Ultrahigh-toughness concrete and preparation method thereof

An ultra-high toughness, concrete technology, applied in the field of concrete, can solve the problems of not being able to resist deformation and crack propagation, limiting the toughening effect of steel fibers, reducing the workability of concrete, etc., to improve fatigue resistance and isotropy, and high toughness. , Enhance the effect of interface combination

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

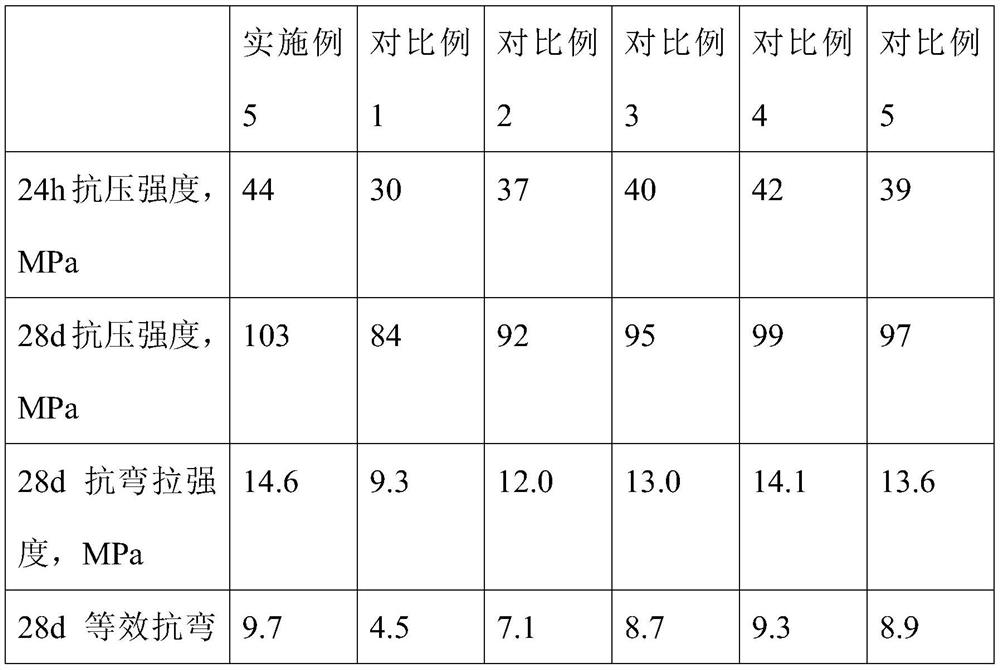

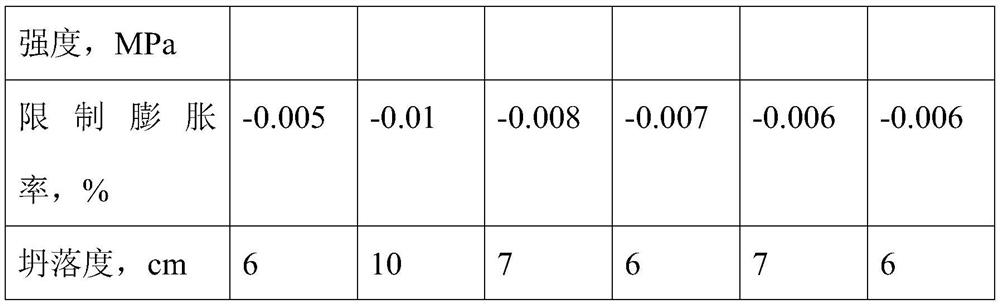

Examples

Embodiment 1

[0026] A kind of ultra-high toughness concrete, its raw materials include: 20kg of Portland cement with a strength grade of 42.5, 1kg of water-based epoxy resin emulsion with a solid content of 60%, polypropylene fibers with a diameter of 18-22μm and a length of 2.5-3.5mm 8kg, the specific surface area is 20015m 2 / kg of silica fume 5kg, clay ceramsite 2kg, UEA series expansion agent with a limit expansion rate of 0.03% 2kg, polycarboxylate superplasticizer with a water reduction rate of 20%, 2kg, polyamide polyamine 0.1kg, triethylene Tetramine 6kg, methyl methacrylate 1kg, polyvinyl alcohol fiber 4kg.

[0027] The particle size of clay ceramsite is 5-16mm, and the apparent density is 1200kg / m 3 , bulk density is 700kg / m 3 , Cylinder compressive strength ≥ 6.5MPa.

[0028] The preparation method of the above-mentioned ultra-high toughness concrete comprises the following steps:

[0029] S1. Add triethylenetetramine to 60kg nitrogen nitrogen dimethylformamide, stir evenly ...

Embodiment 2

[0033] A kind of ultra-high toughness concrete, its raw materials include: 40kg of Portland cement with a strength grade of 42.5, 4kg of water-based epoxy resin emulsion with a solid content of 50%, polypropylene fibers with a diameter of 18-22μm and a length of 2.5-3.5mm 4kg, the specific surface area is 29057m 2 1 kg of silica fume per kg, 8 kg of clay ceramsite, 1 kg of UEA series expansion agent with a limited expansion rate of 0.03%, 1 kg of polycarboxylate superplasticizer with a water reduction rate of 40%, 1 kg of alicyclic polyamine, triethylene Tetramine 2kg, methyl methacrylate 3kg, polyvinyl alcohol fiber 1kg.

[0034] The particle size of clay ceramsite is 5-16mm, and the apparent density is 1500kg / m 3 , bulk density is 1100kg / m 3 , Cylinder compressive strength ≥ 6.5MPa.

[0035] The preparation method of the above-mentioned ultra-high toughness concrete comprises the following steps:

[0036] S1. Add triethylenetetramine to 30kg nitrogen nitrogen dimethylfor...

Embodiment 3

[0040] A kind of ultra-high toughness concrete, its raw materials include: 25kg of Portland cement with a strength grade of 42.5, 2kg of water-based epoxy resin emulsion with a solid content of 58%, polypropylene fibers with a diameter of 18-22μm and a length of 2.5-3.5mm 7kg, the specific surface area is 22240m 2 / kg of silica fume 4kg, clay ceramsite 4kg, UEA expansion agent with a limited expansion rate of 0.03% 1.7kg, polycarboxylate superplasticizer with a water reduction rate of 25% 1.8kg, hydroxyethyldiethylenetriamine 0.3kg, triethylenetetramine 5kg, methyl methacrylate 1.5kg, polyvinyl alcohol fiber 3kg.

[0041] The particle size of clay ceramsite is 5-16mm, and the apparent density is 1300kg / m 3 , bulk density is 800kg / m 3 , Cylinder compressive strength ≥ 7MPa.

[0042] The preparation method of the above-mentioned ultra-high toughness concrete comprises the following steps:

[0043] S1. Add triethylenetetramine to 40kg nitrogen nitrogen dimethylformamide, stir ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com