A method for multi-directional pre-deformation rolling of the edge of a wide magnesium alloy thick plate

A magnesium alloy, pre-deformation technology, applied in the direction of metal rolling, metal rolling, metal rolling racks, etc., can solve the problems of high magnesium plate prices, plate edge cracks and even surface cracks, etc., to improve the edge Stress distribution state and anisotropy, preventing the generation and expansion of cracks at corners, and improving the yield of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

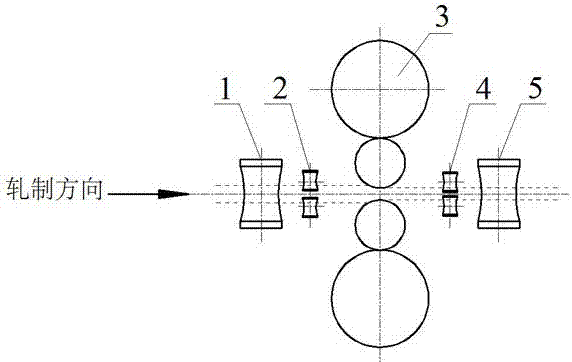

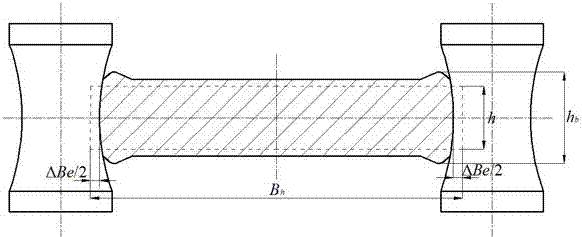

[0033] The size of the wide-width magnesium alloy thick plate slab in this embodiment is: 1500mm×1000mm×300mm, and a wide-width magnesium alloy plate with a width of 2300mm and a thickness of 50mm is prepared. The rolling method includes the following three process sequences:

[0034] Process sequence 1: Edge pre-deformation rolling, front and rear vertical rolls and inclined rolls combined reciprocating rolling 4 passes: the process parameters of each pass are set as shown in the table below:

[0035]

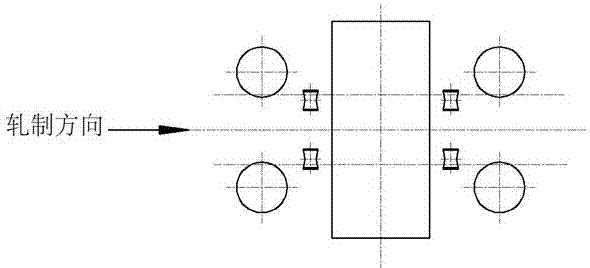

[0036] Process sequence two: widening and rolling, the magnesium plate is rotated 90°, cross-rolled by a four-roll mill for 3 passes, and the reduction in each pass is: 20%, 30%, and 30%, and rolled to a specified width of 2300mm. The following table shows the process parameter settings:

[0037]

[0038] Process sequence 3: Combined rolling of stretching length and multi-directional compression deformation at the edge, the rolled piece is rotated 90° again, the distanc...

Embodiment 2

[0041] The size of the wide-width magnesium alloy thick plate slab in this embodiment is: 2000mm×1500mm×200mm, and a wide-width magnesium alloy plate with a width of 2000mm and a thickness of 60mm is prepared. The rolling method includes the following three process sequences:

[0042] Process sequence 1: 5 passes of reciprocating rolling with vertical rolls and skewed rolls before and after flat roll rolling: the process parameters of each pass are set as shown in the table below:

[0043]

[0044] Process sequence 2: Rotate the magnesium plate by 90°, and cross-roll it with a four-high rolling mill for 2 passes. The reduction in each pass is 15% and 17%, and it is rolled to a specified width of 2000mm. The process parameters for each pass are set as shown in the table below. Show:

[0045]

[0046] Process sequence three: the rolled piece is rotated 90° again, the distance between each pair of vertical rolls is 2000mm, no adjustment is made, and the vertical rolls, inc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com