Patents

Literature

73results about How to "Improve sensor accuracy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cellulosic-based interference domain for an analyte sensor

ActiveUS7651596B2Improve sensor accuracyImmobilised enzymesBioreactor/fermenter combinationsAnalyteD-Glucose

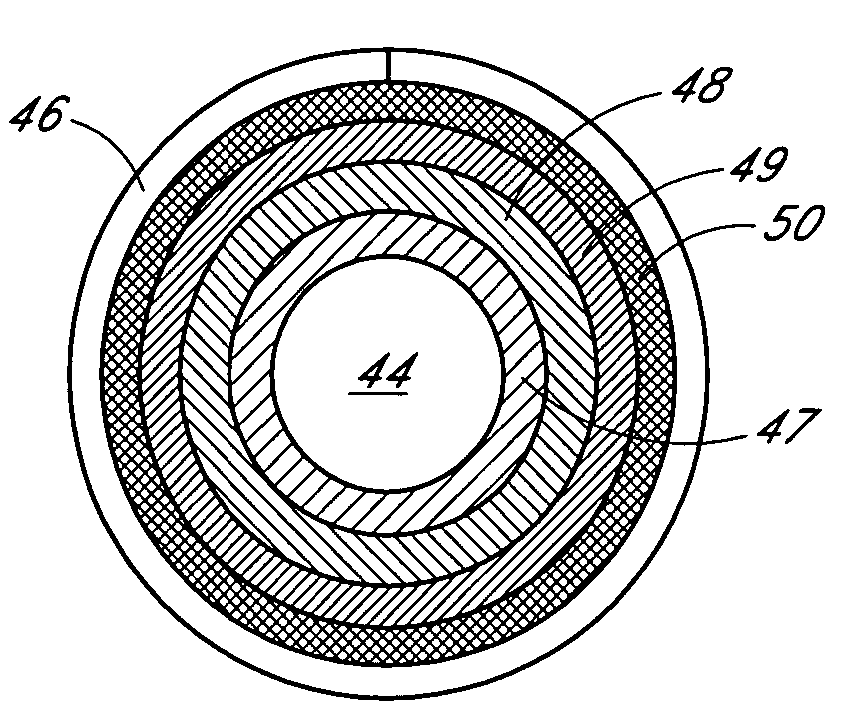

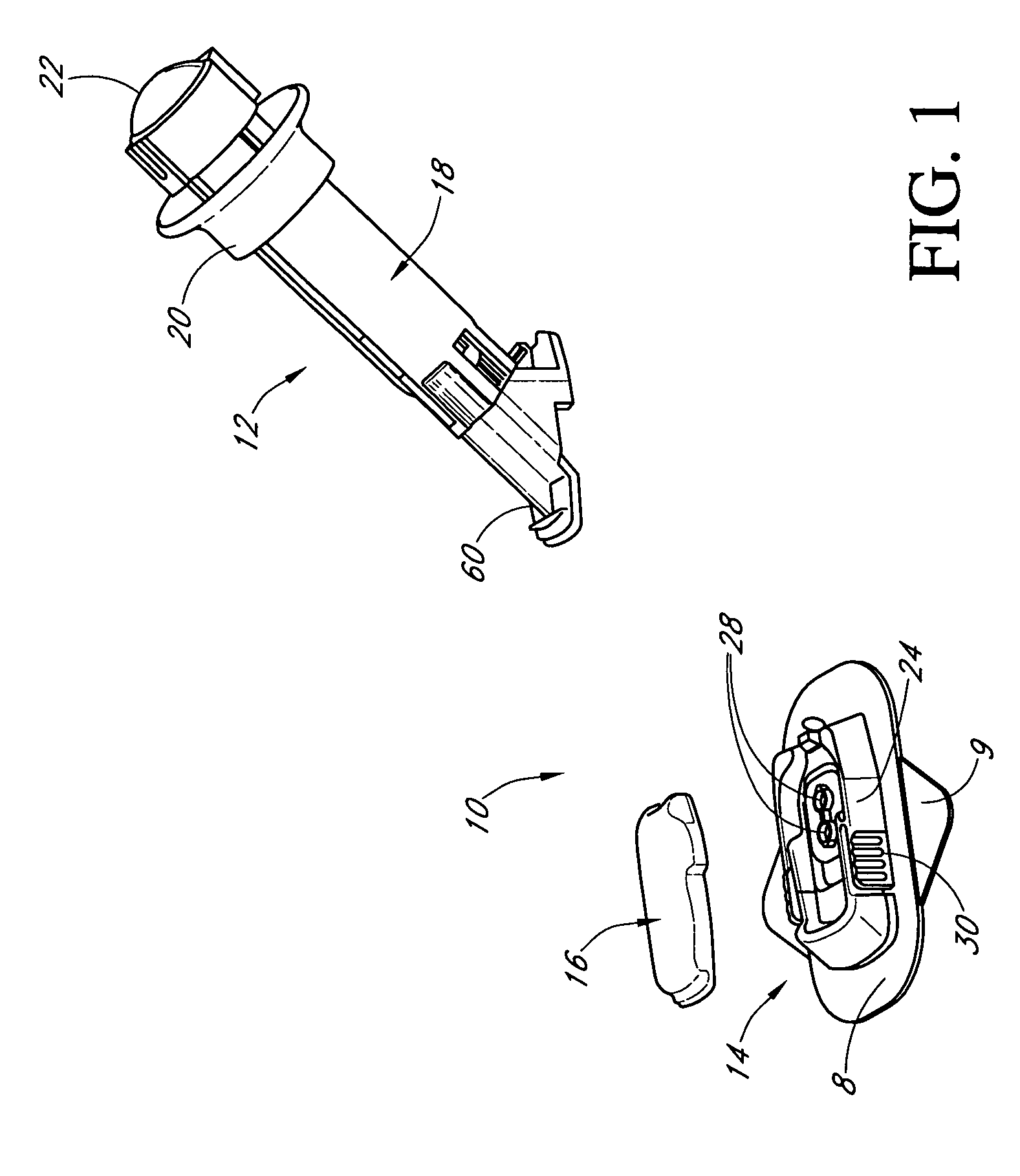

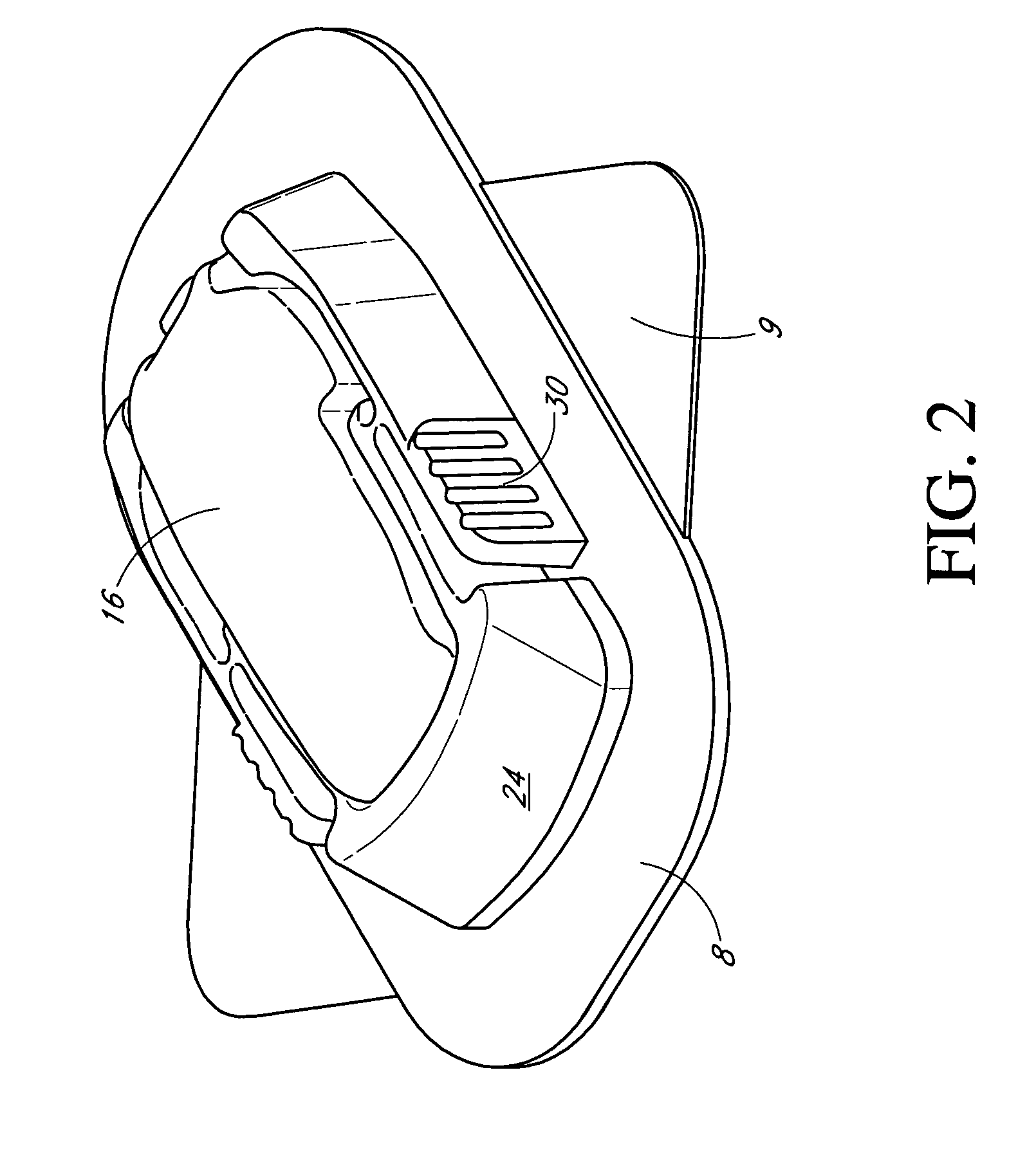

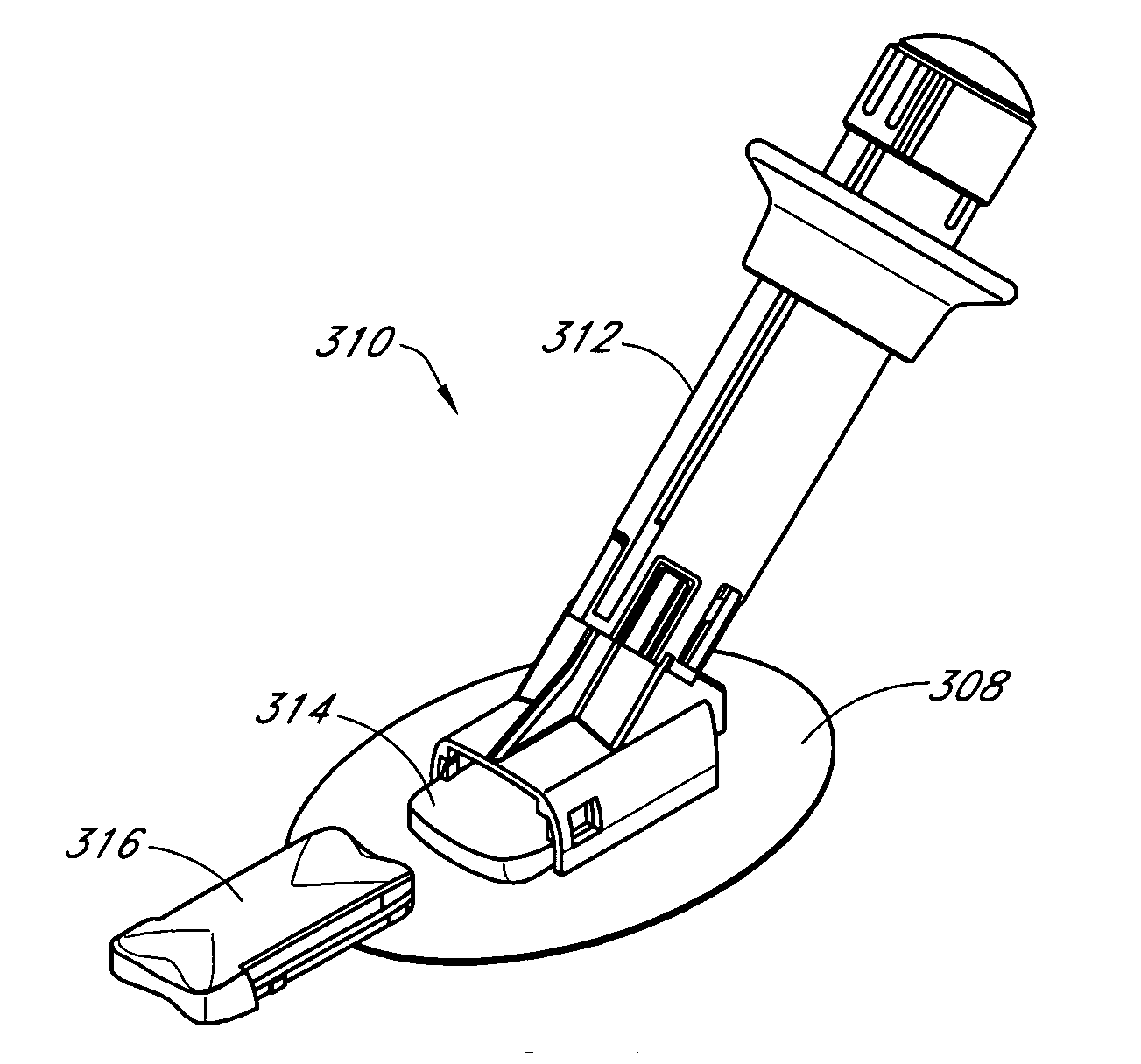

The present invention relates generally to devices for measuring an analyte in a host. More particularly, the present invention relates to devices for measurement of glucose in a host that incorporate a cellulosic-based interference domain.

Owner:DEXCOM

Cellulosic-based interference domain for an analyte sensor

ActiveUS20060229512A1Improve sensor accuracyImmobilised enzymesBioreactor/fermenter combinationsAnalyteEngineering

Owner:DEXCOM

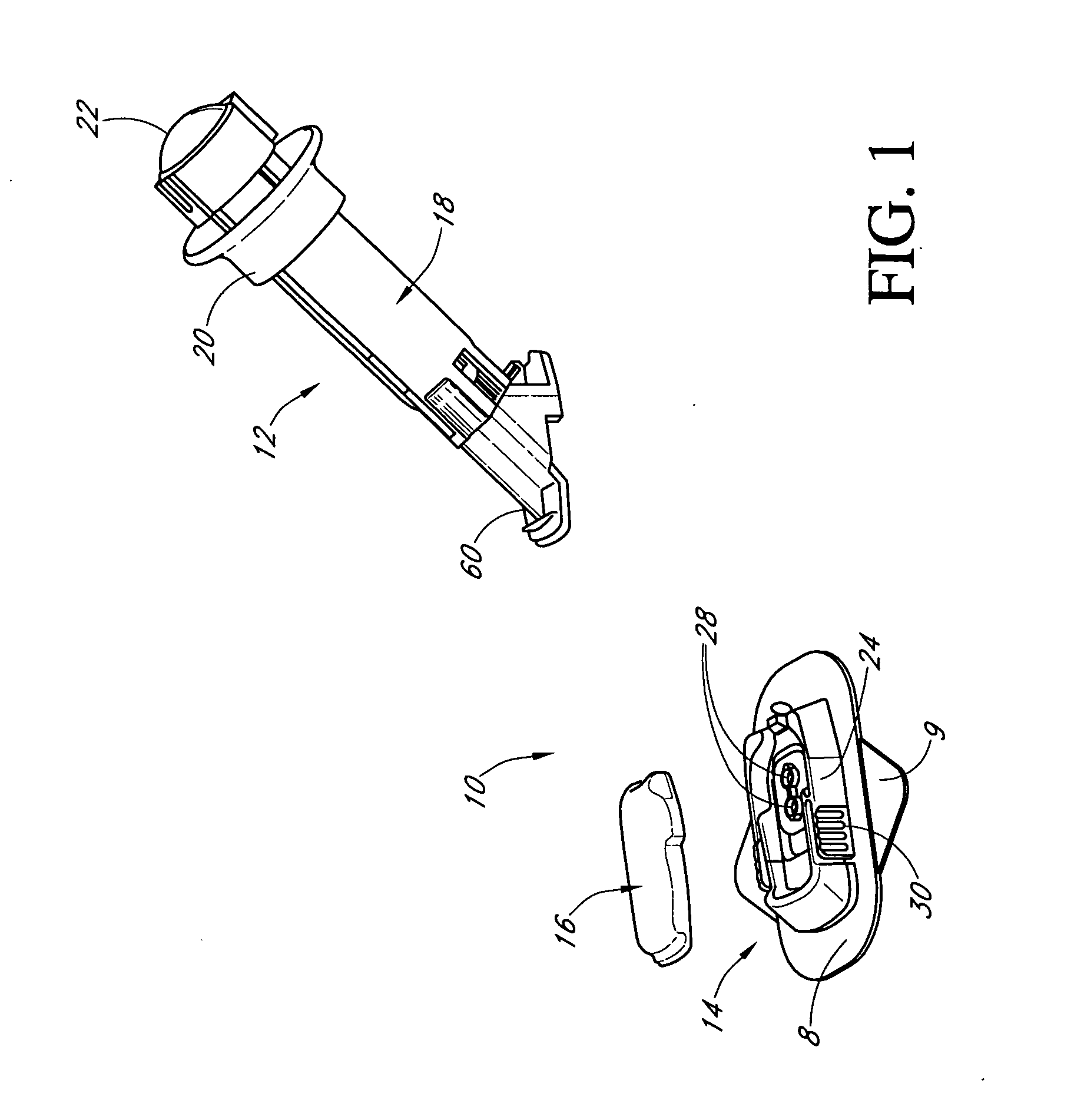

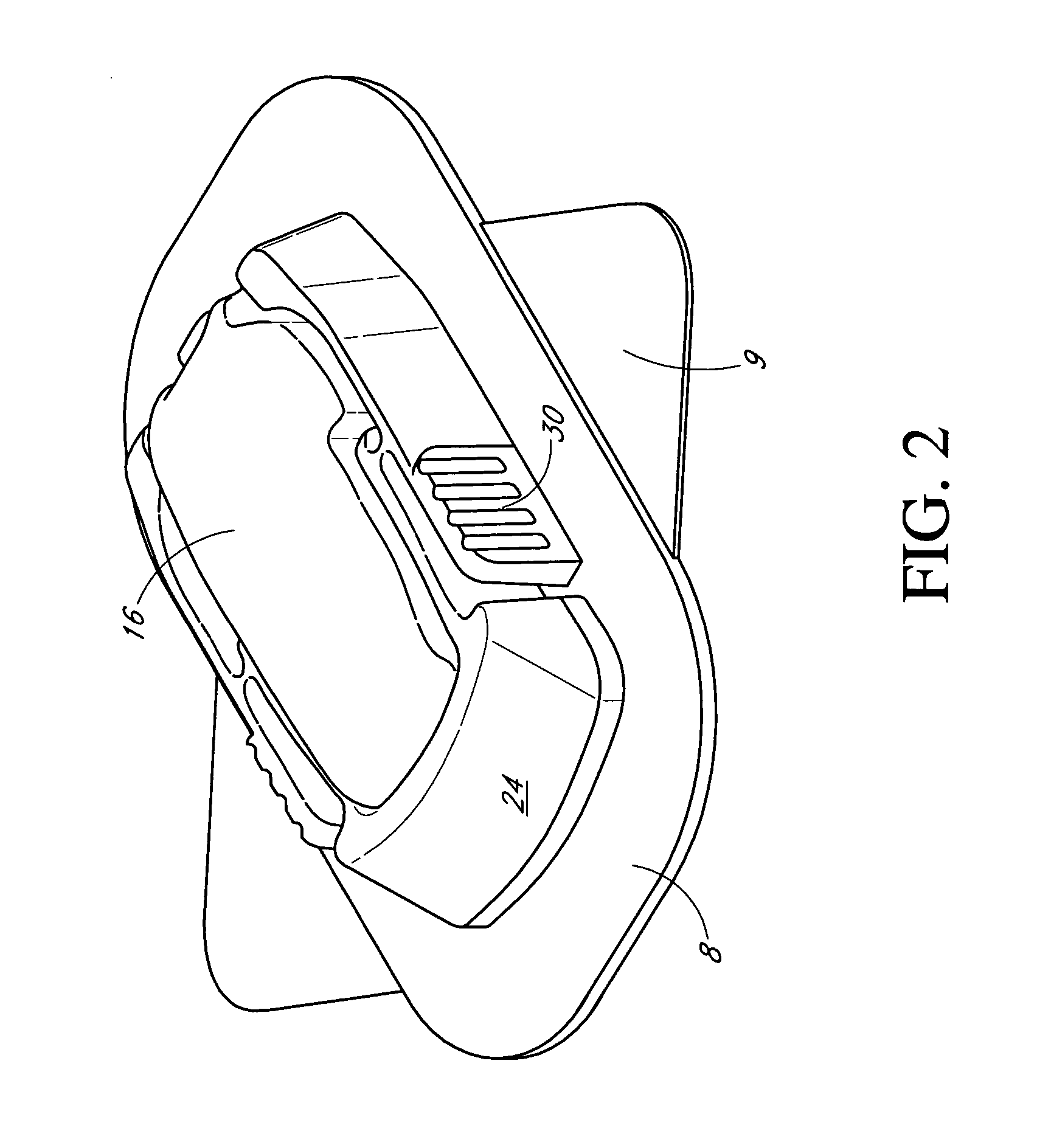

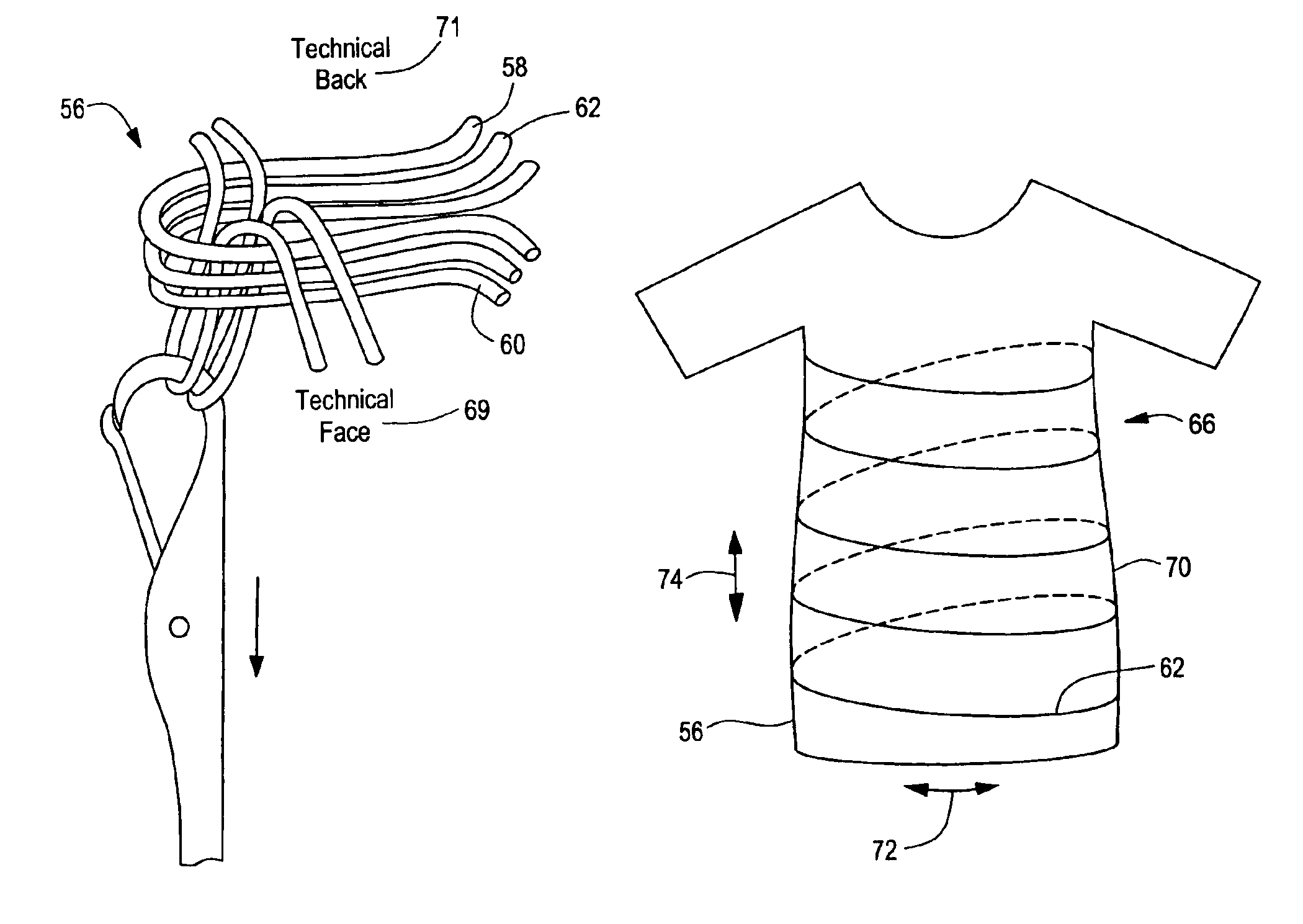

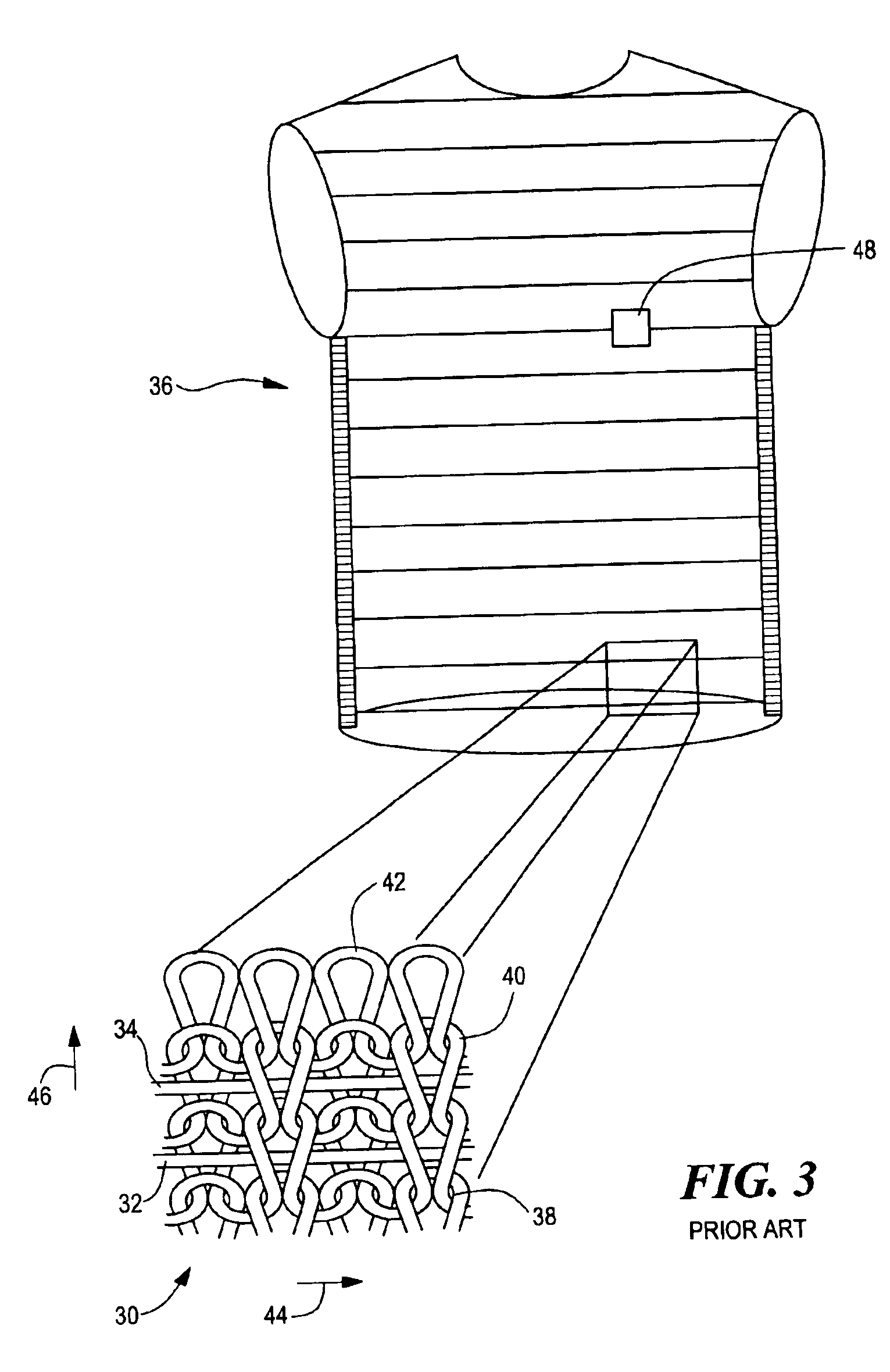

Tubular knit fabric and system

ActiveUS6941775B2Comfortable to wearAccurate and reliableOrnamental textile articlesDiagnostic recording/measuringYarnBiomedical engineering

A tubular knit fabric comprising at least one insulative yarn, at least one stretchable yarn, and at least one functional yarn, the insulating yarn, the stretchable yarn, and the functional yarn knitted together to define a tubular fabric sleeve having the functional yarn embedded in the tubular fabric sleeve in a continuous spiral configuration which longitudinally extends the length of the sleeve.

