Hybrid composite energy absorbing part for automobile and manufacturing method thereof

An energy absorption and composite material technology, which is applied in the field of aramid fiber hybrid reinforced three-dimensional structure energy absorption parts and carbon fiber, which can solve the problems of unsatisfactory, heavy weight, and unsatisfactory energy absorption performance of metal energy absorption parts, so as to reduce damage. , high energy absorption, high modulus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] 1. Raw materials

[0029] Epoxy resin (Mitsubishi Chemical Corporation, 308A3801); aramid fiber; carbon fiber.

[0030] 2. Production method

[0031] 2.1 soak the aramid fiber and carbon fiber into the epoxy resin matrix for later use;

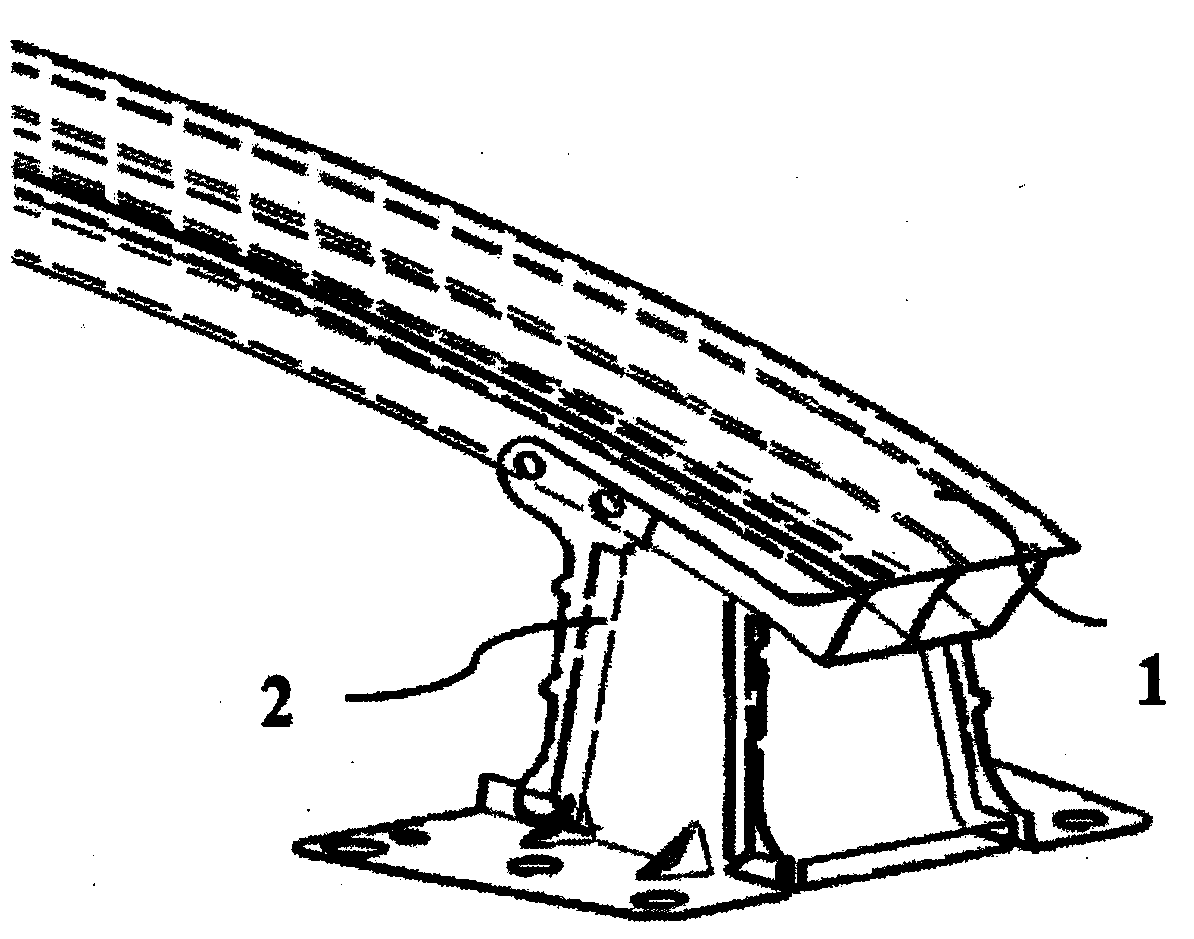

