Handheld power tool, in particular power drill or power screwdriver

A technology of hand-held machine tools and auger drills, which is applied in the field of drilling rigs or auger drills, can solve the problems of increased cost, high cost, troublesome cost, etc., and achieve the effect of simple electrical coupling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

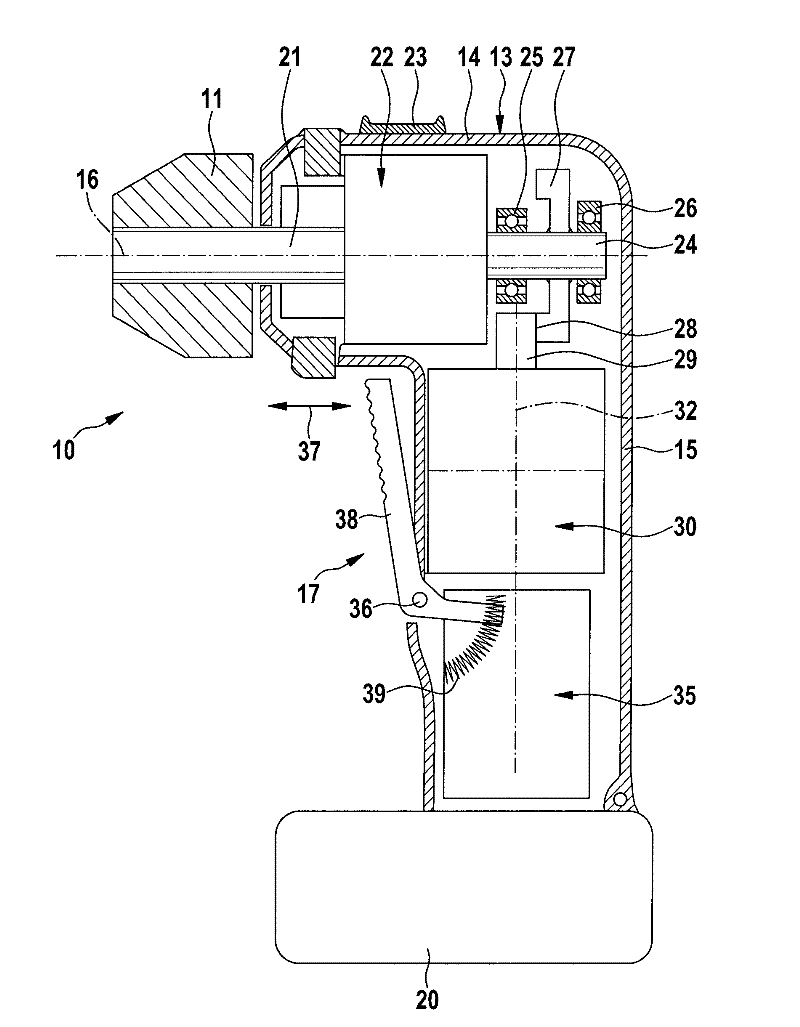

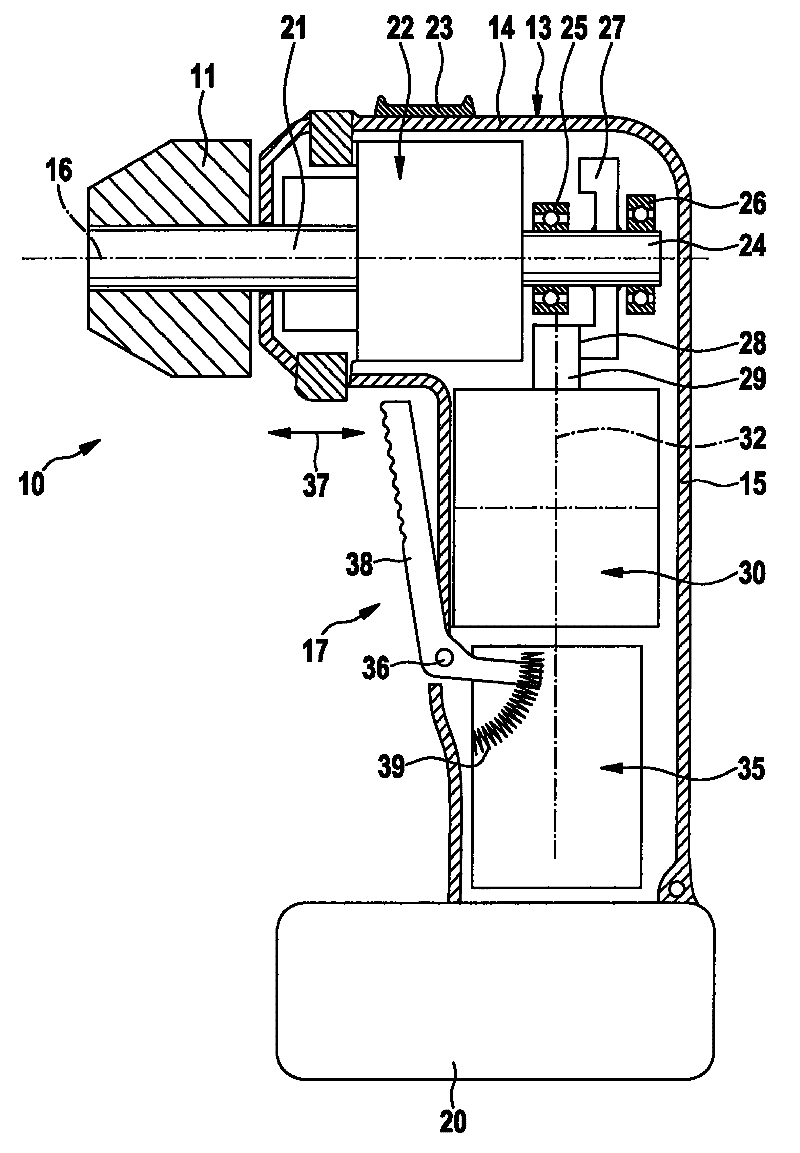

[0012] In the single figure, hand power tool 10 is shown in a very simplified manner. In this case, hand power tool 10 is formed in particular as a drill or screw drill. For this purpose, the handheld power tool 10 has a tool receptacle 11 formed by a spindle, in which a tool such as a screwdriver set or a drill can generally be clamped or locked.

[0013] The hand power tool 10 has a housing 13 , for example, consisting of two half-shells, in particular made of an injection-molded part, the parting planes of which are parallel to the plane of the drawing. The housing 13 essentially has two housing parts 14 , 15 , the first housing part 14 being aligned at least substantially in the direction of the longitudinal axis 16 of the tool receptacle 11 . The second housing part 15 of the housing 13 is arranged at least substantially perpendicularly to the first housing part 14 and forms a handle 17 for the user to hold the hand-held power tool.

[0014] Arranged on the housing 13 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com