Owner:MMI IPCO +1

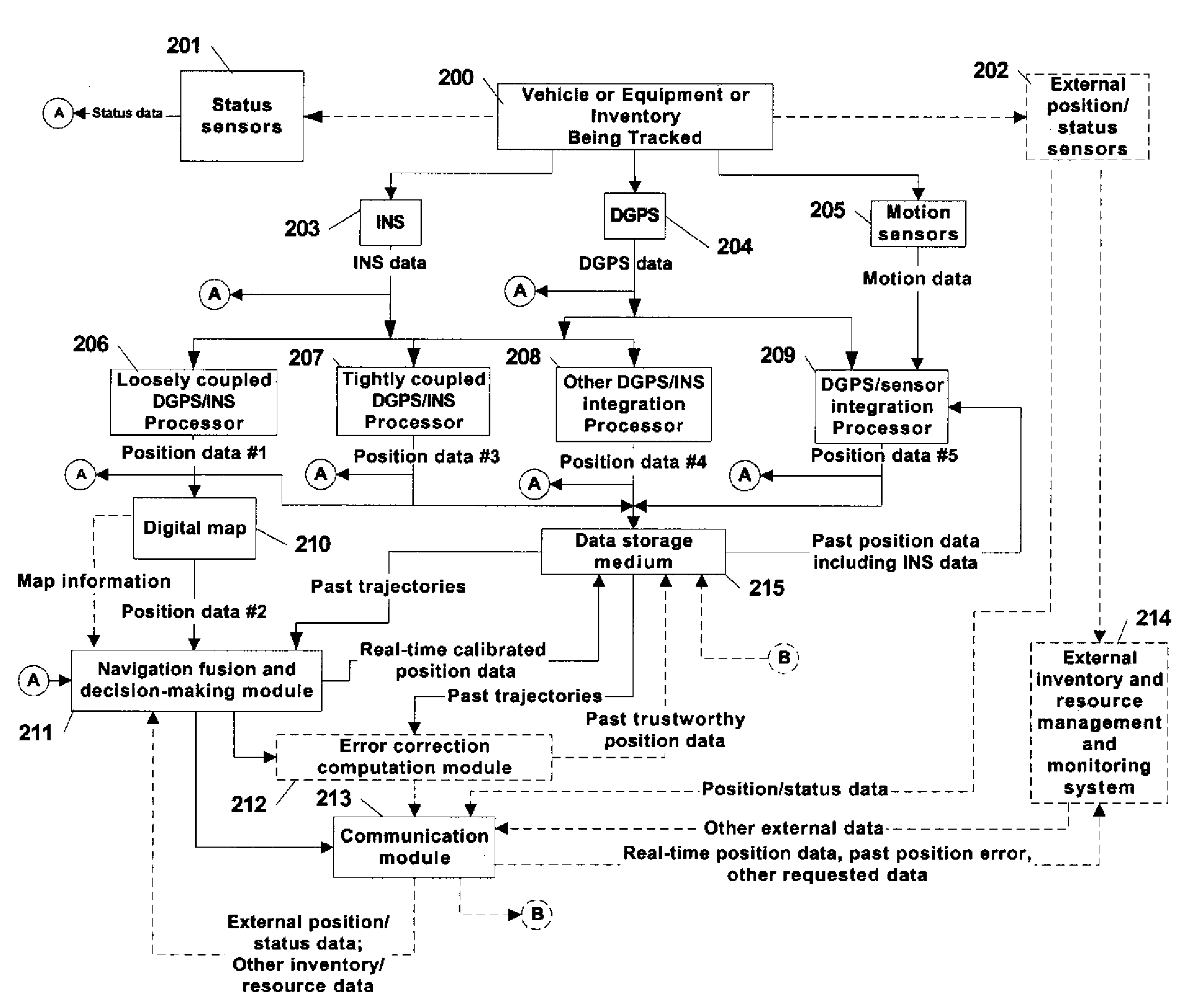

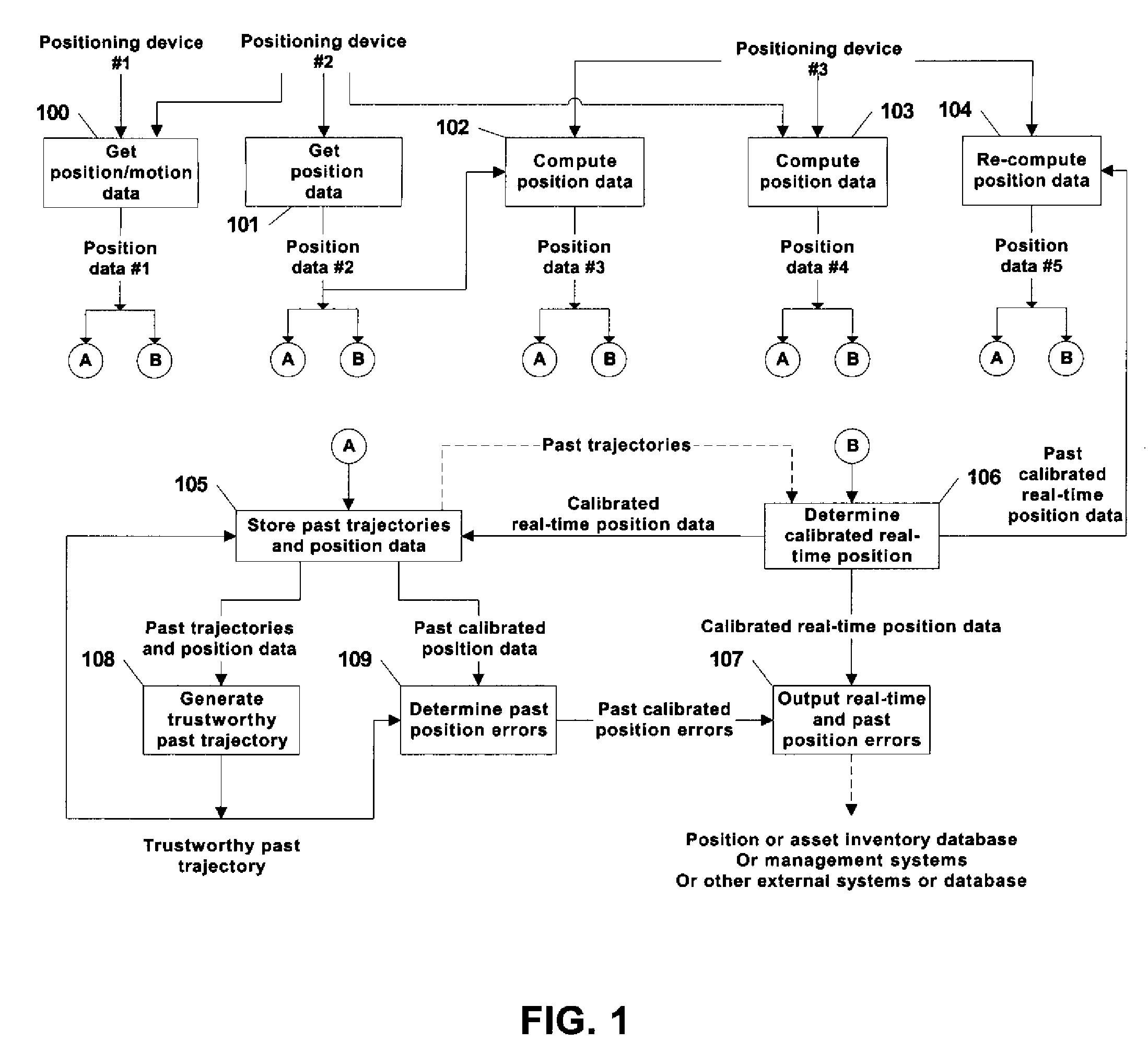

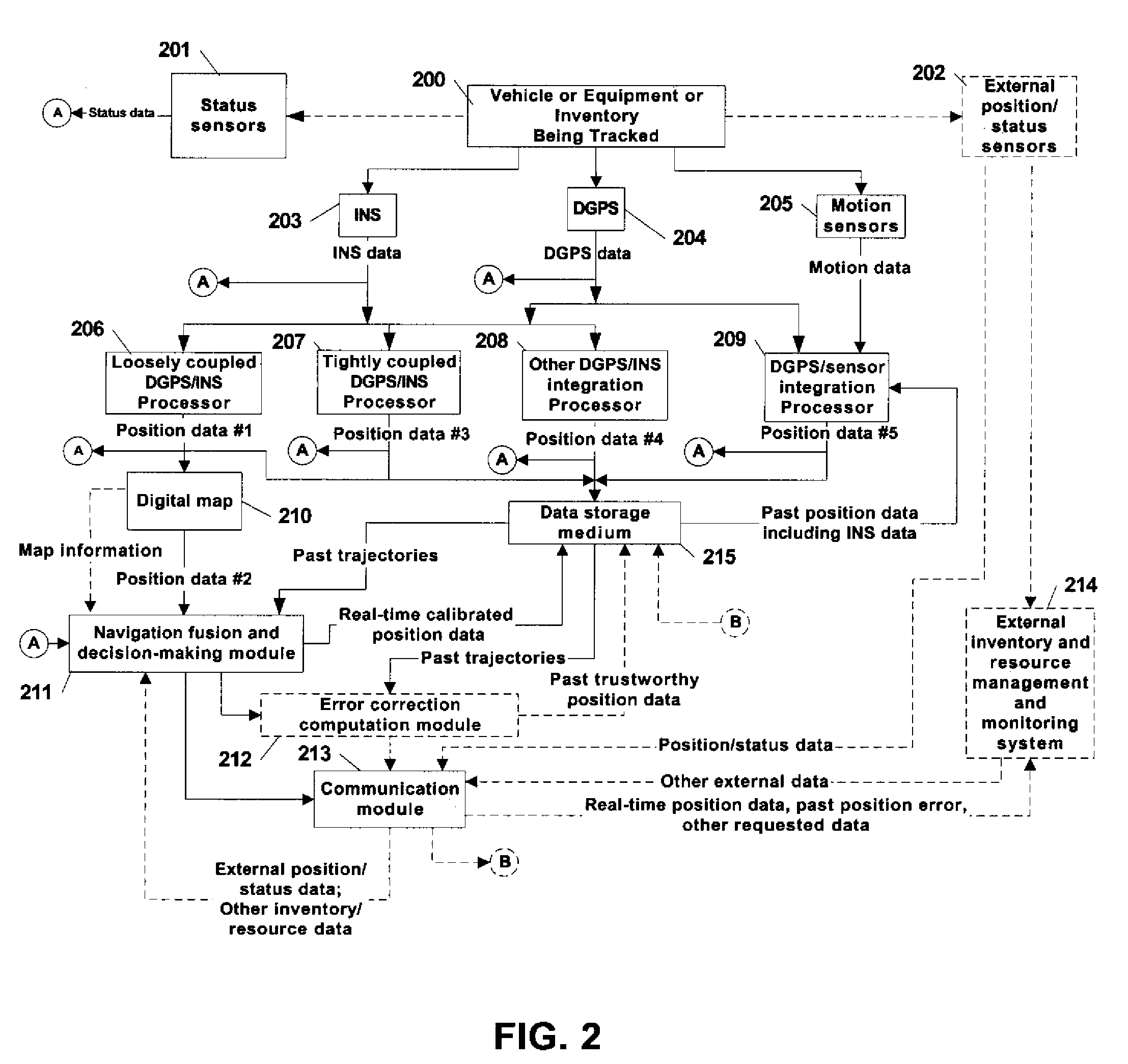

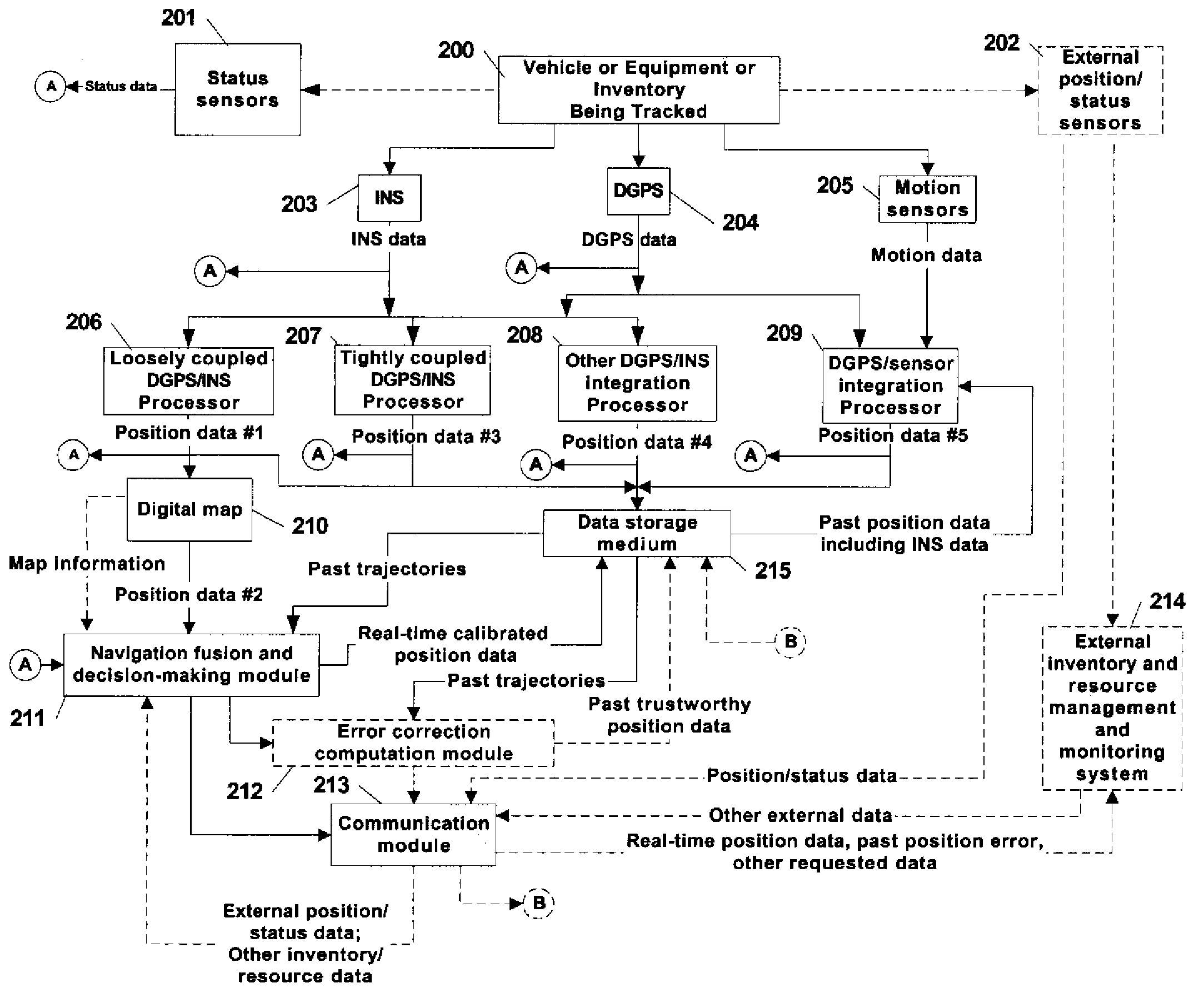

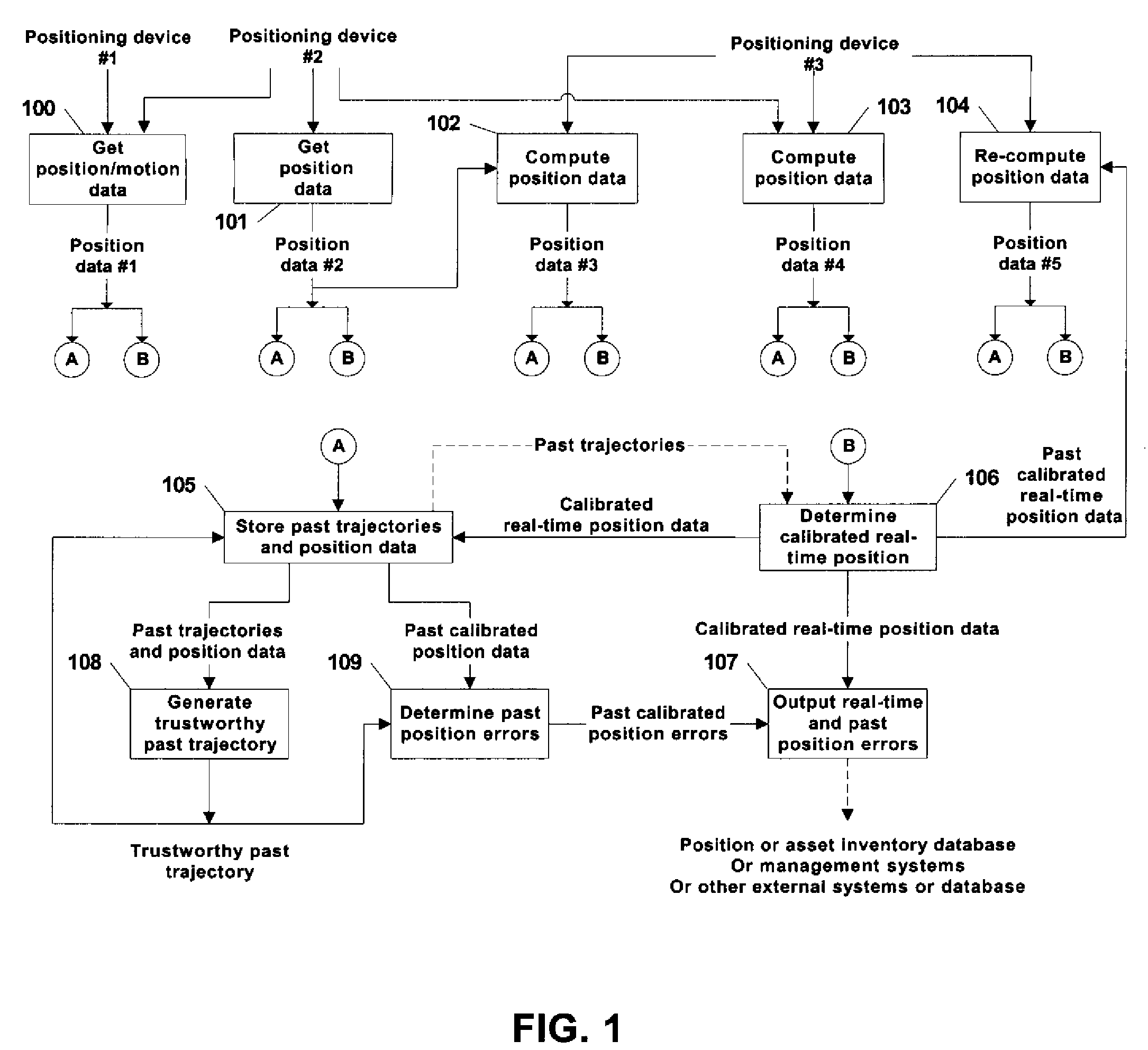

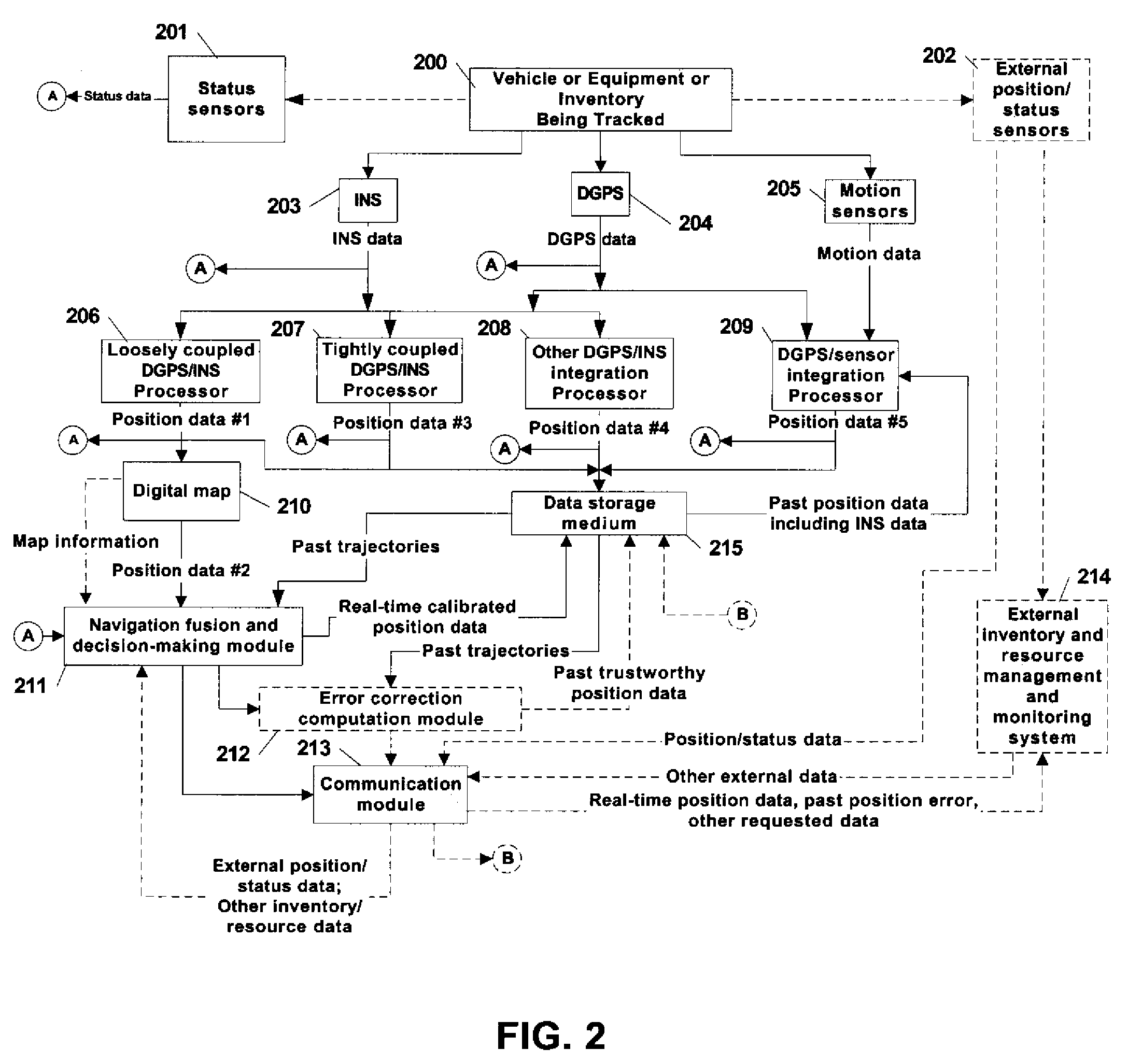

Automated asset positioning for location and inventory tracking using multiple positioning techniques

InactiveUS20070222674A1Accurate locationImprove accuracyDirection finders using radio wavesPosition fixationCorrection algorithmPosition error

A system and method is provided for tracking and maintaining a highly accurate inventory of shipping containers that are stored within container storage facilities. The invention includes using multiple complementary real-time and post-processing positioning techniques associated with various positioning sensors that are associated with inventory pieces or equipment. Examples of such positioning techniques are DGPS, GPS with RTK, DGPS loosely-coupled with INS, DGPS tightly-coupled with INS, and DGPS deeply-coupled with INS. Data correction and fusion techniques are applied to these positioning stages to re-compute a calibrated position with an improved accuracy. An additional trajectory can be iteratively determined using the fusing technique until the position data becomes statistically trustworthy. Further, combinations of multiple real-time positioning techniques combined with past position error correction algorithms provide a high accuracy needed for inventory tracking.

Owner:MI JACK PRODS

Automated asset positioning for location and inventory tracking using multiple positioning techniques

InactiveUS7646336B2Improve accuracyImprove data accuracyDirection finders using radio wavesPosition fixationCorrection algorithmPosition error

Owner:MI JACK PRODS

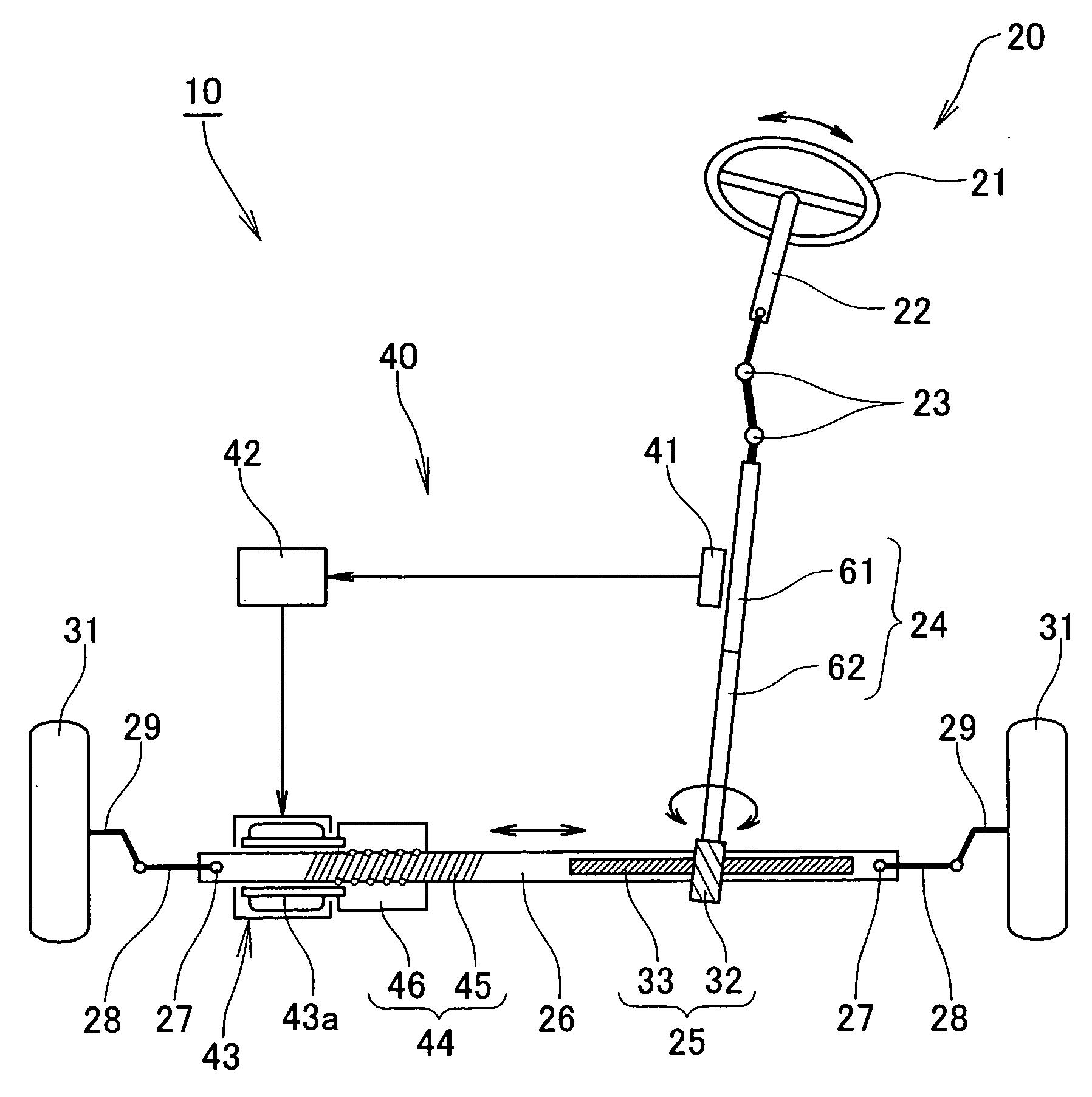

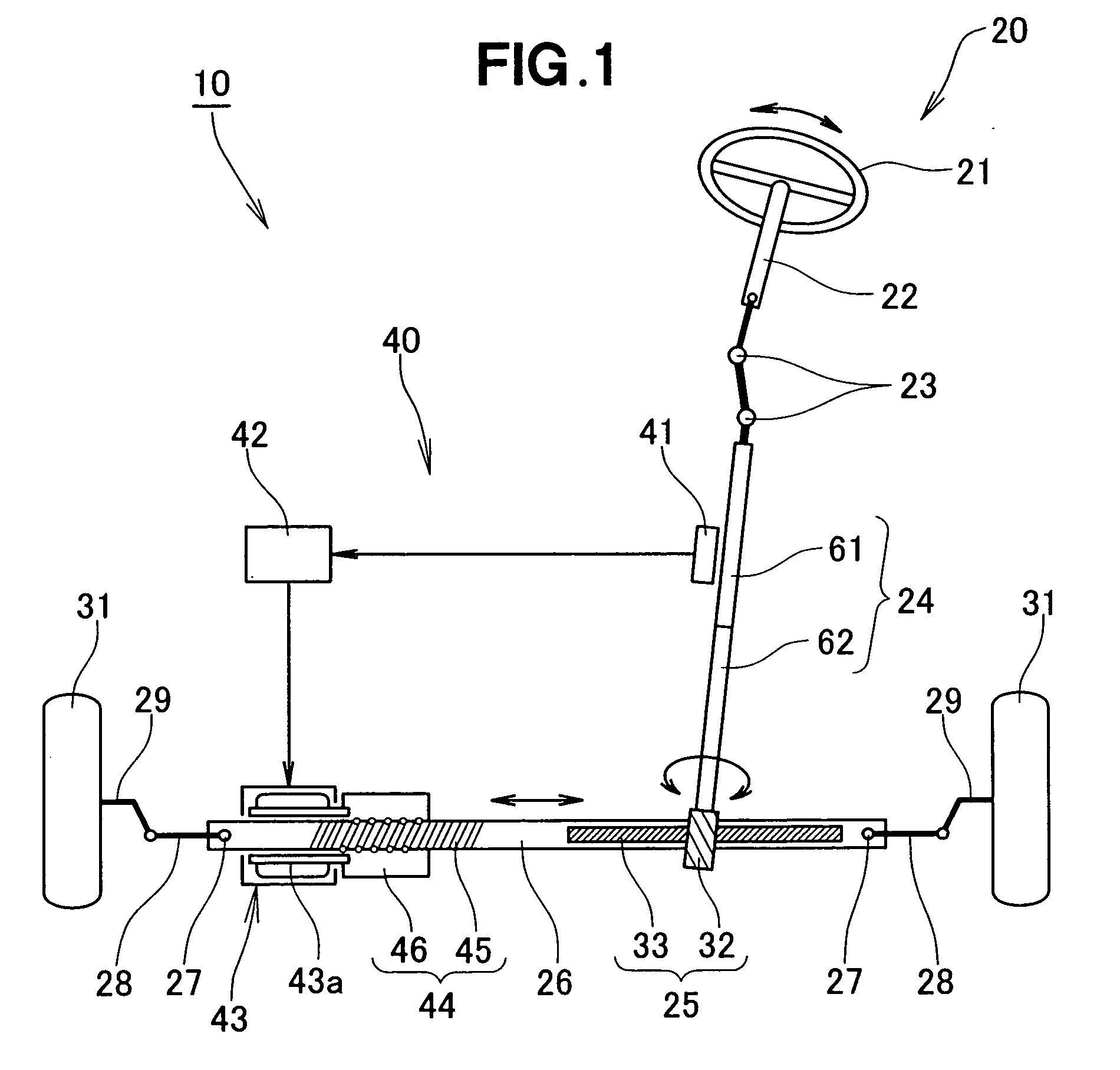

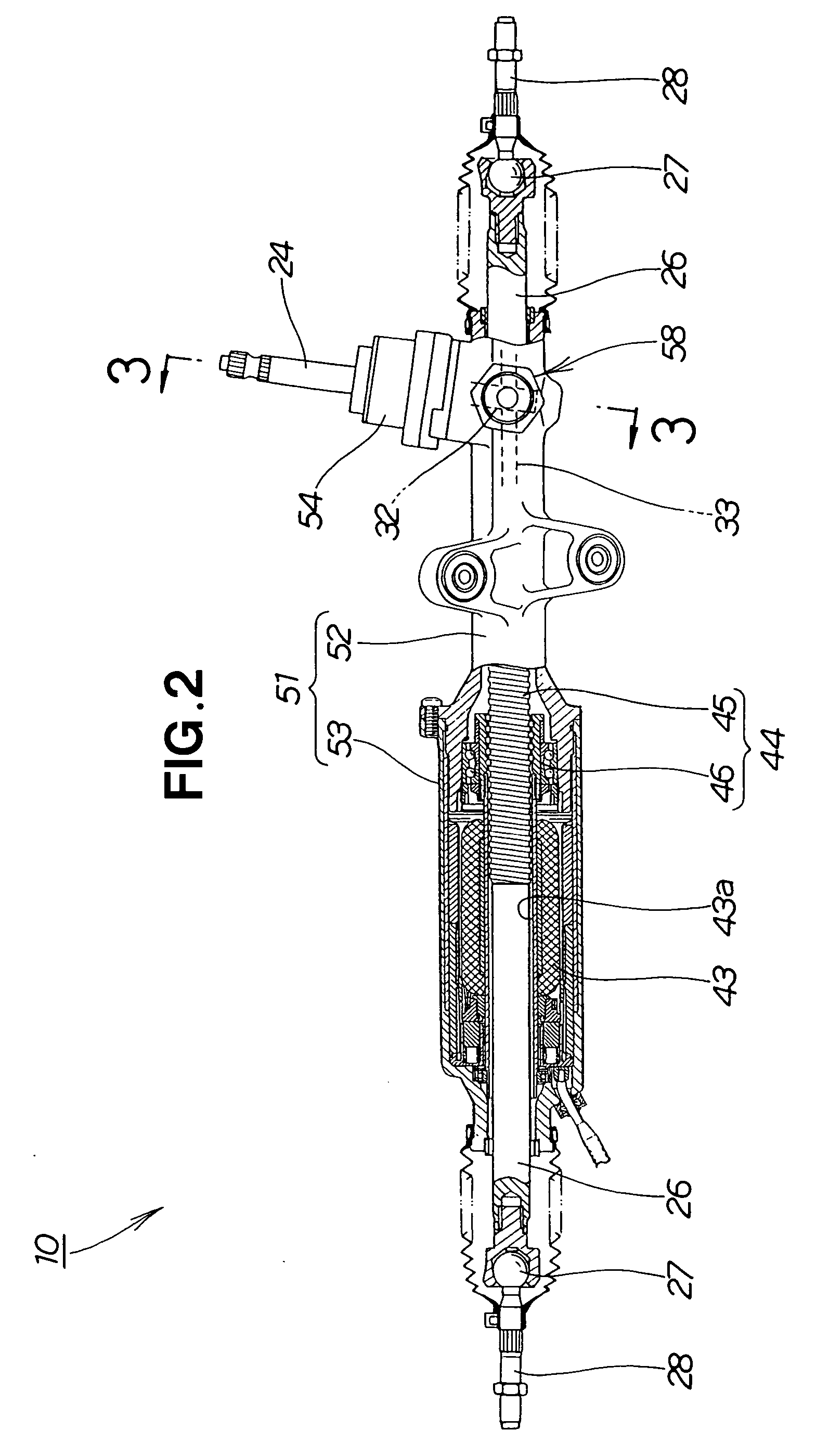

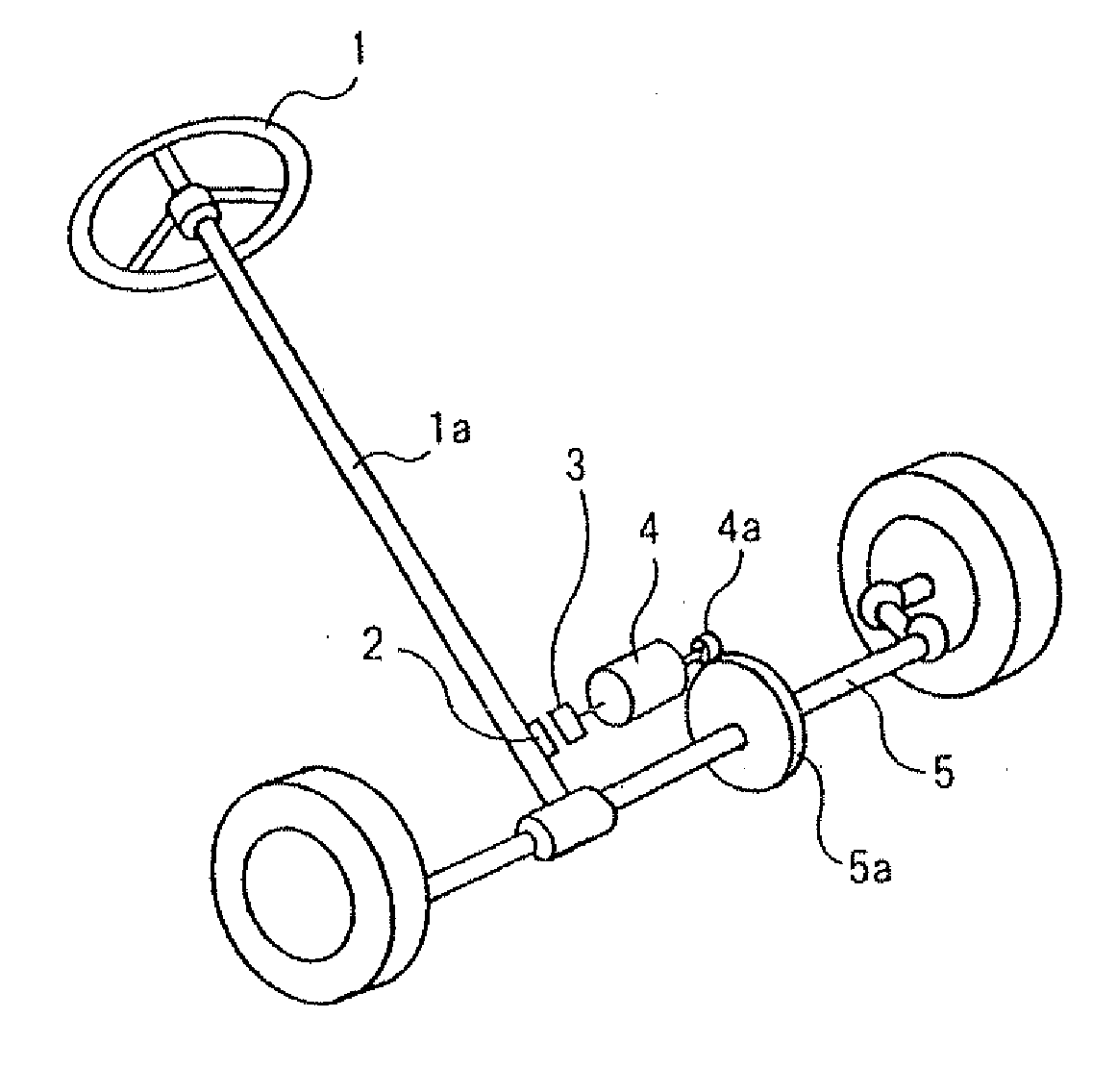

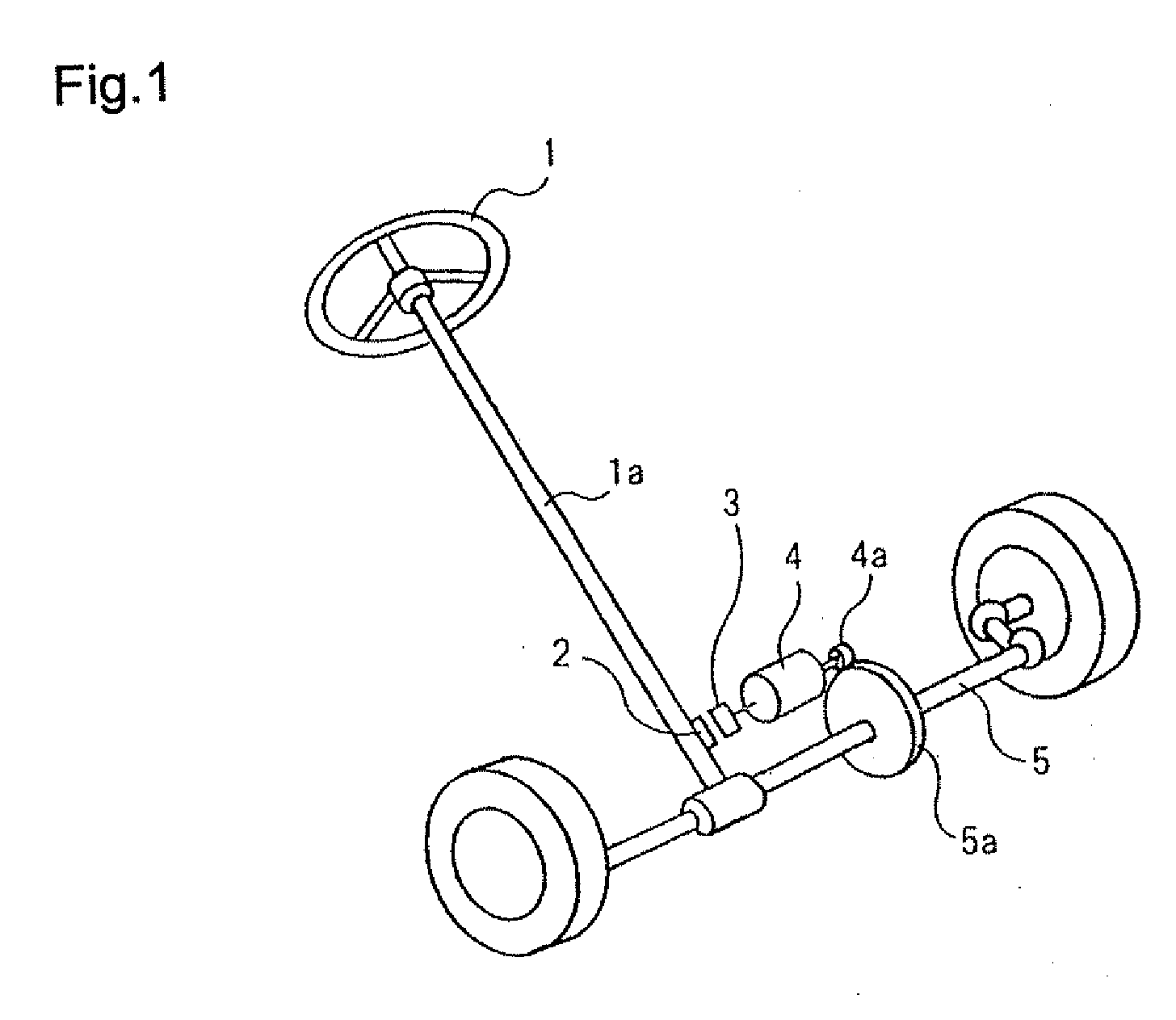

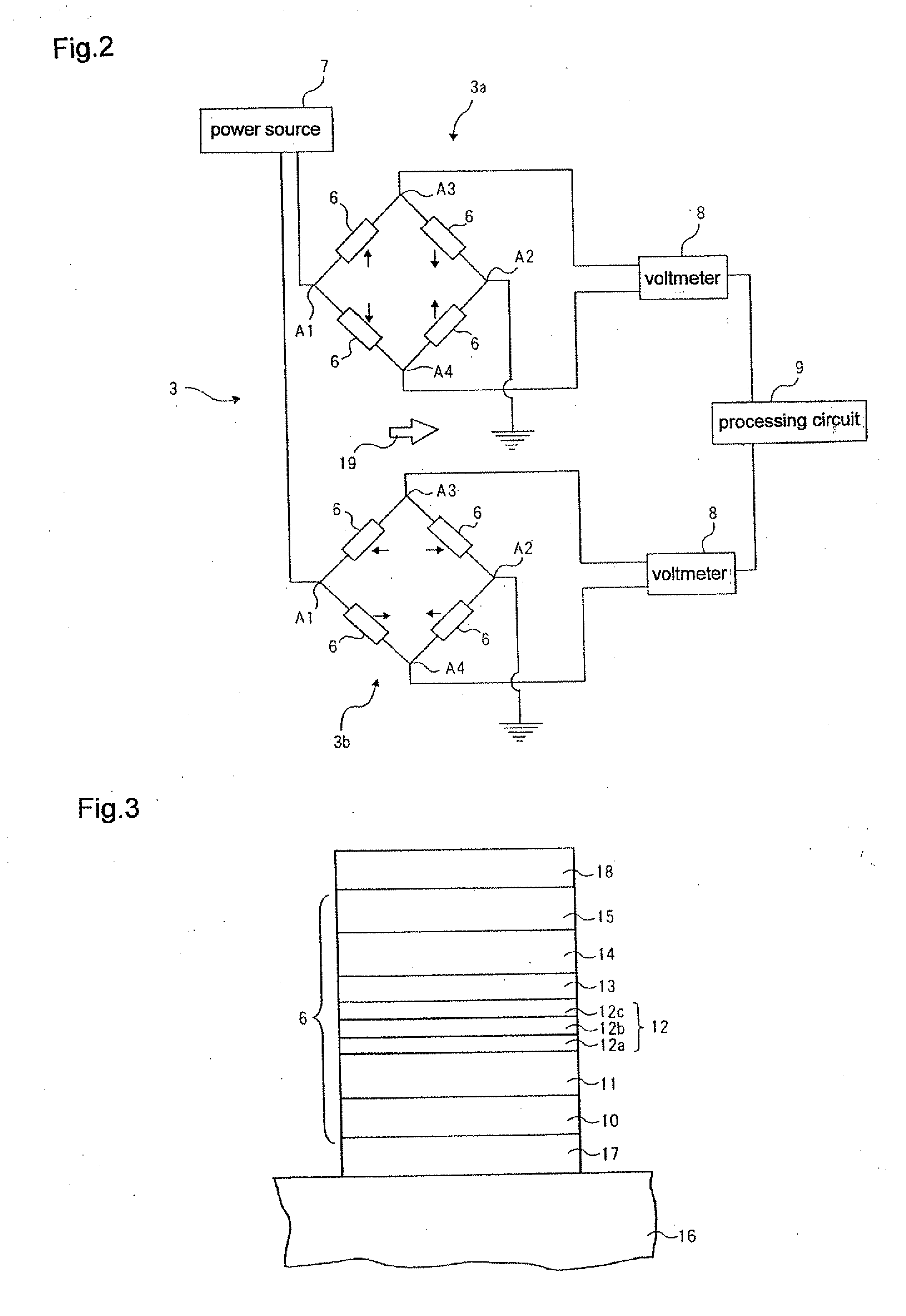

Electrically powered steering apparatus

InactiveUS20070068726A1Improve stabilityImprove workabilityWork measurementMechanical steering gearsGear wheelTorque transmission

An electrically powered steering apparatus in which at least one torque selected from a steering torque and a motor torque is transmitted from a torque transmission shaft to a rack-and-pinion mechanism to steer steered wheels. The torque transmission shaft has a torque-side shaft provided with a magnetostrictive film of a magnetostrictive sensor for sensing torque; and a pinion shaft provided with a pinion of the rack-and-pinion mechanism. The torque-side shaft and the pinion shaft are separate components which are linked together.

Owner:HONDA MOTOR CO LTD

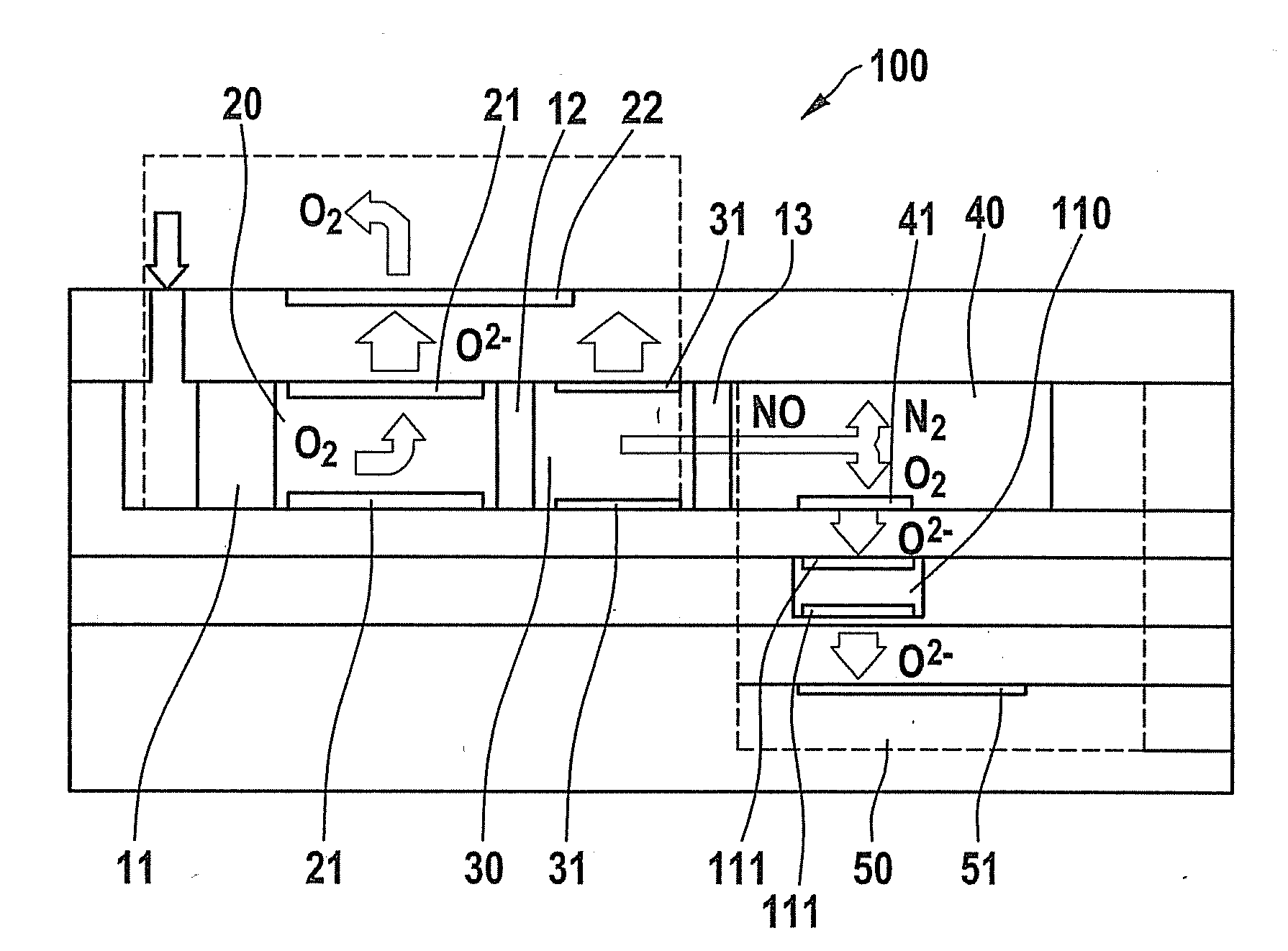

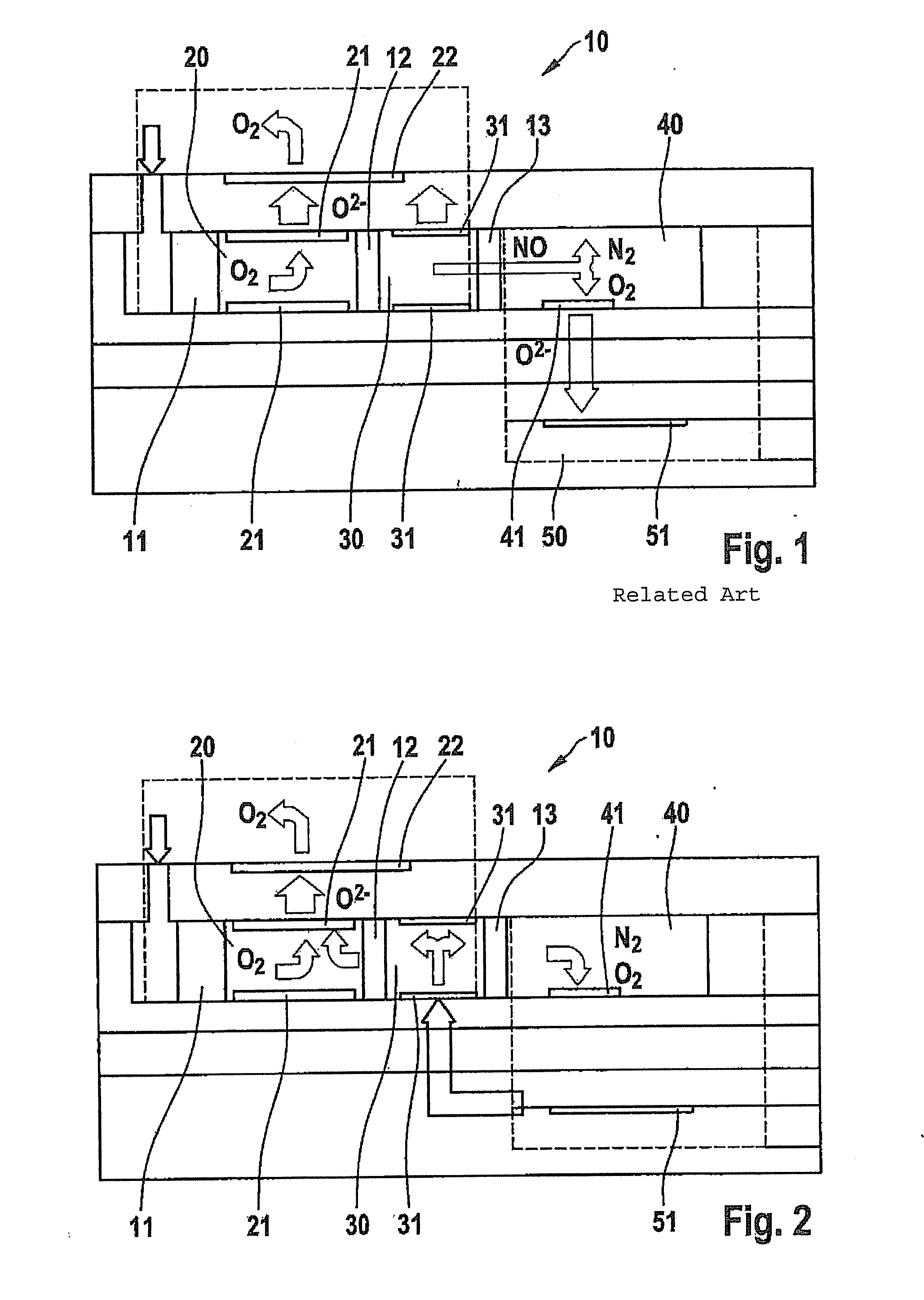

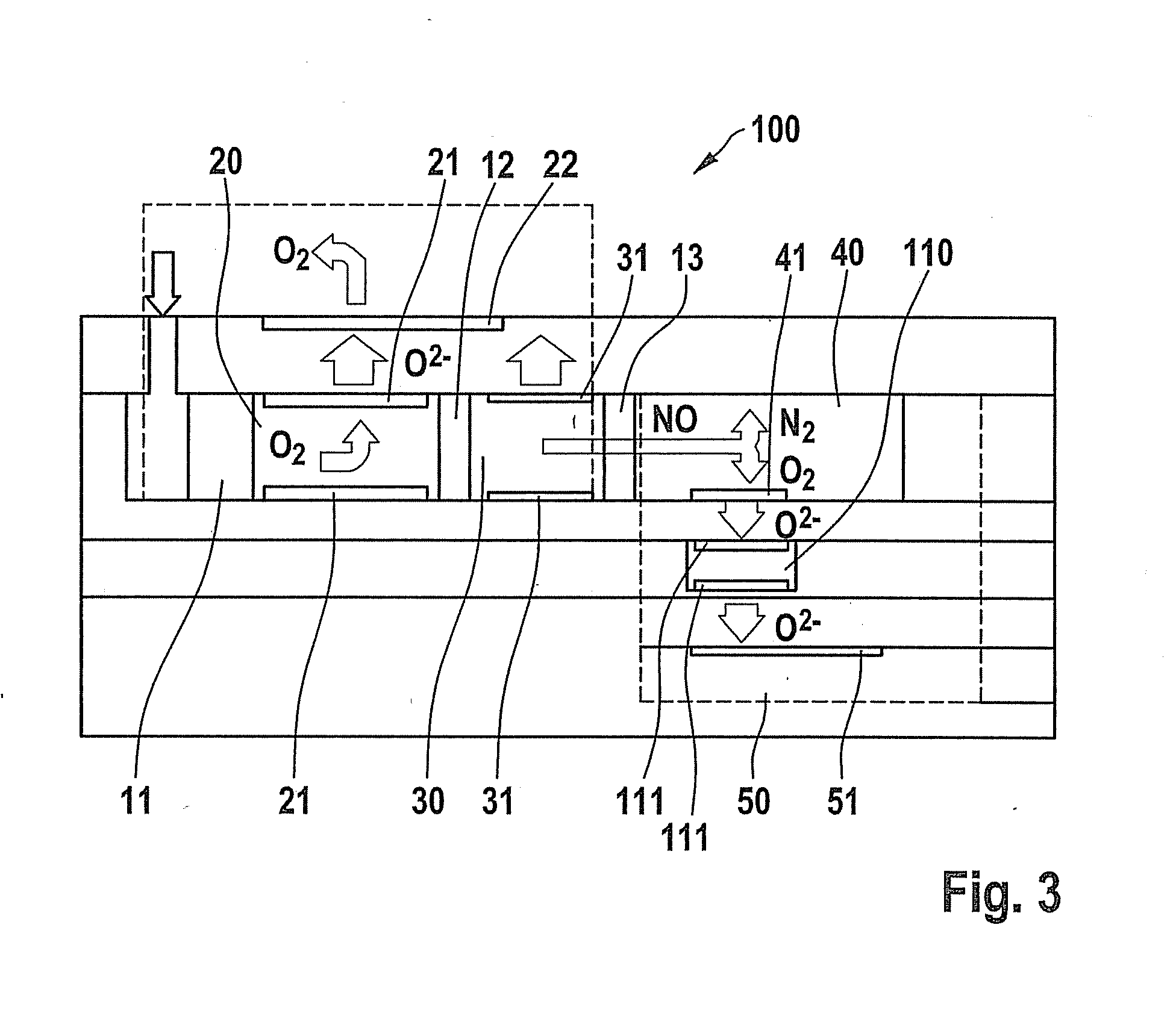

Method for measuring and/or calibrating a gas sensor

InactiveUS20120097553A1Readily uploaded and usedImprove sensor accuracyInternal combustion piston enginesWeather/light/corrosion resistanceCalibration gasCombustion

A method for measuring and / or calibrating a gas sensor for determining oxygenic gas components in gas mixtures in exhaust gases of internal combustion engines. The gas sensor has one internal pump electrode IPE, one external pump electrode APE and one decomposition electrode NOE. The measurement and / or calibration may be carried out during the ongoing operation of the gas sensor by removing the gas component and / or oxygen from one of the chambers, by introducing oxygen in a controlled manner into one of the chambers with the aid of electrochemical pumping processes. The changes caused by the introduced oxygen are measured against an additional electrode and the gas sensor may be measured and / or calibrated using the measured values.

