Cement-based telegraph pole

A utility pole, cement-based technology, applied in coating, construction, anti-corrosion coating, etc., can solve the problems of corroded steel skeleton, affecting the durability and service life of cement utility poles, and achieve the effect of reducing quantity and improving durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

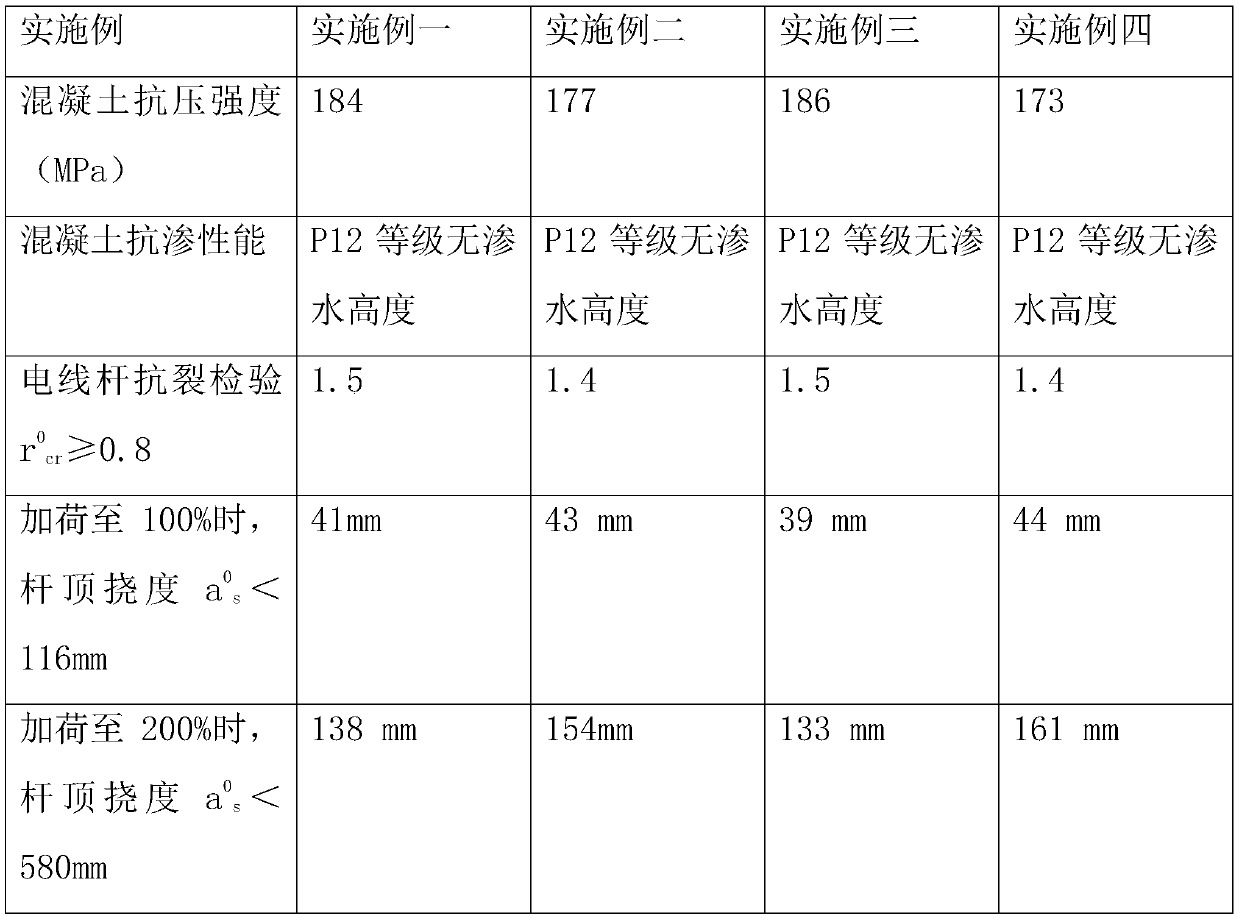

Examples

Embodiment 1

[0020] The cement-based utility pole provided in this embodiment includes a pole body formed by composite steel frame and concrete material; the steel frame is anti-corrosion treated by epoxy resin anticorrosion coating; the raw material components of the concrete material include by weight: 42.5 100 parts of ordinary Portland cement, 250 parts of basalt gravel, 150 parts of quartz sand, 10 parts of polyvinyl alcohol fiber, 5 parts of modified loofah fiber, 15 parts of nanomaterial capsule, 5 parts of rubber powder, modified sepiolite powder 30 parts, 20 parts of palygorskite powder, 0.5 parts of polycarboxylate superplasticizer, 6 parts of polyethylene oxide, and 60 parts of water; the nanomaterial capsule is a hard shell capsule filled with nano calcium carbonate and nano silicon dioxide.

[0021] In this embodiment, the preparation method of the nanomaterial capsule comprises the following steps: taking sodium alginate, nanometer calcium carbonate, nanometer silicon dioxide ...

Embodiment 2

[0029]The cement-based utility pole provided in this embodiment includes a pole body formed by composite steel frame and concrete material; the steel frame is anti-corrosion treated by epoxy resin anticorrosion coating; the raw material components of the concrete material include by weight: 42.5 100 parts of ordinary Portland cement, 260 parts of basalt gravel, 160 parts of quartz sand, 8 parts of polyvinyl alcohol fiber, 7 parts of modified loofah fiber, 20 parts of nanomaterial capsule, 6 parts of rubber powder, modified sepiolite powder 25 parts, 15 parts of palygorskite powder, 0.5 parts of polycarboxylate superplasticizer, 5 parts of polyethylene oxide, and 50 parts of water; the nanomaterial capsule is a hard shell capsule filled with nano calcium carbonate and nano silicon dioxide.

[0030] In the present embodiment, the preparation method of the nanomaterial capsule and the modified sepiolite powder are the same as in the first embodiment; the epoxy resin anticorrosion ...

Embodiment 3

[0032] The cement-based utility pole provided in this embodiment includes a pole body formed by composite steel frame and concrete material; the steel frame is anti-corrosion treated by epoxy resin anticorrosion coating; the raw material components of the concrete material include by weight: 42.5 Ordinary Portland cement 100 parts, basalt gravel 260 parts, quartz sand 160 parts, polyvinyl alcohol fiber 10 parts, modified loofah fiber 7 parts, nanomaterial capsule 20 parts, rubber powder 6 parts, modified sepiolite powder 30 parts, 20 parts of palygorskite powder, 1.0 part of polycarboxylate superplasticizer, 6 parts of polyethylene oxide, and 60 parts of water; the nanomaterial capsule is a hard shell capsule filled with nano calcium carbonate and nano silicon dioxide.

[0033] In the present embodiment, the preparation method of the nanomaterial capsule and the modified sepiolite powder are the same as in the first embodiment; the epoxy resin anticorrosion coating, steel skele...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com