Connecting chain link for saw chain

A technology for connecting chains and saw chains, applied in the direction of saw chains, etc., can solve the problem of high production and installation costs, and achieve the effects of improving chip discharge, avoiding bending stress, and expanding chip channels

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

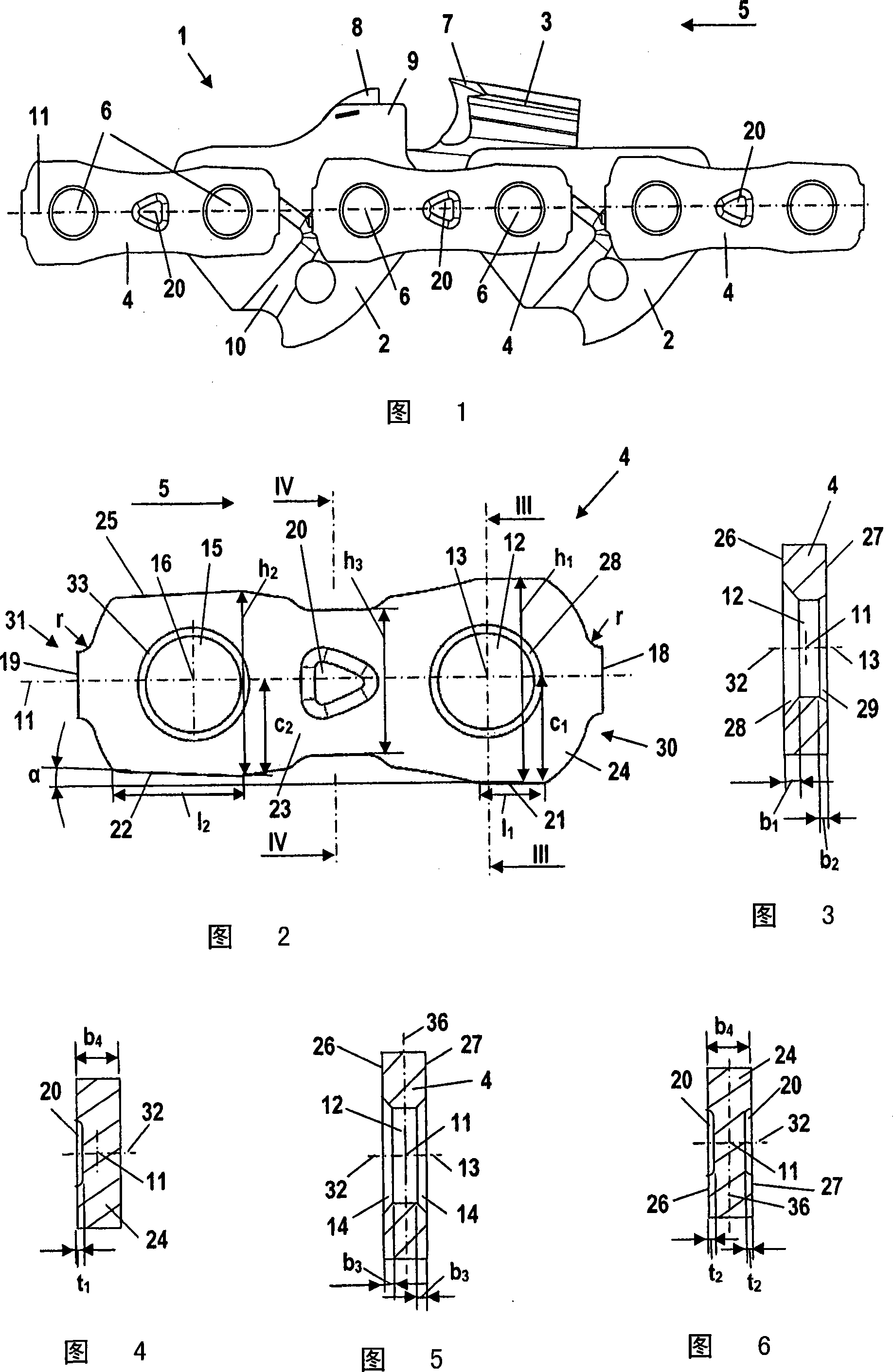

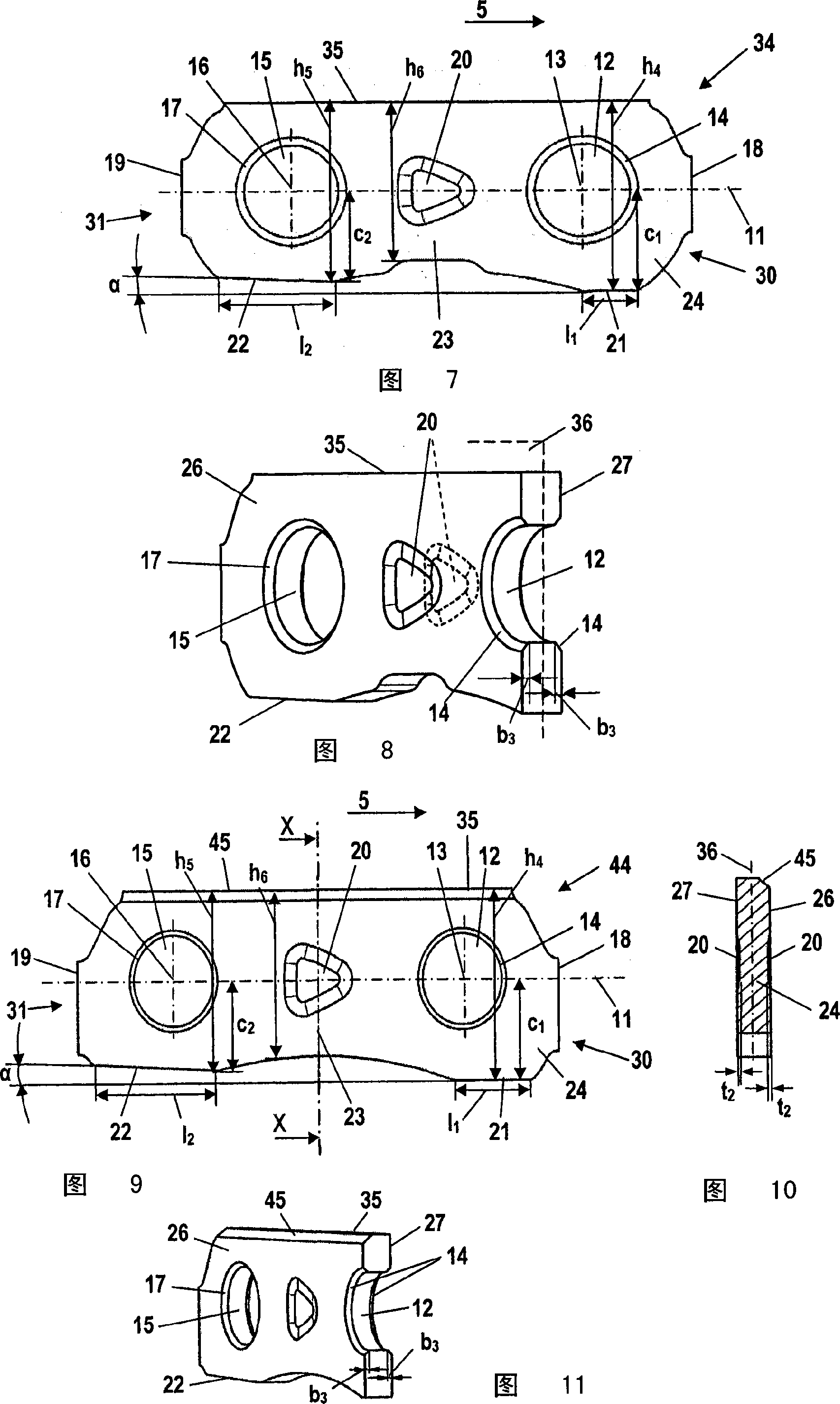

[0025] FIG. 1 shows a section of a saw chain 1 . The saw chain consists of a drive link 2 , a cutting link 3 and a connecting link 4 . The drive chain link 2 , the cutting chain link 3 and the connecting chain link 4 are hingedly connected to each other by rivet bolts 6 . In this case the drive chain links 2 are arranged in the middle, and the connecting chain links 4 are arranged on their outer sides. The rear rivet holes of the driving chain link 2 are respectively connected with the front rivet holes of the connecting chain link 4 , and the front rivet holes of the driving chain link 2 are connected with the rear rivet holes of the connecting chain link 4 . Seen in the chain running direction 5 , instead of a connecting link 4 every two connecting links 4 are provided with a cutting link 3 . In this case, the cutting links 3 are arranged alternately on each longitudinal side of the saw chain 1 . The cutting link 3 has a cutting tooth 7, in front of which a depth limiter ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com