Owner:ROBERT BOSCH GMBH

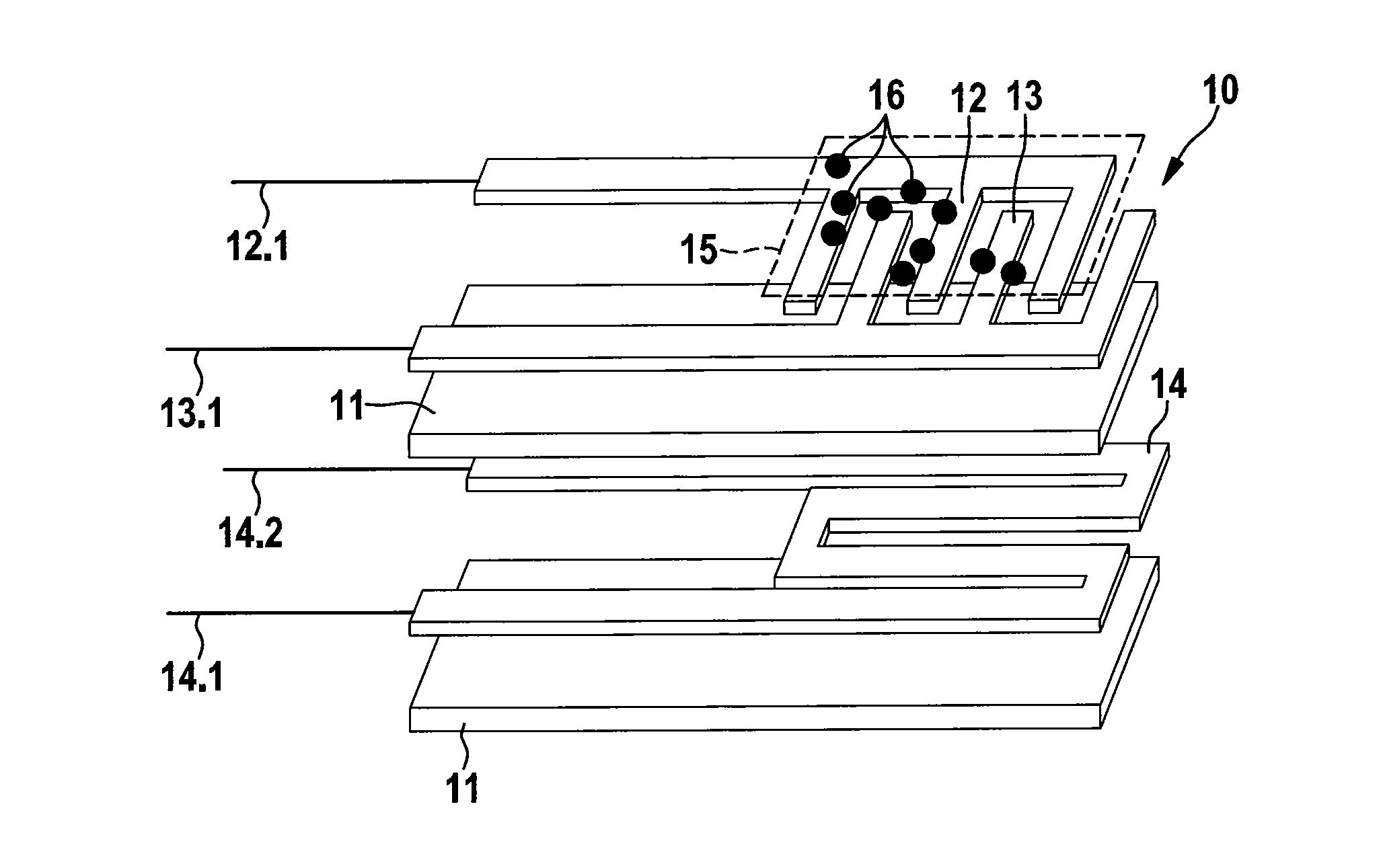

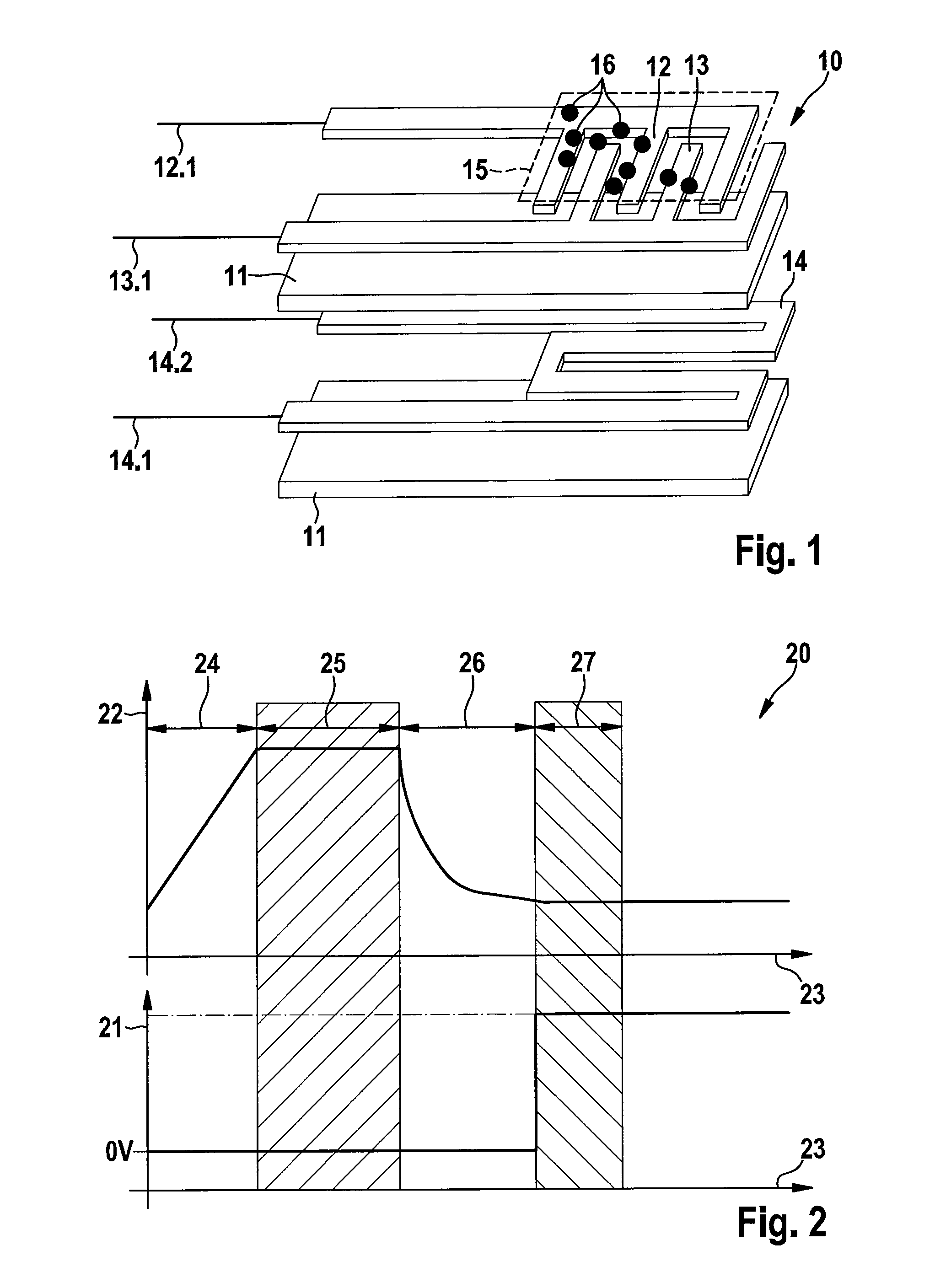

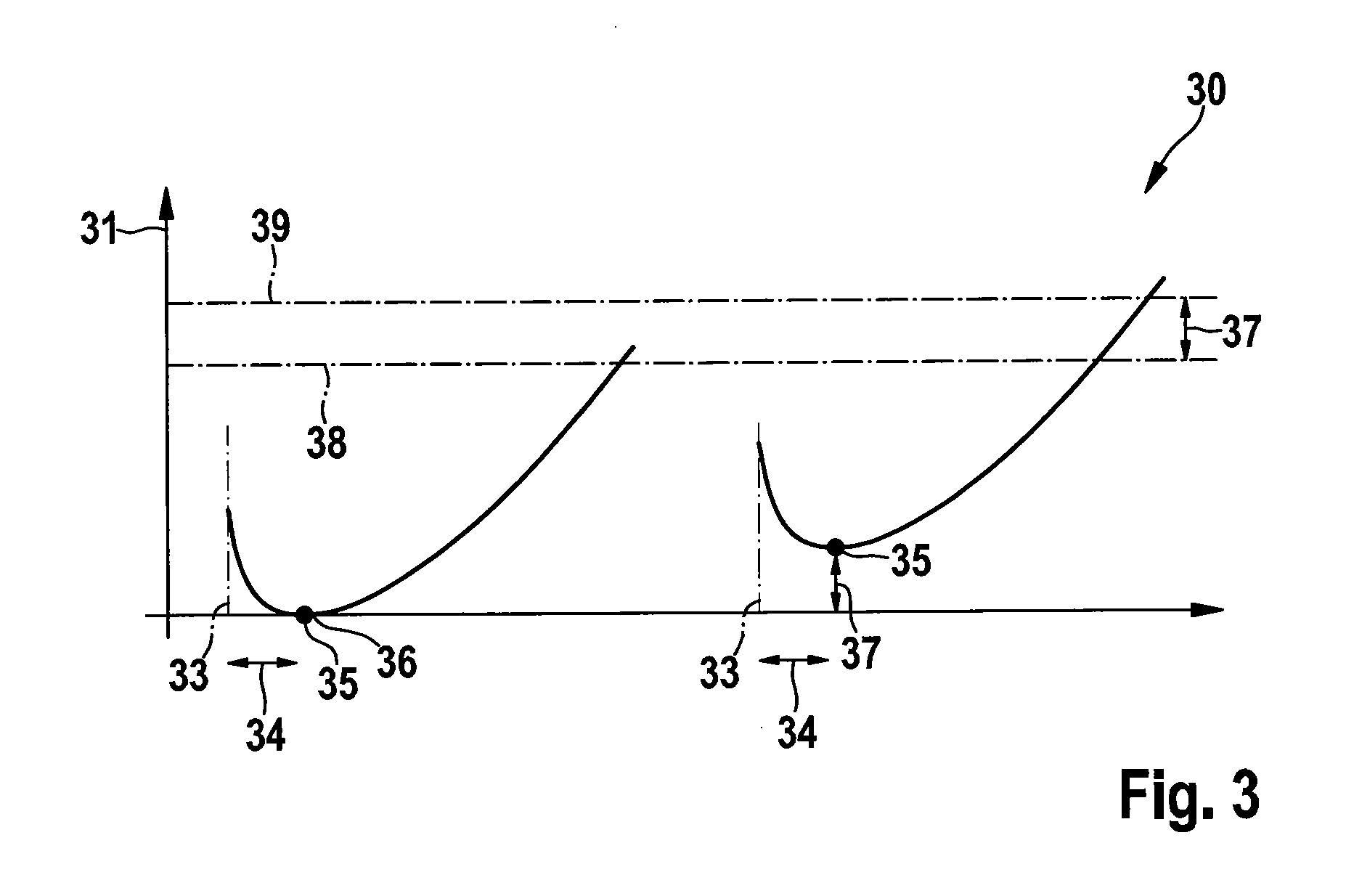

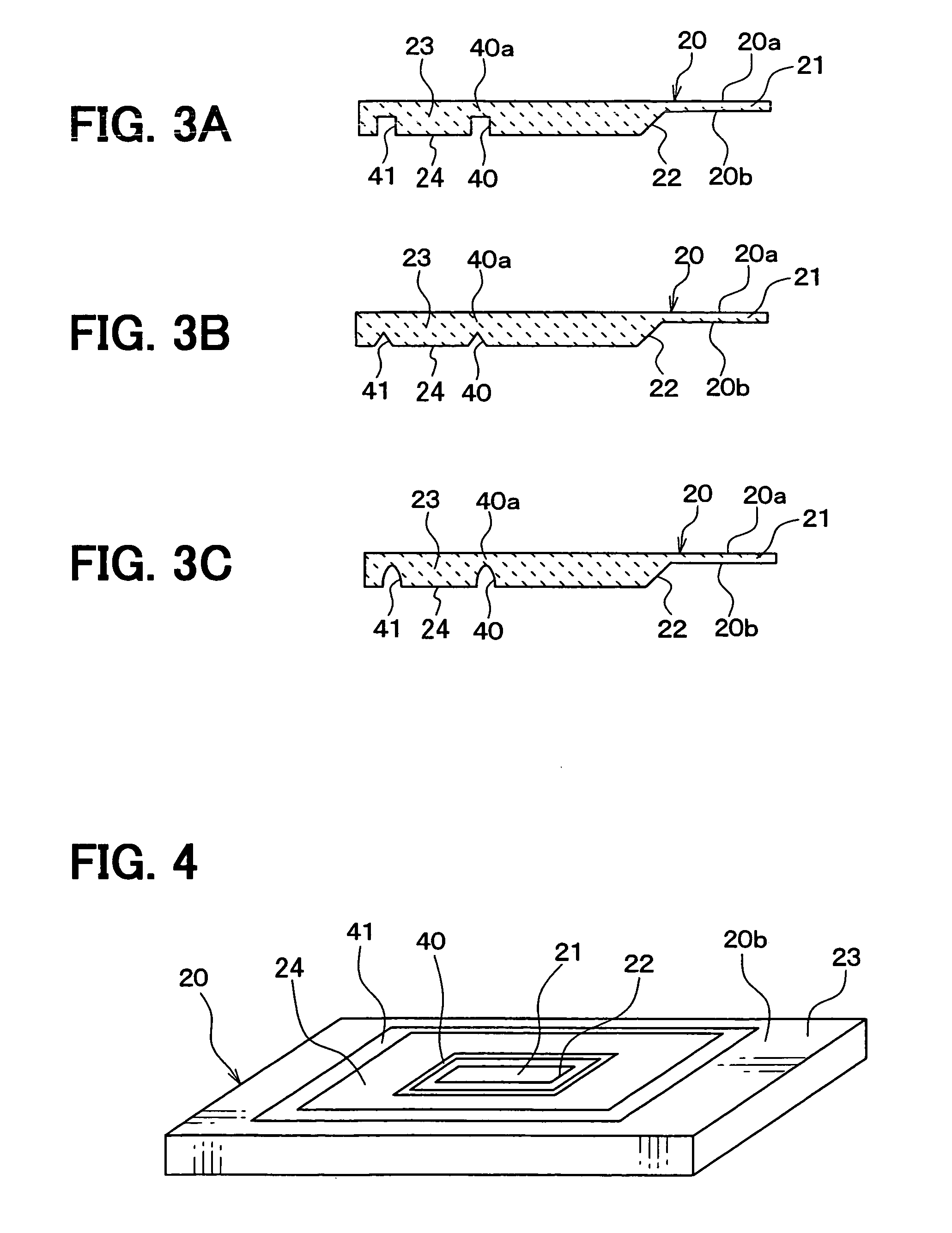

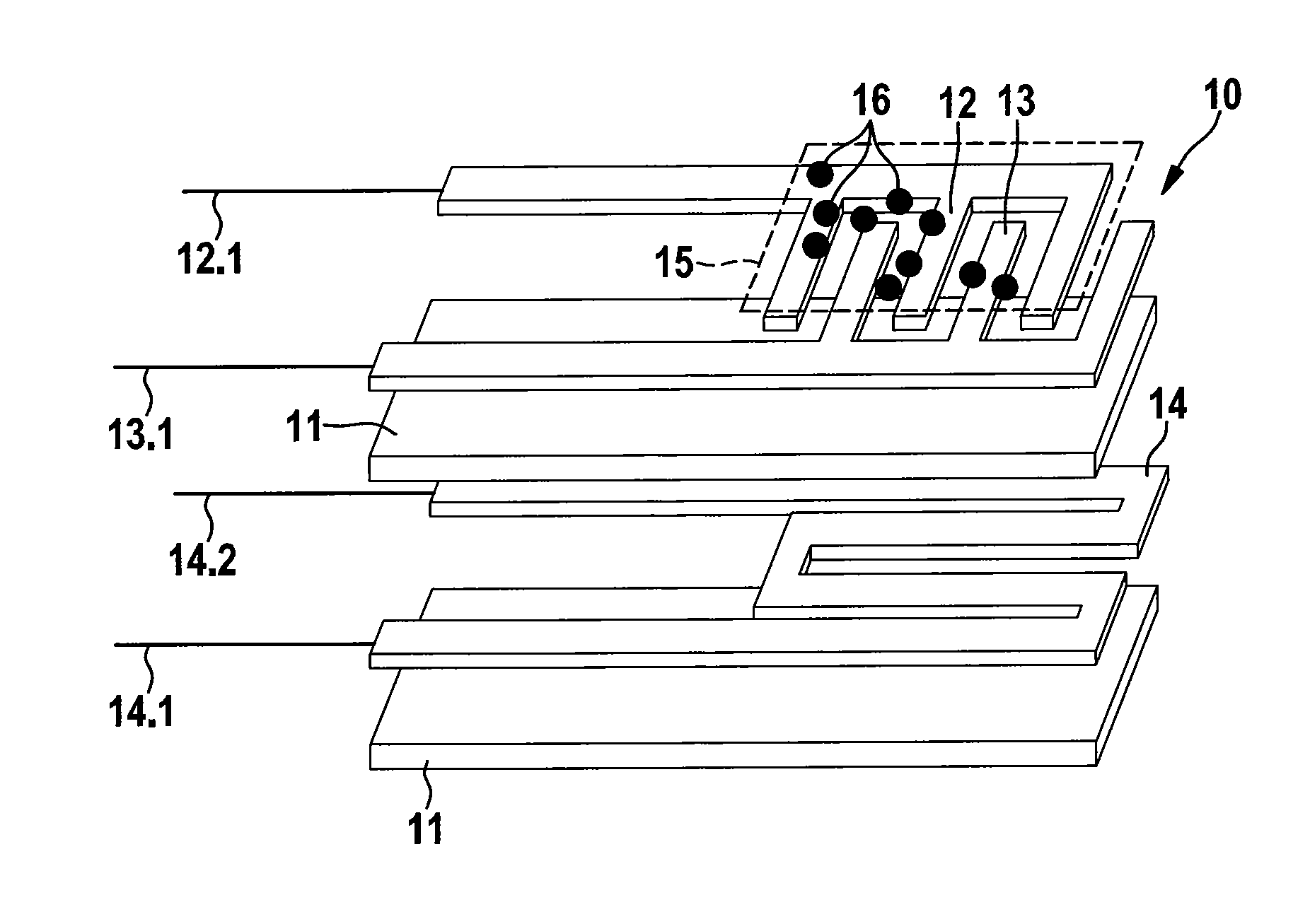

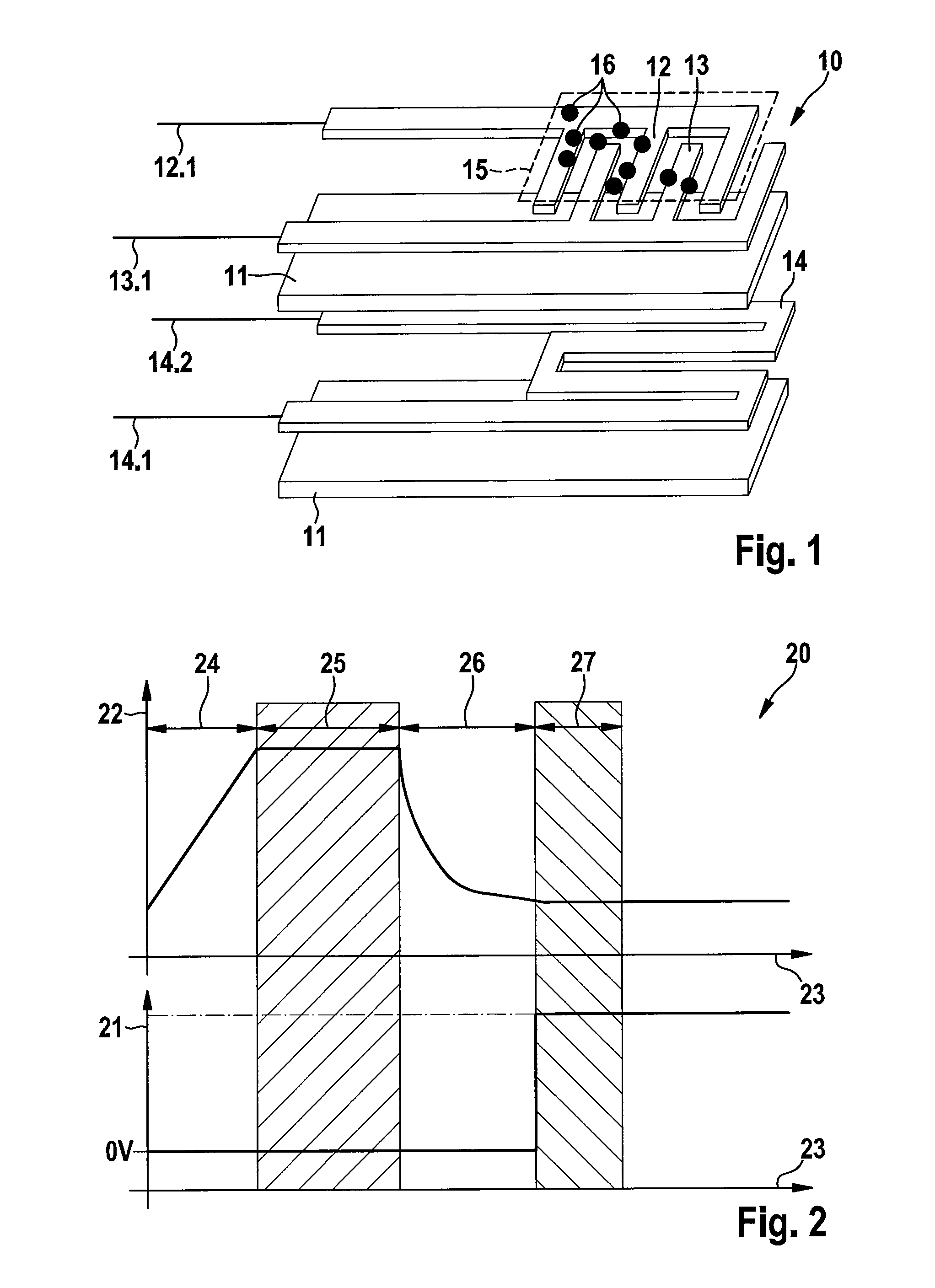

Method and device for operating a particle sensor

ActiveUS20110314899A1Improve self-diagnosisImprove sensor accuracyInternal-combustion engine testingElectrical controlEngineeringSoot particles

A method for operating a particle sensor (10). The particle sensor (10) has at least two inter-digital electrodes (12, 13) which engage one in the other and to which a sensor voltage U(IDE) (21) is applied in order to determine loading of the particle sensor (10) with soot particles (16). A sensor current I(IDE) (31) across the electrodes (12, 13) is measured and evaluated. In order to remove the loading with soot, a heating element (14) heats the particle sensor (10) in a regeneration phase. The method characterized in that the sensor current I(IDE) (31) is determined, and a shunt diagnosis of the particle sensor (10) is carried out in accordance with the measured sensor current I(IDE) (31).

Owner:ROBERT BOSCH GMBH

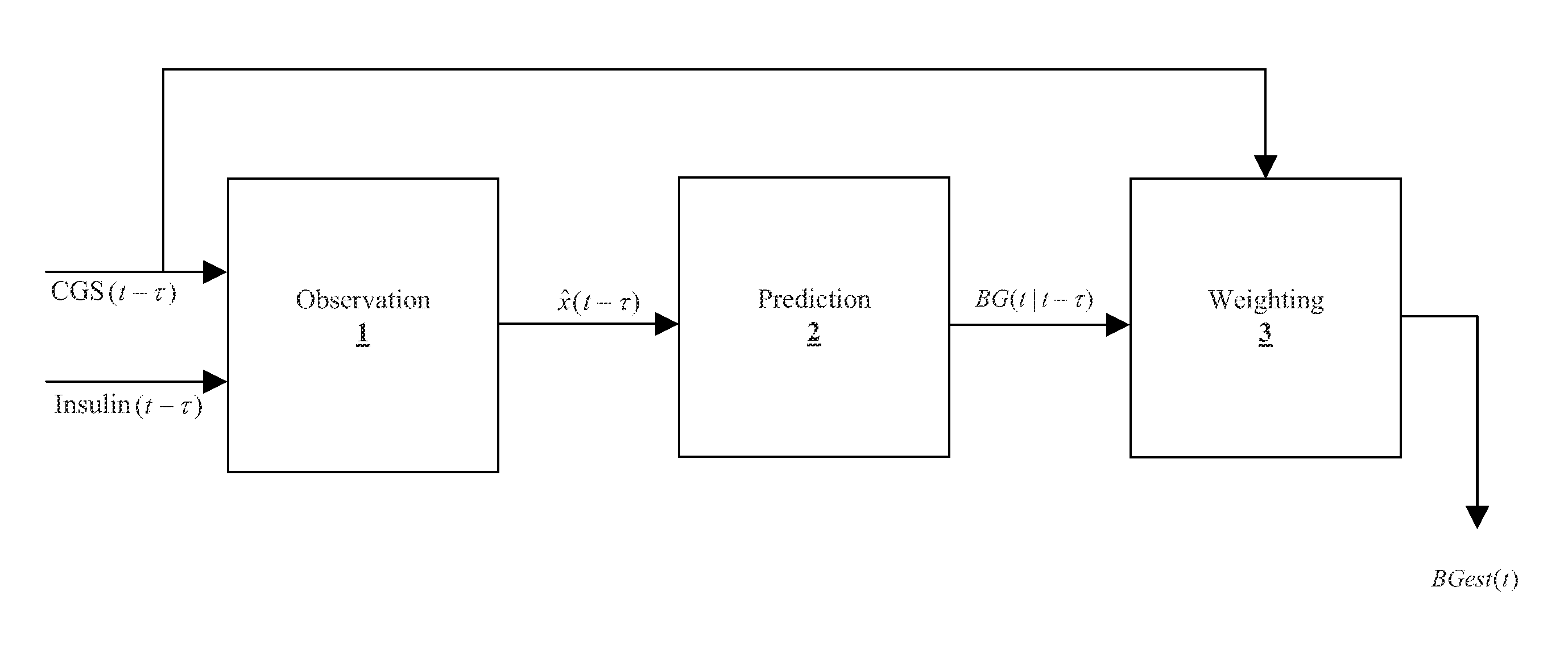

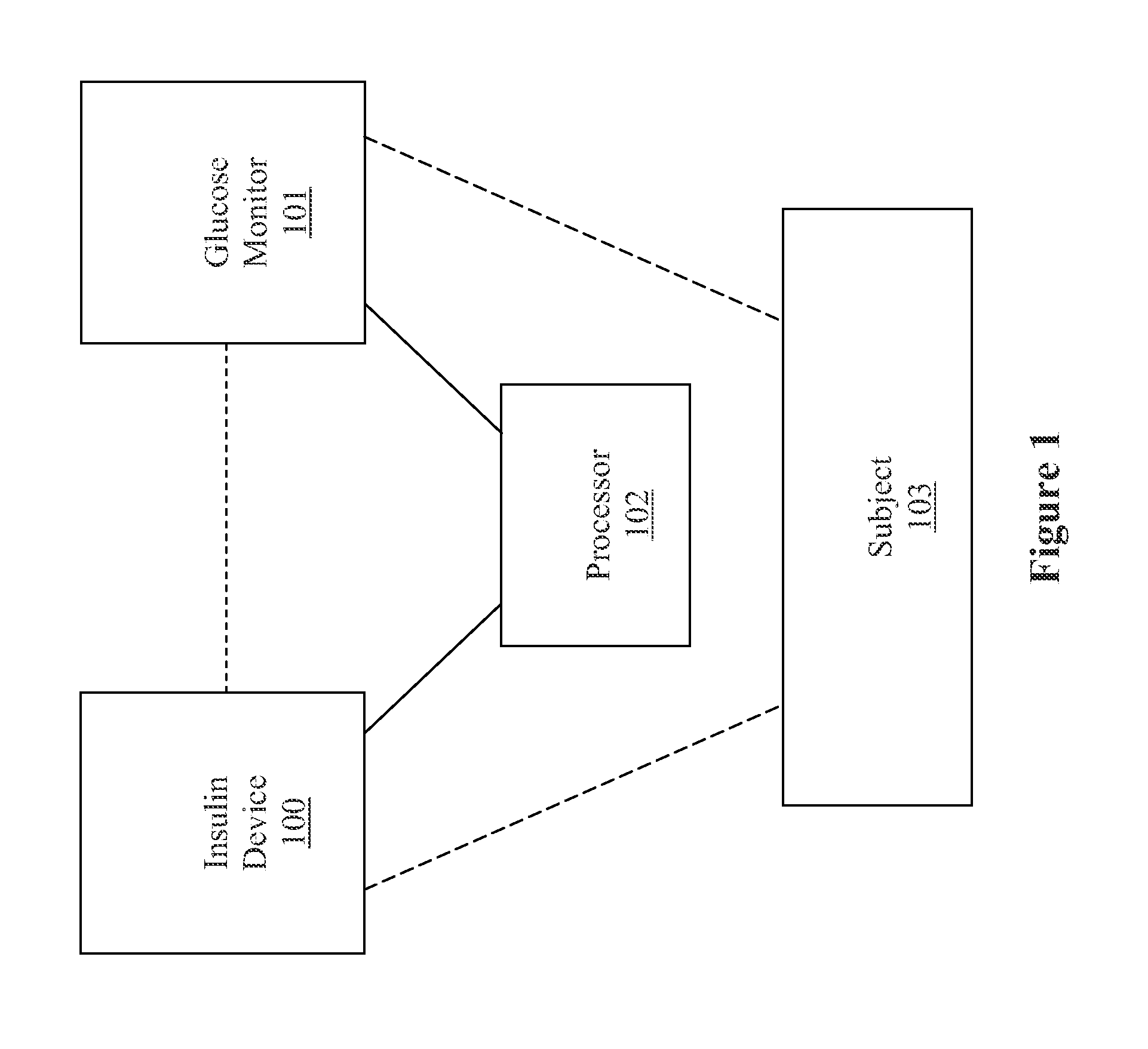

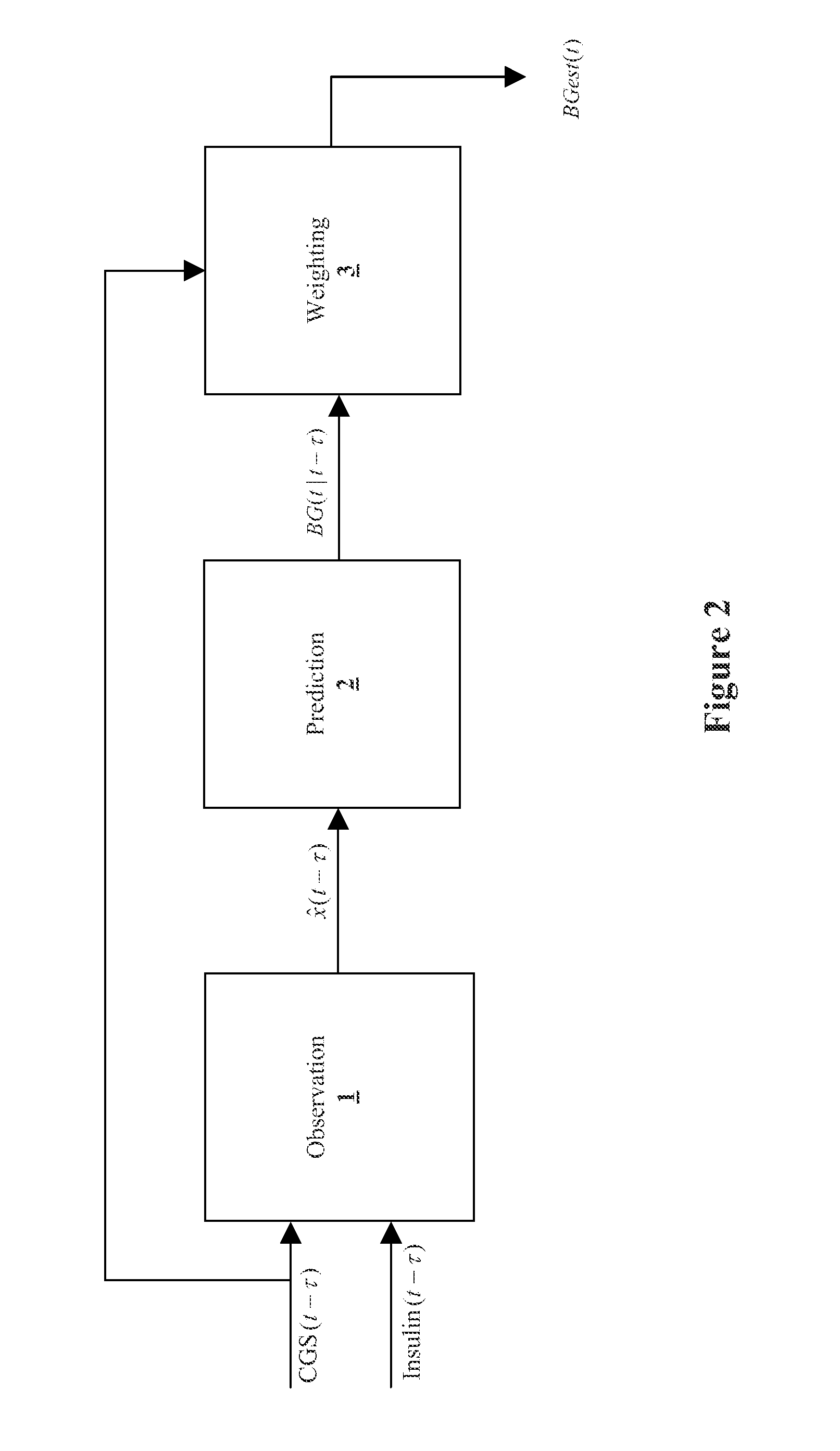

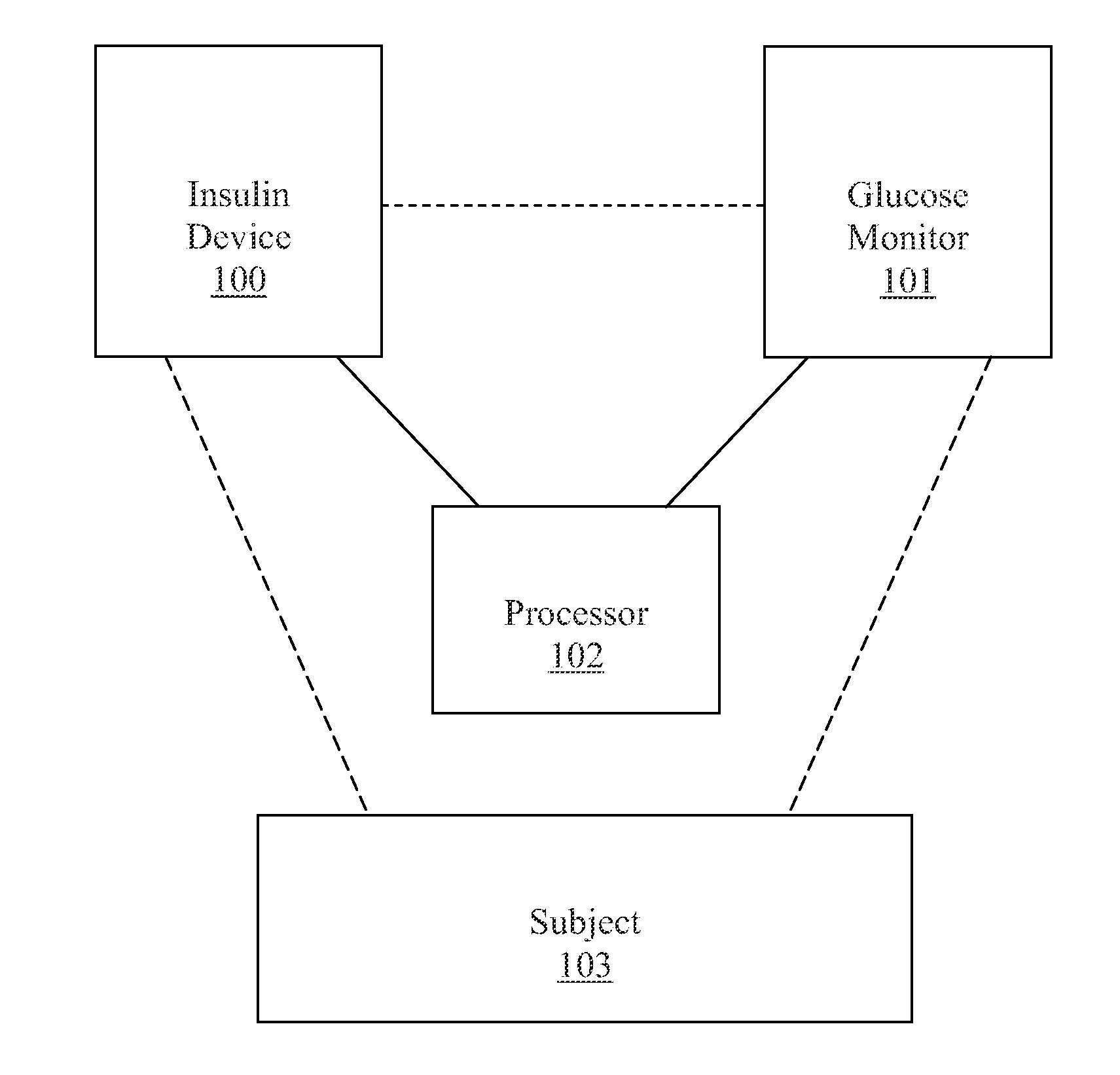

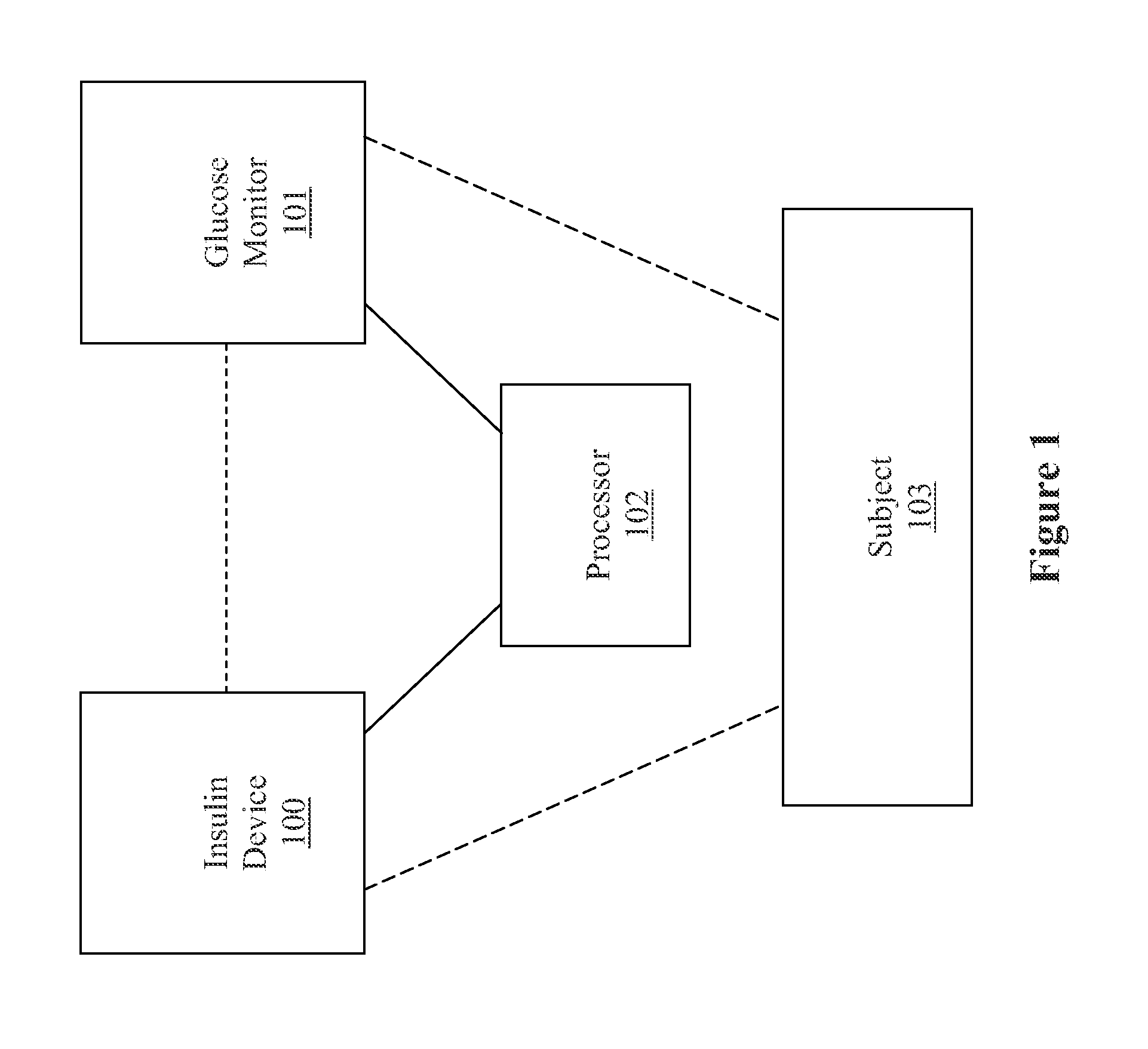

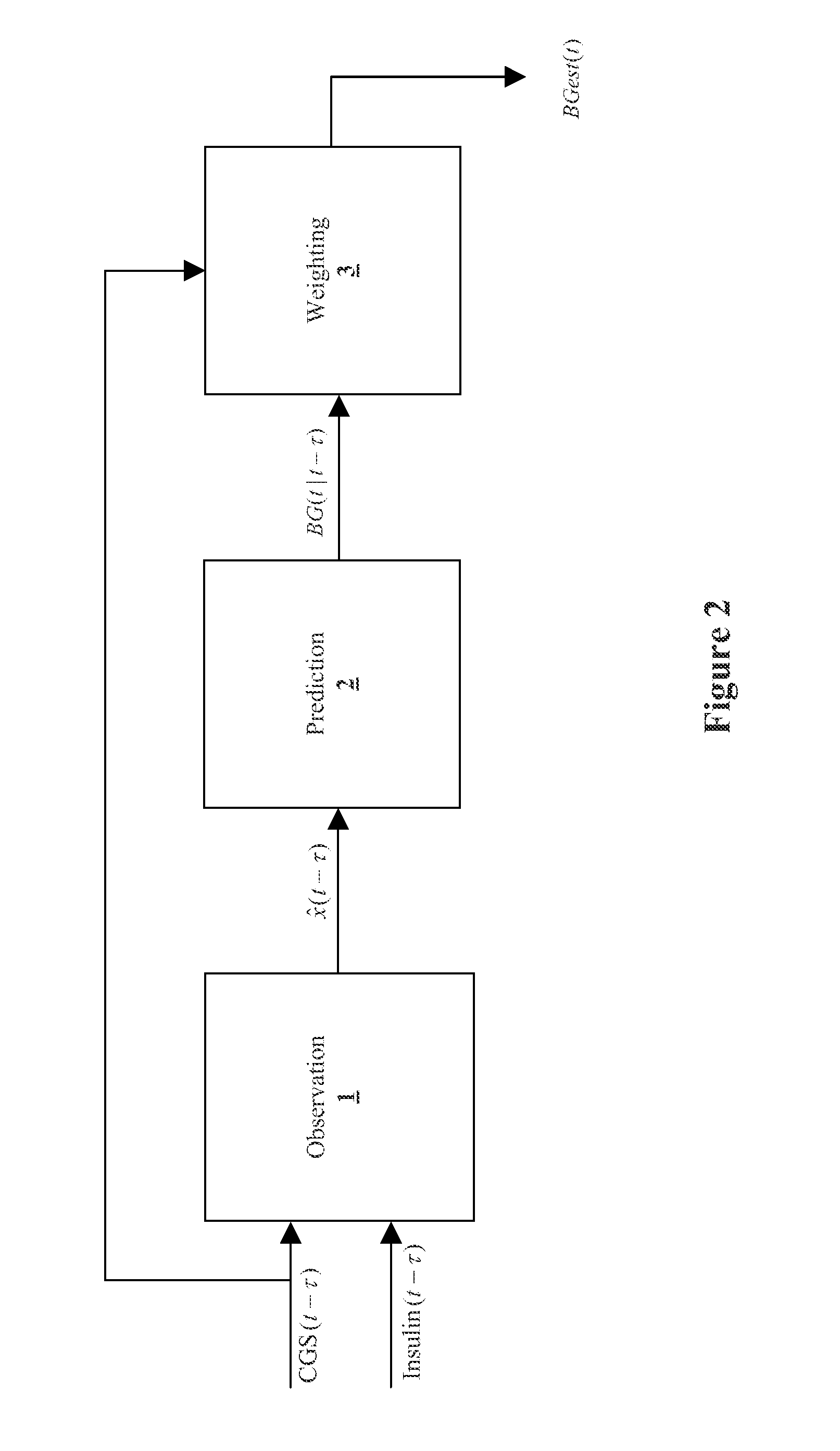

Method, system, and computer program product for improving the accuracy of glucose sensors using insulin delivery observation in diabetes

