Ferromagnetic shape memory alloy with nanometer eutectic lamella structure

A memory alloy and ferromagnetic technology, applied in the field of metal alloys, can solve the problems of high brittleness of memory alloys, and achieve the effects of high toughness, random orientation, and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

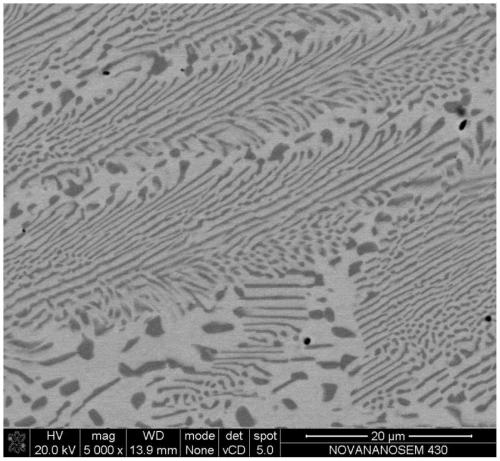

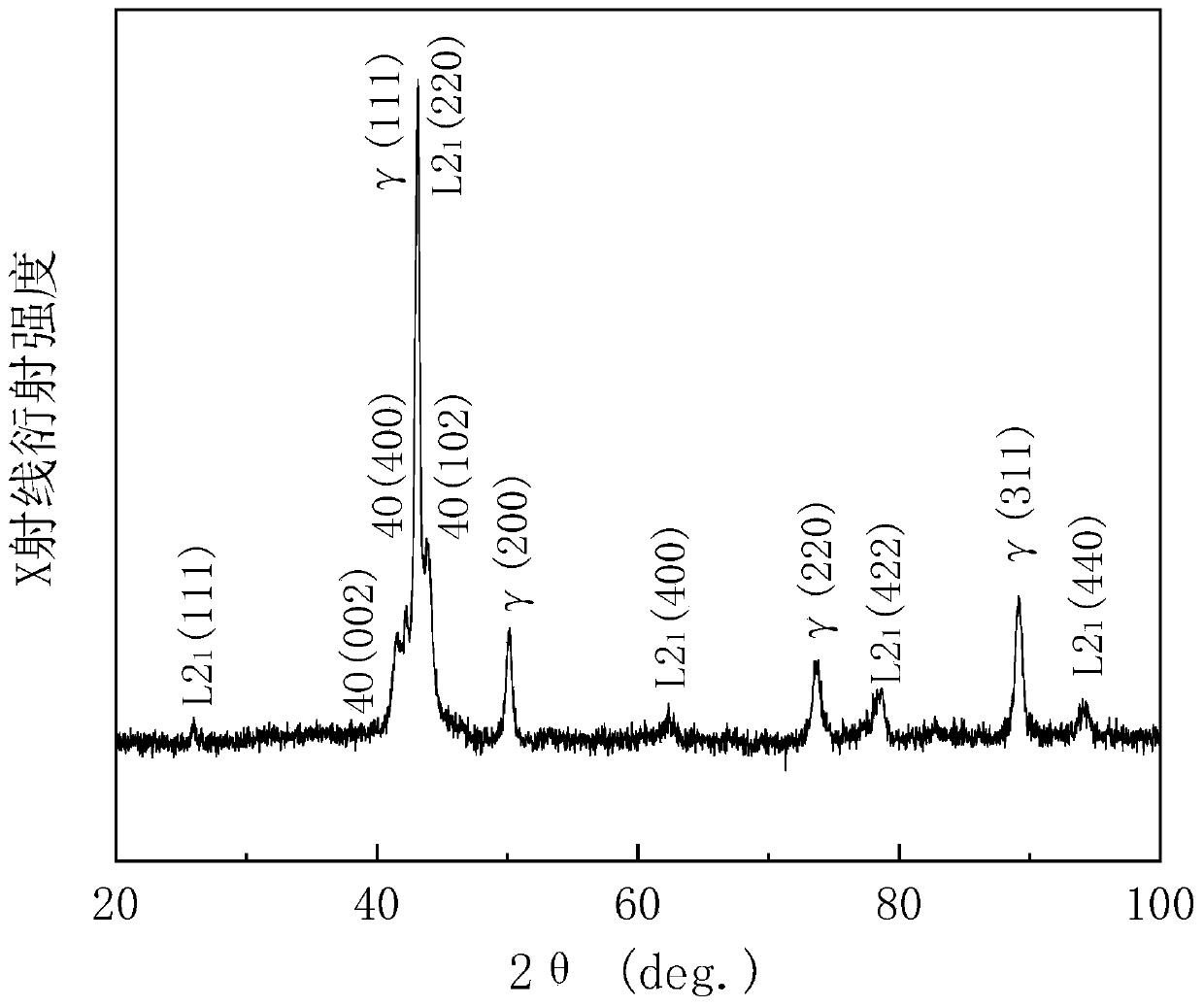

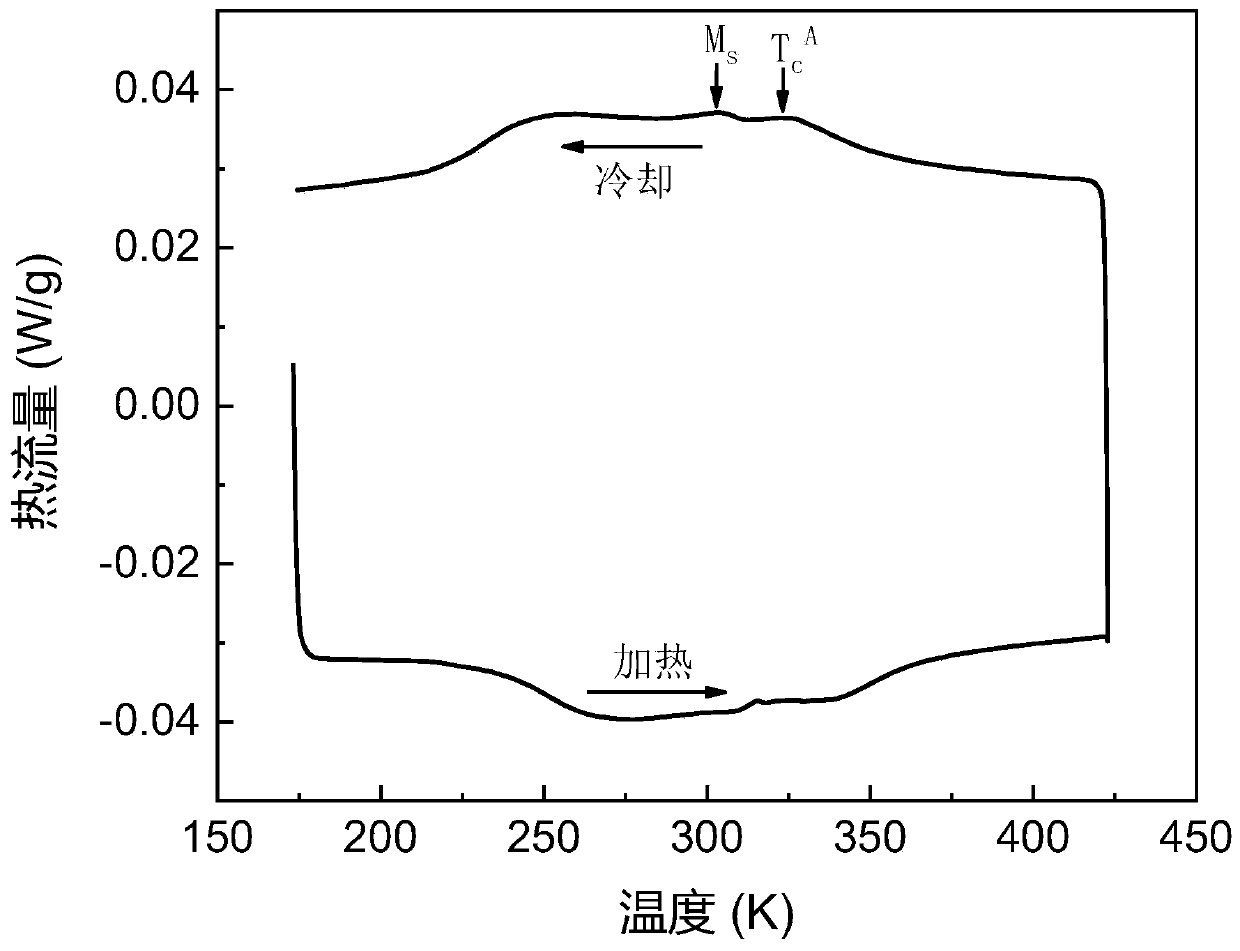

[0038] A ferromagnetic shape memory alloy whose chemical formula is expressed as Ni 51.5 mn 34 Fe 6 sn 8.5 . This Ni 51.5 mn 34 Fe 6 sn 8.5 The ferromagnetic shape memory alloy has a nano-eutectic layer structure, and its preparation method is as follows:

[0039] Clean Ni material, Mn material, Fe material and Sn material with absolute ethanol in an ultrasonic cleaning machine for 5 minutes, dry and set aside;

[0040] According to Ni 51.5 mn 34 Fe 6 sn 8.5 Set atomic percentage, take 51.5 parts by mass of Ni material, 34 parts by mass of Mn material, 6 parts by mass of Fe material and 8.5 parts by mass of Sn material, and supplement the total mass of metal raw materials (Ni material, Mn material, Fe material and Sn material) 1% Mn material, mixed into the MSM20-7 miniature metal melting furnace;

[0041] Under the protection of the inert gas argon, smelting at 1550°C under 80A melting current 4 times, 2 times on the front and back sides, smelting for 5 minutes e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com