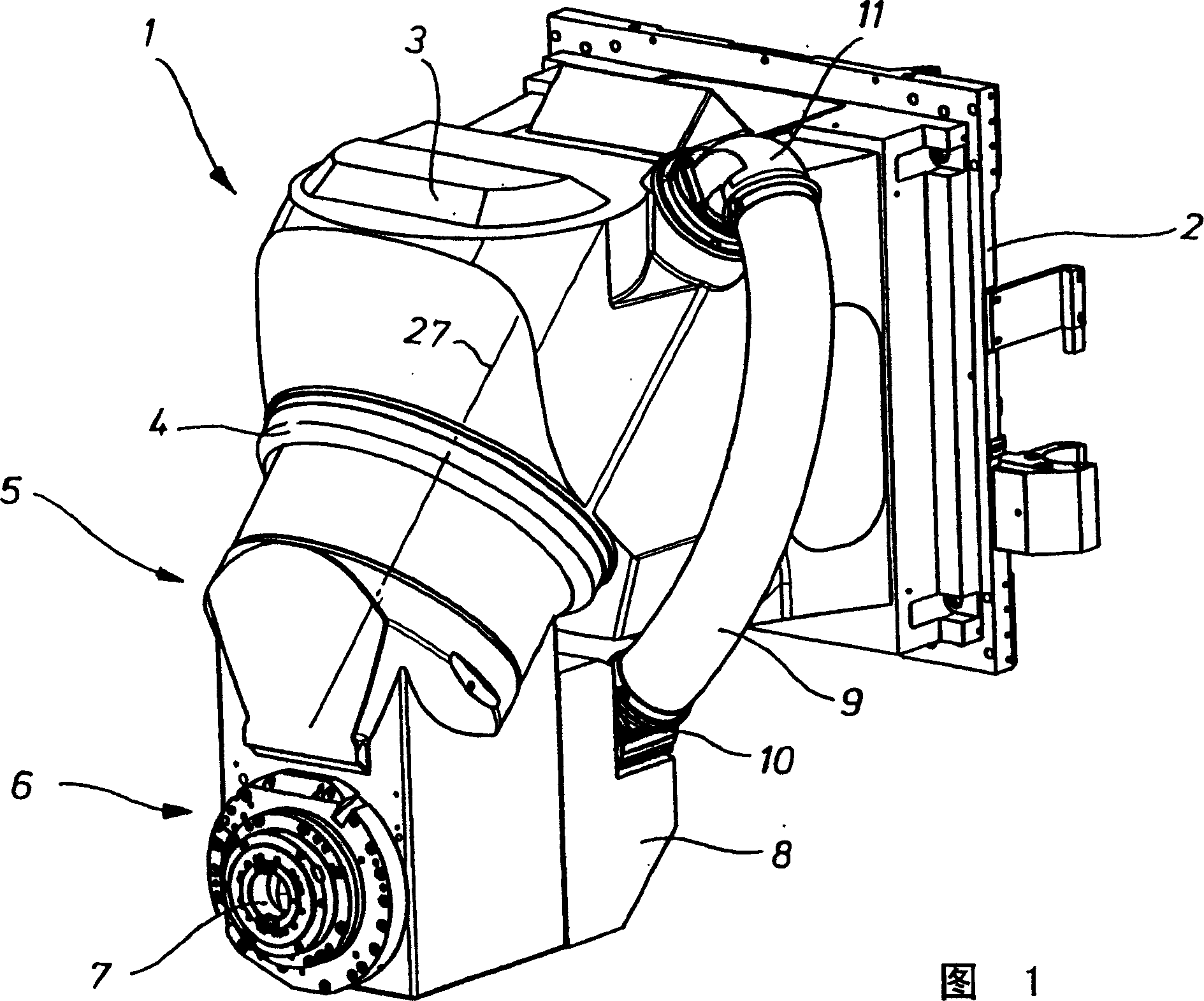

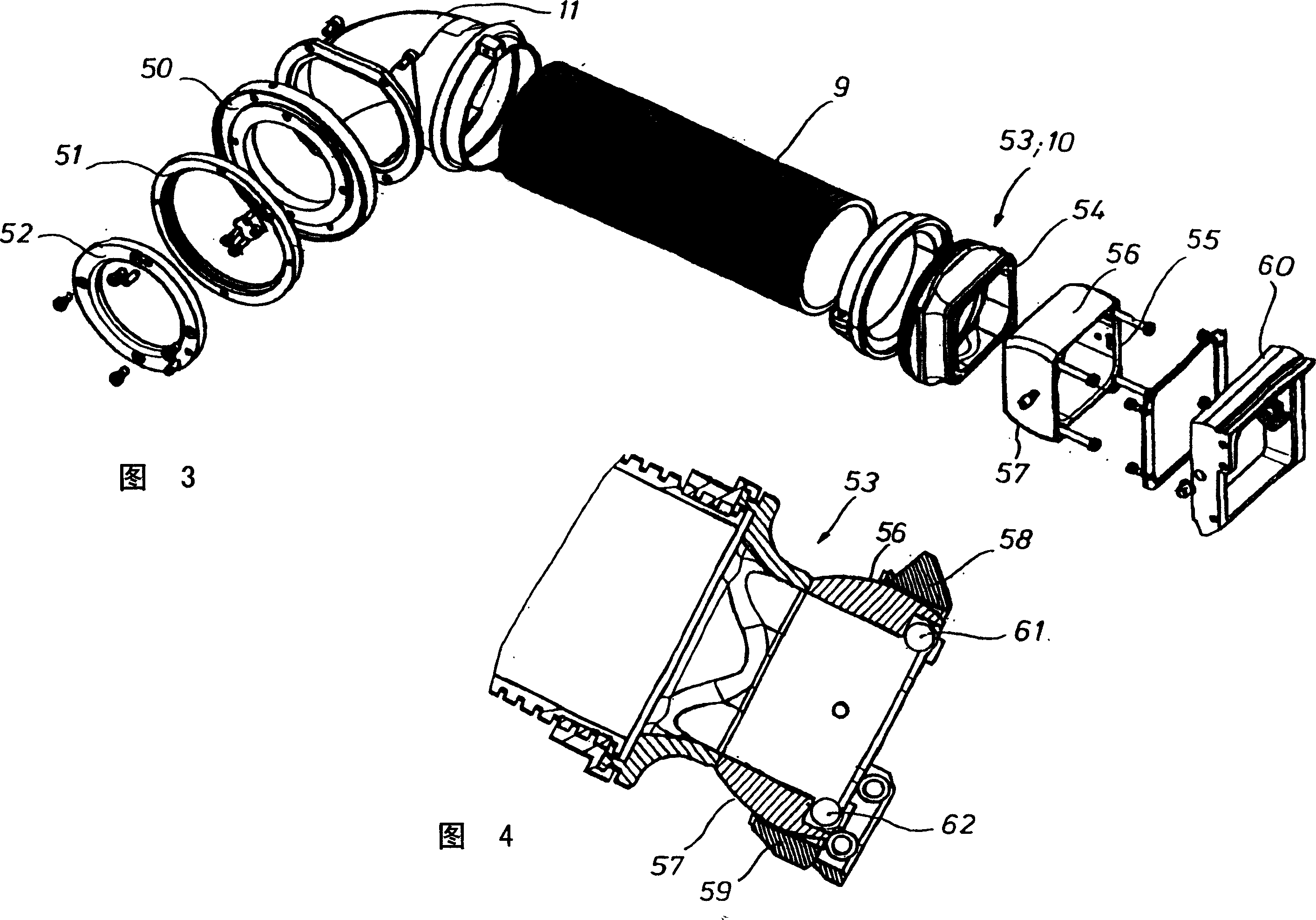

[0014] It can be seen from Fig. 1 that the power head has a cornered head seat 1, which includes a vertical, rearward plate-shaped or frame-shaped support structure 2, a large-volume middle part 3, and a 45° forward and downward slope. Hollow cylindrical shell 4. In the headstock 1, a swivel head 5 is mounted rotatably about the central axis 27 of the hollow-cylindrical housing projection 4, which is fixed rigidly at an angle of 45° to the central axis 27 of the housing projection 4 on the swivel head side. There is a spindle head 6. In the transverse direction of the spindle head 6, a work spindle 7 is supported. By means of an adapter 10, a flexible tube 9 is pivotably connected to the box-shaped rear part 8 of the spindle head 6, the upper end of which is connected to the middle part 3 of the headstock 1 via a rotatable tube elbow 11. connect.