ActiveUS9398869B2Improve accuracyImprove sensor accuracyOther blood circulation devicesPressure infusionGlucose sensorsInsulin pump

Method and System for providing a signal from an insulin pump, artificial pancreas, or another insulin delivery device as a source of information for improving the accuracy of a continuous glucose sensor (CGS). The effect of using insulin information to enhance sensor accuracy is most prominent at low blood glucose levels, i.e. in the hypoglycemic range, which is critical for any treatment. A system for providing a filtering / state estimation methodology that may be used to determine a glucose state estimate at time t-τ. The estimation may be extrapolated to some future time t and then the extrapolated value is used to extract the blood glucose component. The blood glucose component of the extrapolation and the output of the CGS are weighted and used to estimate the blood glucose level of a subject.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

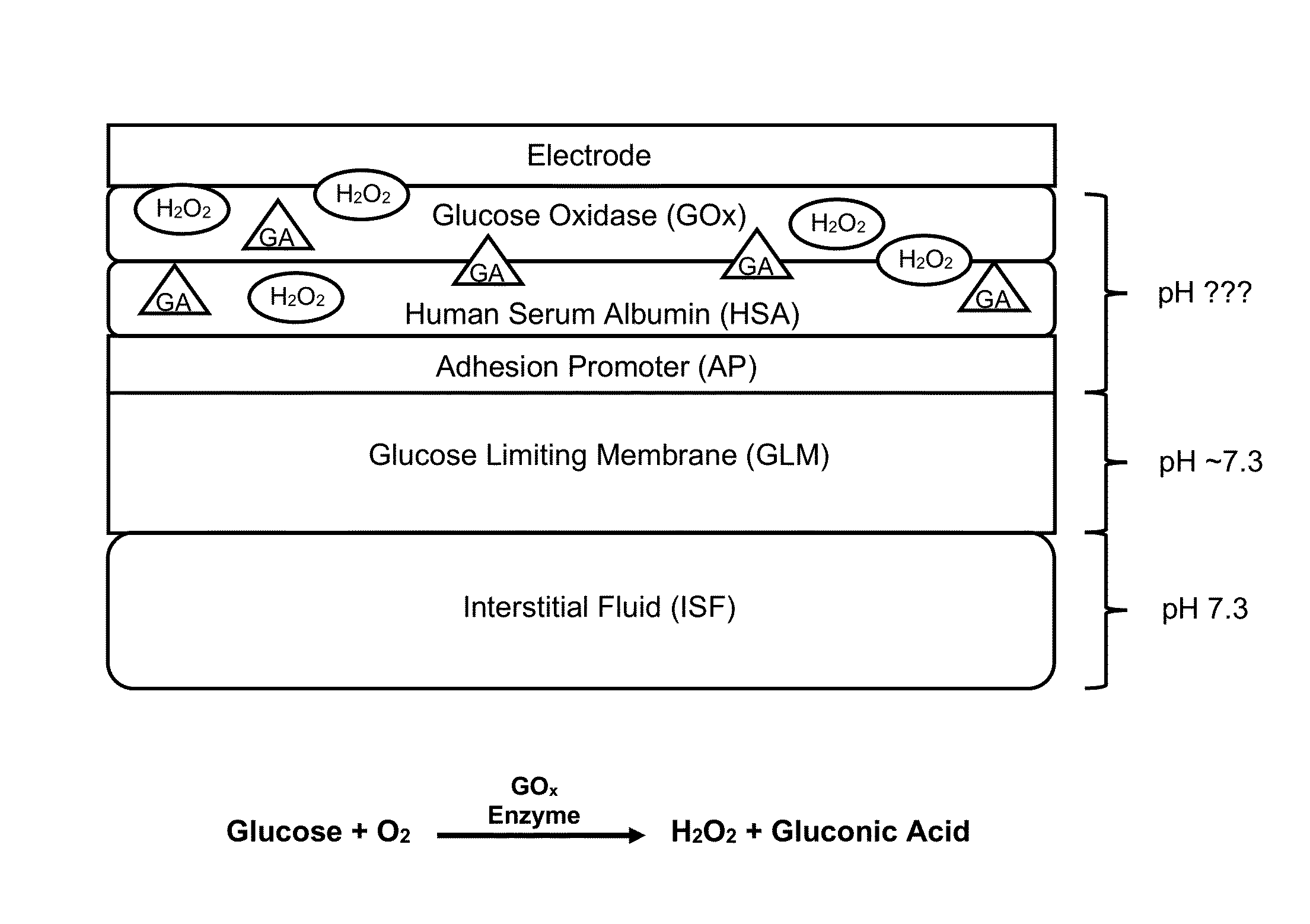

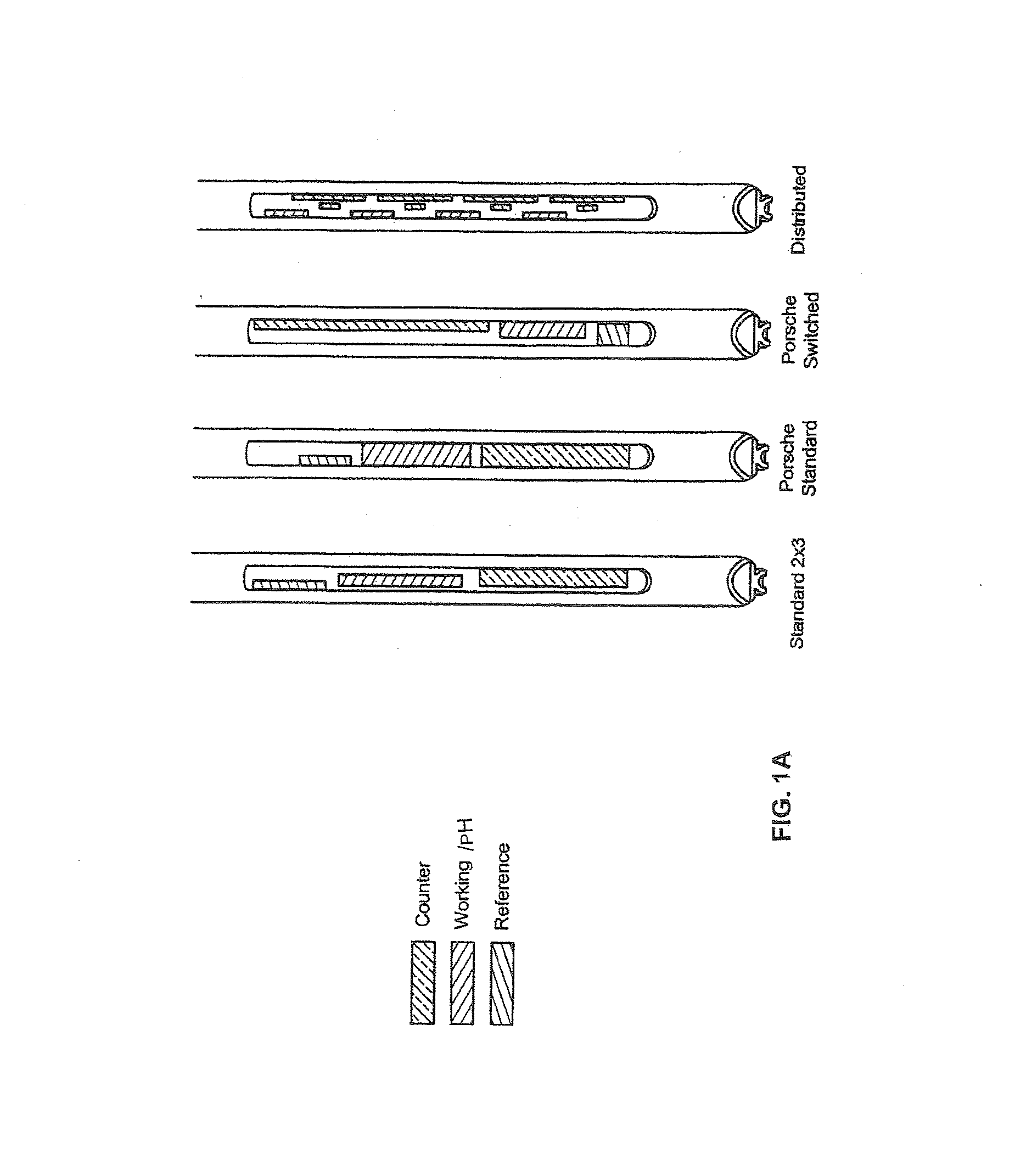

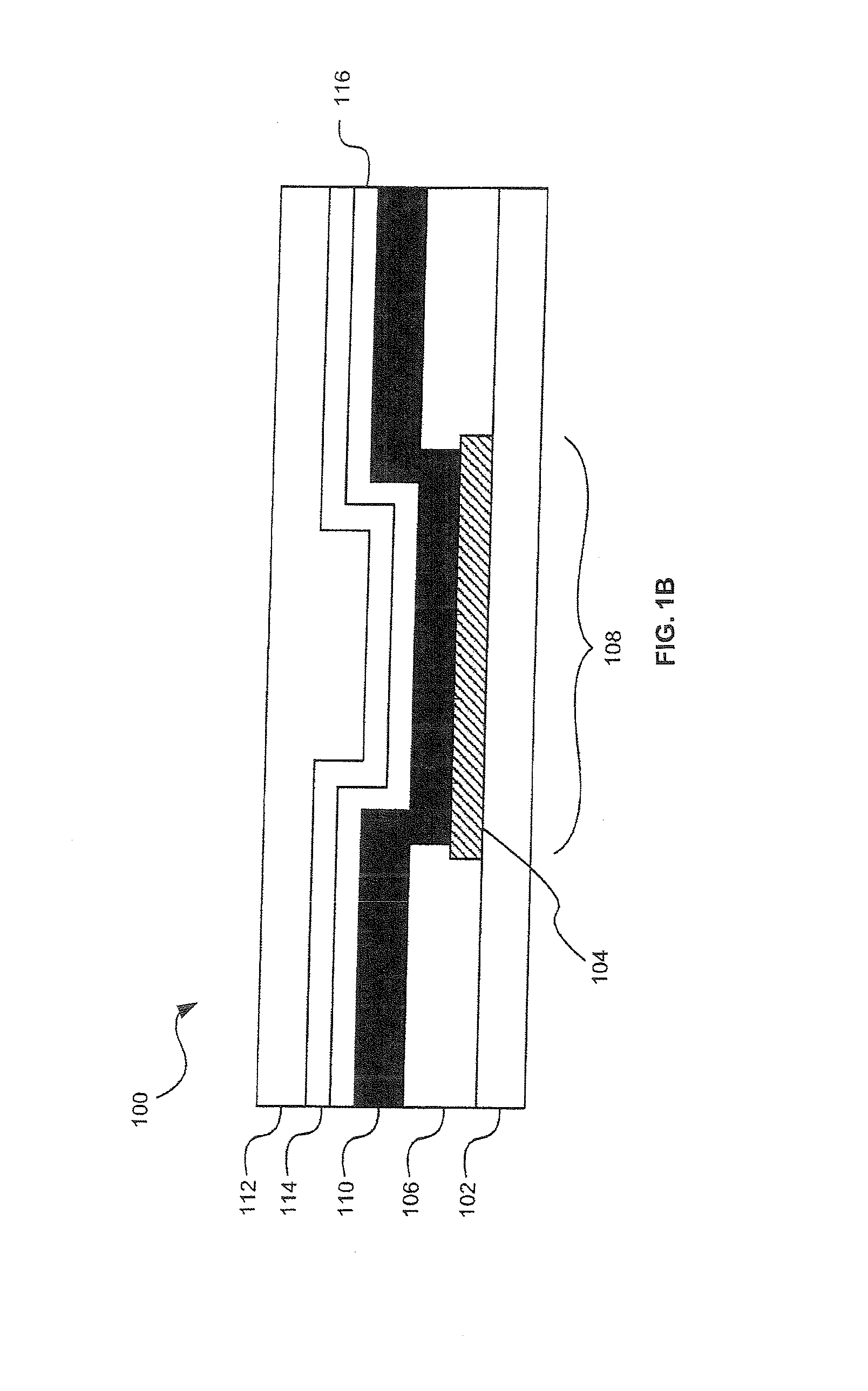

Ph microsensor for glucose and other analyte sensor fault detection

InactiveUS20160249840A1High sensitivityImprove sensor accuracyMicrobiological testing/measurementMaterial analysis by electric/magnetic meansAnalytePower flow

Embodiments of the invention provide amperometric analyte sensor systems comprising a plurality of electrodes including one or more electrodes designed to monitor pH in order to facilitate the sensing of analytes at different pH levels within a sensor environment. Typical embodiments of the invention include glucose oxidase based amperometric sensors used in the management of diabetes.