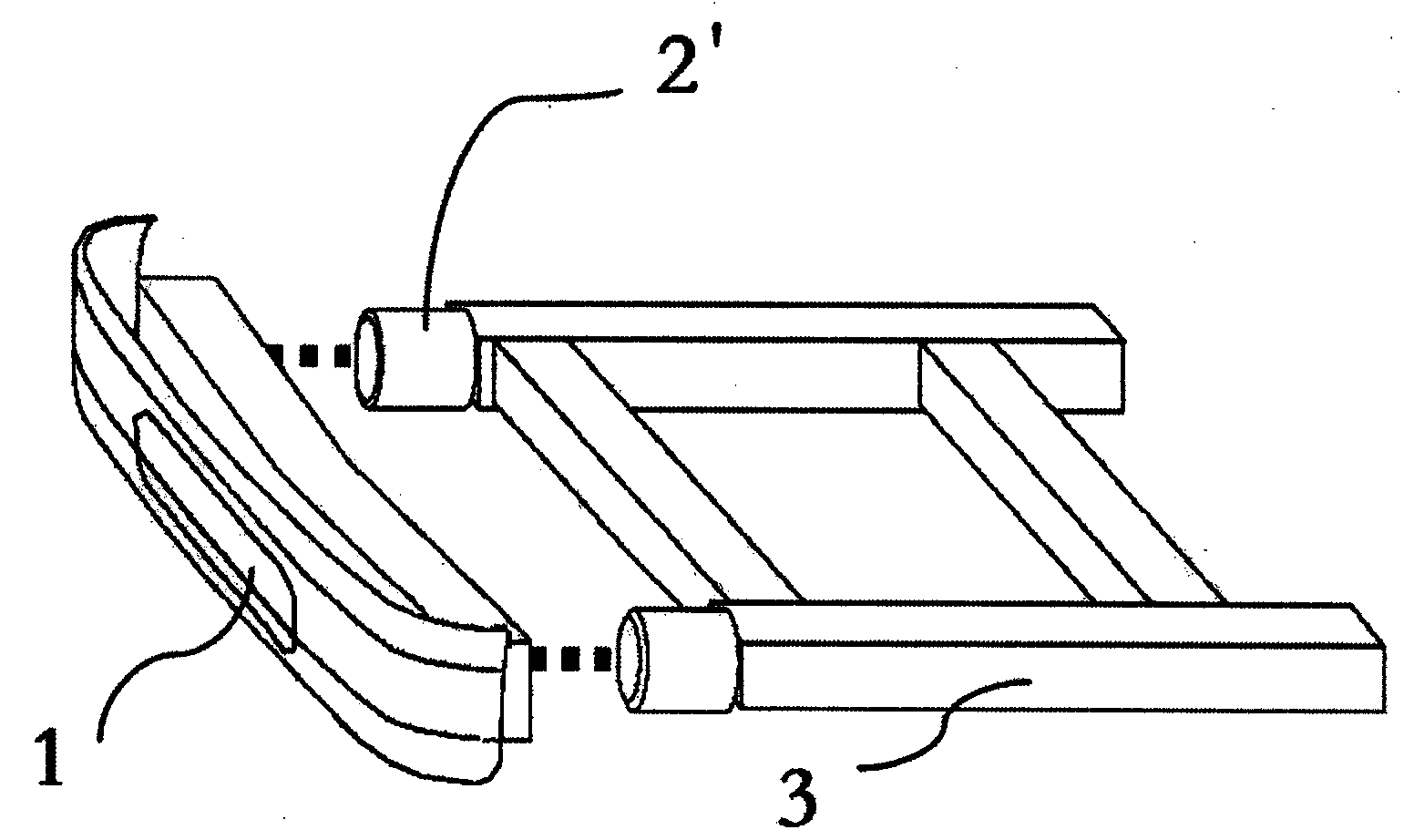

[0032] 2.2 Wrap the aramid fibers, carbon fibers, and aramid fibers prepared in step 2.1 on the mandrel in sequence to form the first aramid fiber layer 4, the carbon fiber layer 5, and the second aramid fiber layer 6 respectively to form a hybrid composite energy Absorbing part 2'; with the axial direction of the tube axis of the mandrel as 0°, the winding angle of the aramid fiber is controlled to be 88°, and the winding angle of the carbon fiber is 17.6°; when winding, the first aramid fiber layer 4 and the carbon fiber layer 5 , The thickness ratio of the second aramid fiber layer 6 is 1:10:2.5; the ratio of the tube wall thickness to the inner tube diameter of the energy absorbing component 2' is 1:22.

[0033] 2.3 The hybrid co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com