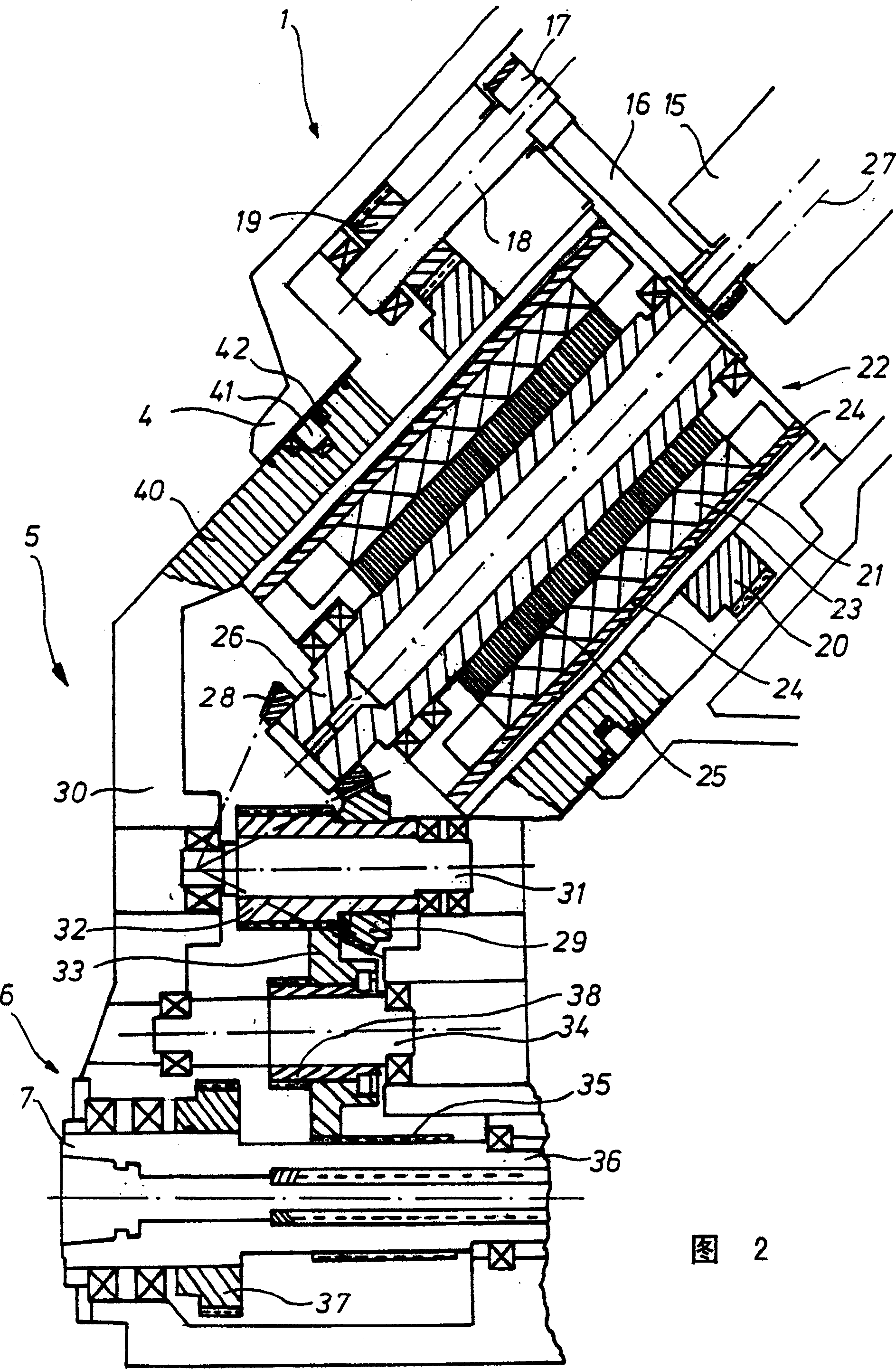

[0015] Figure 2 shows a schematic vertical cross-sectional view of the internal functional parts of the power head of the prese...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com