Owner:MEDTRONIC MIMIMED INC

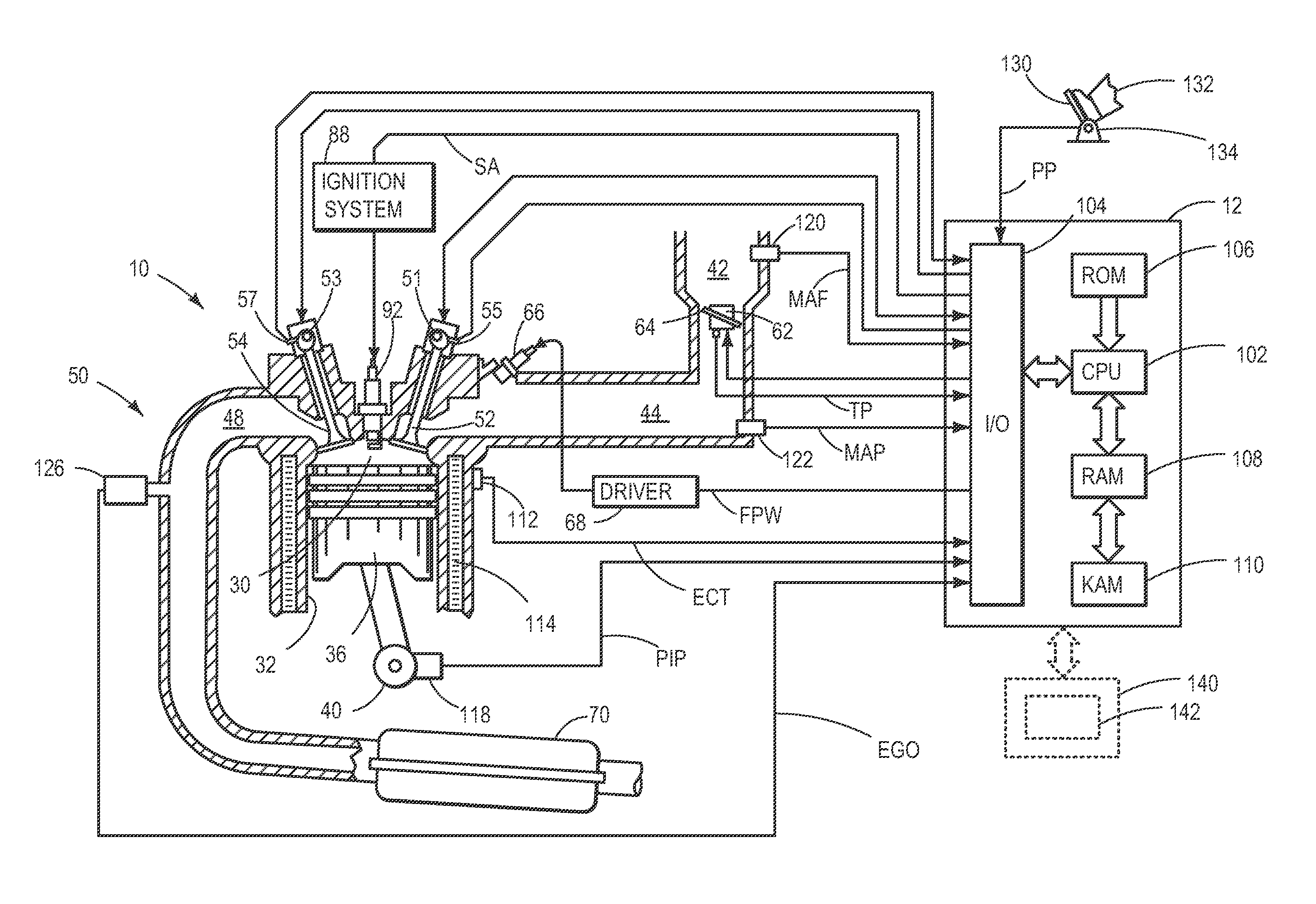

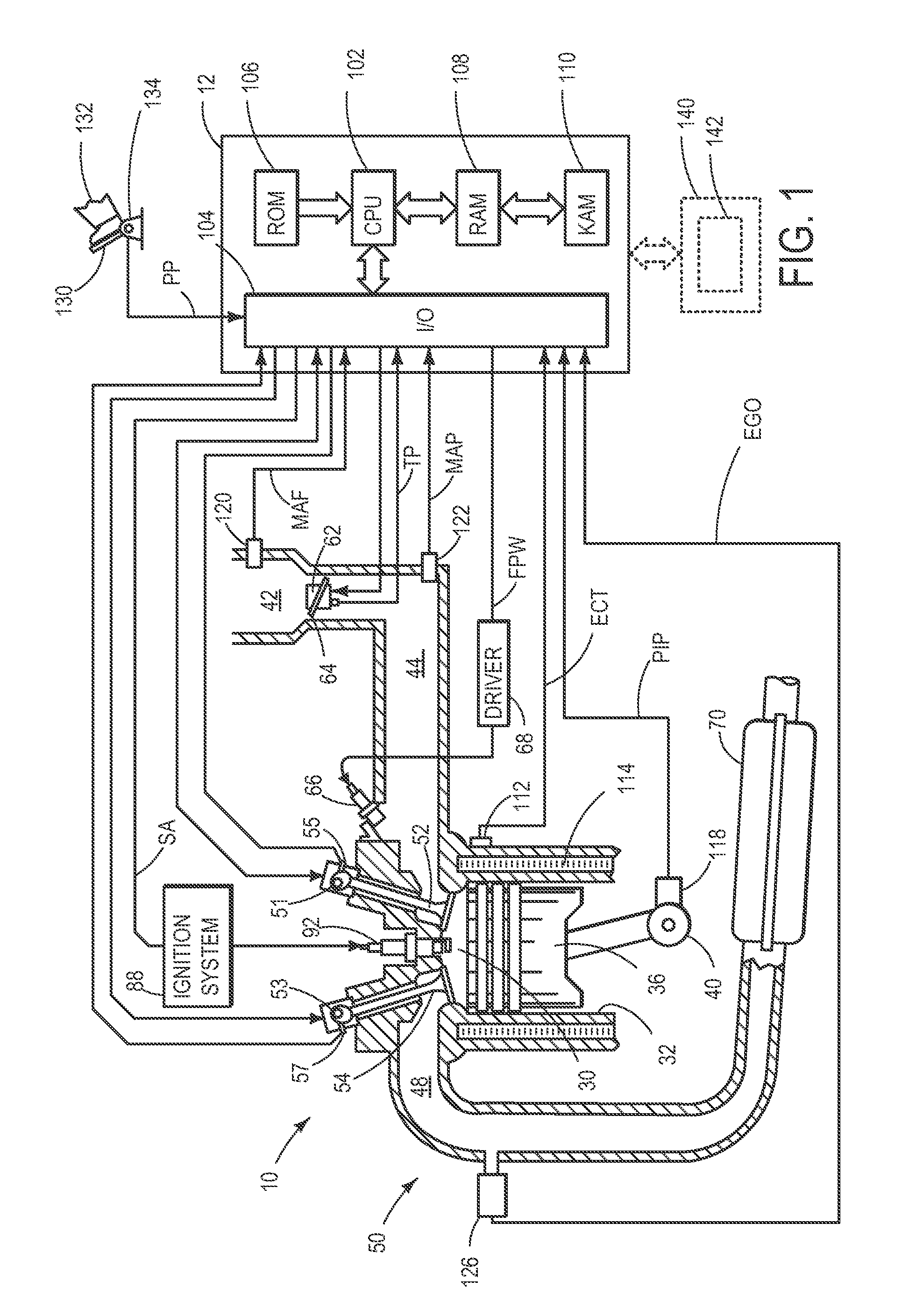

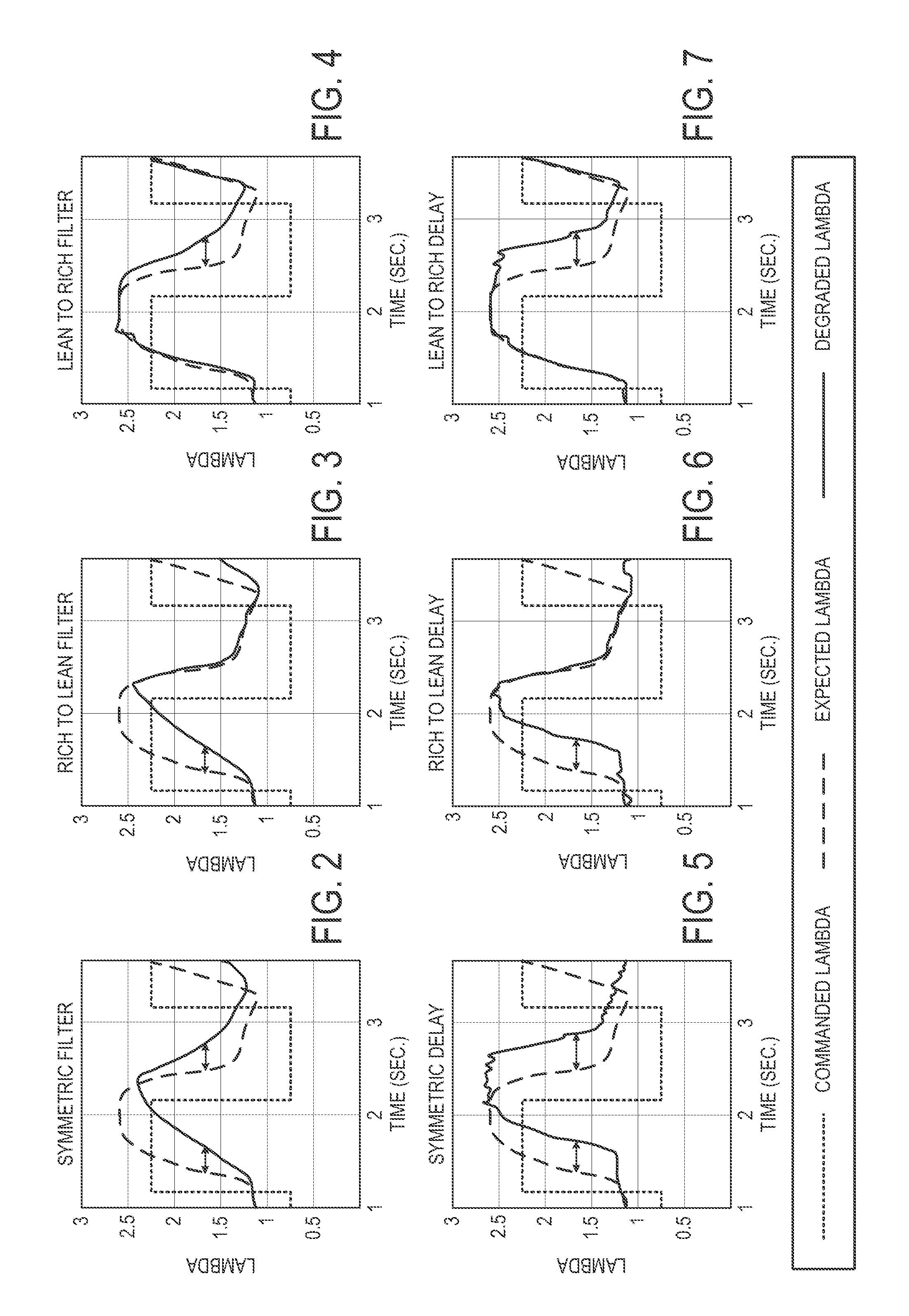

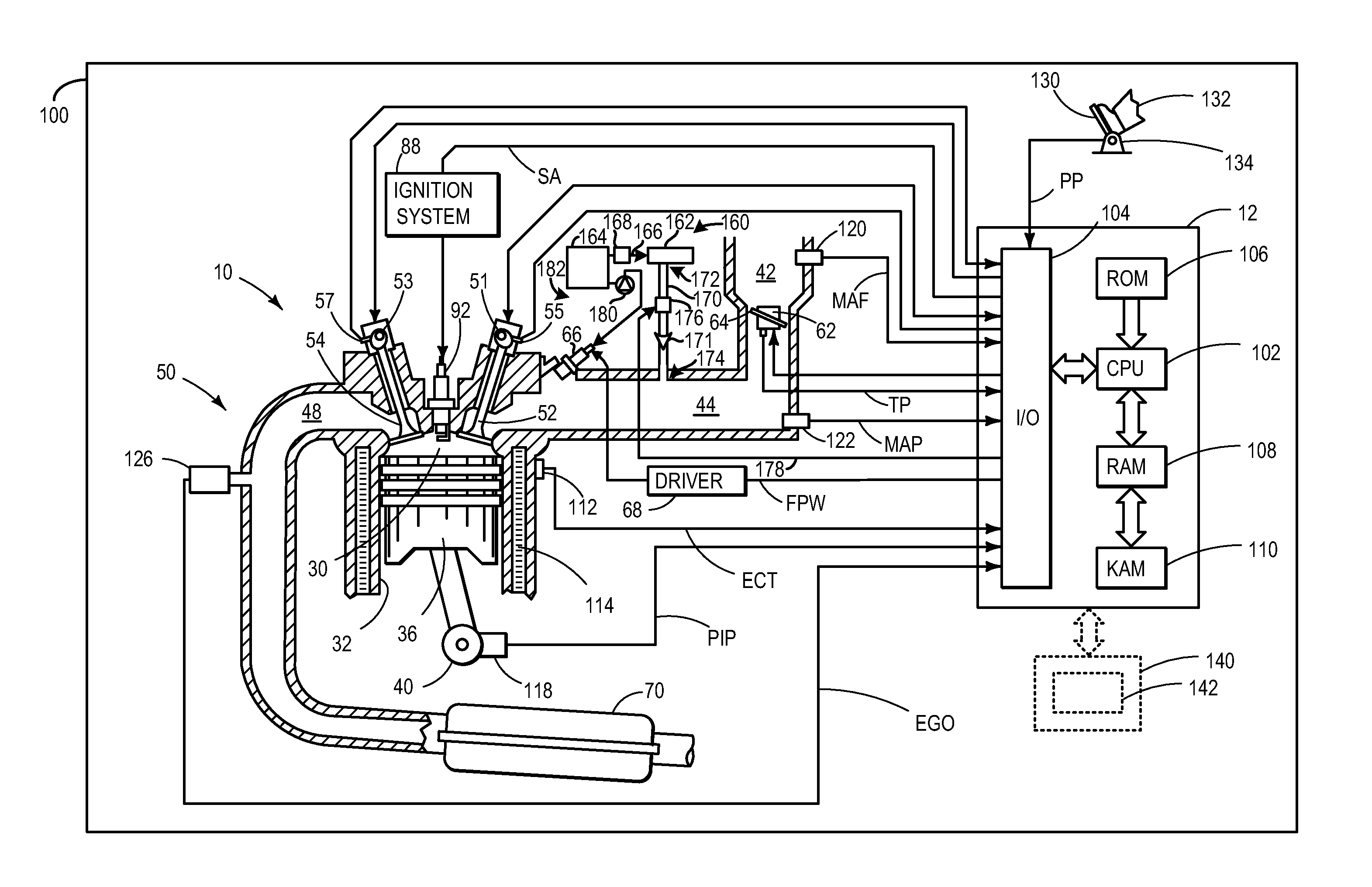

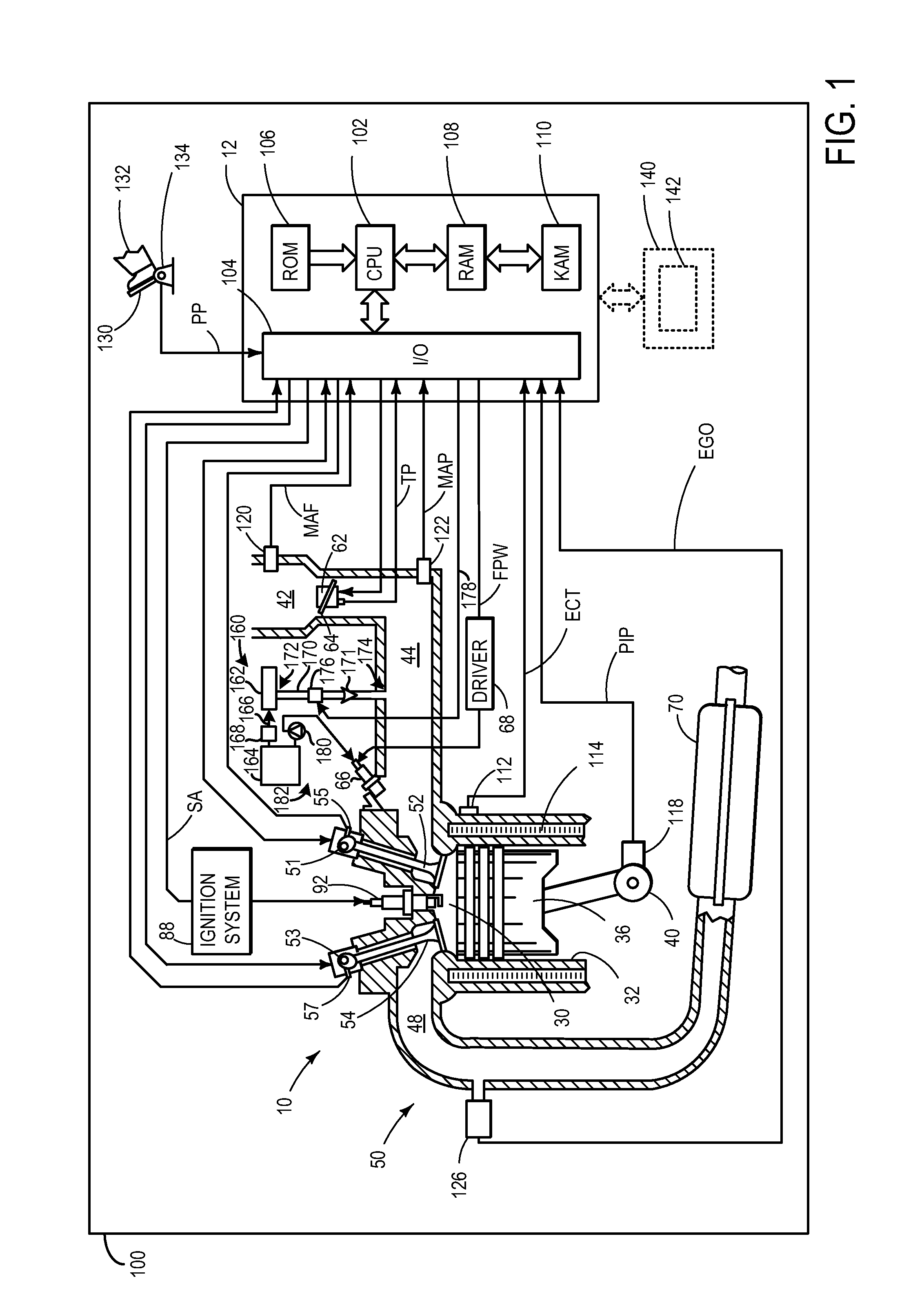

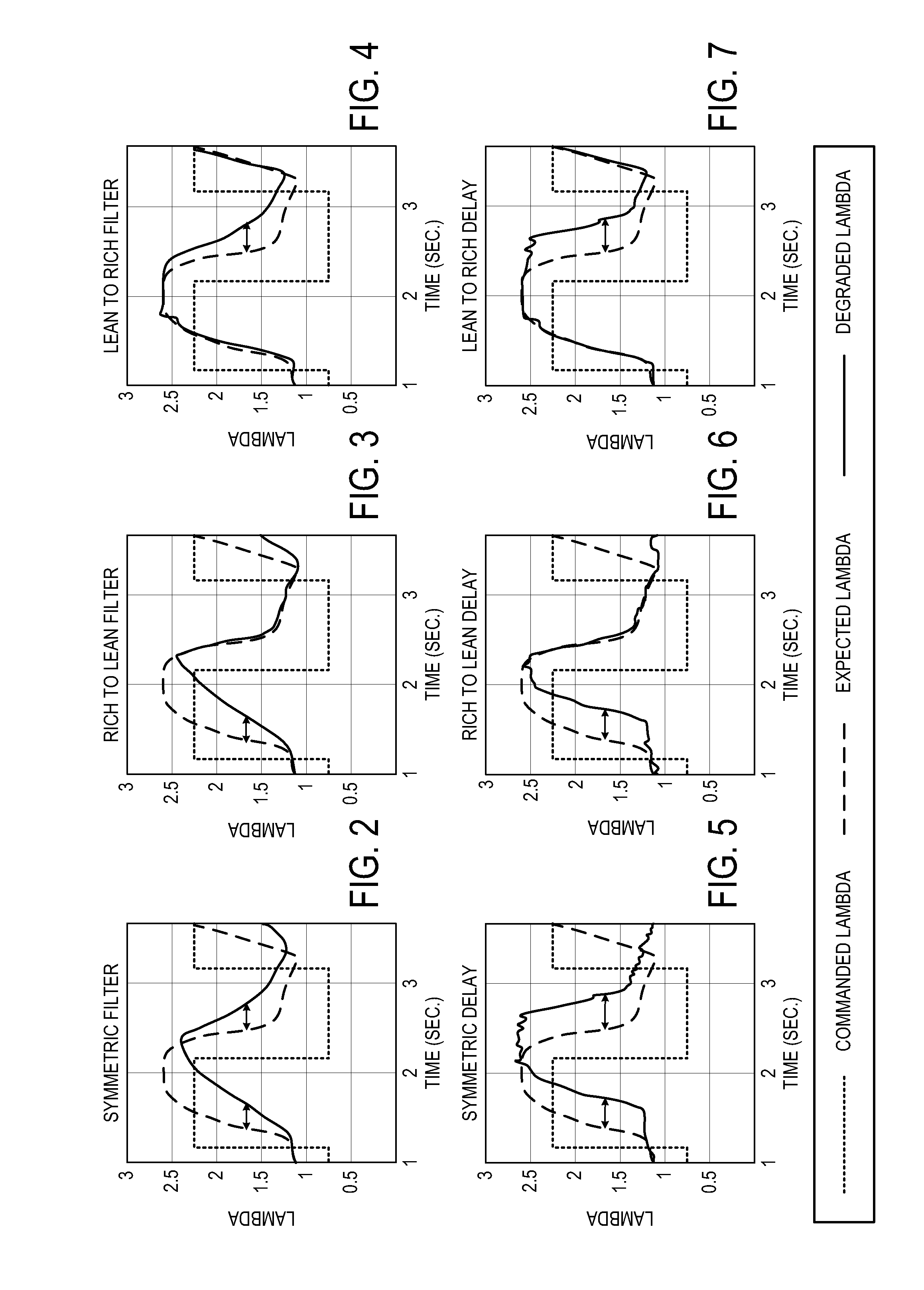

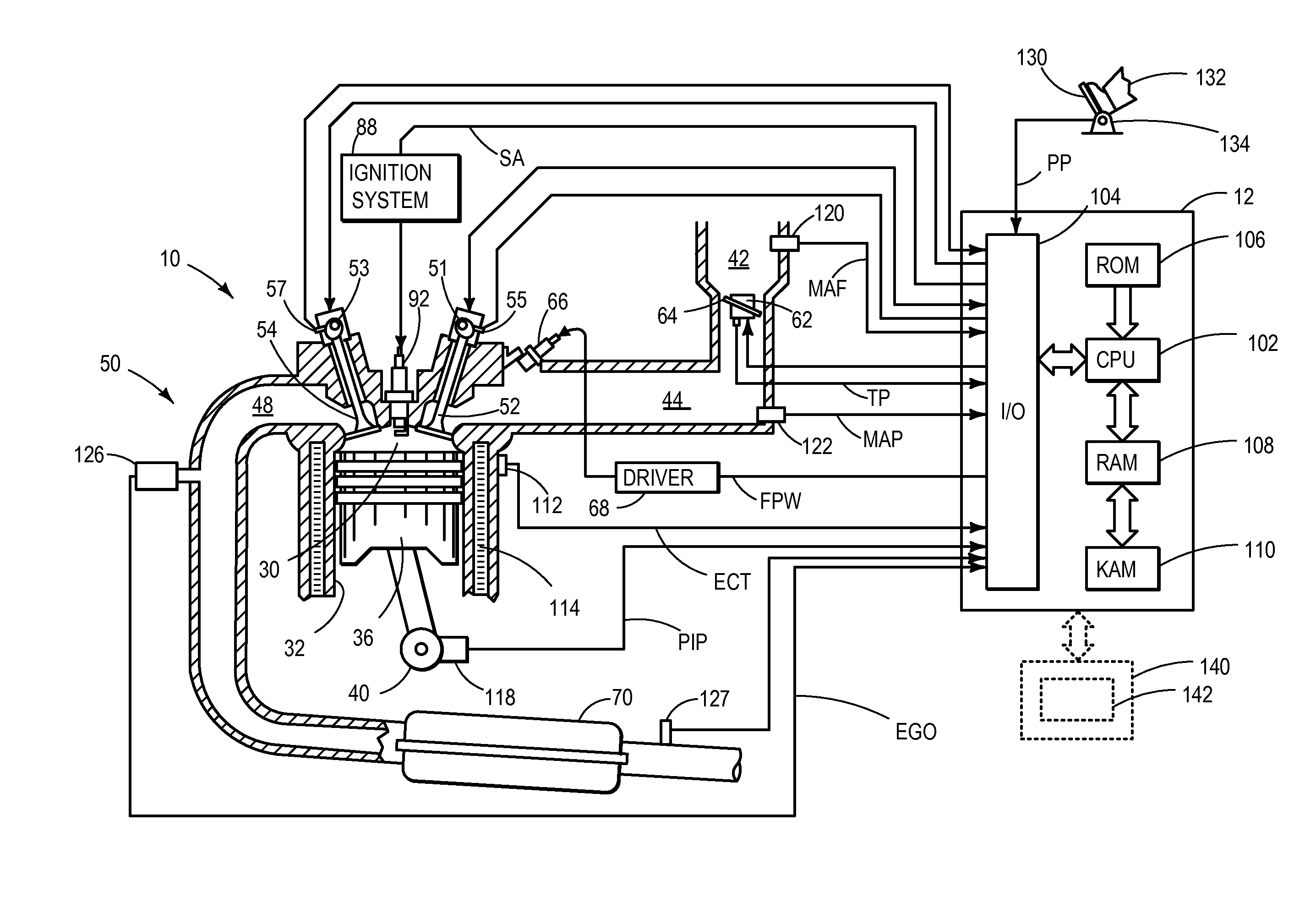

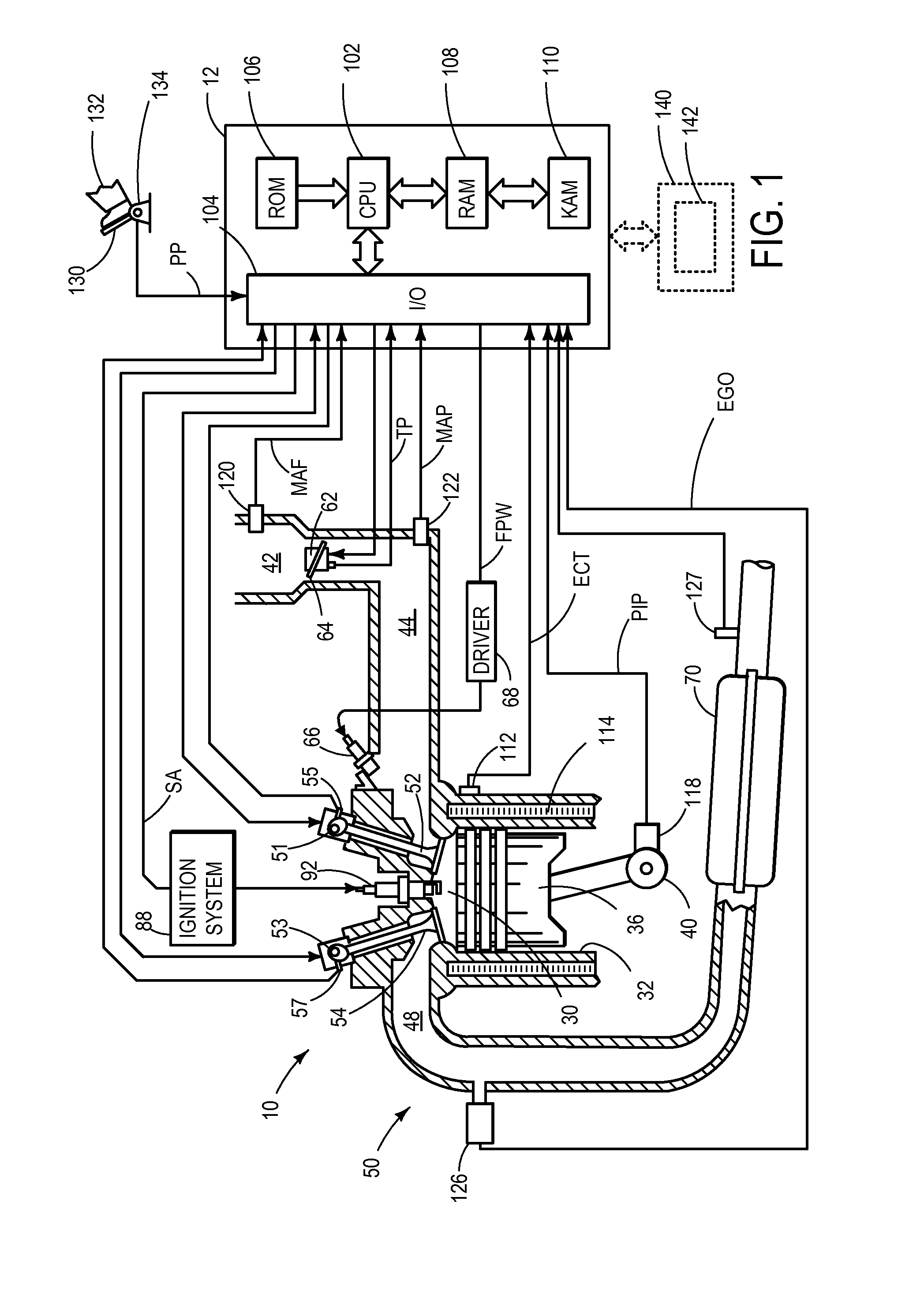

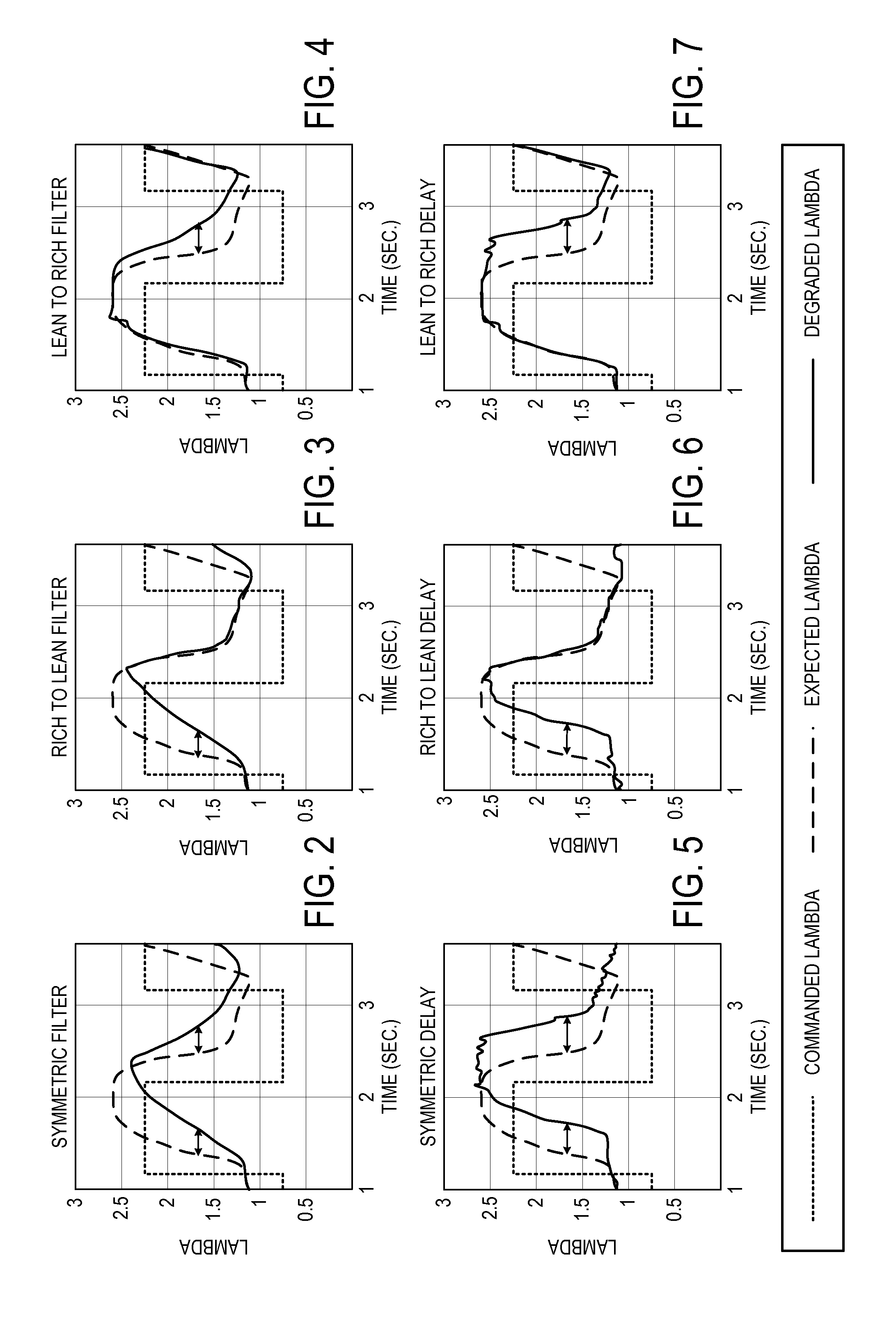

Non-intrusive exhaust gas sensor monitoring

ActiveUS20130231844A1Reduce noiseImprove fidelityAnalogue computers for vehiclesElectrical controlTime delaysExhaust fumes

A method for monitoring an exhaust gas sensor coupled in an engine exhaust is provided. In one embodiment, the method comprises indicating exhaust gas sensor degradation based on a time delay and line length of each sample of a set of exhaust gas sensor responses collected during a commanded change in air-fuel ratio. In this way, the exhaust gas sensor may be monitored utilizing robust parameters in a non-intrusive manner.

Owner:FORD GLOBAL TECH LLC

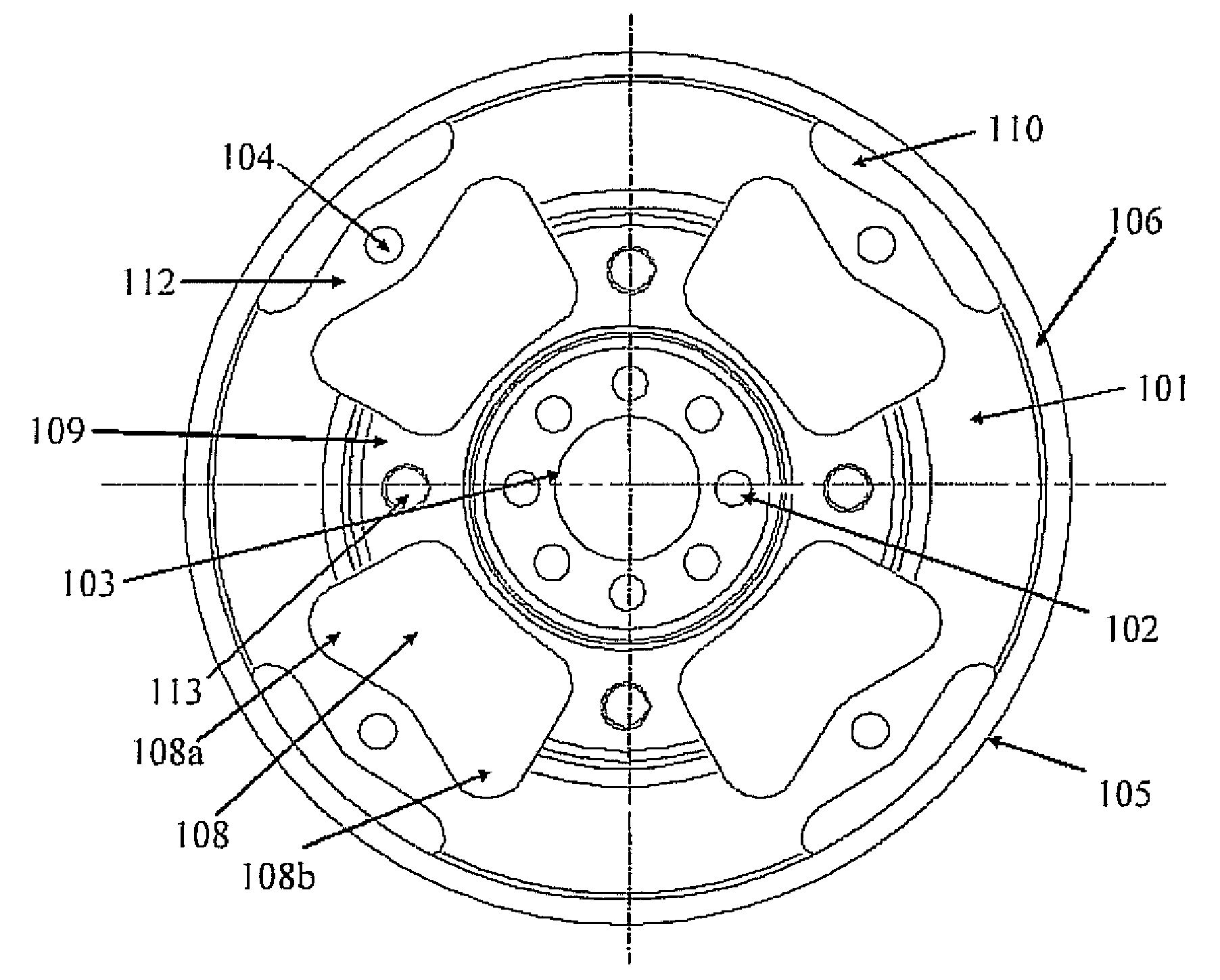

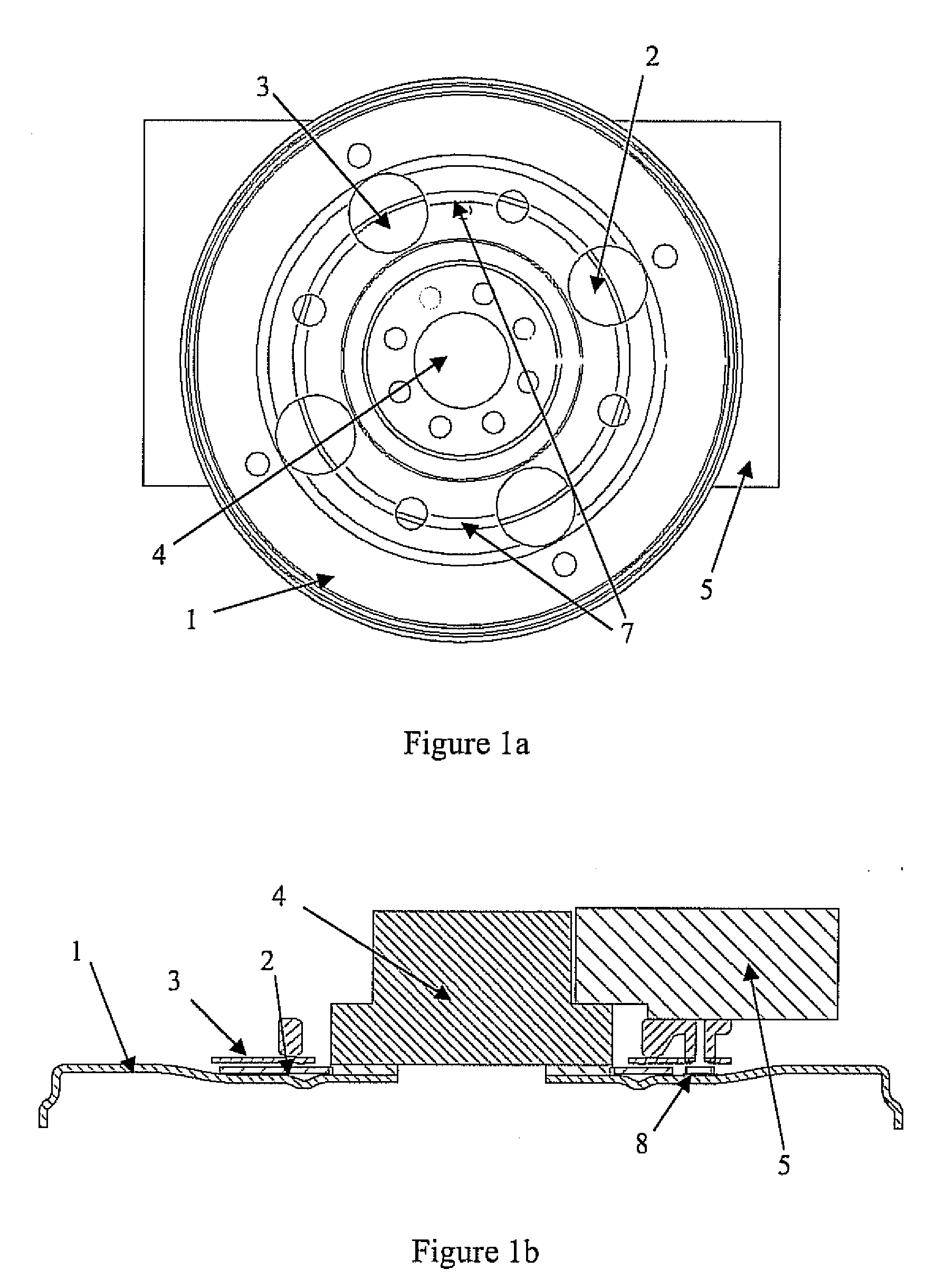

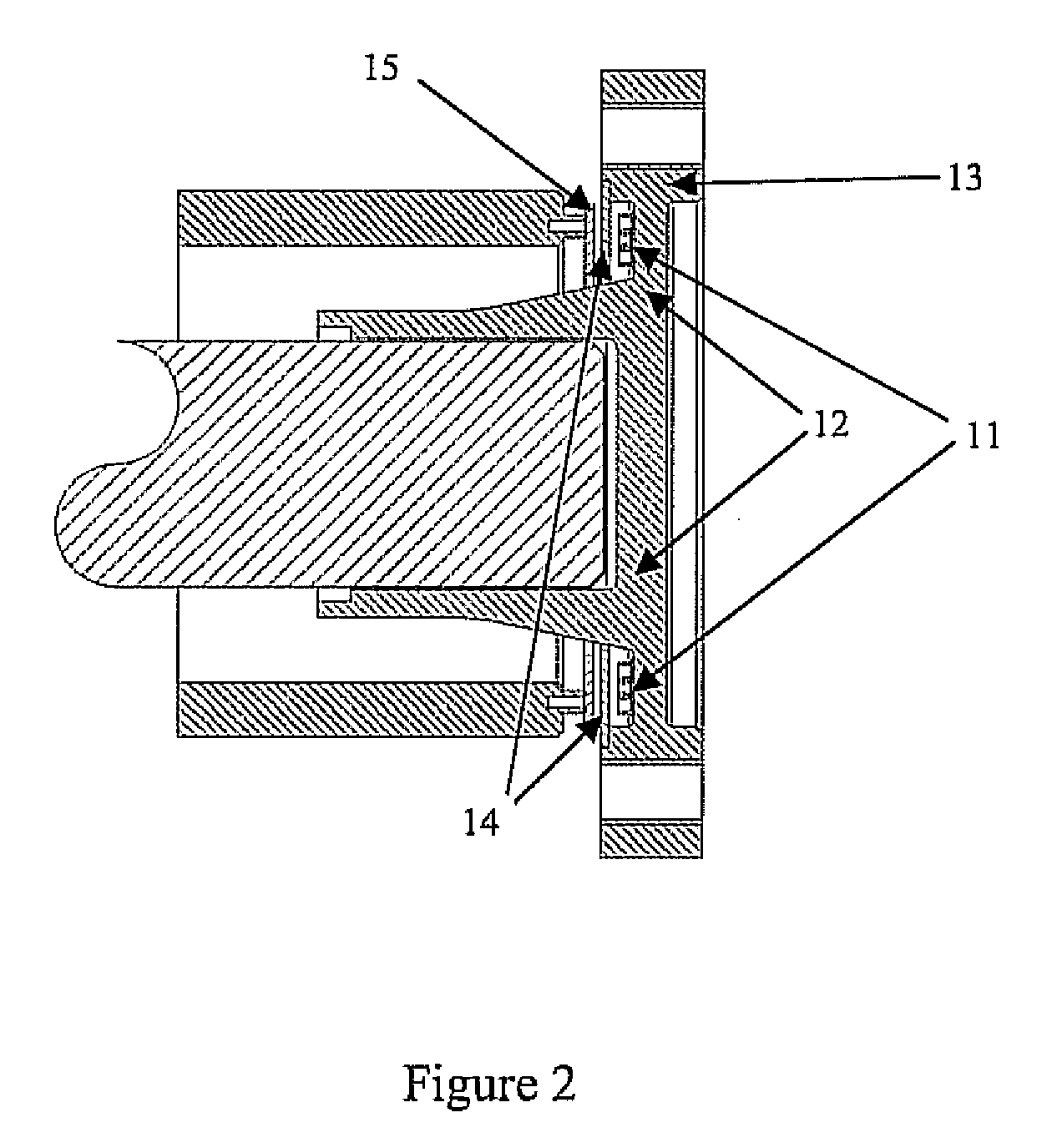

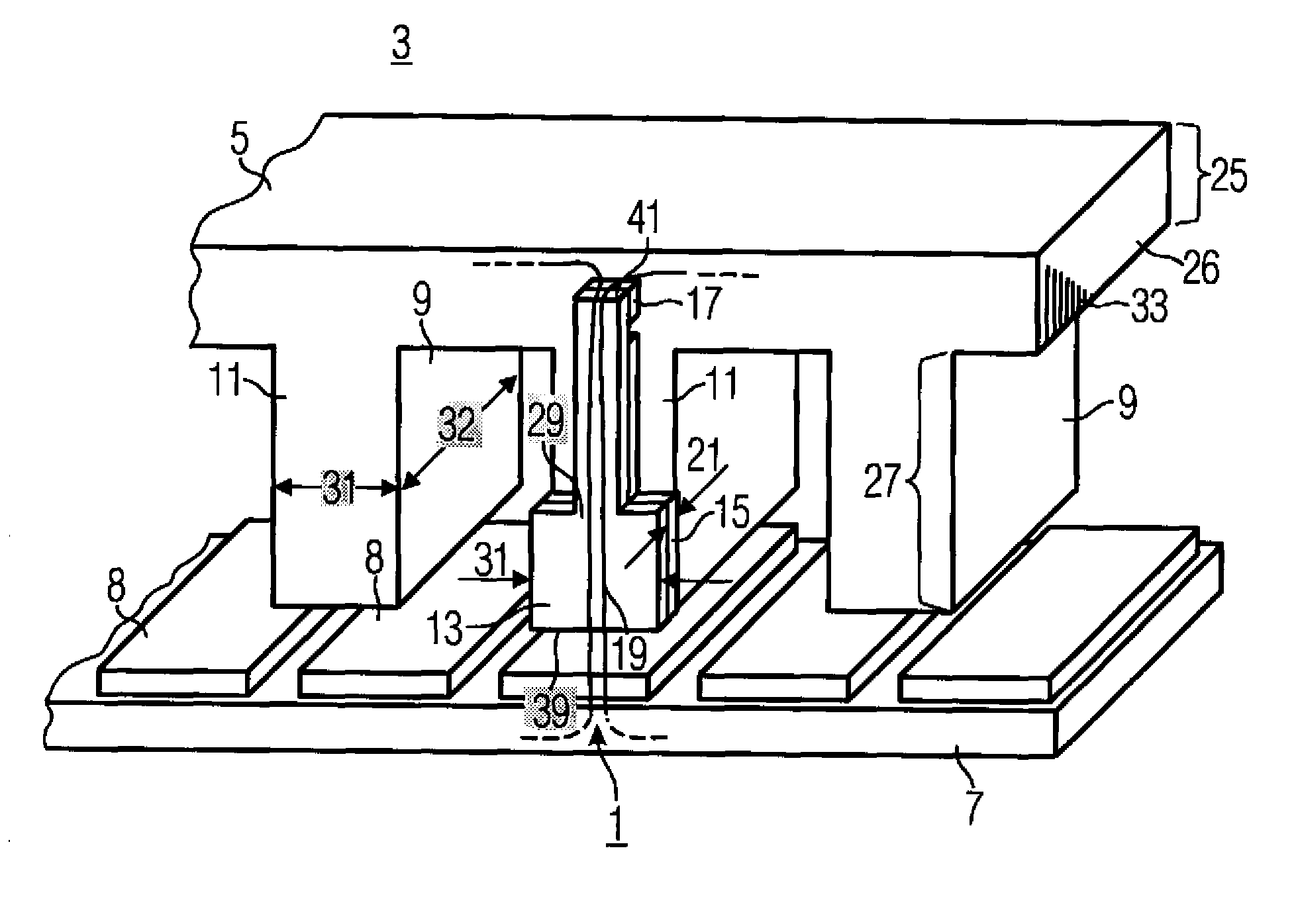

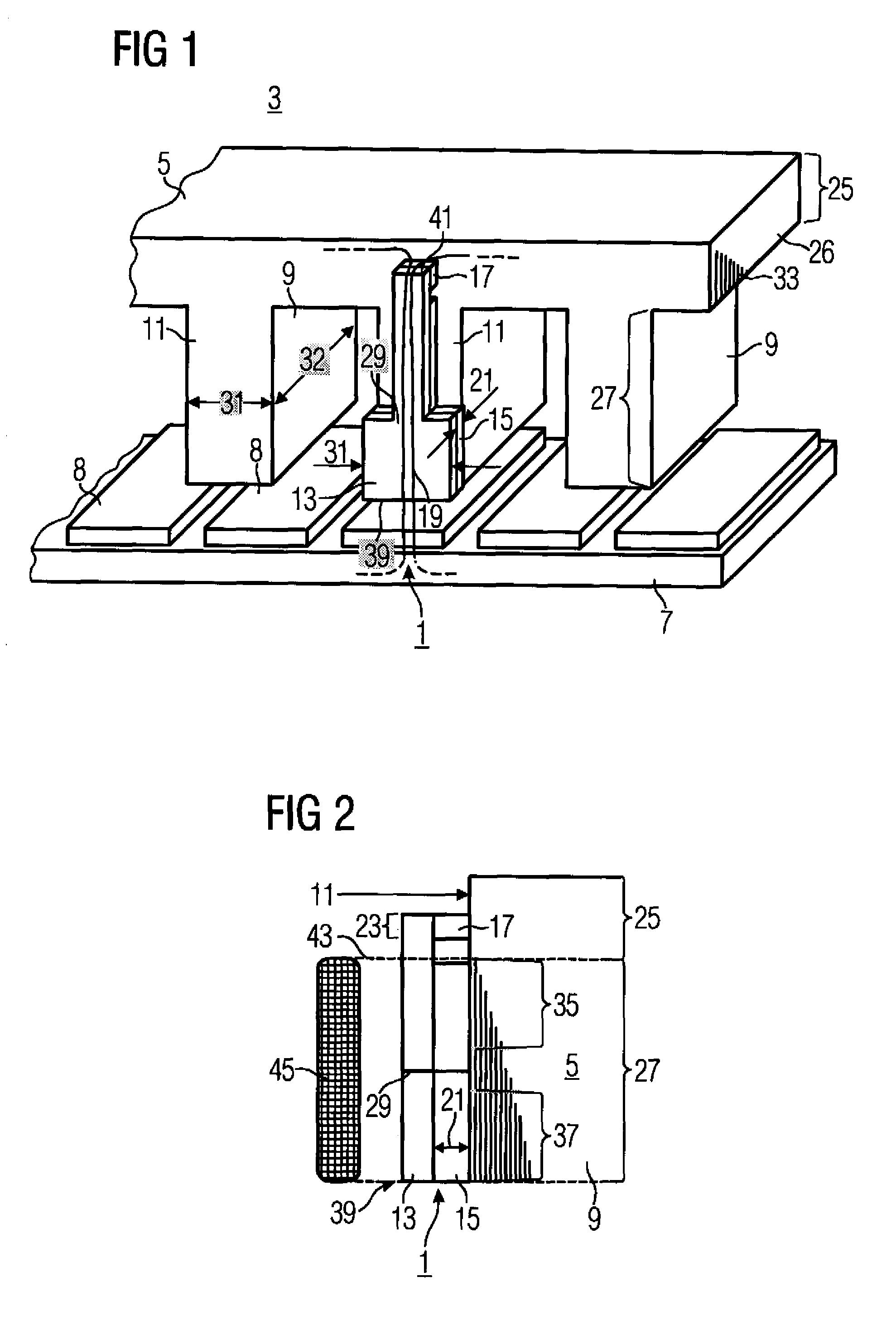

Torque measurement within a powertrain

InactiveUS20090013803A1Minimises superimposed bending strainHigh measurement accuracyForce measurementWork measurementWireless transmissionDrivetrain

A method is provided for measuring torque in a shaft of a drive line including a disc coupling component such as a flexplate 1 or a flanged coupling 13, as well as a drive coupling system for carrying out the method. The disc coupling component 1, 13 is connected between a drive input 4 and a drive output so that all torque transmitted between the input and output passes through said component. The disc coupling component 1, 13 has a radially extending portion, which may include a plurality of spokes 7, to which is attached a SAW based strain sensor which communicates with a stationary coupler 3 fastened to an engine block 5 for wireless transmission of data from the sensor, the strain sensor measuring the strain in the disc coupling component 1, 13 from which the torque carried in the input shaft 4 may be calculated.

Owner:TRANSENSE TECH

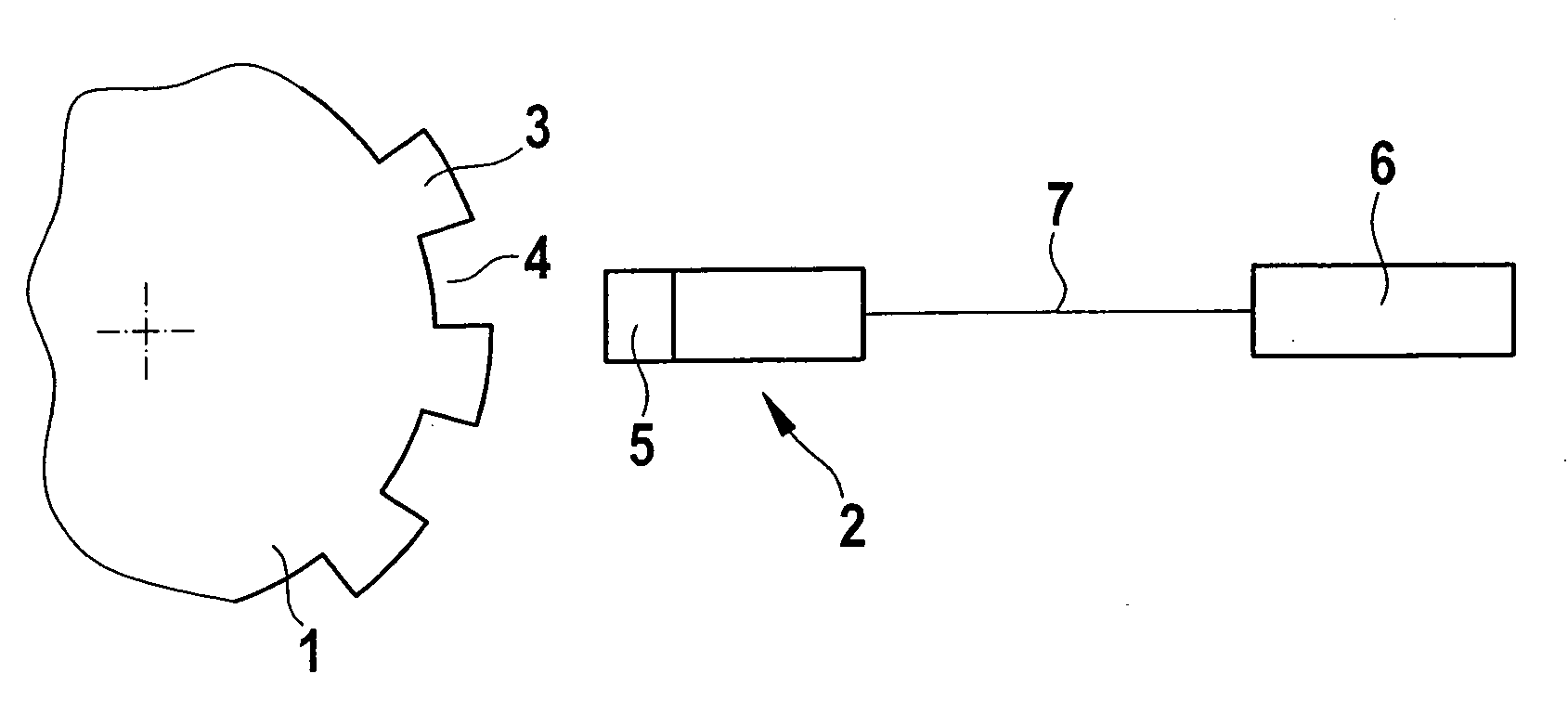

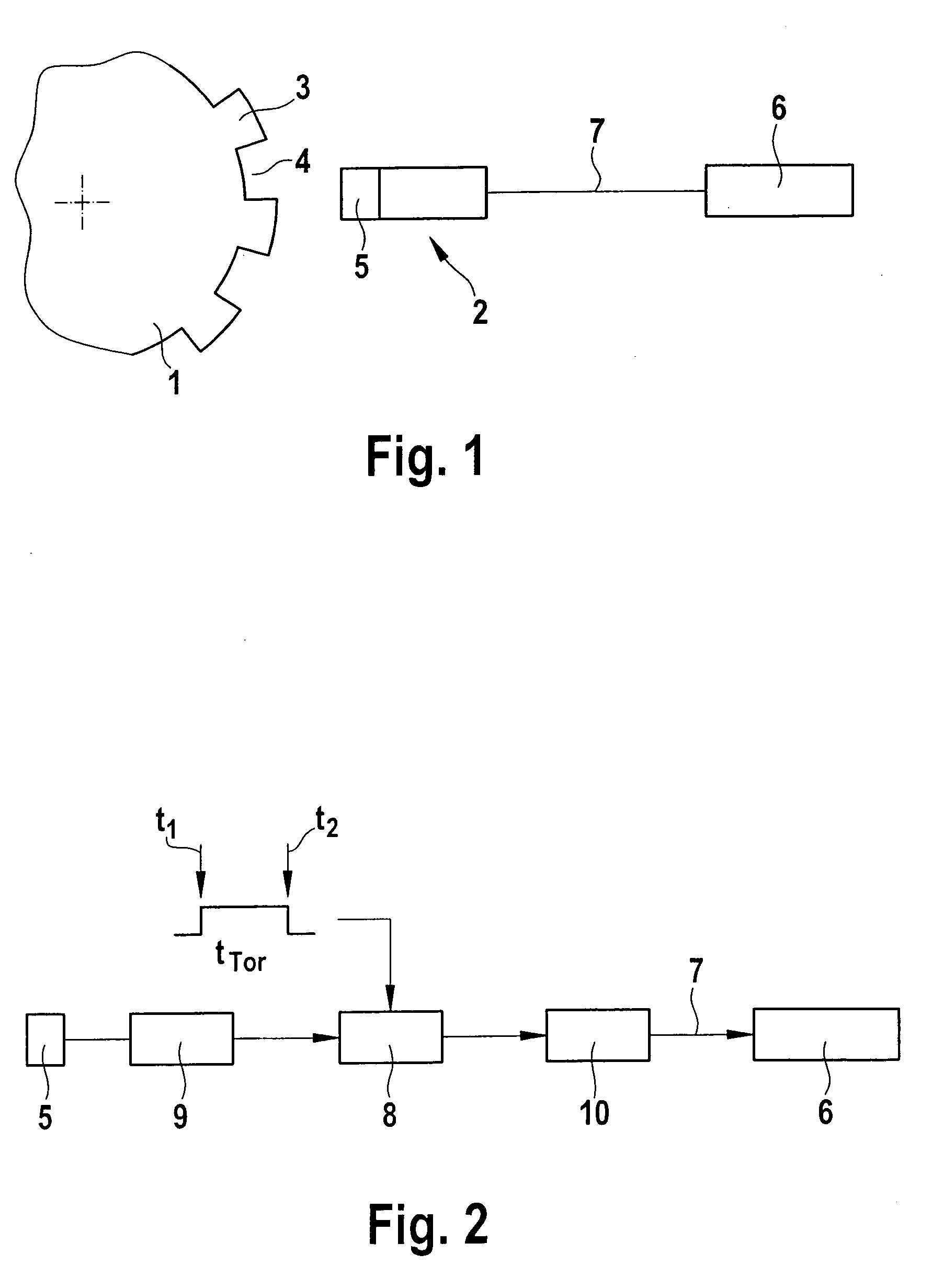

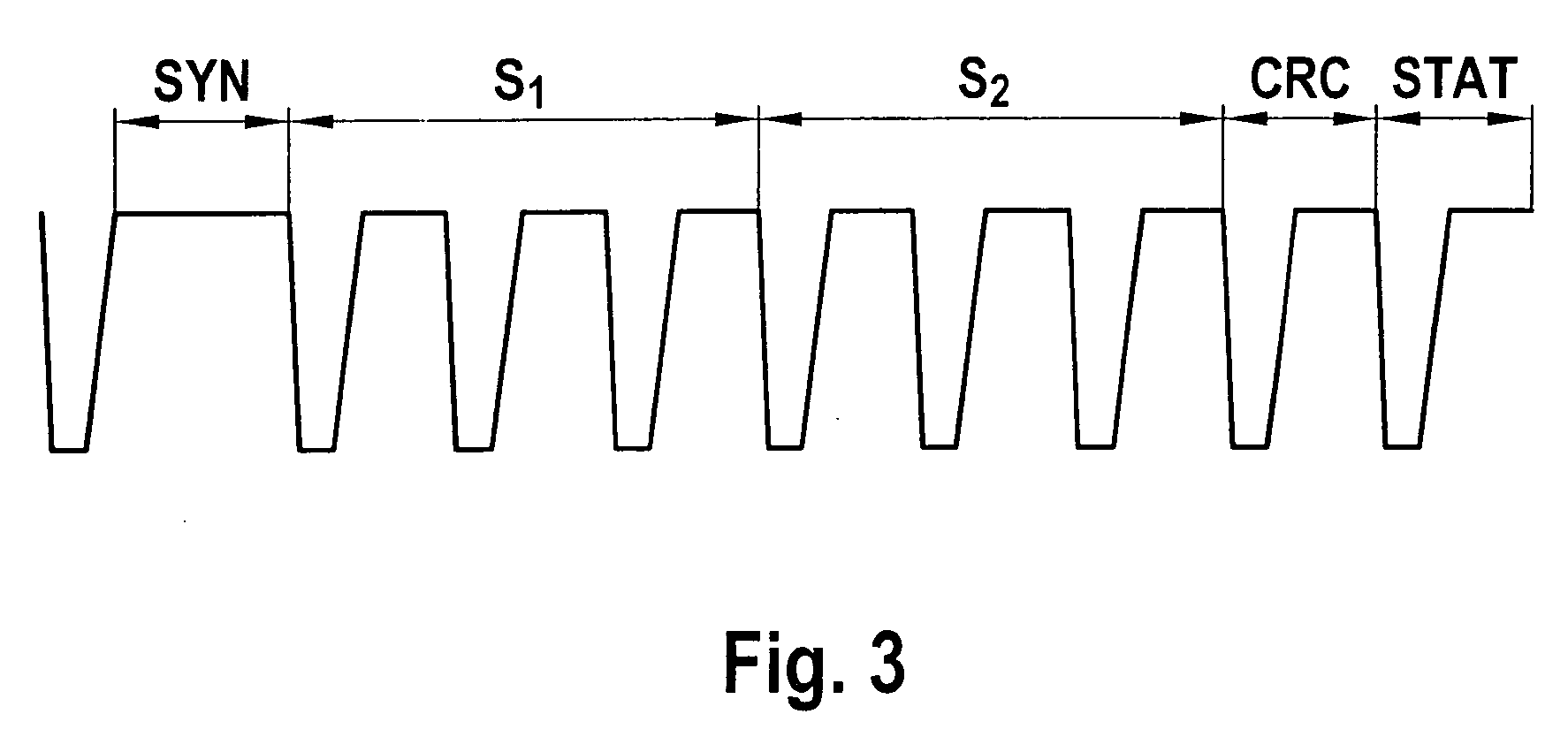

Method for determining the rotation speed of rotating shaft

InactiveUS20080159467A1Improve sensor accuracyElectric unknown time interval measurementDevices using time traversedActual DurationRotation velocity

A method for determining the rotation speed of a rotating shaft that has associated with it a means that has markings which produce an electrical signal upon being carried past a sensor element of a sensor, the sensor encompassing an evaluation device that counts the markings carried past the sensor element within a gate time and transfers them to a control unit as a numerical value. The gate time is derived from a time increment, and a pulse having an actual time duration derived from the time increment is transferred to the control unit and is compared by the control unit with a target time duration, the numerical value being corrected using a correction value that is ascertained from a comparison of the actual time duration with the target time duration.

Owner:ROBERT BOSCH GMBH

Method, system, and computer program product for improving the accuracy of glucose sensors using insulin delivery observation in diabetes

ActiveUS20130079613A1Improve accuracyImprove sensor accuracyOther blood circulation devicesPressure infusionGlucose sensorsInsulin pump

Method and System for providing a signal from an insulin pump, artificial pancreas, or another insulin delivery device as a source of information for improving the accuracy of a continuous glucose sensor (CGS). The effect of using insulin information to enhance sensor accuracy is most prominent at low blood glucose levels, i.e. in the hypoglycemic range, which is critical for any treatment. A system for providing a filtering / state estimation methodology that may be used to determine a glucose state estimate at time t-τ. The estimation may be extrapolated to some future time t and then the extrapolated value is used to extract the blood glucose component. The blood glucose component of the extrapolation and the output of the CGS are weighted and used to estimate the blood glucose level of a subject.

Owner:UNIV OF VIRGINIA ALUMNI PATENTS FOUND

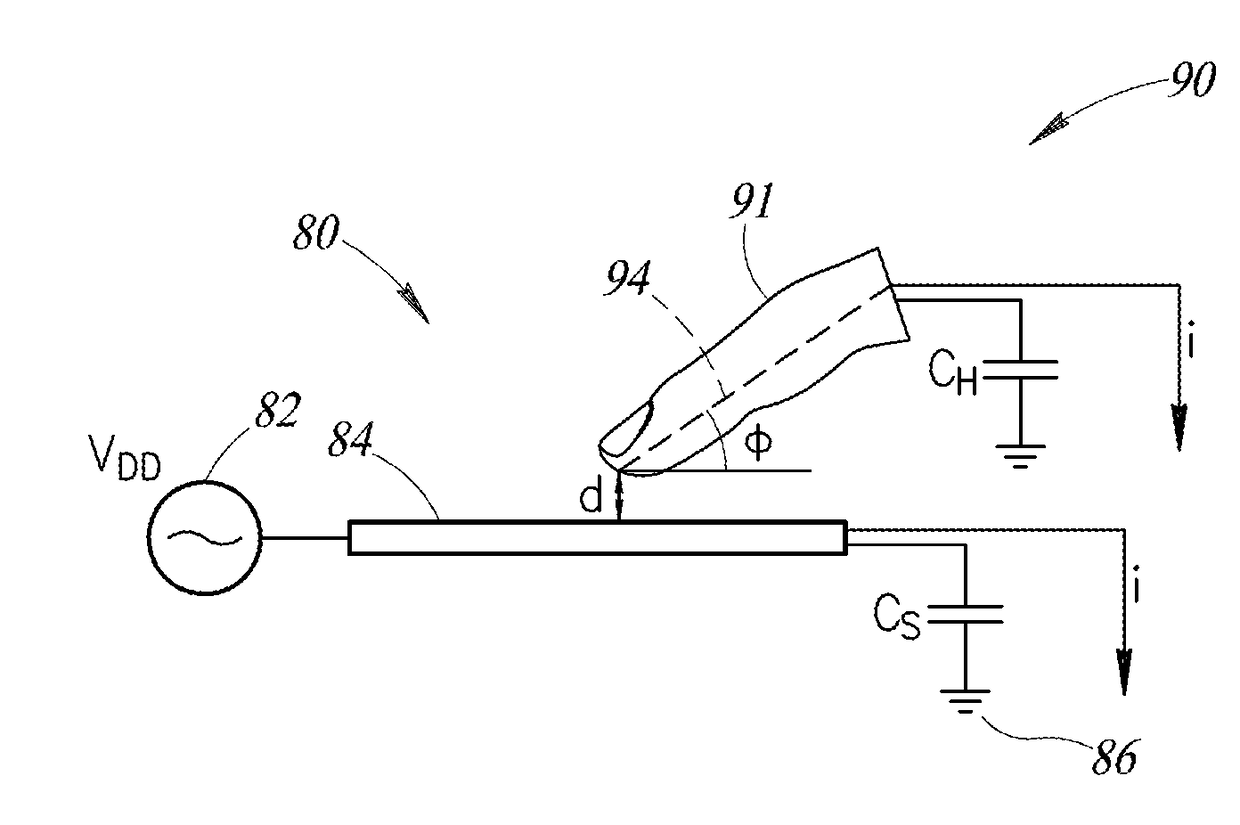

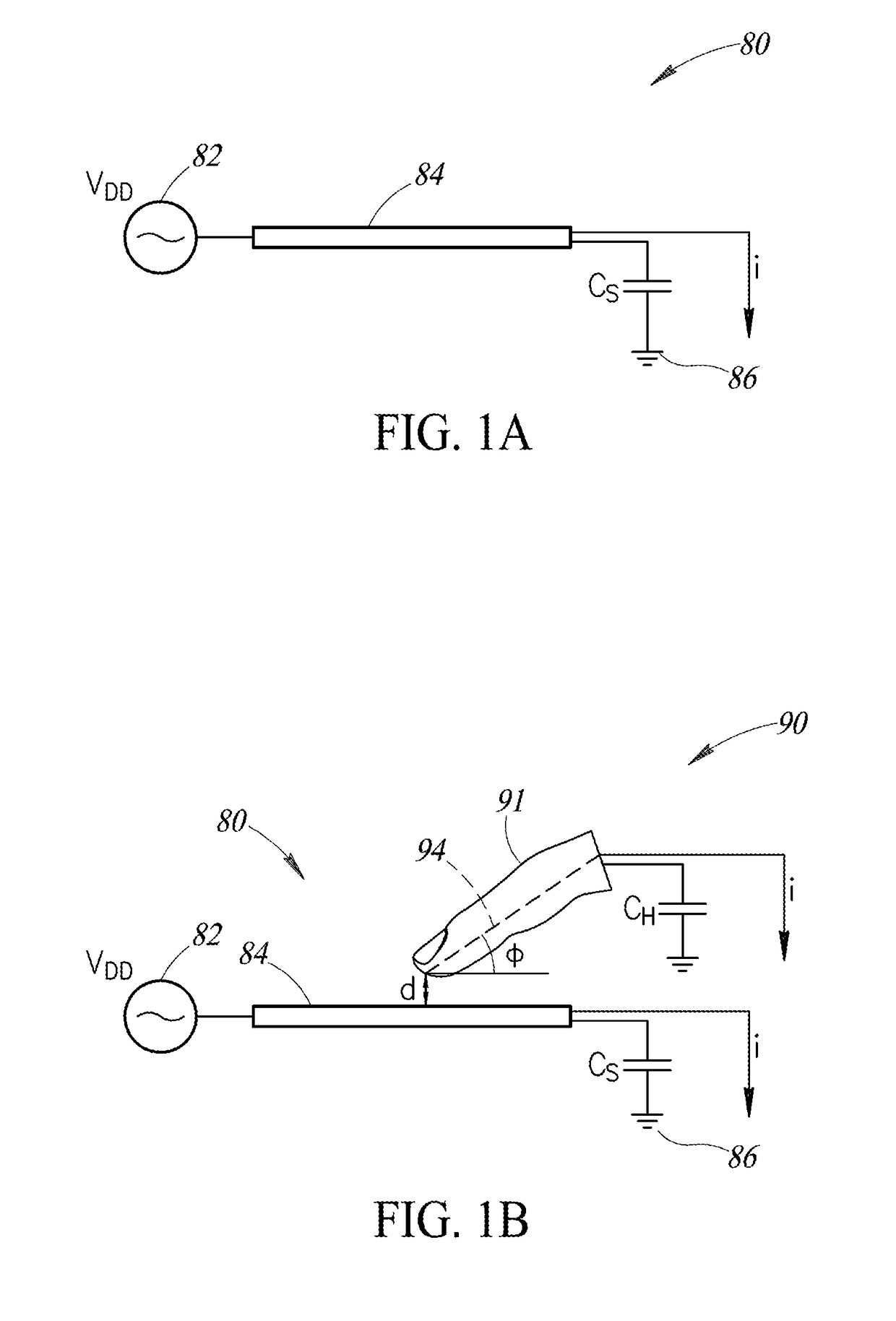

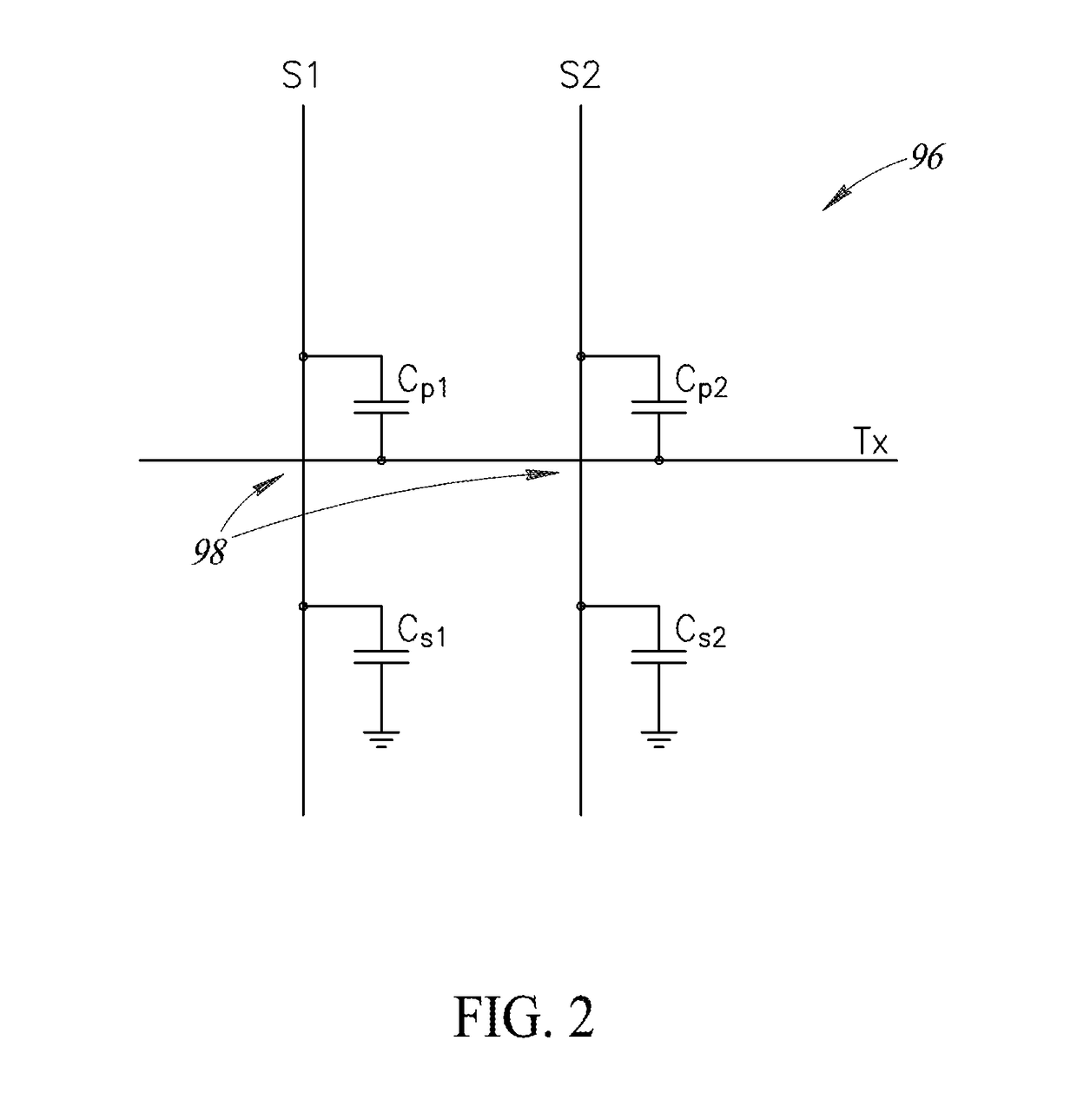

Self-sensing touch panel

ActiveUS20180004349A1Increasing touch sensor accuracyHigh sensitivityInput/output processes for data processingCapacitanceSignal-to-noise ratio (imaging)

A method of differential self-capacitance measurement is used to enhance a signal-to-noise ratio of sense lines in a touch panel display, thereby improving touch sensor accuracy. The differential self-capacitance measurement is implemented for a touch panel using charge sharing between adjacent sense lines of the touch panel matrix. Sequential differential self-capacitance measurements can be compared with one another by computing the difference |CS1−CS2|−|CS2−CS1| to sense a change caused by an intervening event. By scanning the entire touch panel matrix, events can be tracked across the touch panel.

Owner:STMICROELECTRONICS ASIA PACIFIC PTE

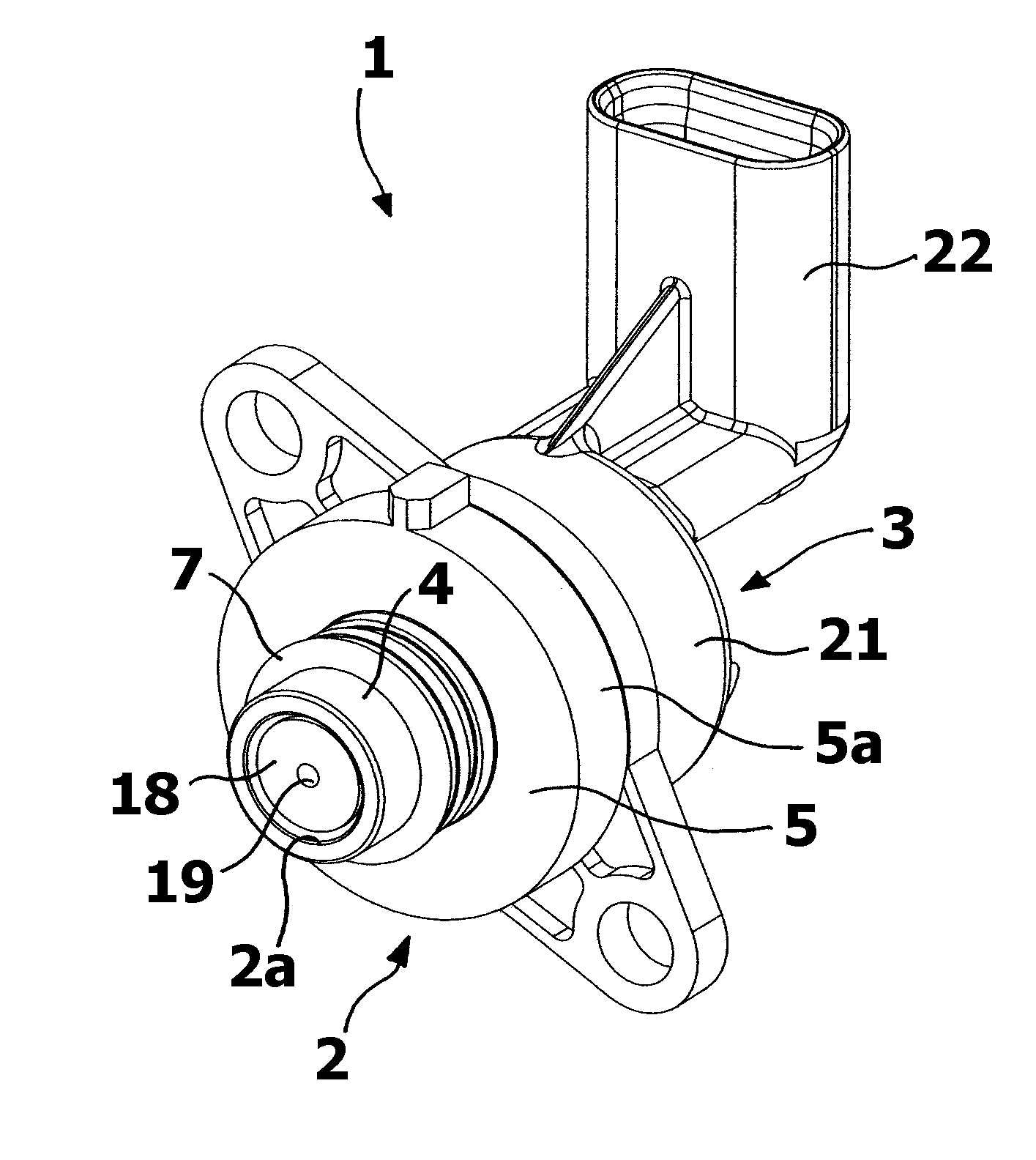

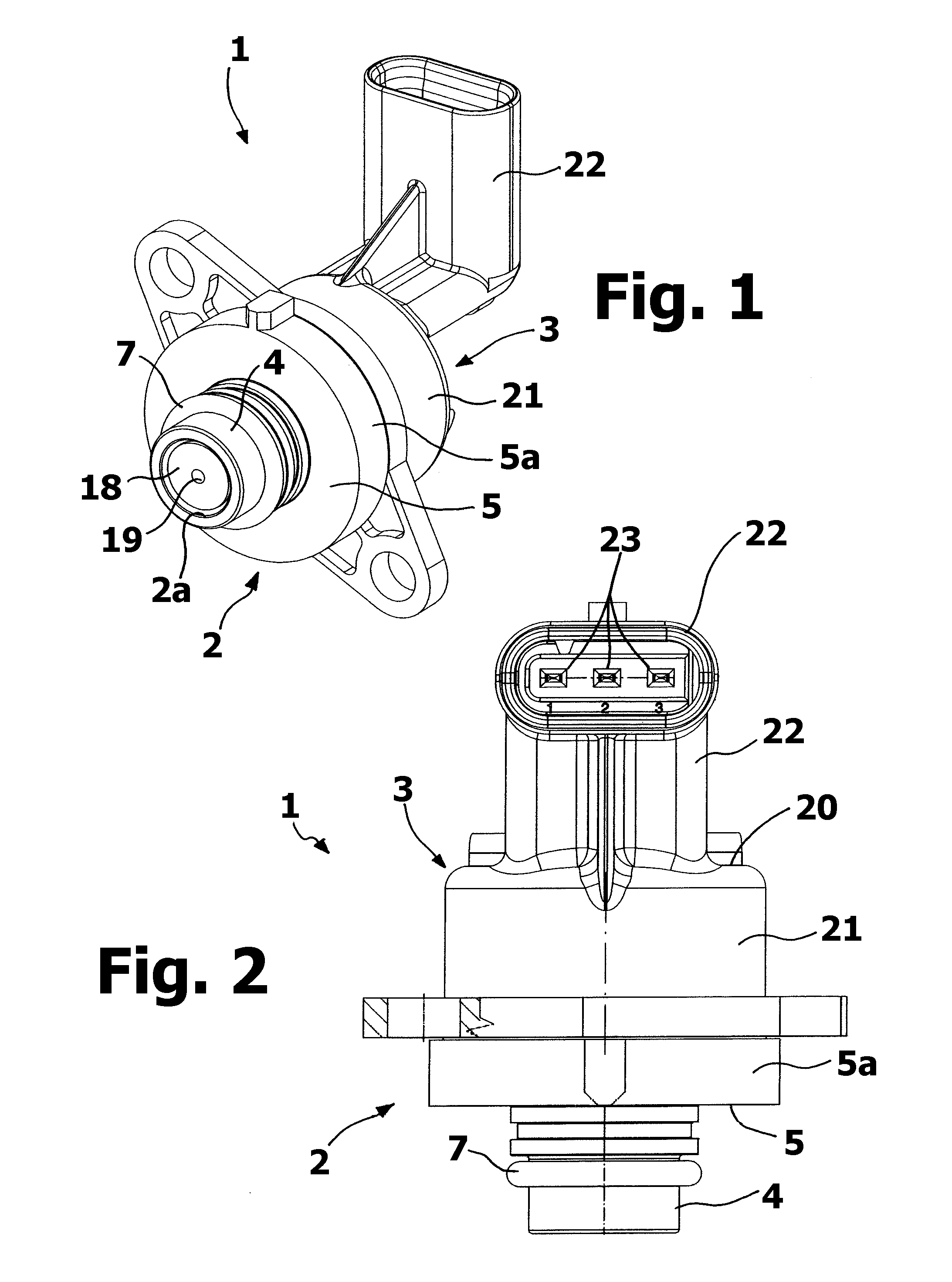

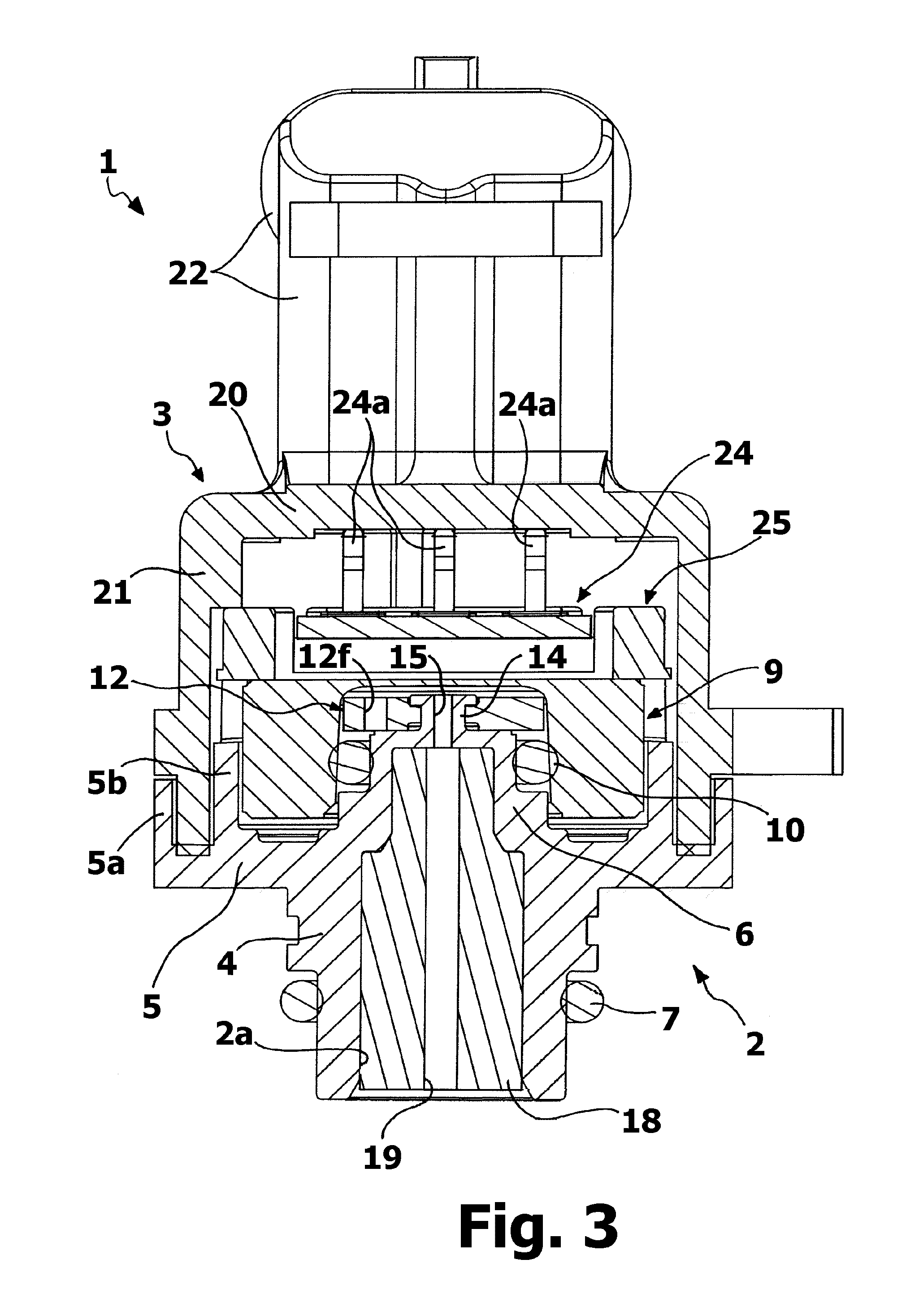

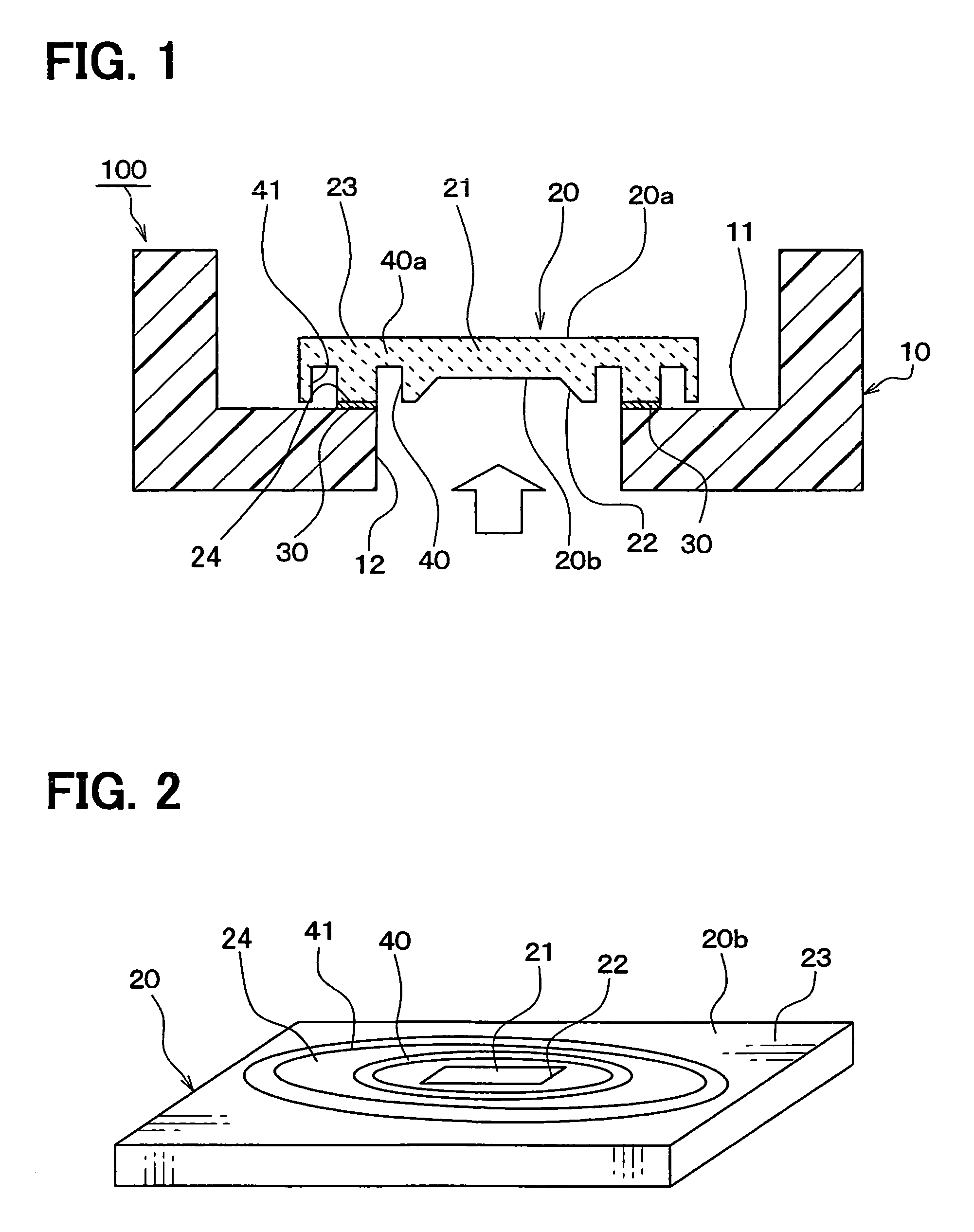

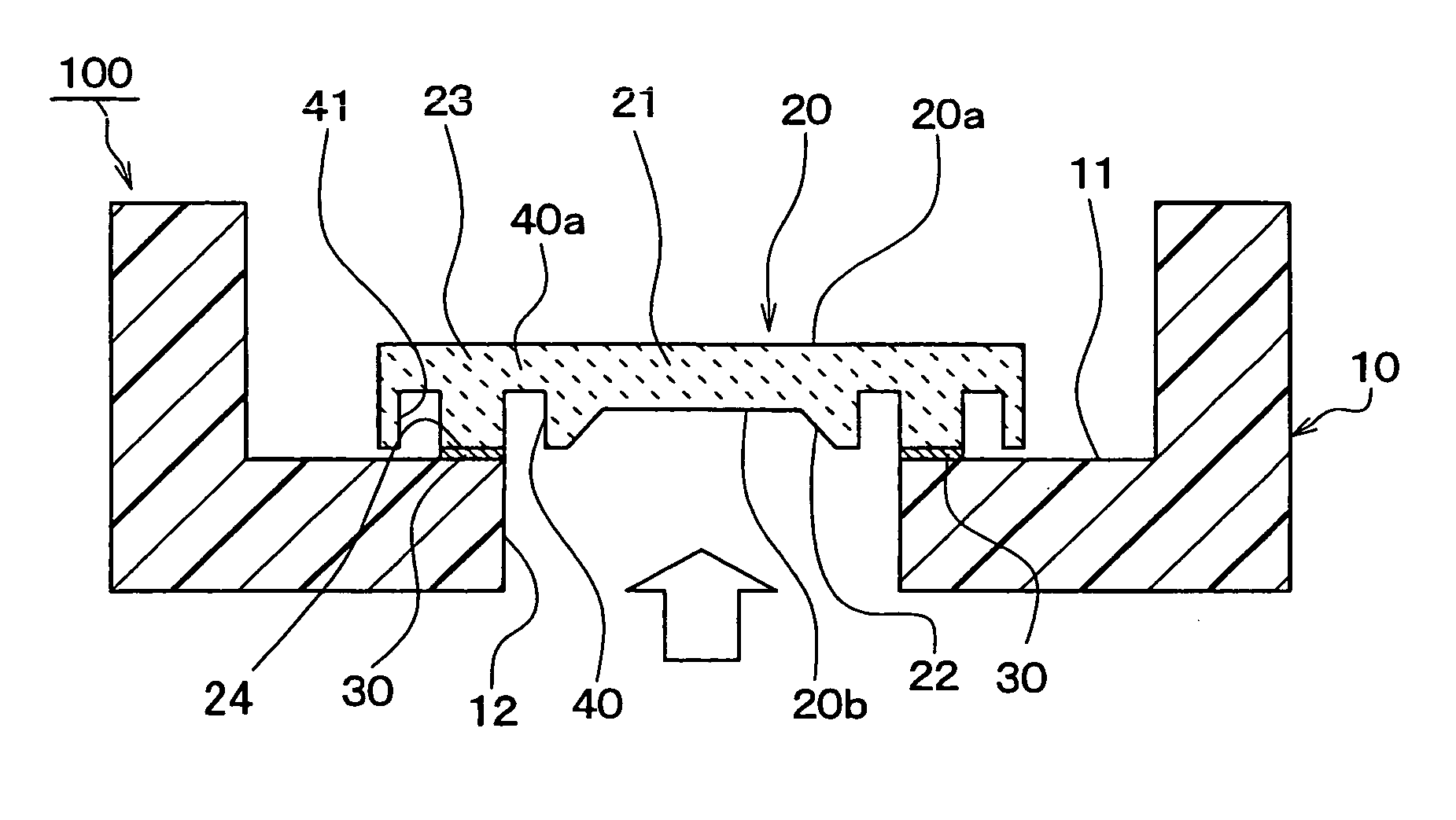

Pressure sensor device

ActiveUS20110174080A1Improve reliabilityImprove sensor accuracyFluid pressure measurement by electric/magnetic elementsFluid pressure measurement by mechanical elementsMembrane configurationBiomedical engineering

A pressure sensor device (1) comprises: a pressure sensor (9) having a sensor body (9a) defined in which is a cavity (11) with a bottom surface (11a) belonging to a membrane portion (9′) of the body itself, a detection element operatively being associated to the membrane portion (9′), a connection structure (2) having a duct (2a, 15, 19) in communication with the abovementioned cavity (11), designed to receive a fluid a pressure of which is to be detected. The connection structure comprises a body (2) for supporting the pressure sensor (9), defining at least one respective passage (2a), and one compressible element (12) designed to be in contact with the fluid and configured to compensate possible volume variations thereof, the compressible element (12) being positioned at least partially within the cavity (11), in such a manner to substantially divide it into two opposite regions. The device (1) is provided with connection passages (12f) for maintaining different regions of the cavity (11) in fluid communication, i.e. equilibrate in pressure.

Owner:ELTEK

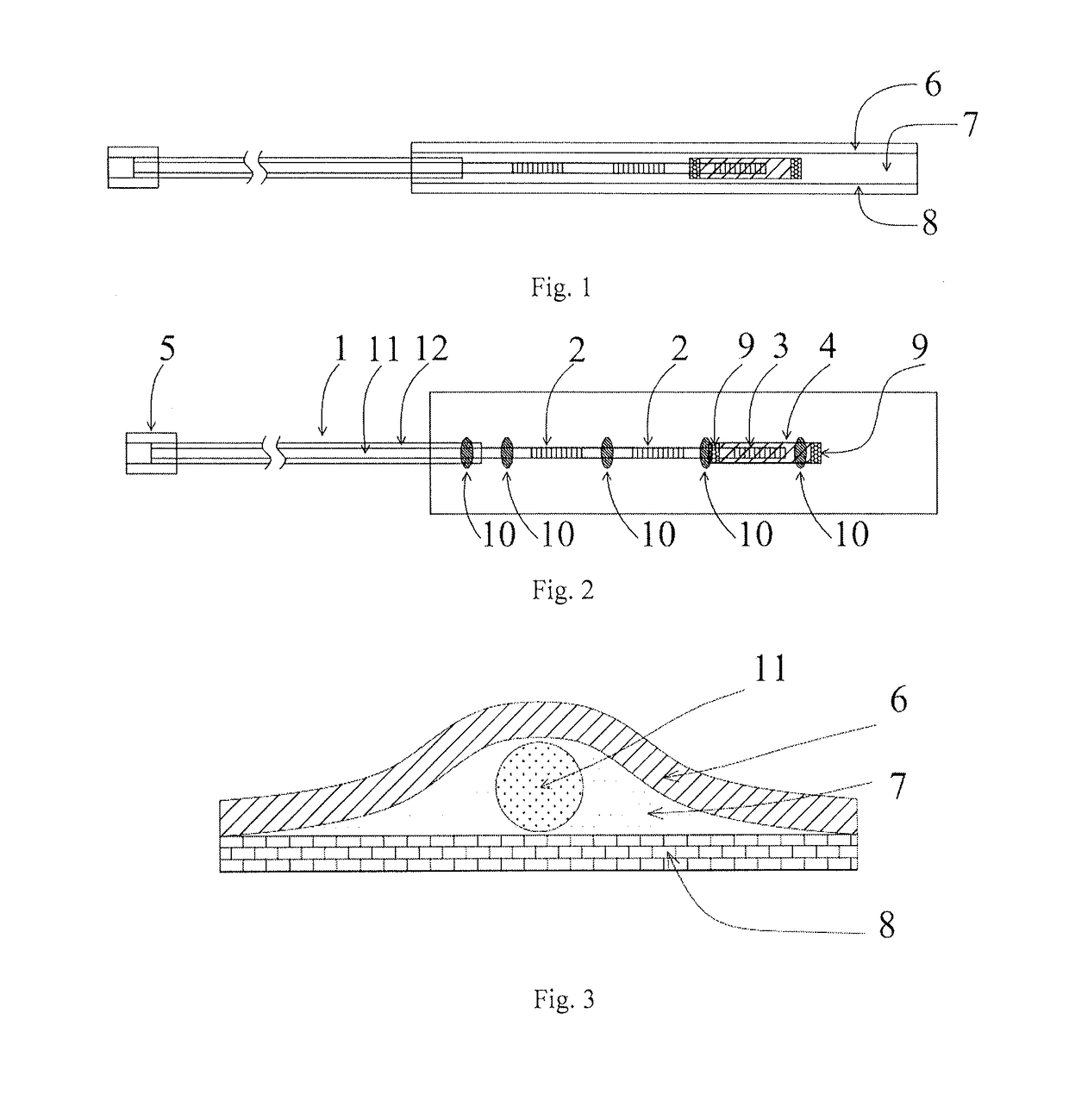

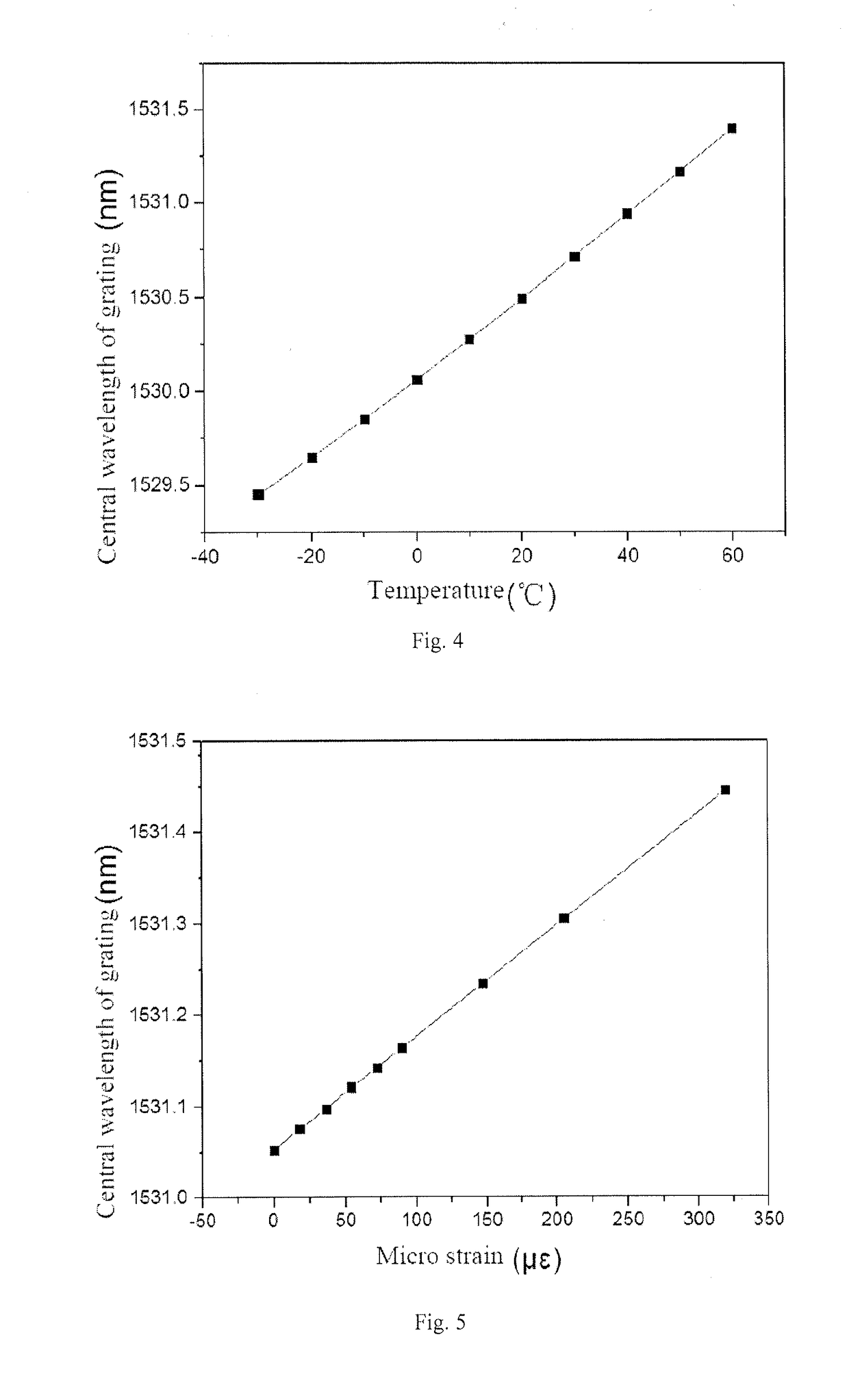

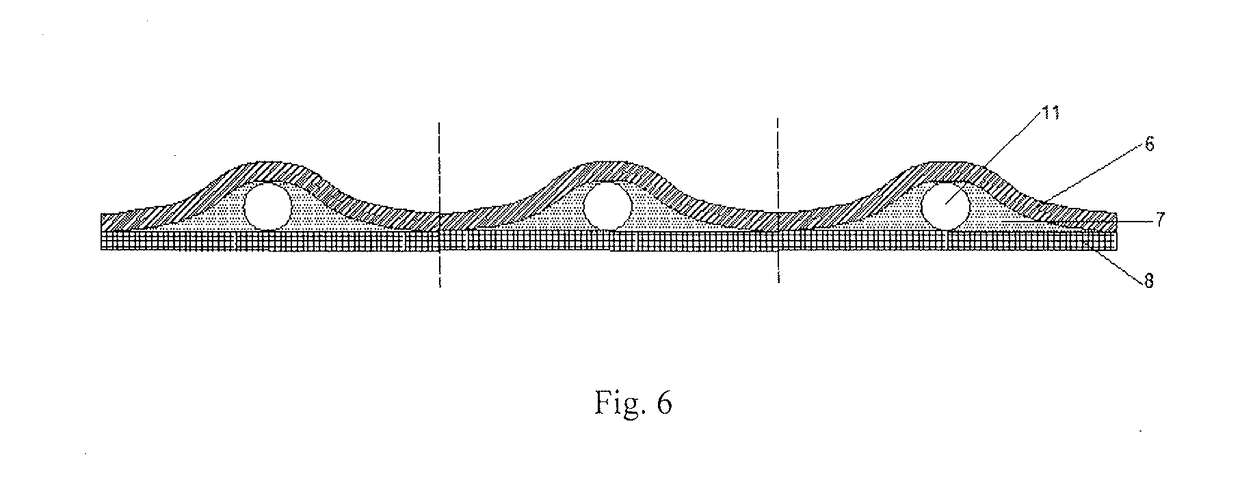

Composite material packaged fiber grating sensor and manufacturing method thereof

ActiveUS20190016065A1Improve sensor accuracyHigh strengthLayered productsForce measurement by measuring optical property variationGratingFiber gratings

A composite material packaged fiber grating sensor and a manufacturing method thereof. The sensor includes a fiber grating sensor component, a composite material coverage layer, a resin package layer and a composite material substrate layer. In the sensor, a temperature fiber grating and a strain fiber grating are packaged in a composite material structure, so that the structure is light and simple, its computability with the composite material is good, the measurement accuracy is high, and the survival rate and the service life of the installed sensor can be greatly improved, the sensor component can be externally pasted on to or inter-implanted in a composite material structural part, and can be applied to the distributed online health monitoring on the structural part. The manufacturing method of the composite material packaged fiber grating sensor is simple, efficient and stable, and is suitable for rapid mass production by enterprises.

Owner:SHANDONG UNIV +2

Non-intrusive exhaust gas sensor monitoring based on fuel vapor purge operaton

ActiveUS20140067235A1Increase confidenceDecrease likelihoodAnalogue computers for vehiclesElectrical controlAutomotive engineeringExhaust gas sensor

A method of monitoring an exhaust gas sensor coupled in an engine exhaust in an engine is provided. The method includes adjusting engine operation responsive to exhaust gas sensor degradation, the degradation identified during deceleration fuel shut-off (DFSO) and compensated based on whether vapor purge operation is occurring in the engine during DFSO.

Owner:FORD GLOBAL TECH LLC

Non-intrusive exhaust gas sensor monitoring

ActiveUS20130231847A1Reduce noiseImprove fidelityElectrical controlDigital data processing detailsMonitoring systemAir–fuel ratio

Systems and methods for monitoring an exhaust gas sensor coupled in an engine exhaust are provided. In one example approach, a method comprises indicating exhaust gas sensor degradation based on a downstream exhaust gas sensor responding before the upstream exhaust gas sensor during a commanded change in air-fuel ratio.

Owner:FORD GLOBAL TECH LLC

Magneto-resistance effect element and sensor

ActiveUS20110025322A1Improve sensing accuracyWeakening rangeMagnetic sensor geometrical arrangementsMagnitude/direction of magnetic fieldsMagnetizationMagneto resistance

A magneto-resistance effect element for a sensor to sense a variation in externally applied magnetism includes a pinned layer having a fixed magnetization direction, a free layer having a magnetization direction which varies in response to an external magnetic field, and an intermediate layer provided between the pinned layer and the free layer. The pinned layer has a planar shape which is long in the fixed magnetization direction and which is short in a direction orthogonal to the fixed magnetization direction. Moreover, the pinned layer preferably has a planar shape in which the pinned layer is divided into a plurality of sections.

Owner:TDK CORPARATION

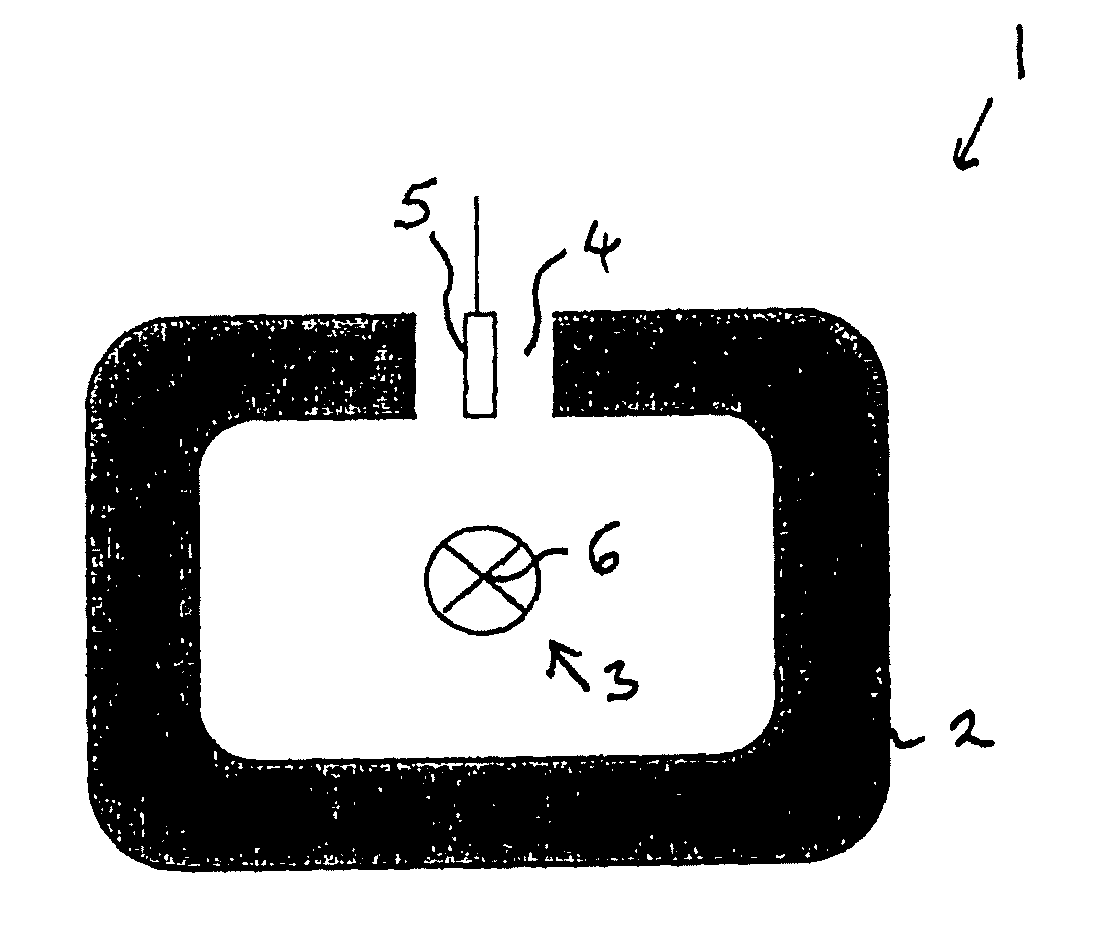

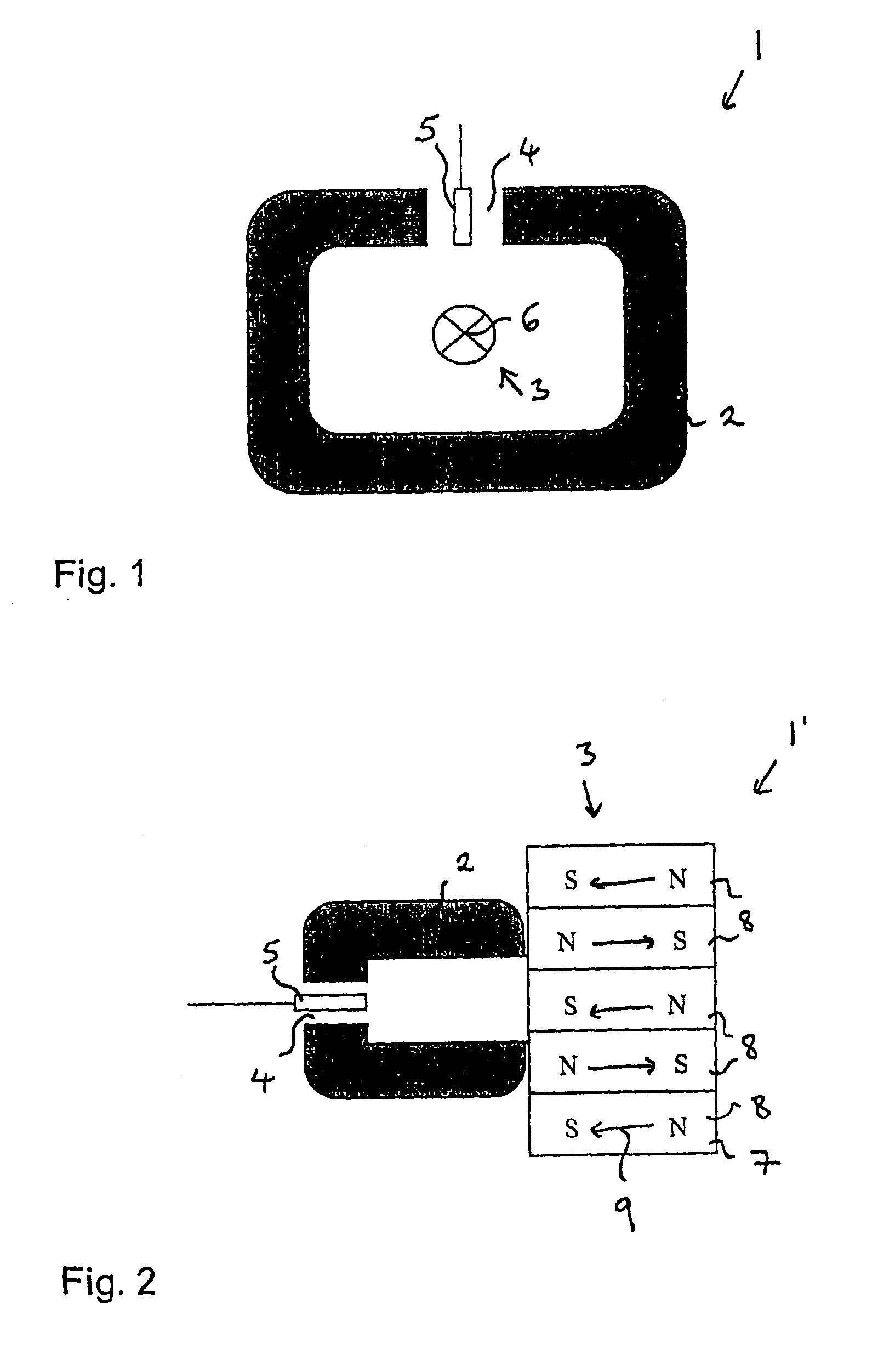

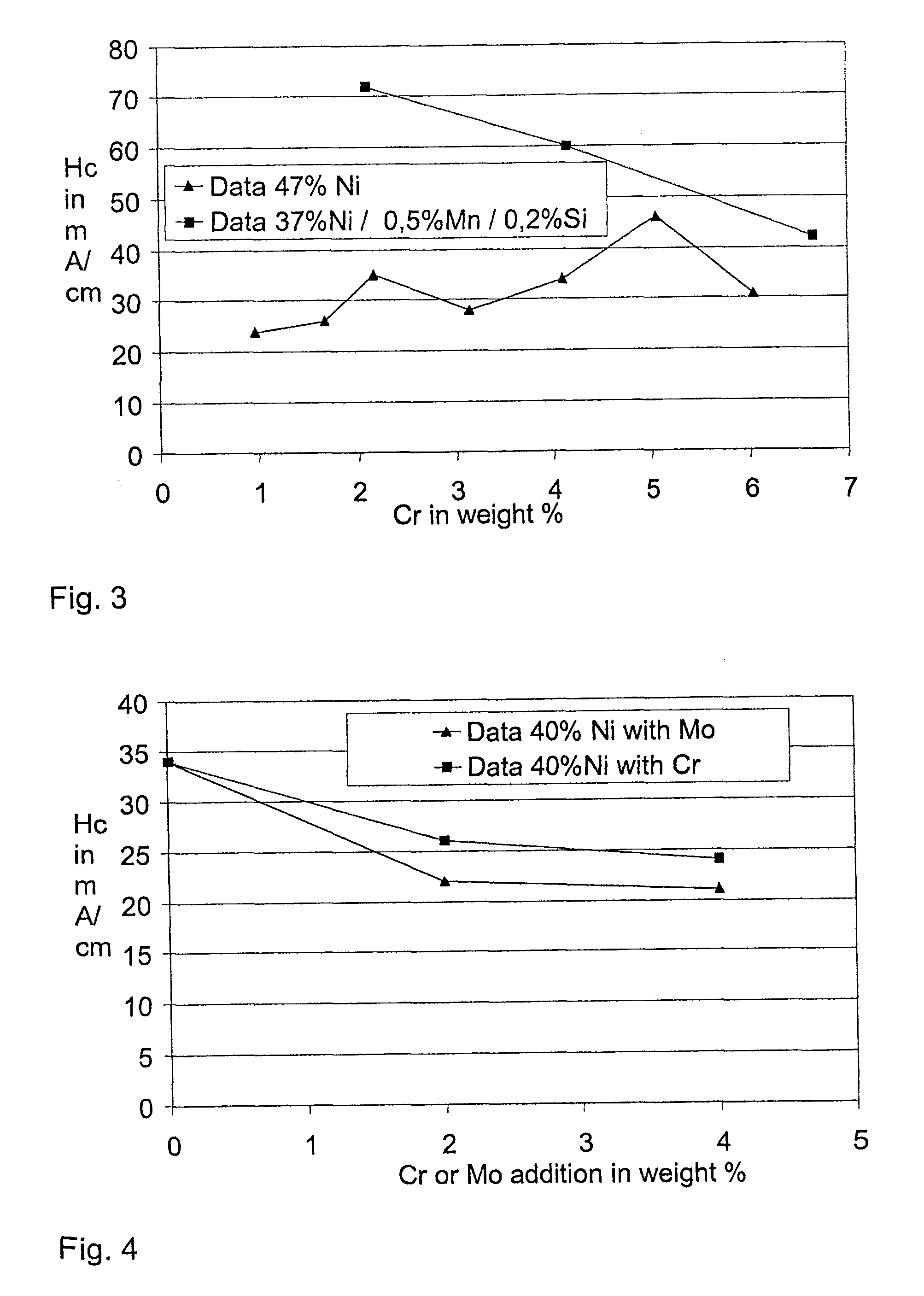

Low Hysteresis Sensor

ActiveUS20100231204A1Simple structureAccurate measurementElectric/magnetic position measurementsMagnetic field measurement using galvano-magnetic devicesHysteresisImpurity

A sensor comprises a magnetic field source, at least one flux conducting soft magnetic element with at least one air gap and at least one magnetic field sensor located in the air gap and measuring a change of the magnetic field of the magnetic field source. The flux conducting soft magnetic element consists of 35% by weight≦Ni≦50% by weight, 0% by weight≦Co≦2% by weight, 0% by weight≦Mn≦1.0% by weight, 0% by weight≦Si≦0.5% by weight and 0.5% by weight≦Cr≦8% by weight and / or 0.5% by weight≦Mo≦8% by weight, wherein (Mo+Cr)≦8, rest iron and unavoidable impurities.

Owner:VACUUMSCHMELZE GMBH & CO KG

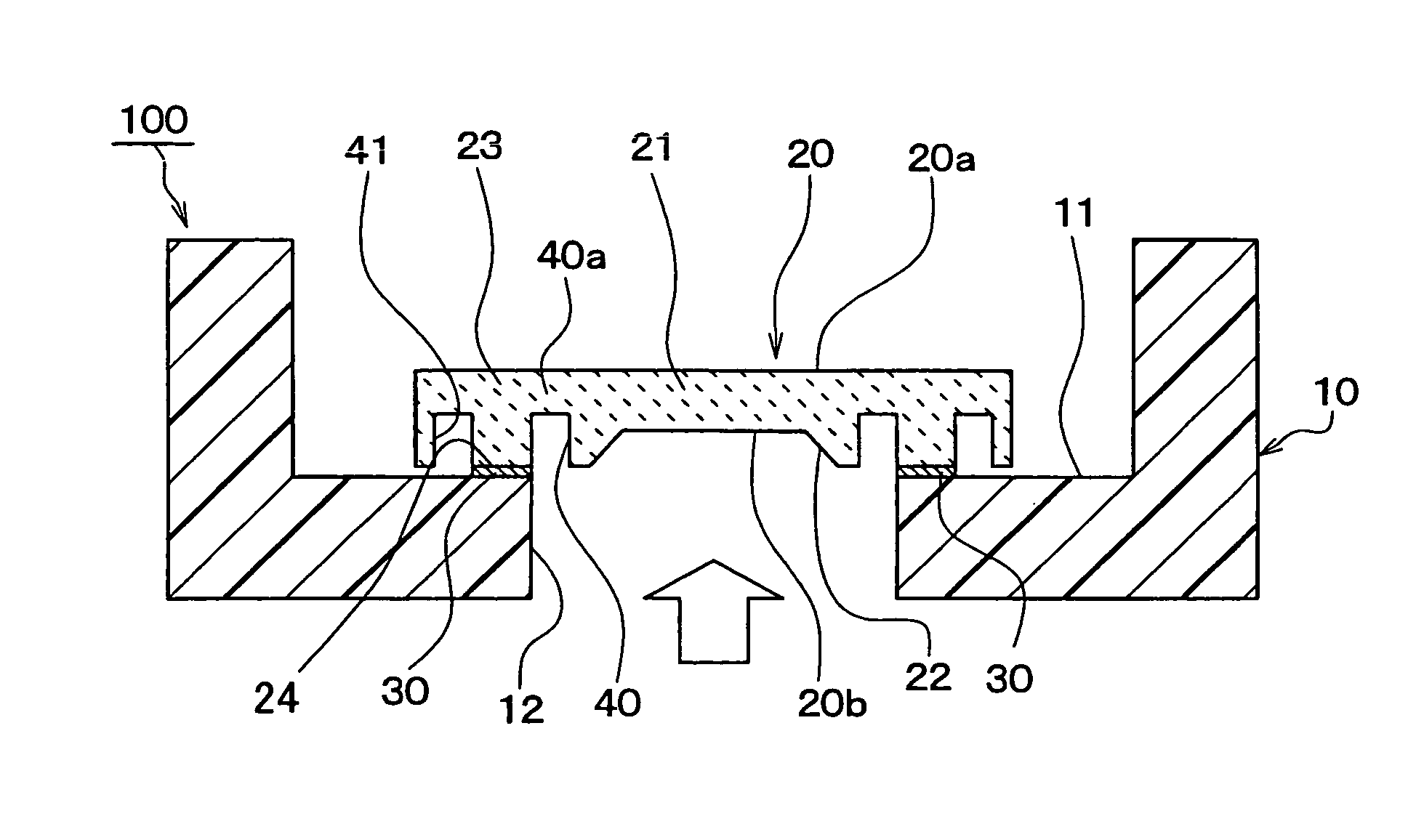

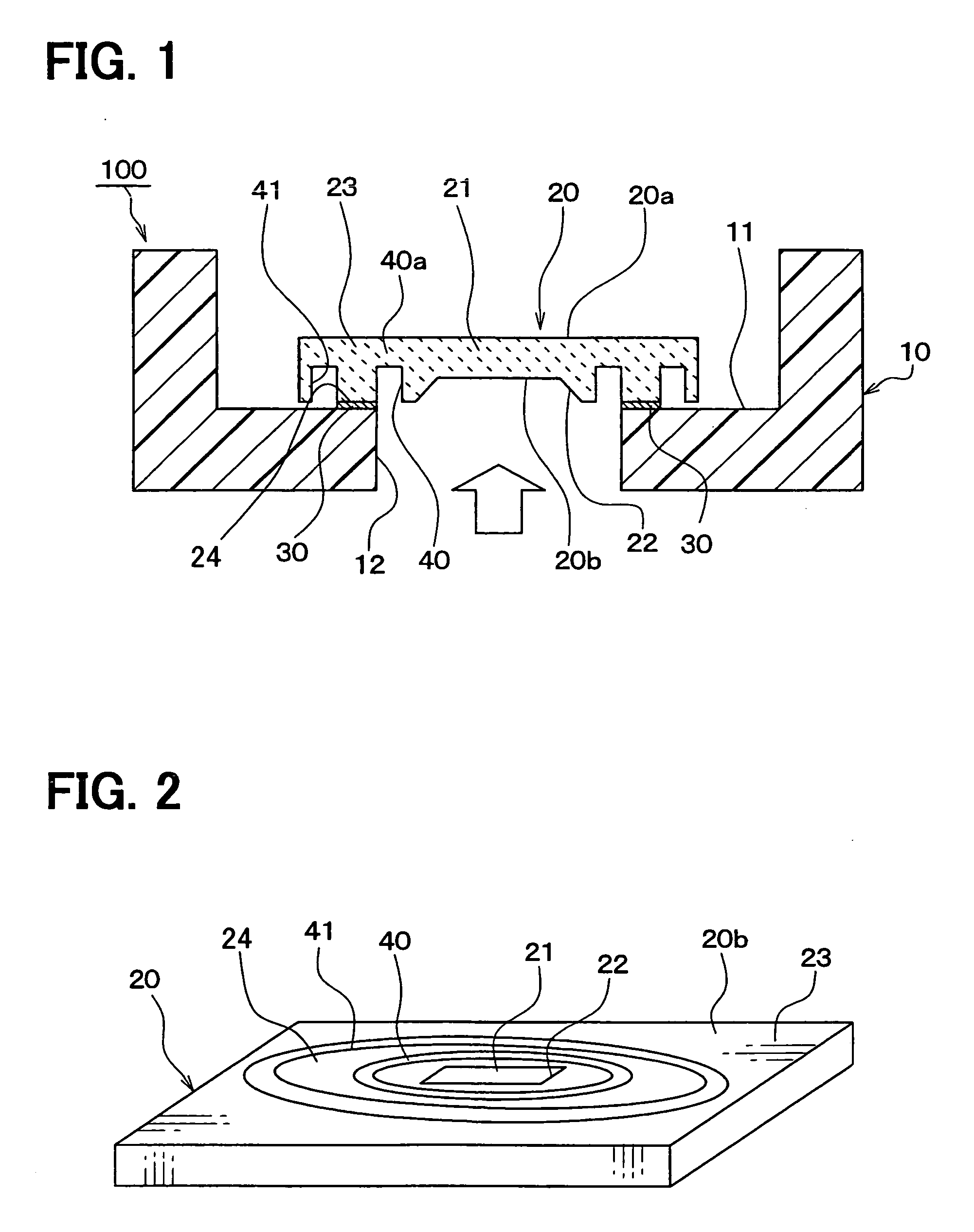

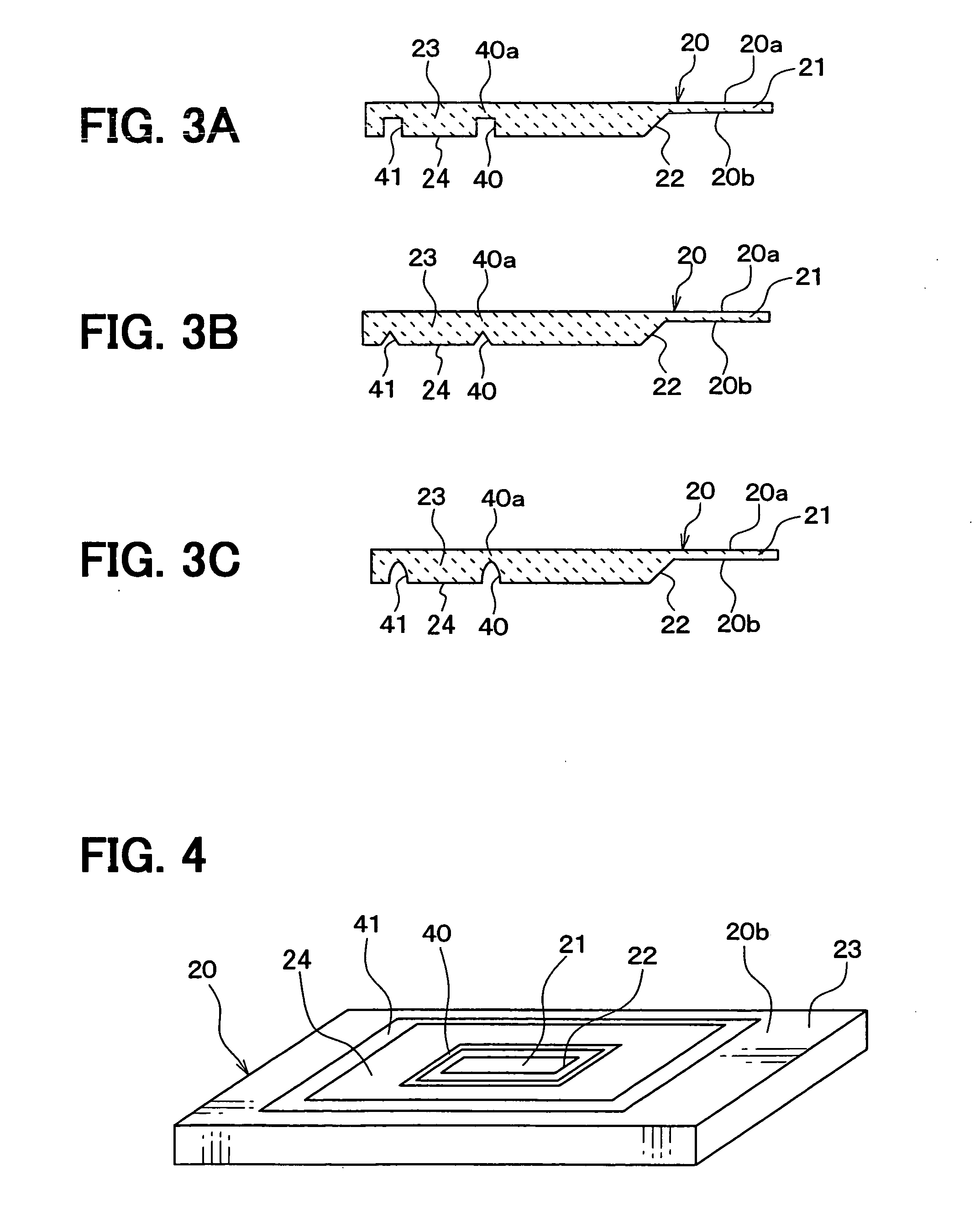

Pressure sensing element and sensor incorporating the same

InactiveUS7320250B2Relieve stressImprove sensor accuracyFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsAdhesivePressure sense

A pressure sensor includes a sensor chip in which a diaphragm is provided, and a case to which the sensor chip is directly mounted by an adhesive. A groove that surrounds the diaphragm is provided on the rear surface of the sensor chip between the bonded part and the diaphragm. The groove prevents thermal stress, which occurs at the bonded part, from reaching the diaphragm through the sensor chip, and thereby the accuracy of the sensor output is highly accurate. Further, the groove may store any excessive adhesive that may be applied when the sensor chip is bonded to the case to prevent the adhesive from flowing and adhering to the diaphragm.

Owner:DENSO CORP

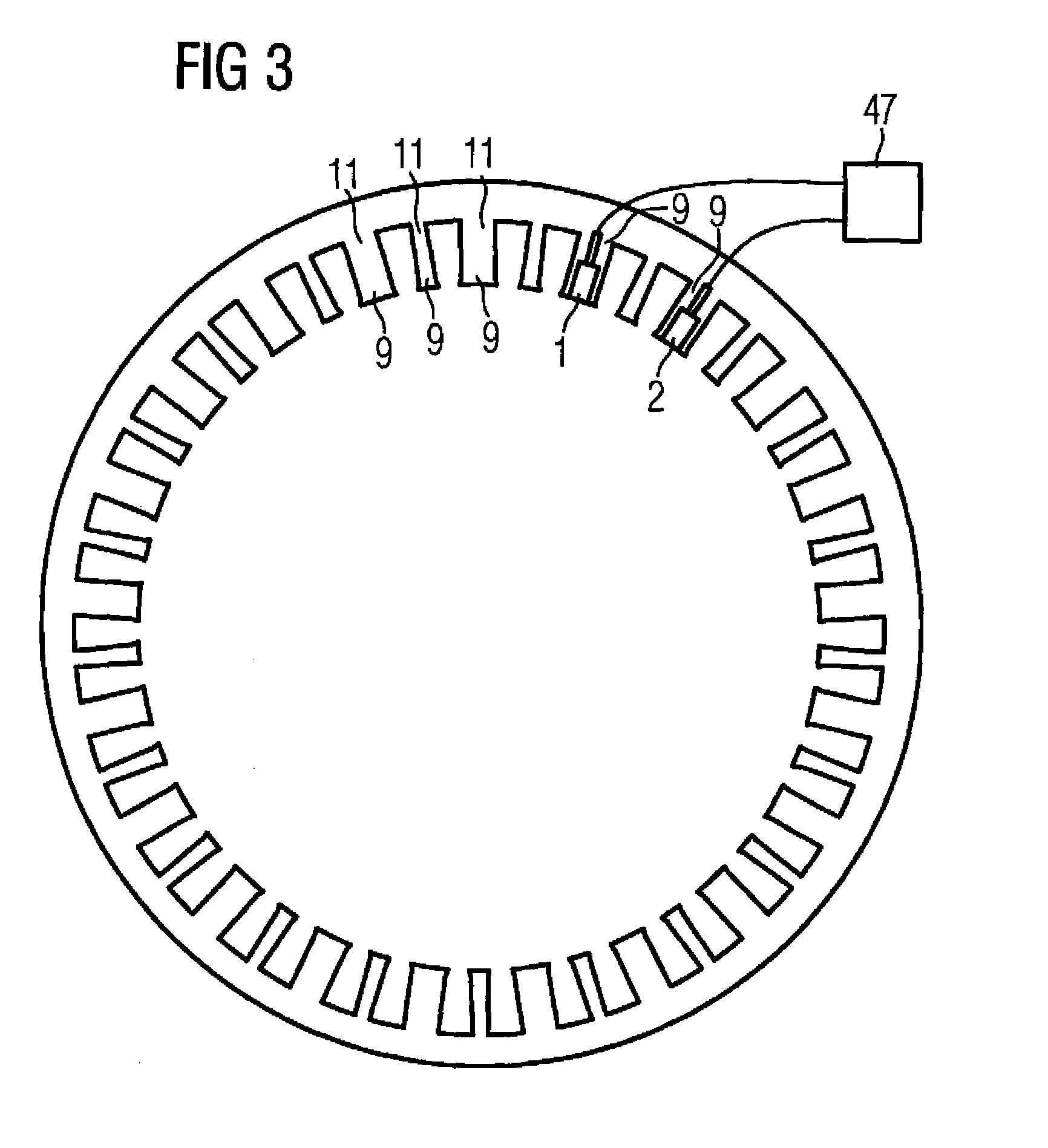

Sensor device for measuring a magnetic field

InactiveUS7969144B2Improve sensor sensitivityGreat cross-sectional areaSolid-state devicesMagnetic field measurement using galvano-magnetic devicesAcousticsMagnetic field

A sensor device for measuring a magnetic field in the region of a primary part of a permanently excited electrical machine or a corresponding primary part having teeth includes a sensor metal plate for conducting a magnetic field, a spacer, and a sensor for measuring a magnetic field. A distance between the sensor metal plate and a flank of a tooth of the primary part can be created by the spacer. The sensor may be a Hall sensor and is arranged in a region of the sensor metal plate between the sensor metal plate and the primary part.

Owner:SIEMENS AG

Pressure sensing element and sensor incorporating the same

InactiveUS20060179953A1Relieve stressImprove sensor accuracyFluid pressure measurement using elastically-deformable gaugesFluid pressure measurement by electric/magnetic elementsAdhesivePressure sense

A pressure sensor includes a sensor chip in which a diaphragm is provided, and a case to which the sensor chip is directly mounted by an adhesive. A groove that surrounds the diaphragm is provided on the rear surface of the sensor chip between the bonded part and the diaphragm. The groove prevents thermal stress, which occurs at the bonded part, from reaching the diaphragm through the sensor chip, and thereby the accuracy of the sensor output is highly accurate. Further, the groove may store any excessive adhesive that may be applied when the sensor chip is bonded to the case to prevent the adhesive from flowing and adhering to the diaphragm.

Owner:DENSO CORP

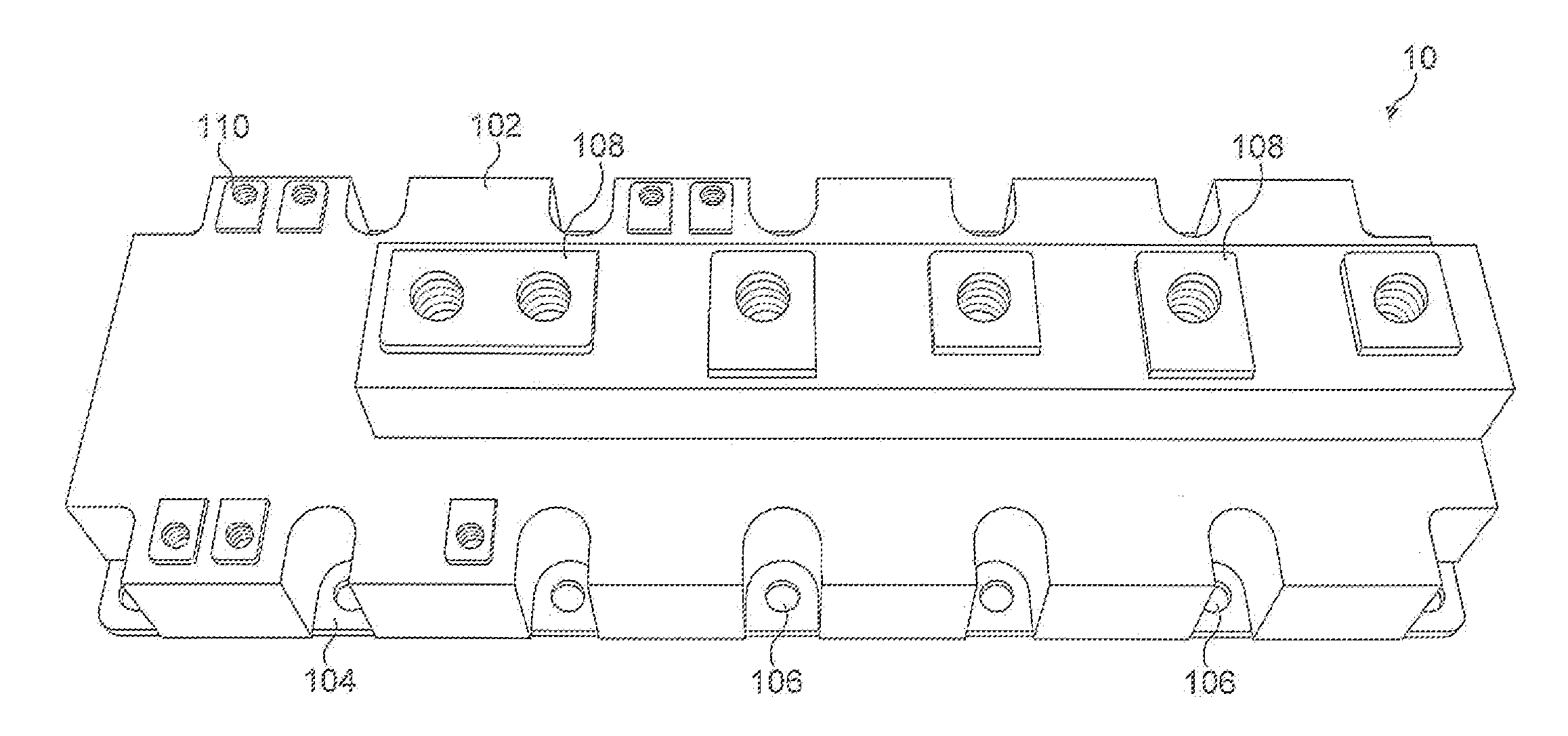

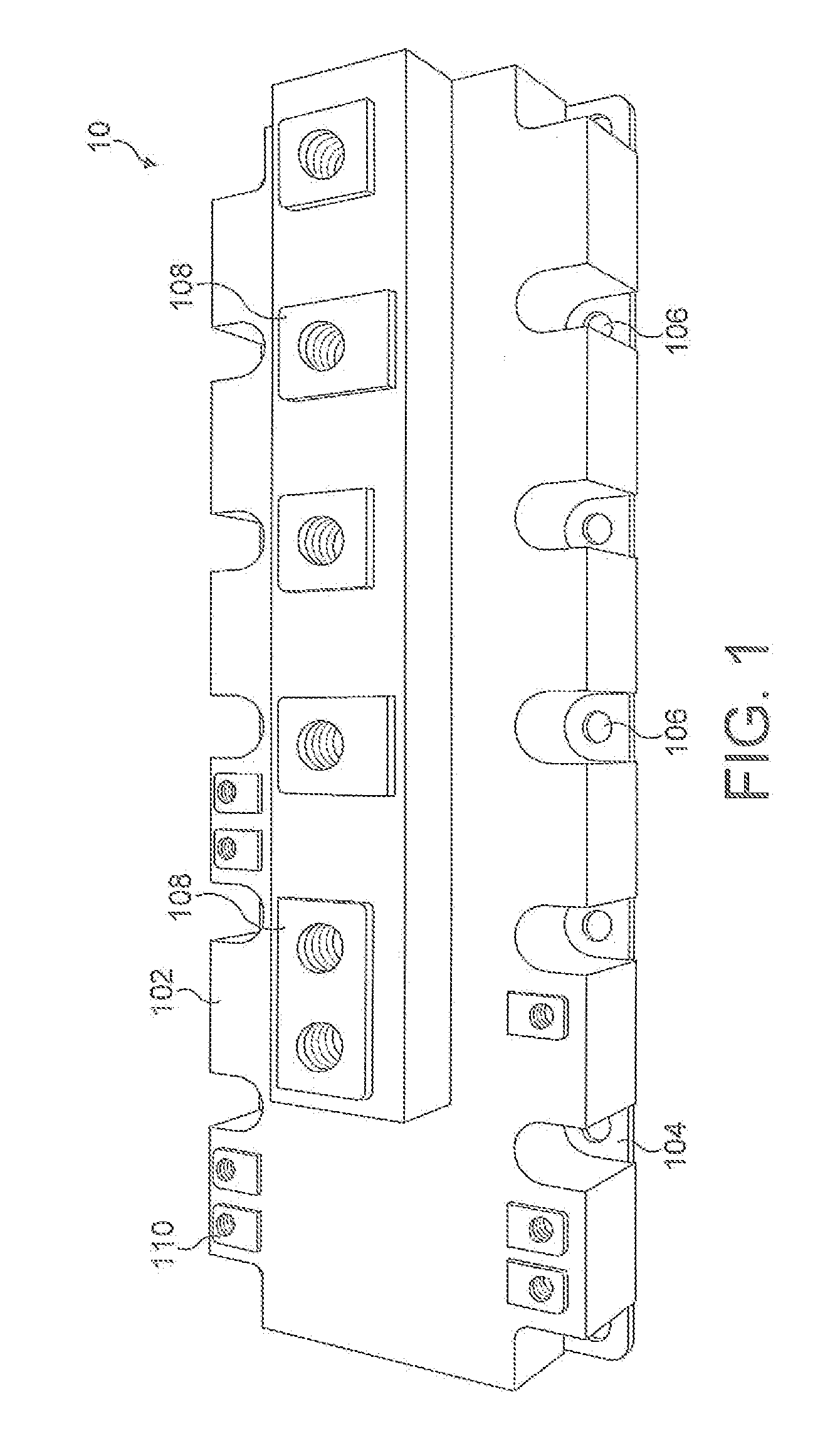

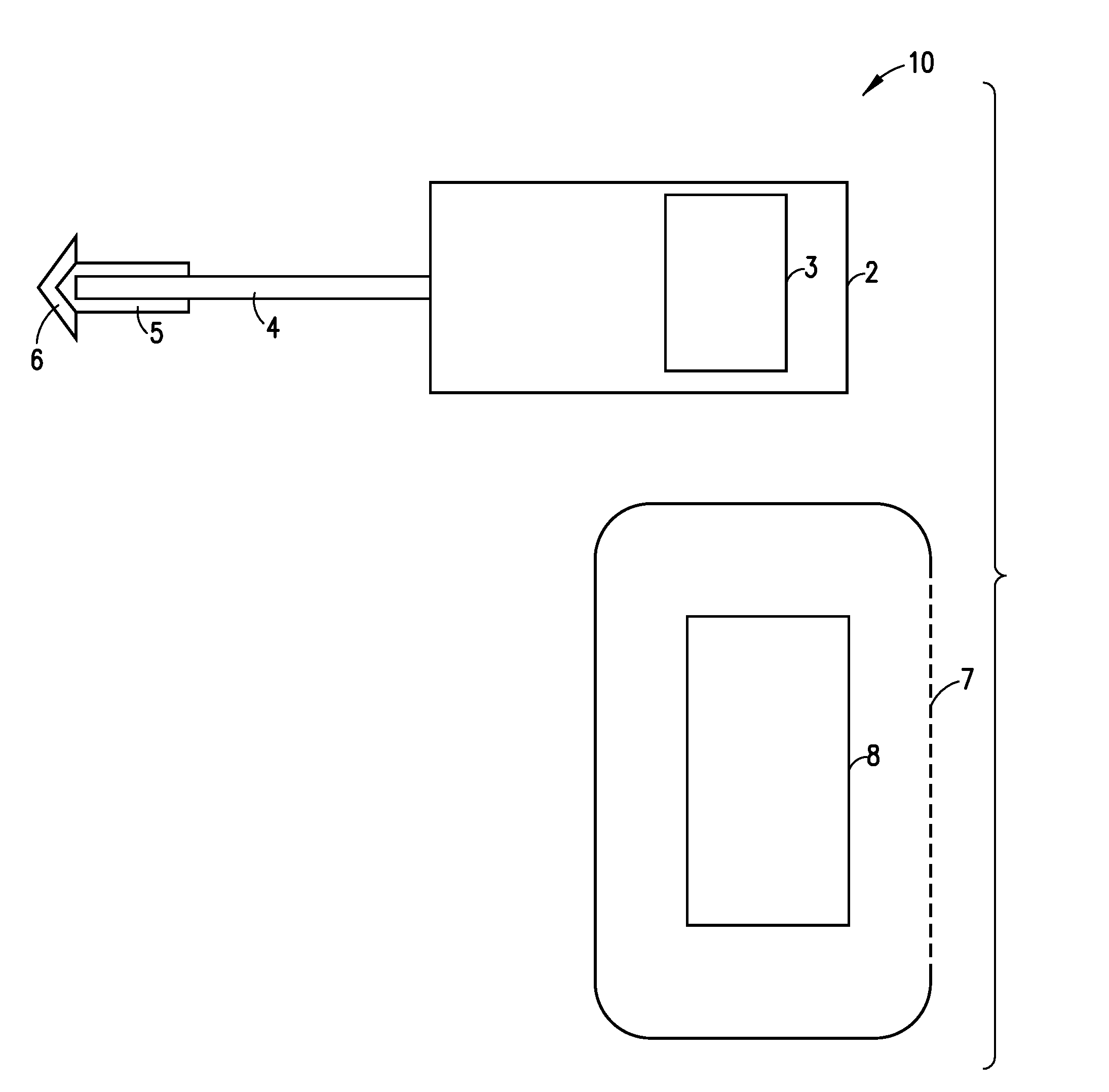

Optical sensor system and detecting method for an enclosed semiconductor device module

InactiveUS20110267598A1Not to damageImprove sensor accuracyThermometer detailsSemiconductor/solid-state device detailsGratingEngineering

A sensor system and method for a power electronics module is discussed. The system comprises a optical fibre 318 mounted inside the module housing 302 and connected to an external sensor system 320 (not shown). The optical fibre 318 is arranged so that it lies proximate to one or more semiconductor dies 308 within the housing, and can sense their temperature. The fibre can be connected to the die 308 by glue, mechanical connection, or can in other examples by provided in the underlying support structure such as a DCB (direct copper bonded ceramic structure) or base plate 304. The fibre can contain an optical grating, such as an FBG or LPG, or can operate based on interferometry, to detect temperature or strain.

Owner:VESTAS WIND SYST AS

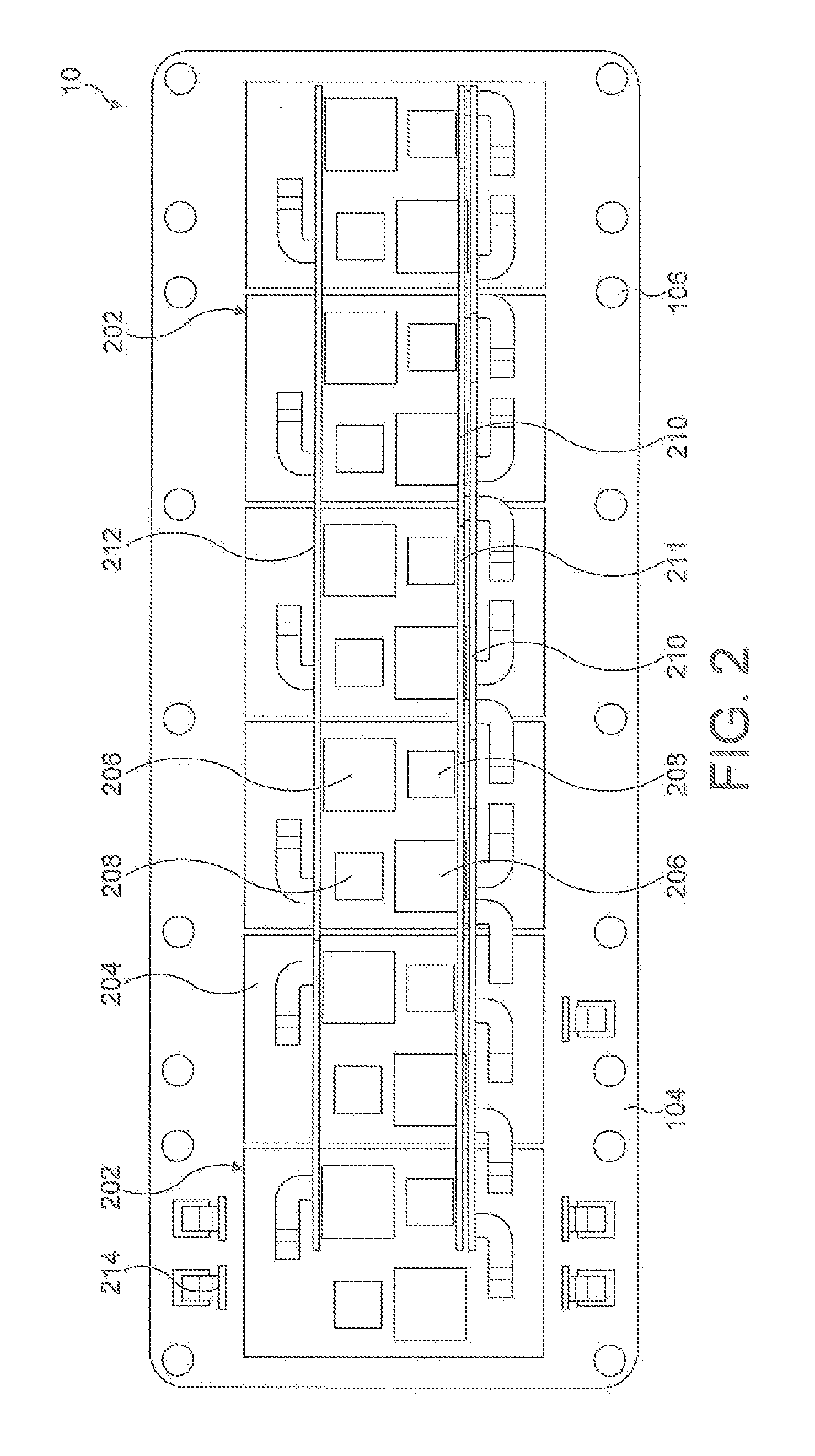

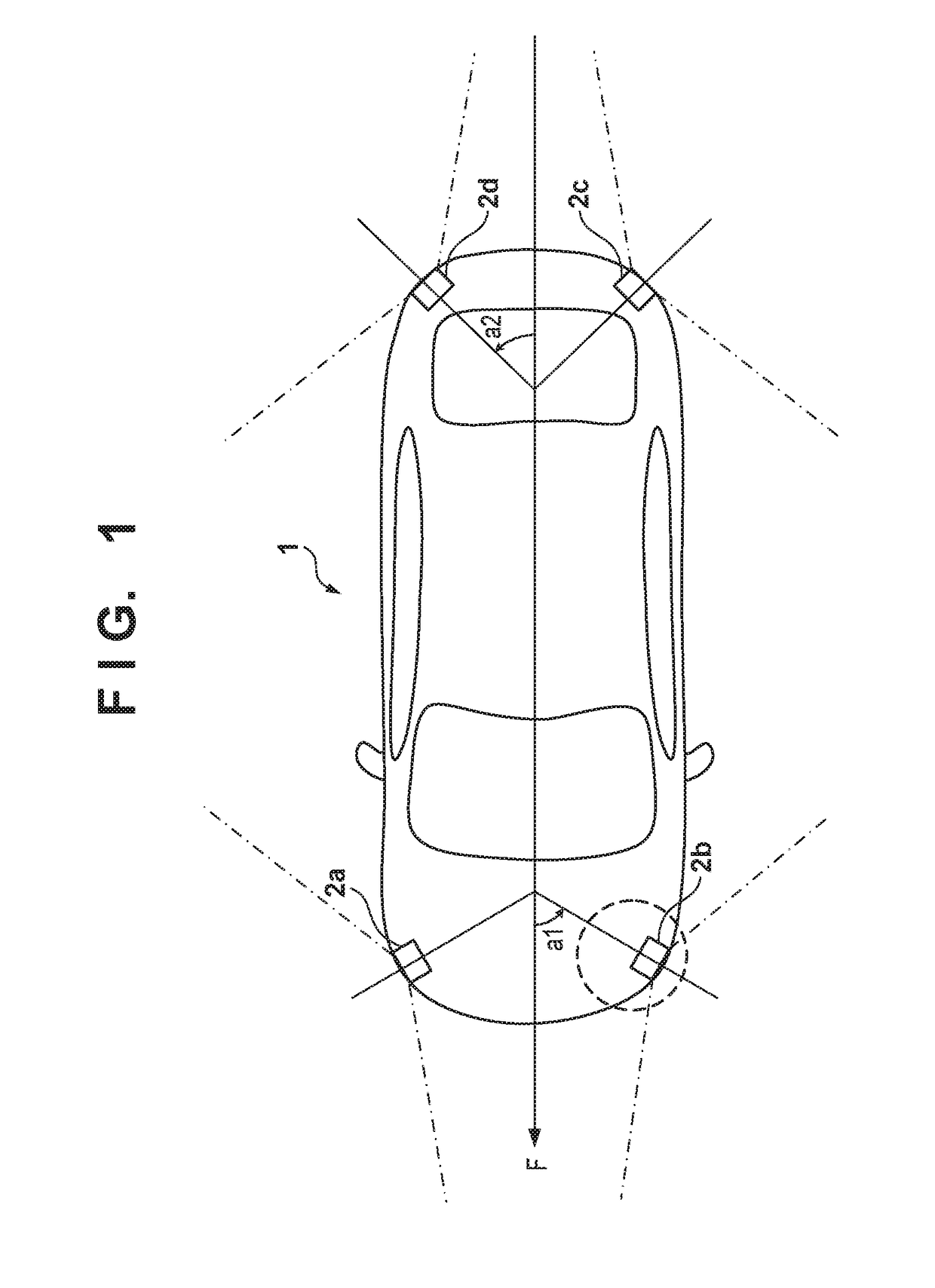

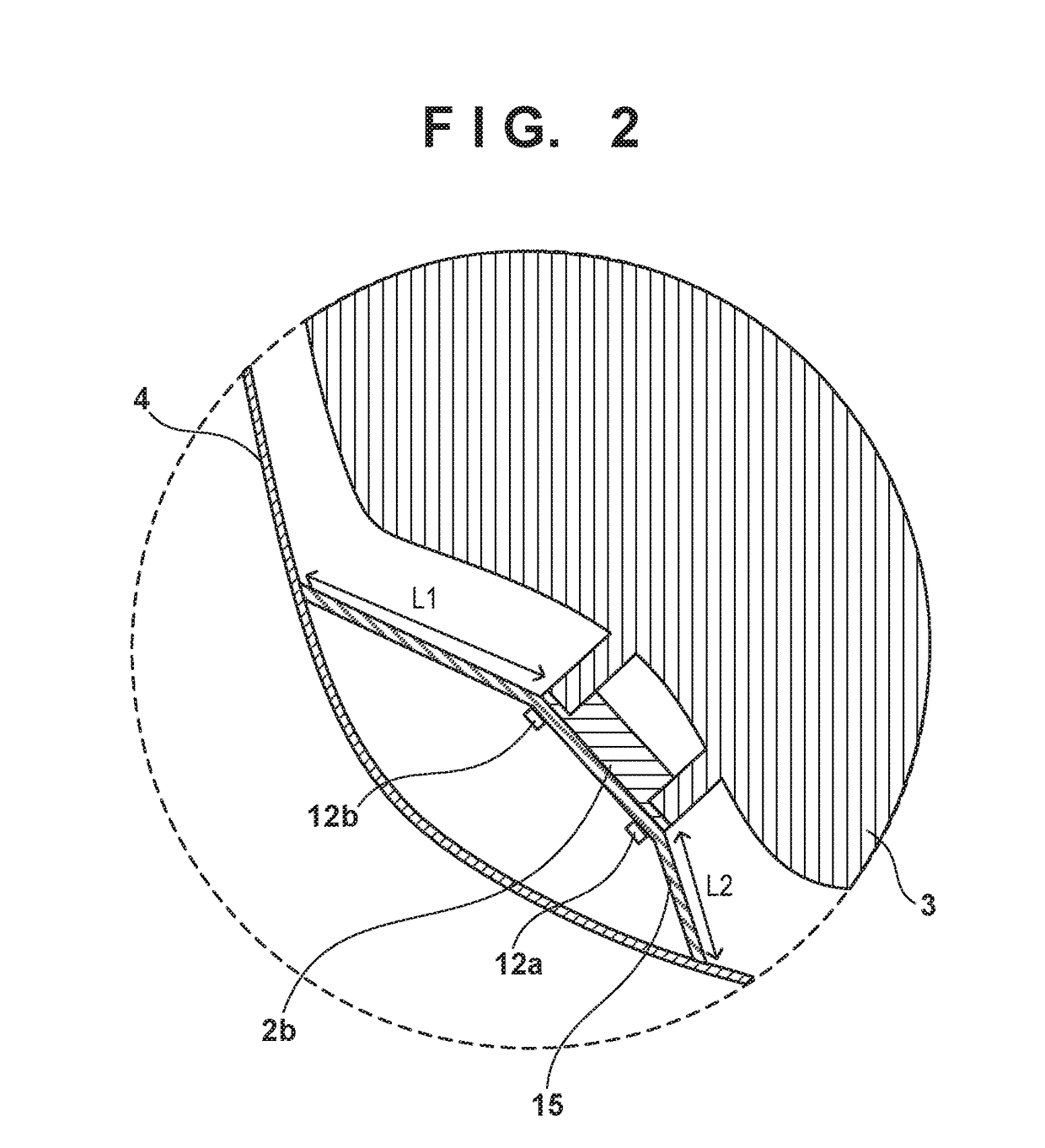

Cover member of sensor configured to detect ambient situation of vehicle and sensor assembly

InactiveUS20180203110A1Improve accuracyNot easy to damageWaveguide hornsAntenna supports/mountingsEngineering

Owner:HONDA MOTOR CO LTD

Method and device for operating a particle sensor

ActiveUS8640526B2Improve self-diagnosisImprove sensor accuracyElectrical controlResistance/reactance/impedenceEngineeringSoot particles

A method for operating a particle sensor (10). The particle sensor (10) has at least two inter-digital electrodes (12, 13) which engage one in the other and to which a sensor voltage U(IDE) (21) is applied in order to determine loading of the particle sensor (10) with soot particles (16). A sensor current I(IDE) (31) across the electrodes (12, 13) is measured and evaluated. In order to remove the loading with soot, a heating element (14) heats the particle sensor (10) in a regeneration phase. The method characterized in that the sensor current I(IDE) (31) is determined, and a shunt diagnosis of the particle sensor (10) is carried out in accordance with the measured sensor current I(IDE) (31).

Owner:ROBERT BOSCH GMBH

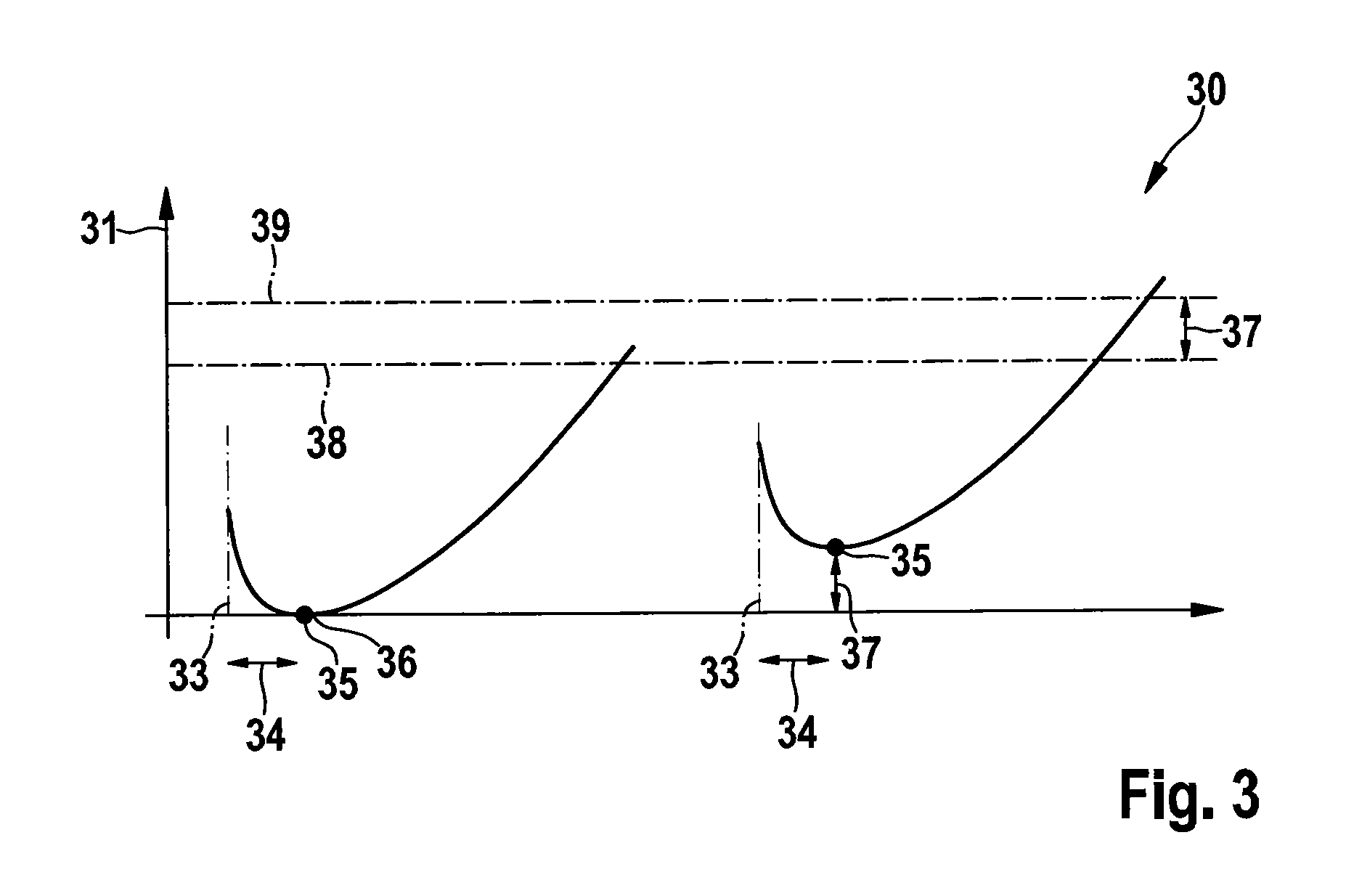

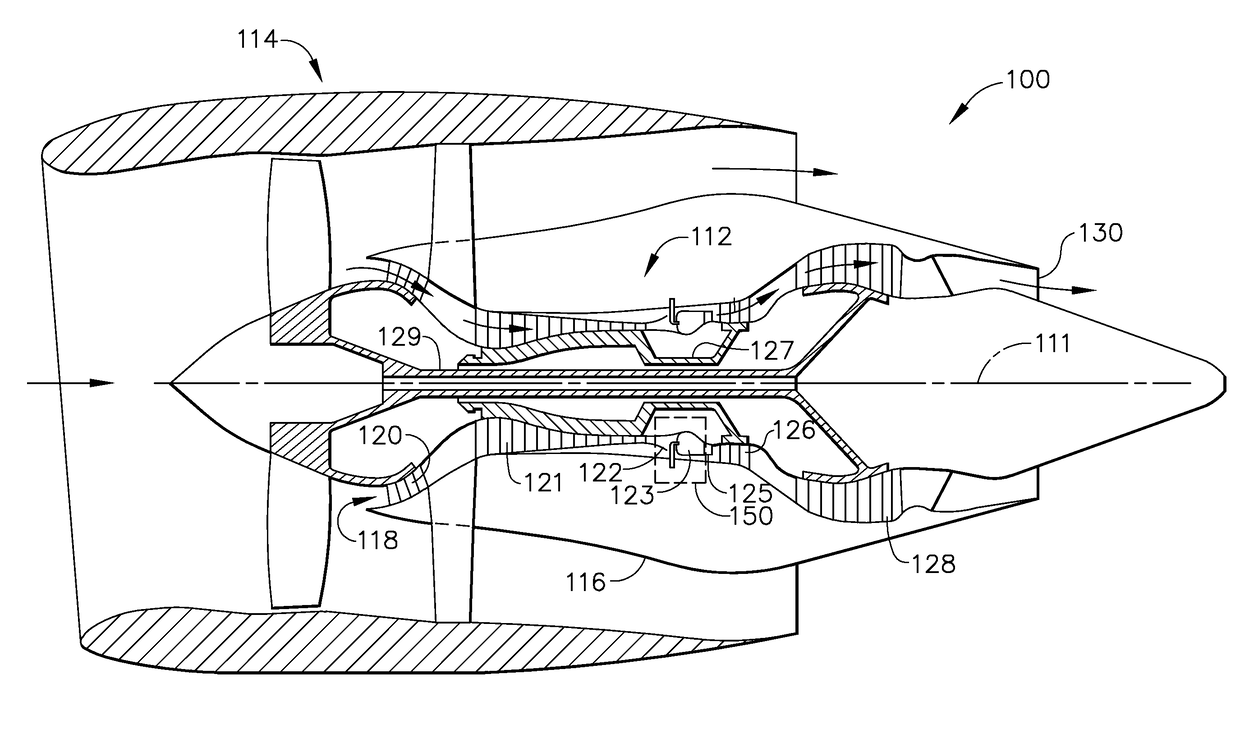

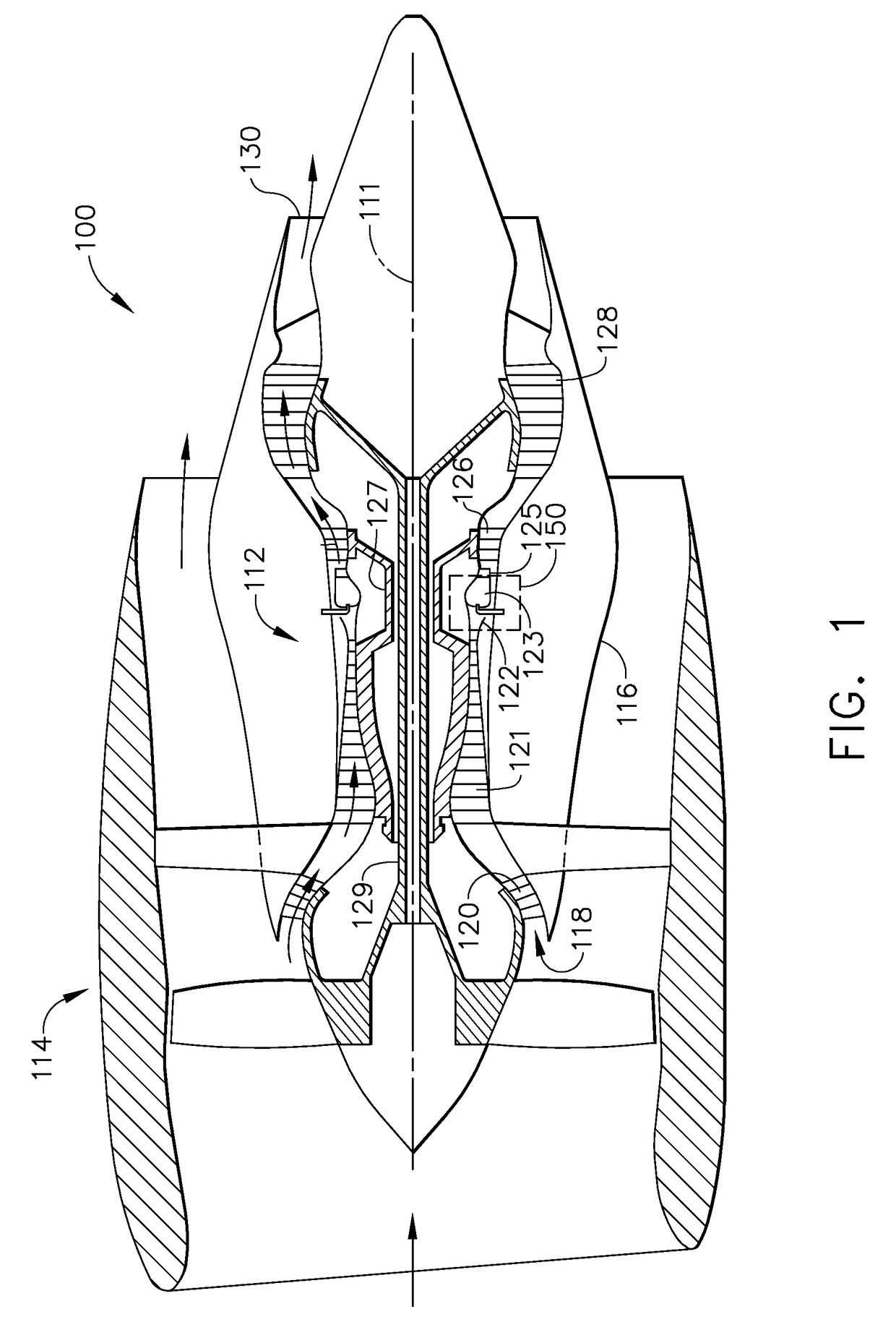

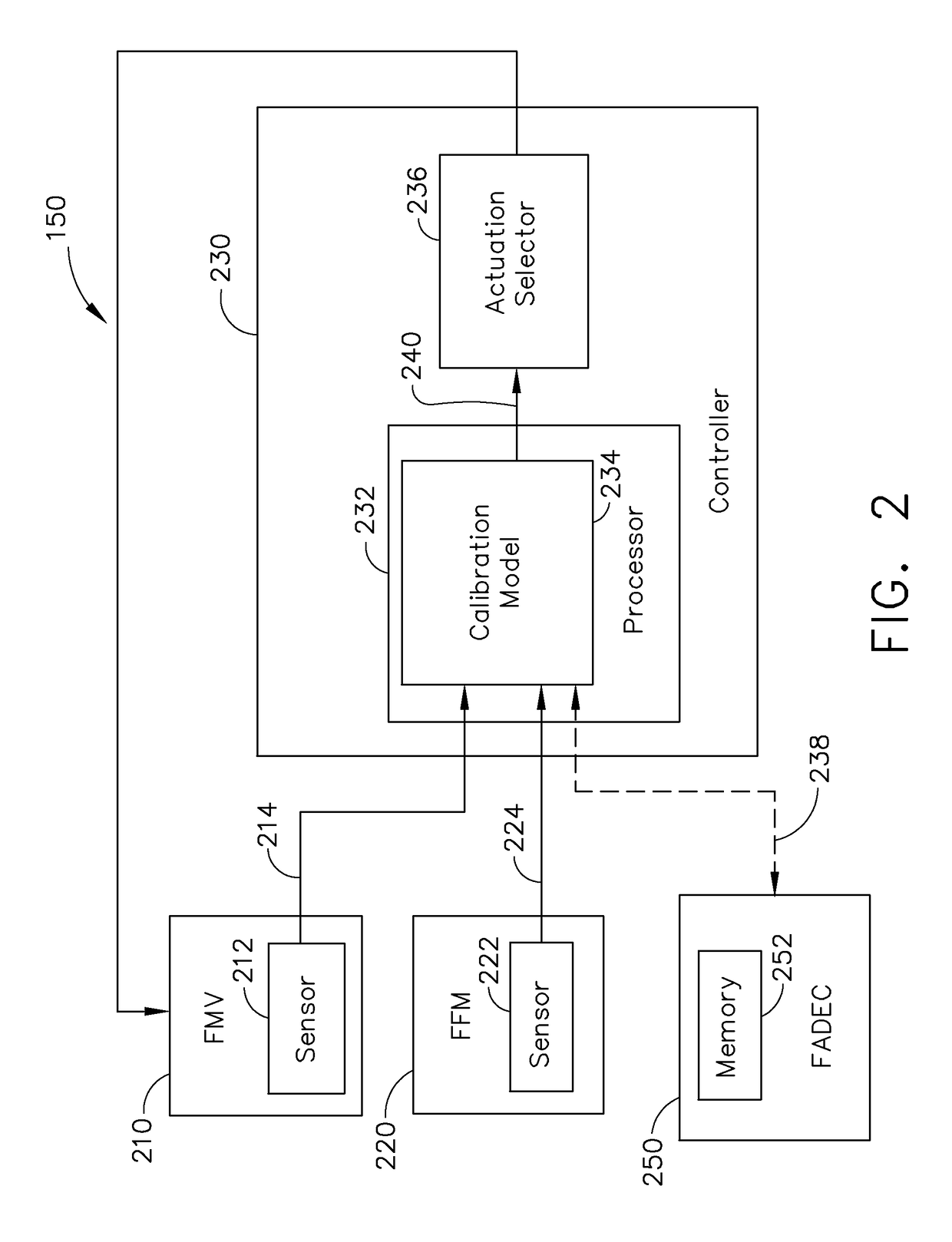

Method and system for improving parameter measurement

InactiveUS20170138781A1Improve accuracyImprove sensor accuracyTurbine/propulsion fuel valvesVolume variation compensation/correction apparatusBiomedical engineeringTransducer calibration

Parameter measurement systems including improved sensor calibration are provided herein. The measurement system includes a first sensor with a first output signal including a plurality of output characteristics, at least one output characteristic being deficient for measuring a desired parameter and at least one output characteristic being suitable for measuring the desired parameter. The measurement system also includes a second sensor with a second output signal comprising at least some of the plurality of output characteristics, the at least one deficient characteristic of the first output signal being suitable in the second output signal for measuring the desired parameter. The measurement system further includes a processor programmed to calibrate the first output signal using the second output signal to generate a third output signal including the at least one suitable characteristic of the first output signal and the at least one suitable characteristic of the second output signal.

Owner:GENERAL ELECTRIC CO

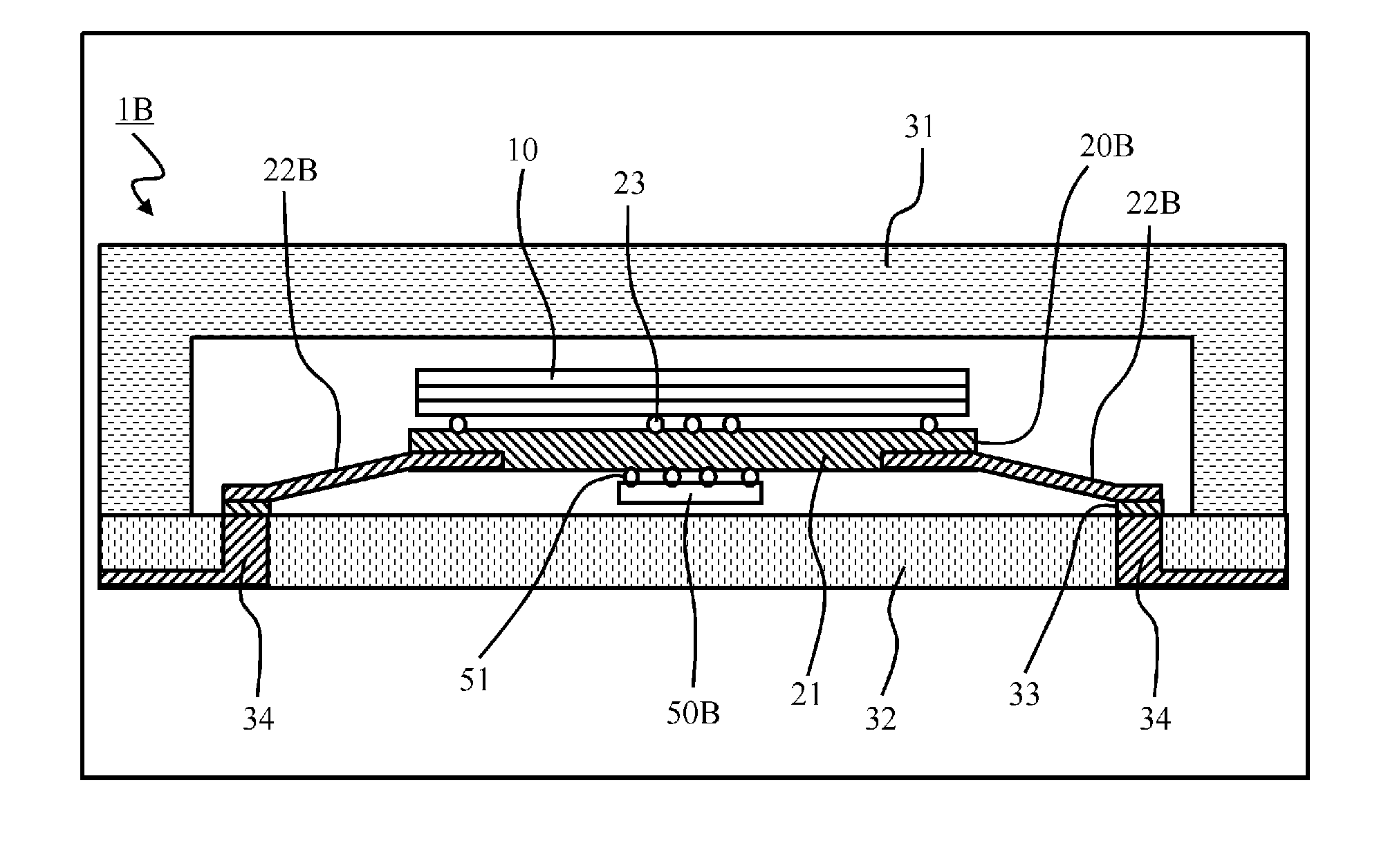

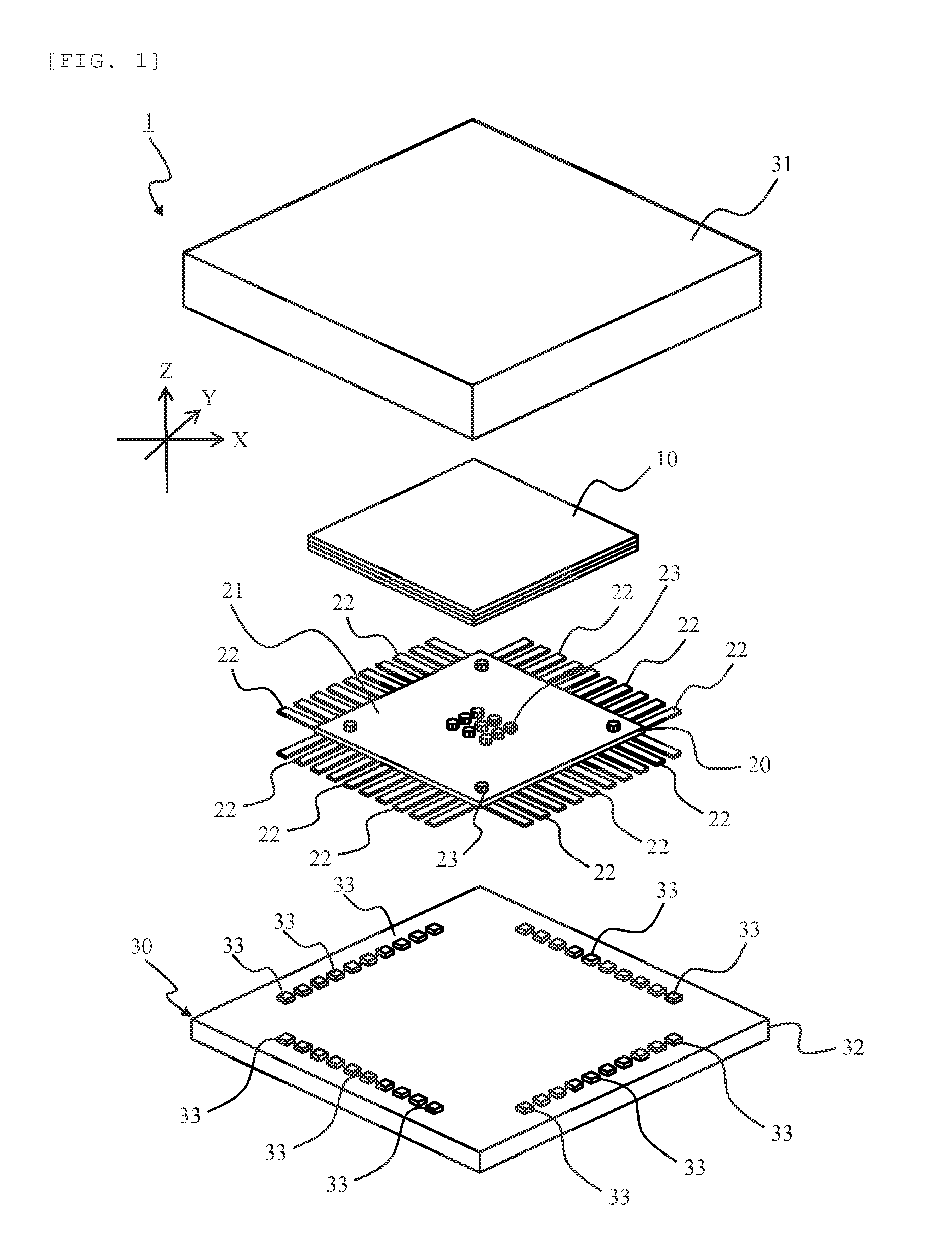

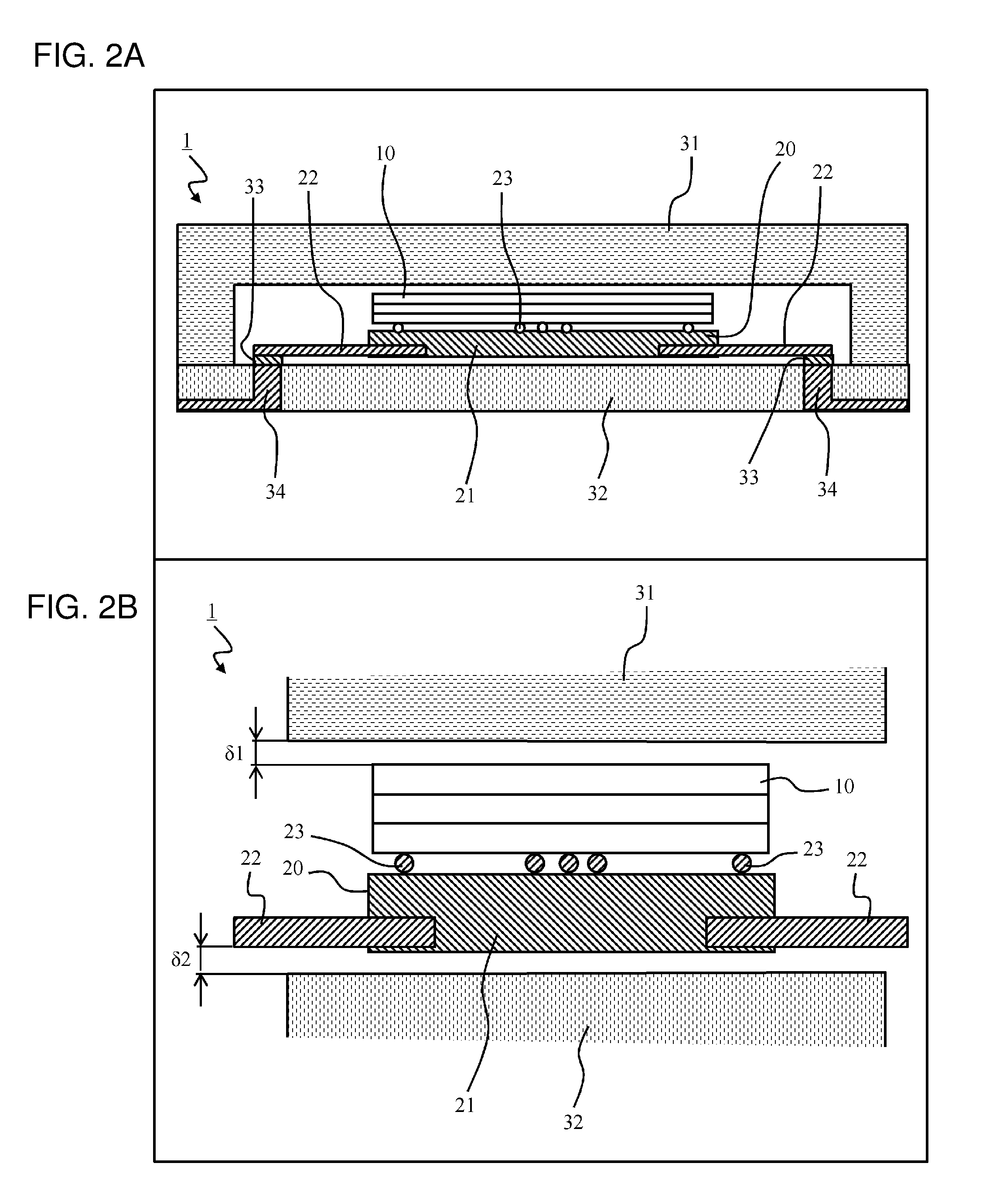

Physical Quantity Sensor

InactiveUS20170018471A1Improve sensor accuracyReduce the impactAcceleration measurement using interia forcesFluid pressure measurement using ohmic-resistance variationEngineeringPhysical quantity

To provide a physical quantity sensor in which the influence of deformation of a package substrate on the measuring accuracy of a sensor element can be suppressed. A physical quantity sensor includes a sensor element that detects a predetermined physical quantity and outputs an electrical signal, a plurality of lead portions that are connected to the sensor element, and a package substrate that accommodates the sensor element and the plurality of lead portions. The plurality of lead portions are connected at proximal end sides thereof to the package substrate side, and connected at distal end sides thereof to the sensor element side, and the plurality of lead portions support the sensor element in such a manner that the sensor element does not contact the package substrate and that the transmission of deformation of the package substrate side to the sensor element is suppressed.

Owner:HITACHI LTD

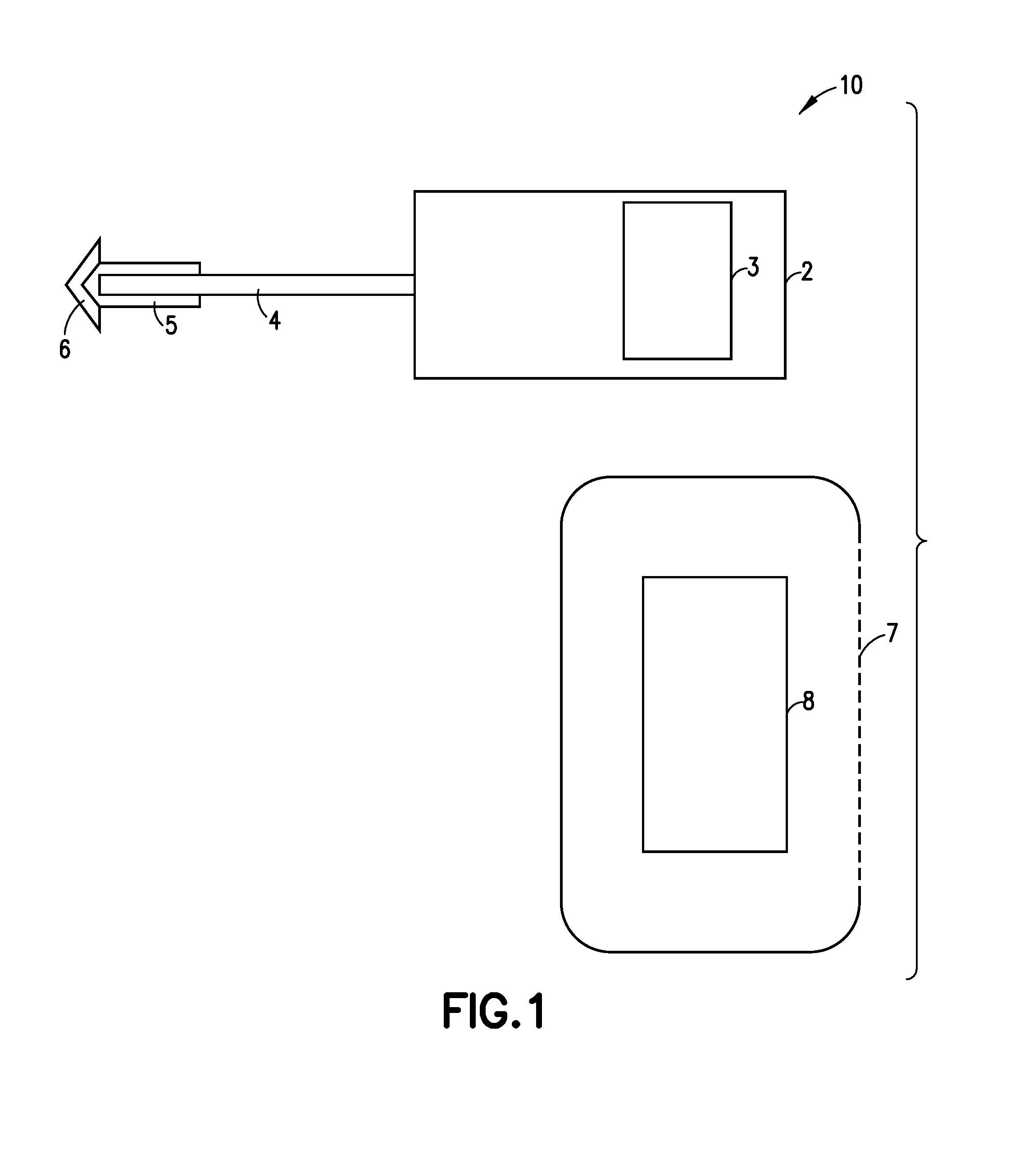

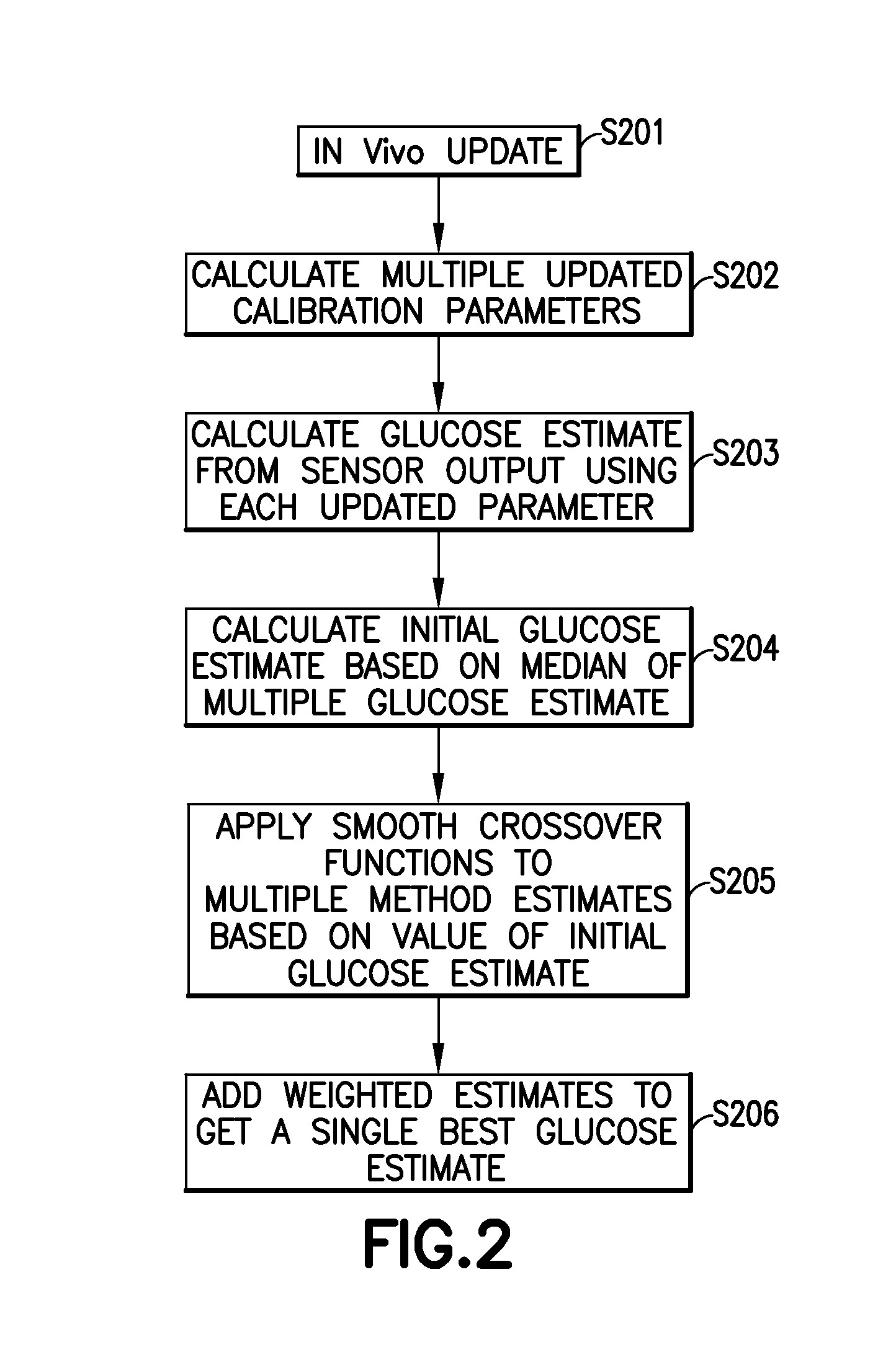

System and method for using multiple sensor calibration methods

ActiveUS20140180048A1Improving glucose sensor accuracyImproved glucose sensor accuracySensorsBlood characterising devicesGlucose sensorsConcentrations glucose

The present invention relates to a system and method for improving glucose sensor accuracy by utilizing multiple calibration methods and selecting the most accurate method depending on a consensus glucose concentration estimate. Embodiments of the present invention comprise the steps of performing at least one in vivo update of surrounding glucose to acquire glucose values; calculating multiple updated calibration estimates using the updated glucose values; calculating an initial consensus glucose estimate from sensor output using each updated calibration estimate; applying a smooth crossover function to the multiple calibration estimates based on the value of the initial consensus glucose estimate; and adding weights to the multiple calibration estimates to acquire a consensus glucose estimate.

Owner:BECTON DICKINSON & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com